Cooling fan for reinforcing diversion cooling

A cooling fan, diversion cooling technology, applied to the components of the pumping device for elastic fluid, non-variable displacement pump, pump device, etc., can solve the impact of the hub, reduce the service life, reduce the fan efficiency and fatigue resistance Impact strength and other issues to achieve the effect of increasing flow rate, reducing noise, and enhancing heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

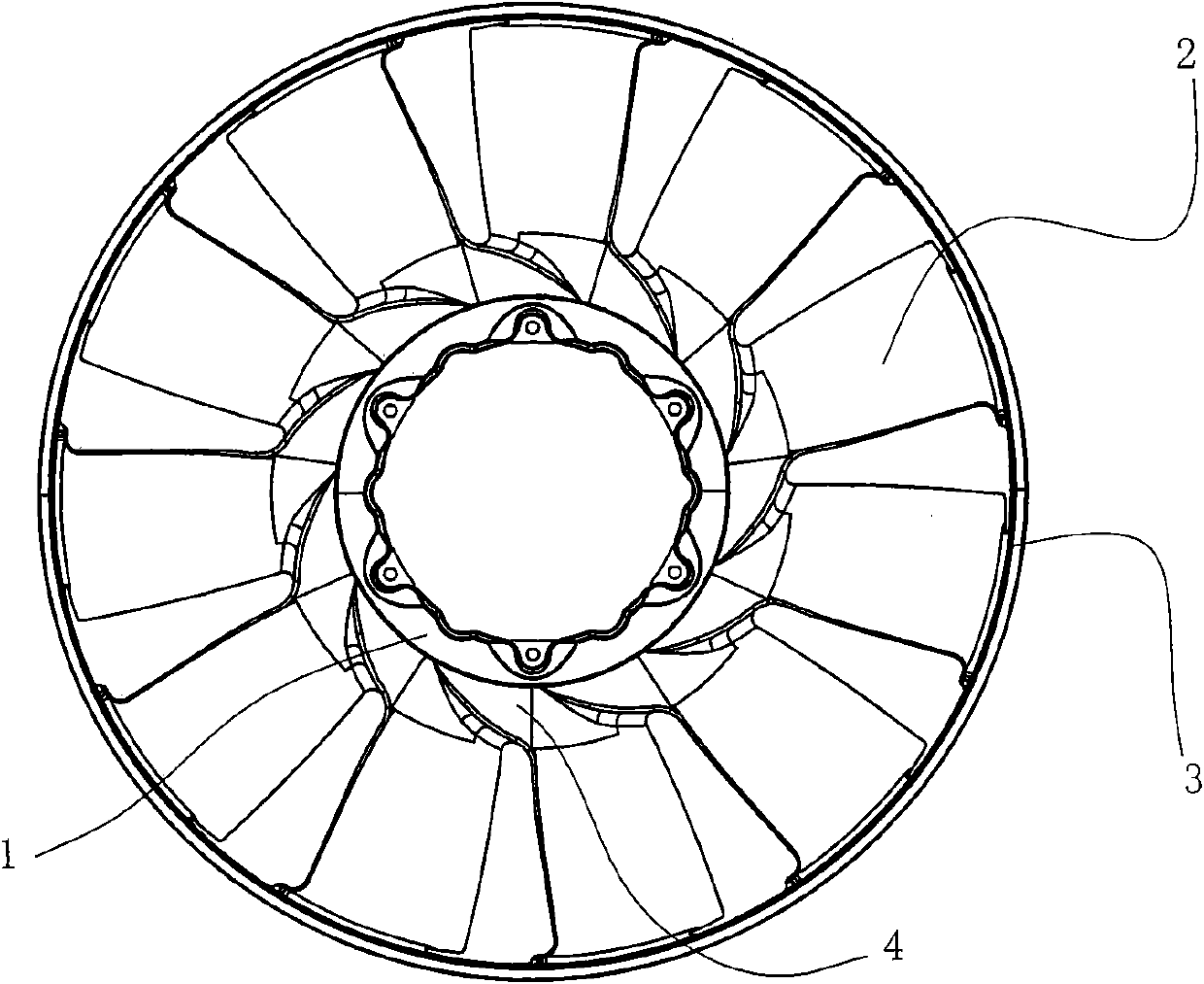

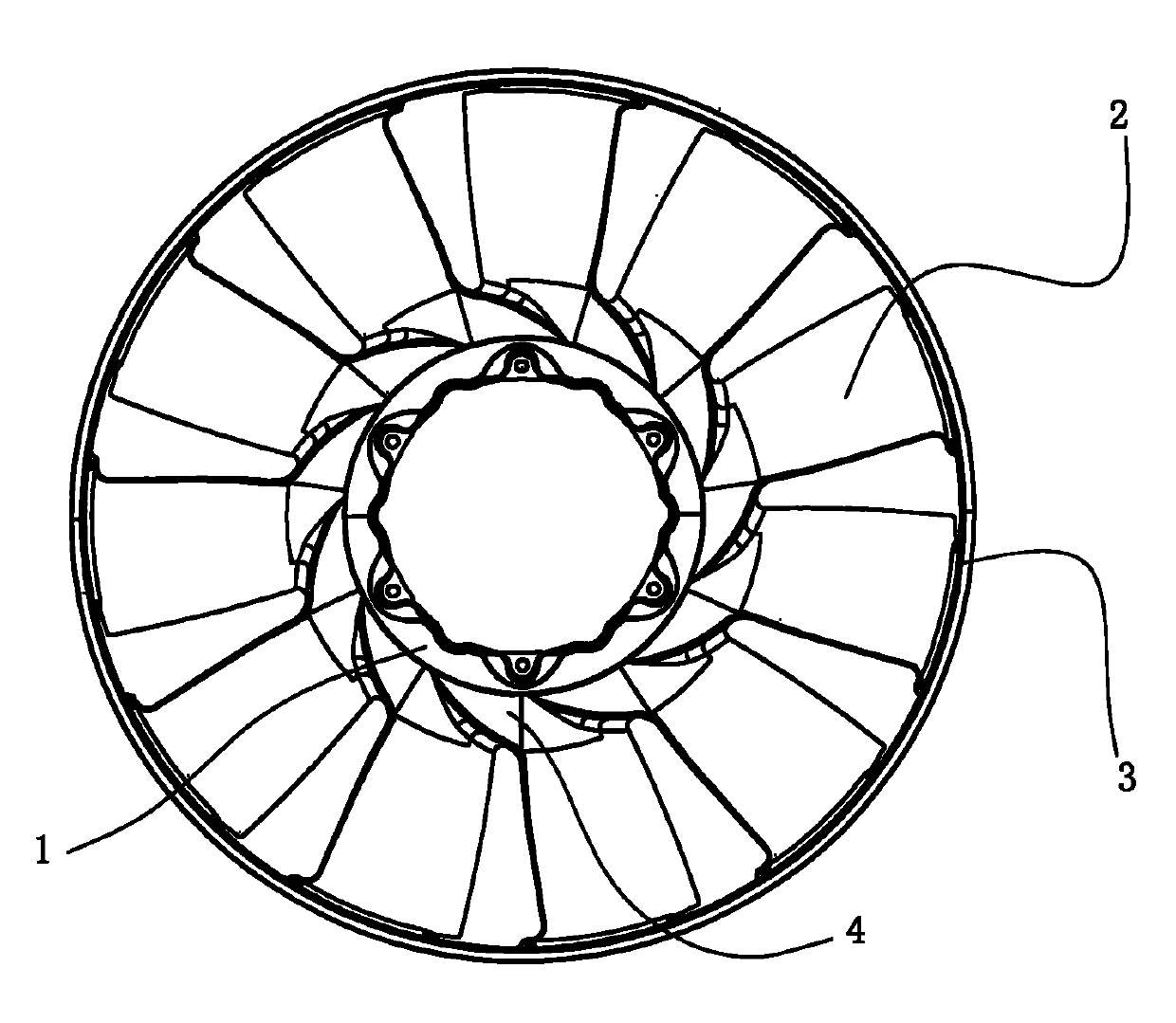

[0016] As shown in the figure, the fan with spiral reinforced diversion cooling new hub design, which at least includes a hub 1, fan blades 2 and guide ring 3, the hub 1 is surrounded by spiral ribs 4, the above fan blades 2 The outer top is connected with the deflector ring 3, and the inner bottom of the fan blade 2 is connected with the rib 4. The traditional hub is a ring design, and the bottom of the fan blade of the traditional fan is directly connected with the ring surface. Due to its structural limitations , so that the head-on wind cannot radiate to the surroundings for effective cooling; the above-mentioned spiral ribs 4 are arranged equidistantly with involutes, which effectively evacuates the head-on wind to the surroundings, and the blades enter the cooling, which can make the cooling The effect is increased by 12% to 14%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com