External assembly type streetlamp wire connector

A connector and assembled technology, which is applied in the field of externally assembled street lamp connectors, can solve the problems of low installation accuracy, time-consuming and laborious, and high installation costs, and achieve the effects of reducing production costs, being friendly to the application environment, and saving box space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

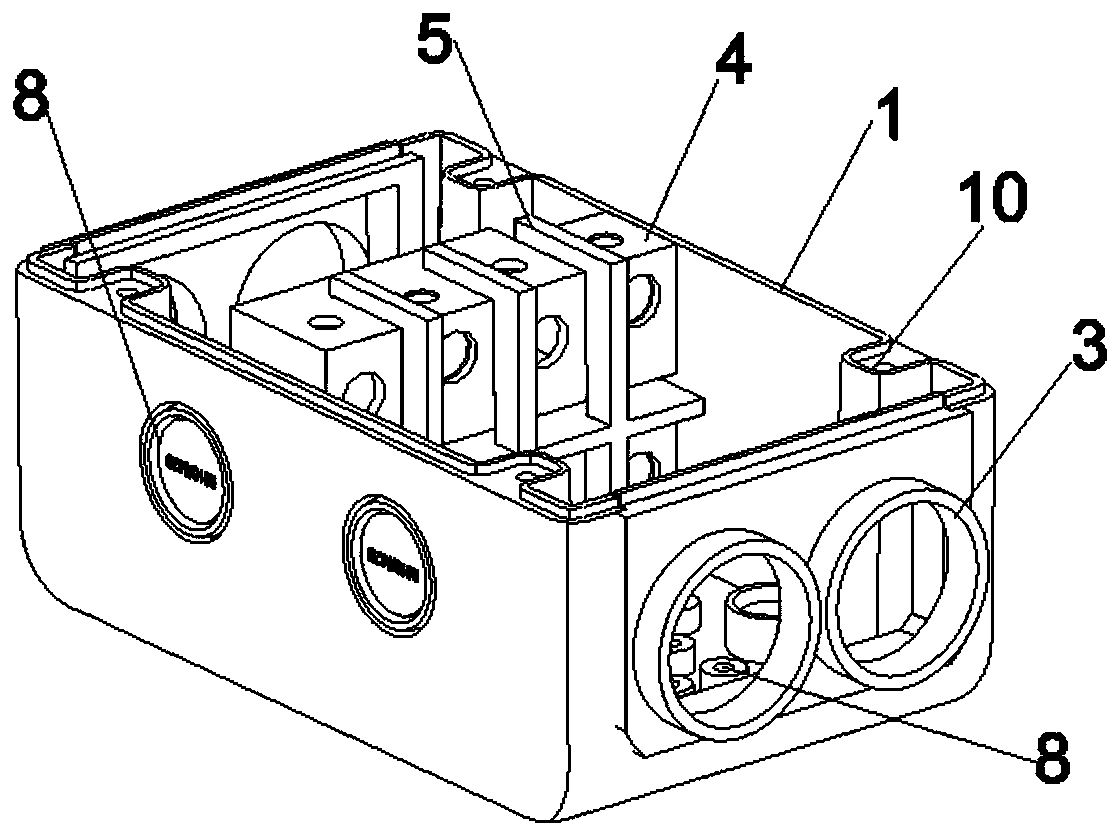

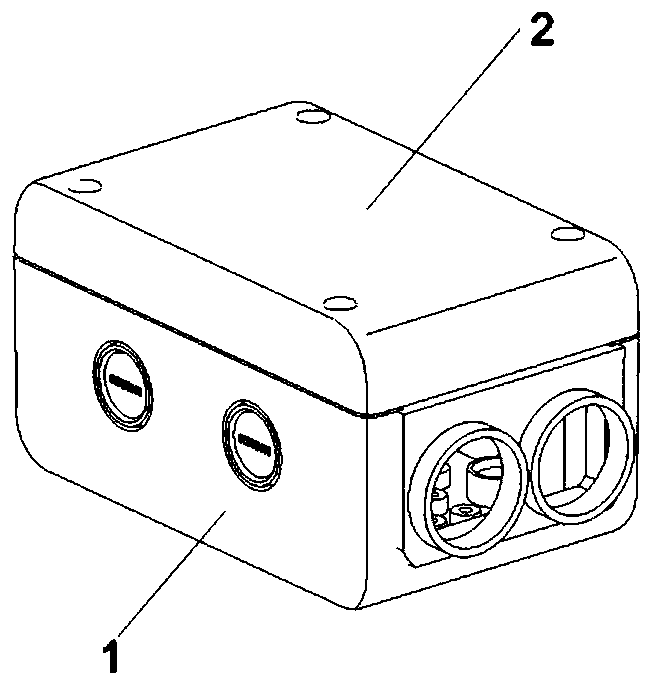

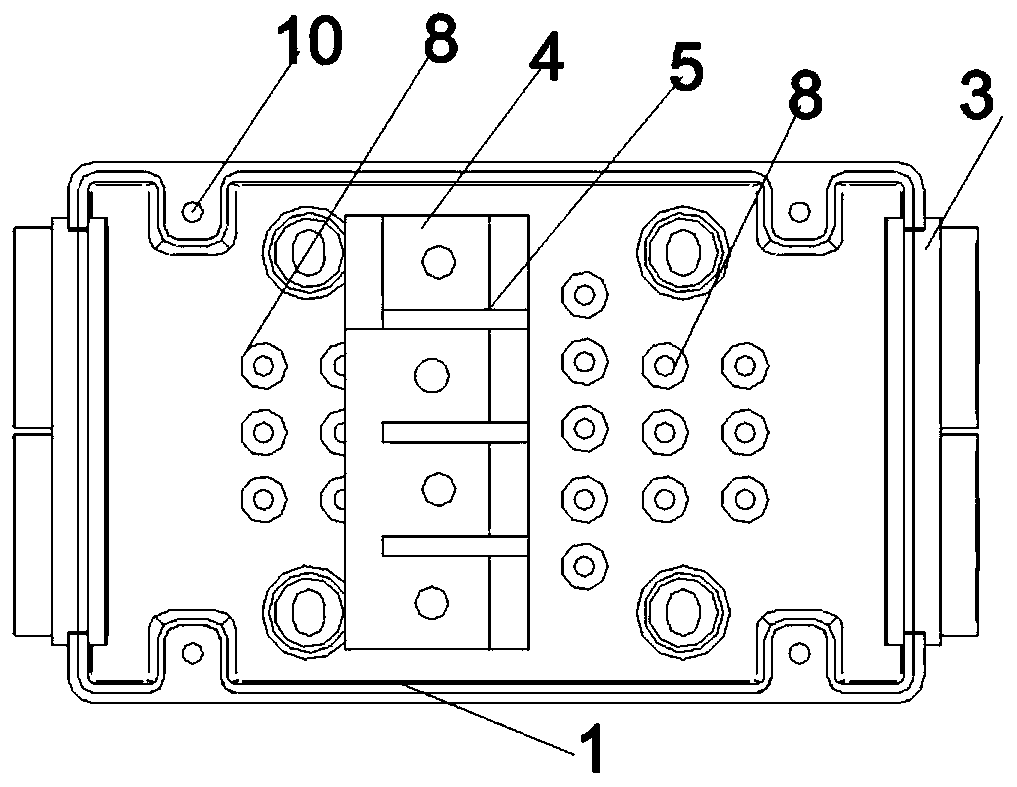

[0024] The main structure of the externally assembled street lamp connector involved in this embodiment includes: box body 1, box cover 2, rubber joint flange 3, plastic terminal sheath 4, terminal fixing insert 5, horizontal terminal 6, vertical terminal 7, Prefabricated hole 8, broken hole 9, connecting hole 10; the two ends of the long side wall of the plastic box body 1 of cuboid structure are respectively provided with connecting hole 10, and box cover 2 is fixed with connecting hole 10 by screw; Box body 1 The two short side walls are respectively opened, and the rubber joint flange 3 is vertically inserted into the opening to realize the removal and insertion of the rubber joint flange 3, and the cables to be connected penetrate through the rubber joint flange 3 for connection; the internal setting of the box body 1 There is a plastic terminal sheath 4, and the horizontal terminal 6 and the vertical terminal 7 are intersected in the plastic terminal sheath 4, and the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com