A New High Efficiency Cyclone

A cyclone and high-efficiency technology, which is applied in the field of new high-efficiency cyclones, can solve the problems of cyclone efficiency decline, difficult installation, and affecting separation efficiency, and achieve the effects of improving efficiency, convenient installation, and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

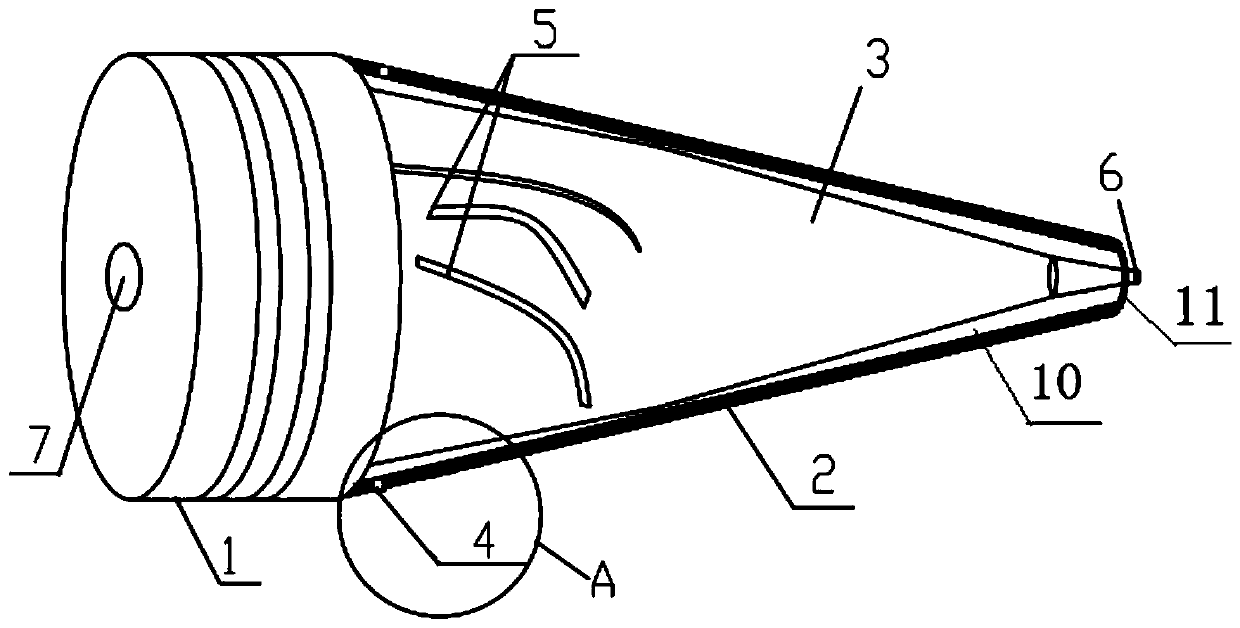

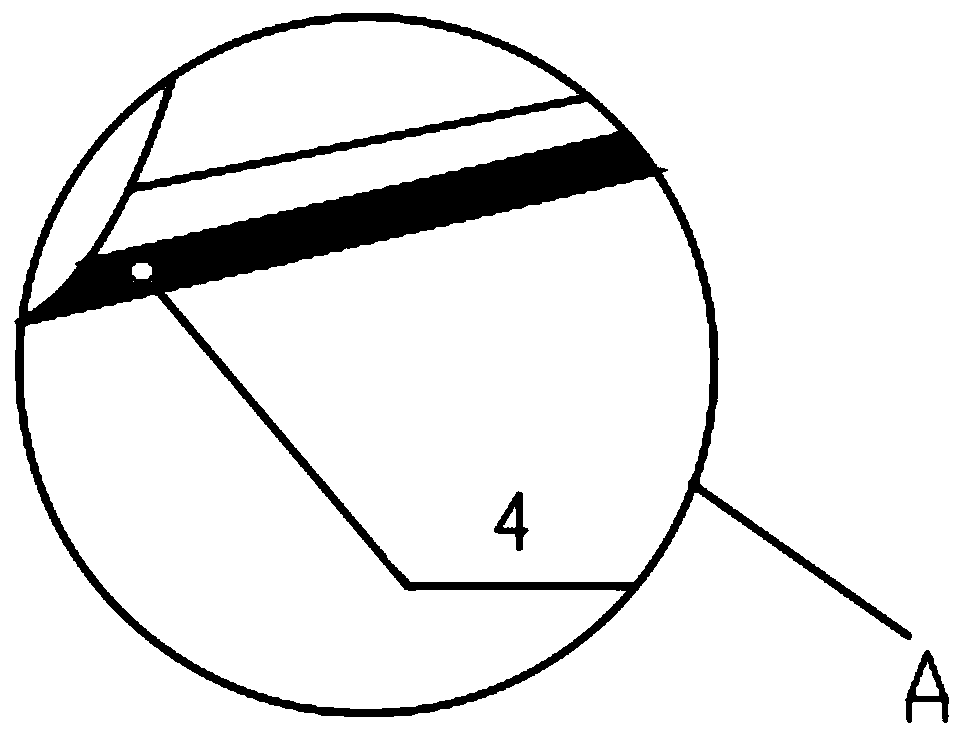

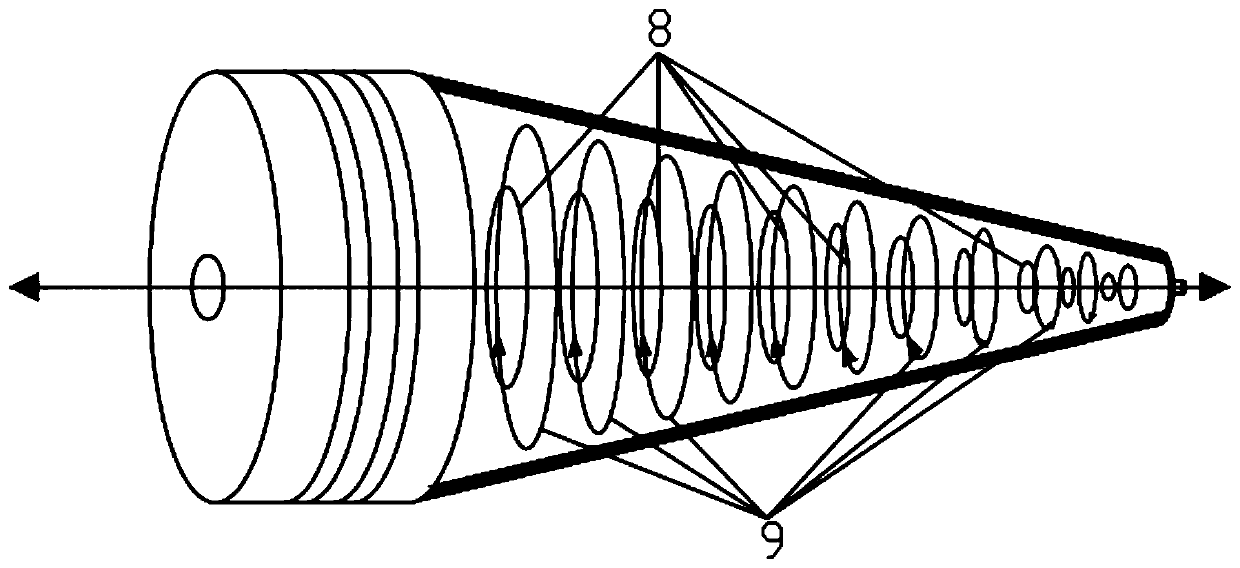

[0019] Such as Figure 1-3 As shown, a new high-efficiency cyclone includes a first shell 1, a second shell 2, and a swirl cavity 3 arranged in the first shell 1 and the second shell 2; wherein, the first shell The body 1 is a cylinder, the second shell 2 is a truncated cone, and the first shell 1 and the second shell 2 are connected to each other; the inner diameter of the second shell 2 starts from the connection with the first shell 1 along the gradually decreases along the axis, that is, the inner diameter of the second shell 2 in contact with the first shell 1 is larger than the inner diameter of the place away from the first shell 2; the swirl cavity 3 located in the second shell 2 corresponds to the second shell The truncated cone of the body 2 is also a truncated cone; correspondingly, the diameter of the cyclone cavity 3 near the first housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com