Bottle pushing apparatus

A technology of glass bottles and cylinders, applied in packaging, packaging bottles, transportation and packaging, etc., can solve problems such as inability to perform complex or special actions, affecting the speed of products being put on the market, and difficult automatic completion of bottle pushing devices. Achieve fast and smart bottling process, reduce packing space, reasonable and practical overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

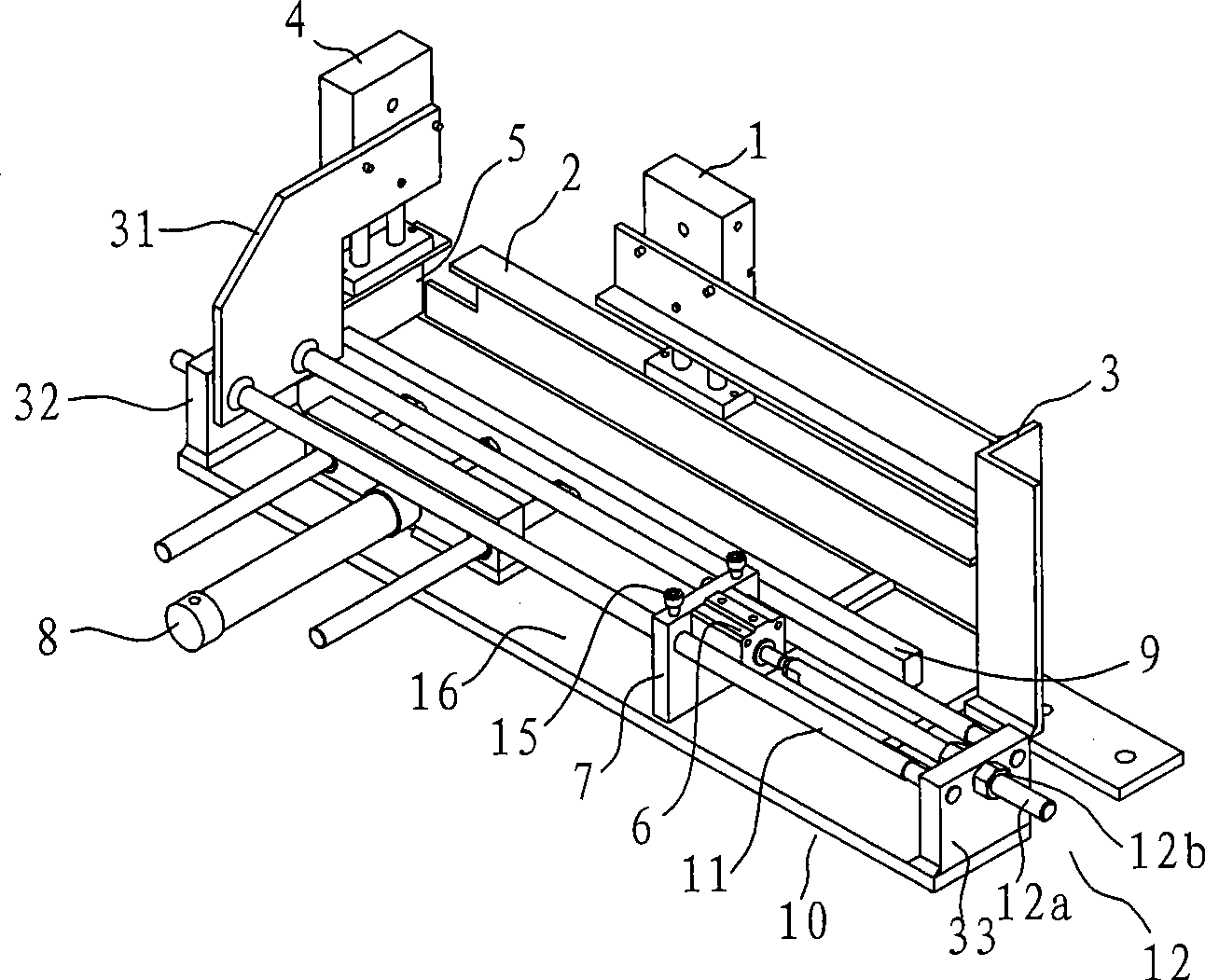

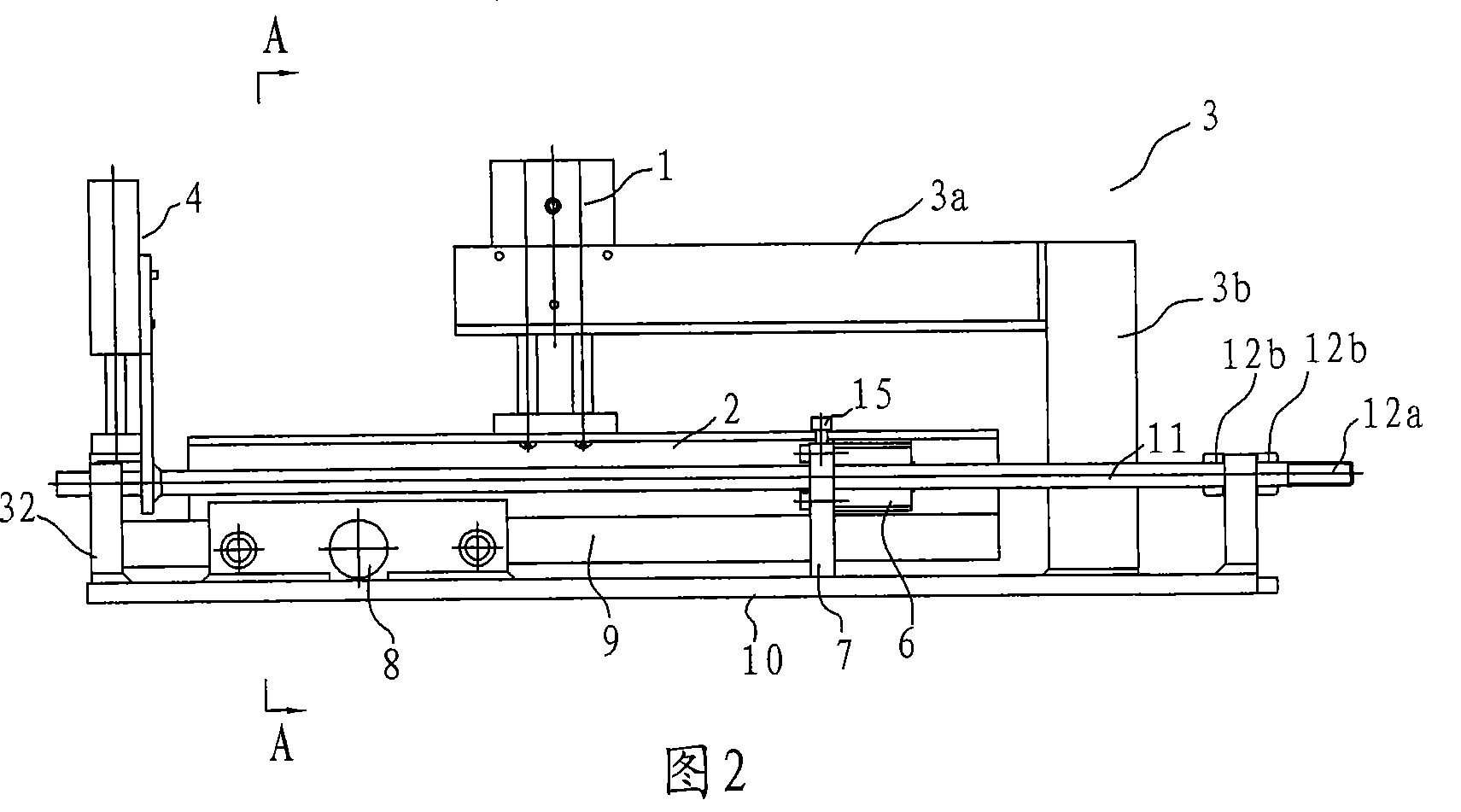

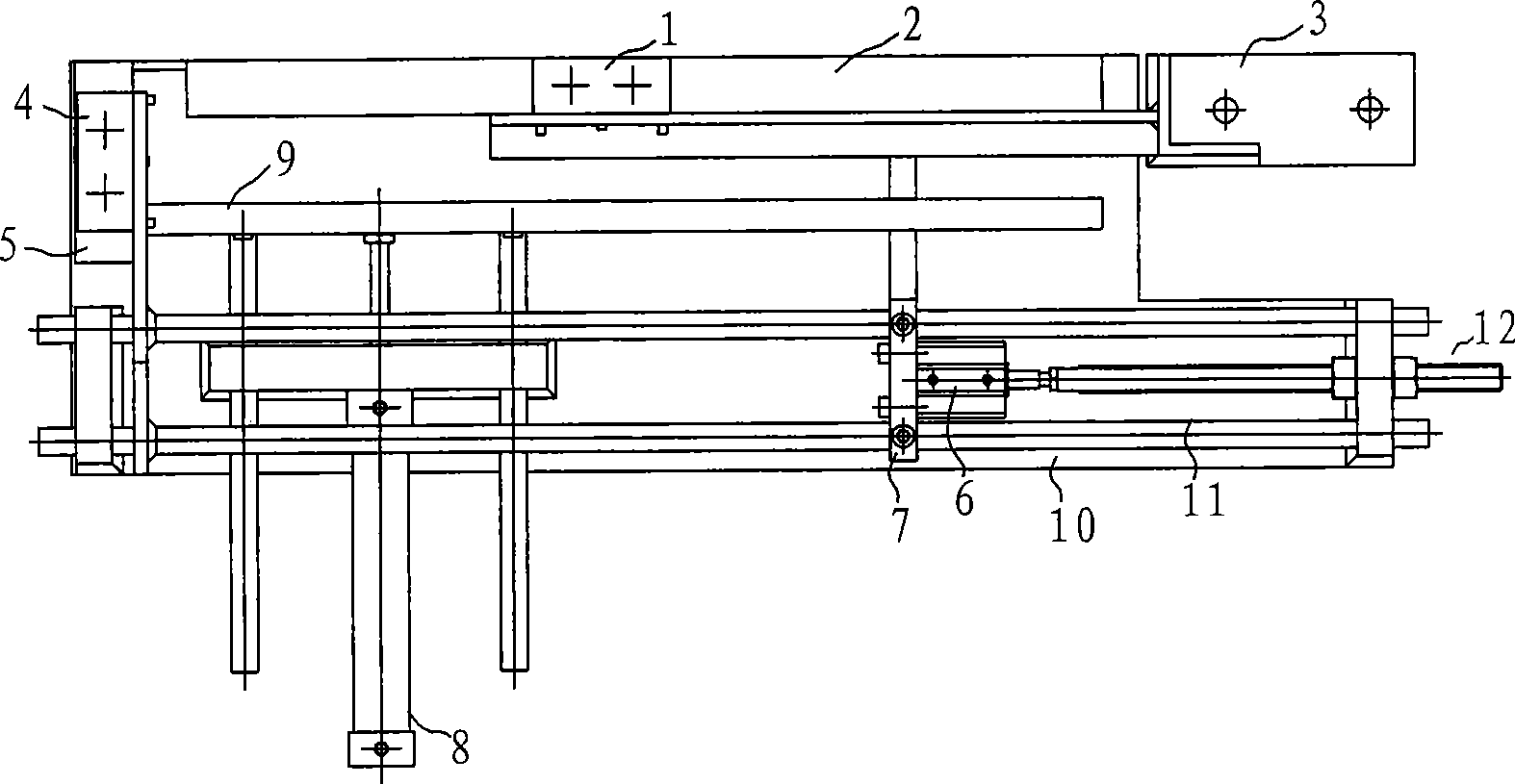

[0031] Example: Reference figure 1 ,figure 2, image 3 and Figure 4 As shown, the bottle pushing device in this embodiment includes a base 10, a front baffle 2, a front cylinder 1, a bottle pushing plate 9, a bottle pushing cylinder 8, a left baffle 5, a left cylinder 4, a right baffle 7 and right cylinder block 6.

[0032] The base 10 is used to carry the glass bottle 22, the front cylinder 1 is used to drive the front baffle 2 to move up and down, the front cylinder 1 is arranged on the front support 3, the front support 3 is L-shaped, and it includes a vertical support part 3b And the horizontal part 3a of the front cylinder block 1 is installed.

[0033] The bottle push plate 9 and the front baffle 2 are arranged at intervals, the bottle push cylinder 8 is used to drive the bottle push plate 9 to move back and forth, the left cylinder 4 is used to drive the left baffle 5 to move up and down, and the left cylinder 4 is arranged on the left bracket 31, and the left brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com