High-precision grease removing device in water

A high-precision, water-collecting pipe technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of short service life of filter medium, poor impact resistance of incoming liquid, Backwashing effect is not good and other problems, to achieve the effect of enhancing separation efficiency and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

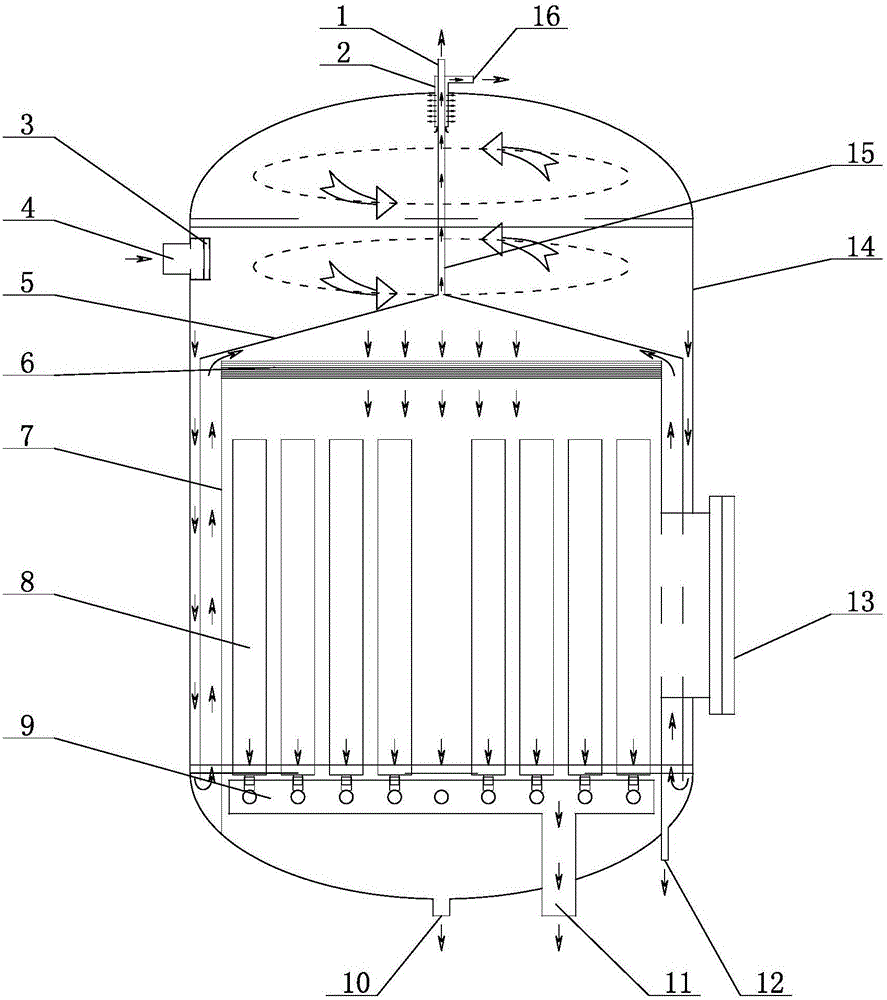

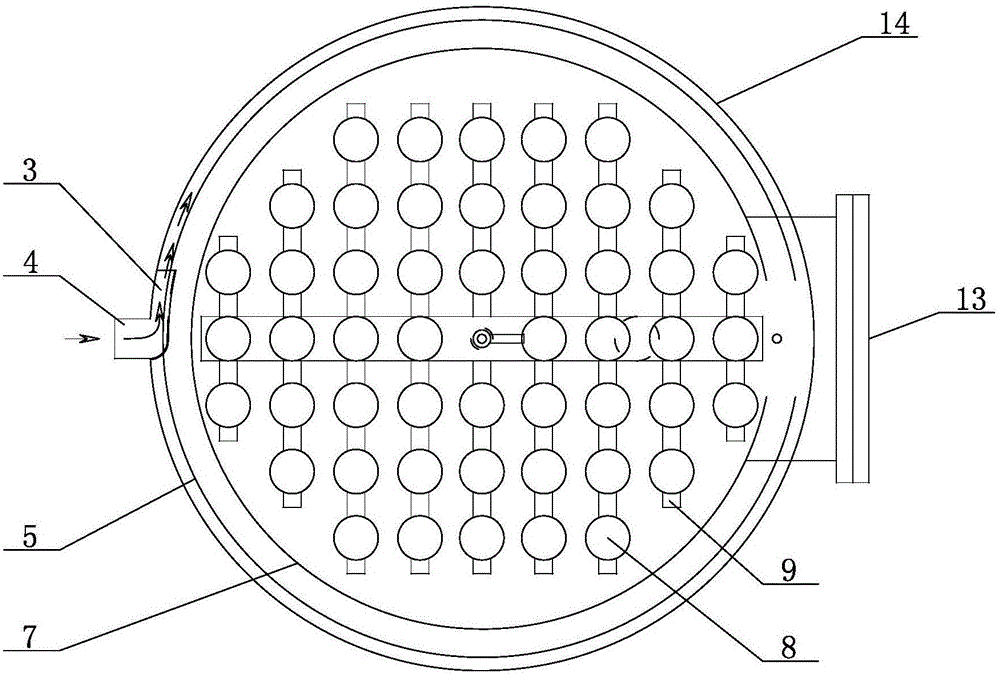

[0025] The present invention will be further described below in conjunction with accompanying drawing:

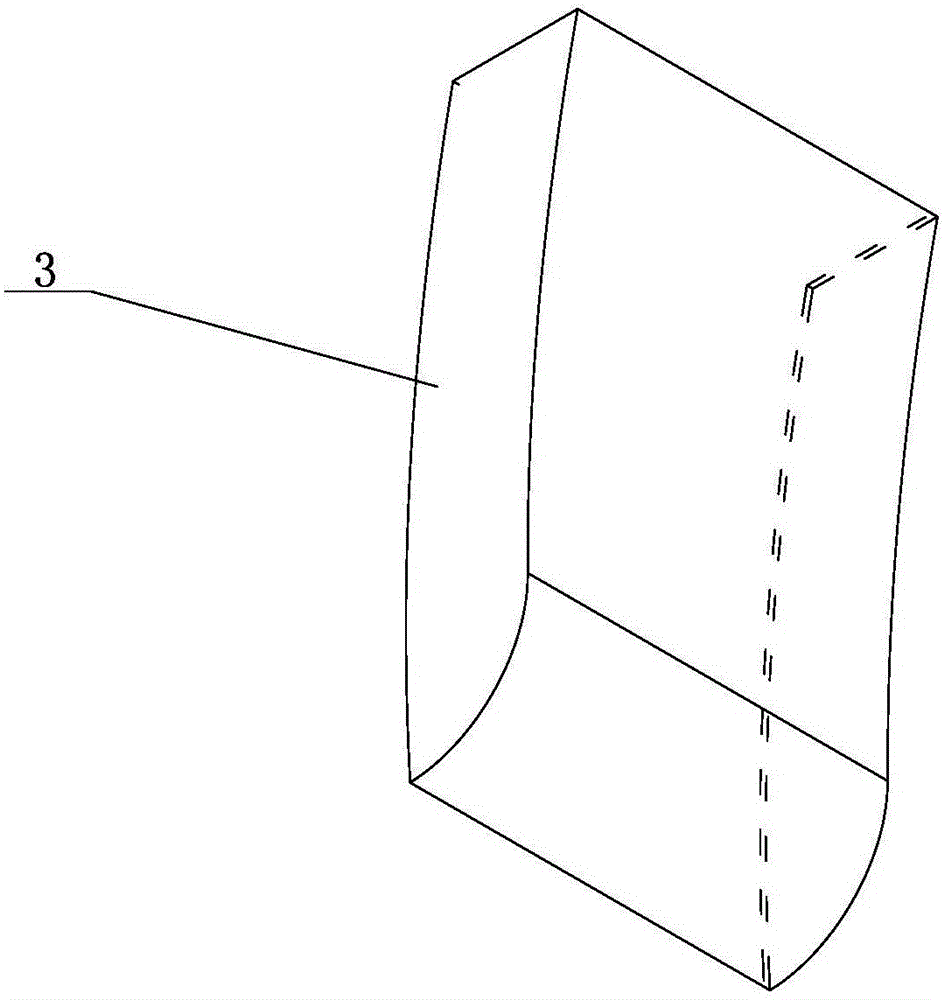

[0026] Such as Figure 1 ~ Figure 3 As shown, the high-precision water degreasing device of the present invention includes a cylinder body 14, a compartment housing 5 is arranged in the cylinder body 14, a gap is provided between the bottom of the compartment housing 5 and the bottom of the cylinder body 14, and the compartment housing 5 The upper part is a cyclone separation chamber, and the lower part is a precision separation chamber. The cyclone separation chamber includes a water inlet 4 and a first overflow port 16. The top of the sub-chamber housing 5 is connected to the second overflow port 1, and the second overflow port 1 is placed in the Outside the cylinder 14, there is a deflector 7 in the precision separation chamber, the bottom of the deflector 7 is sealed and connected with the bottom of the cylinder 14, the top of the deflector 7 is provided with a fiber se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com