Mill of coffee-making machine

A grinder and coffee machine technology, which is applied to coffee grinders, spice grinders, kitchen utensils, etc., can solve the problems of difficult processing, difficult assembly, and high noise, and achieves reasonable and practical structure, uniform grinding thickness, and noise reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

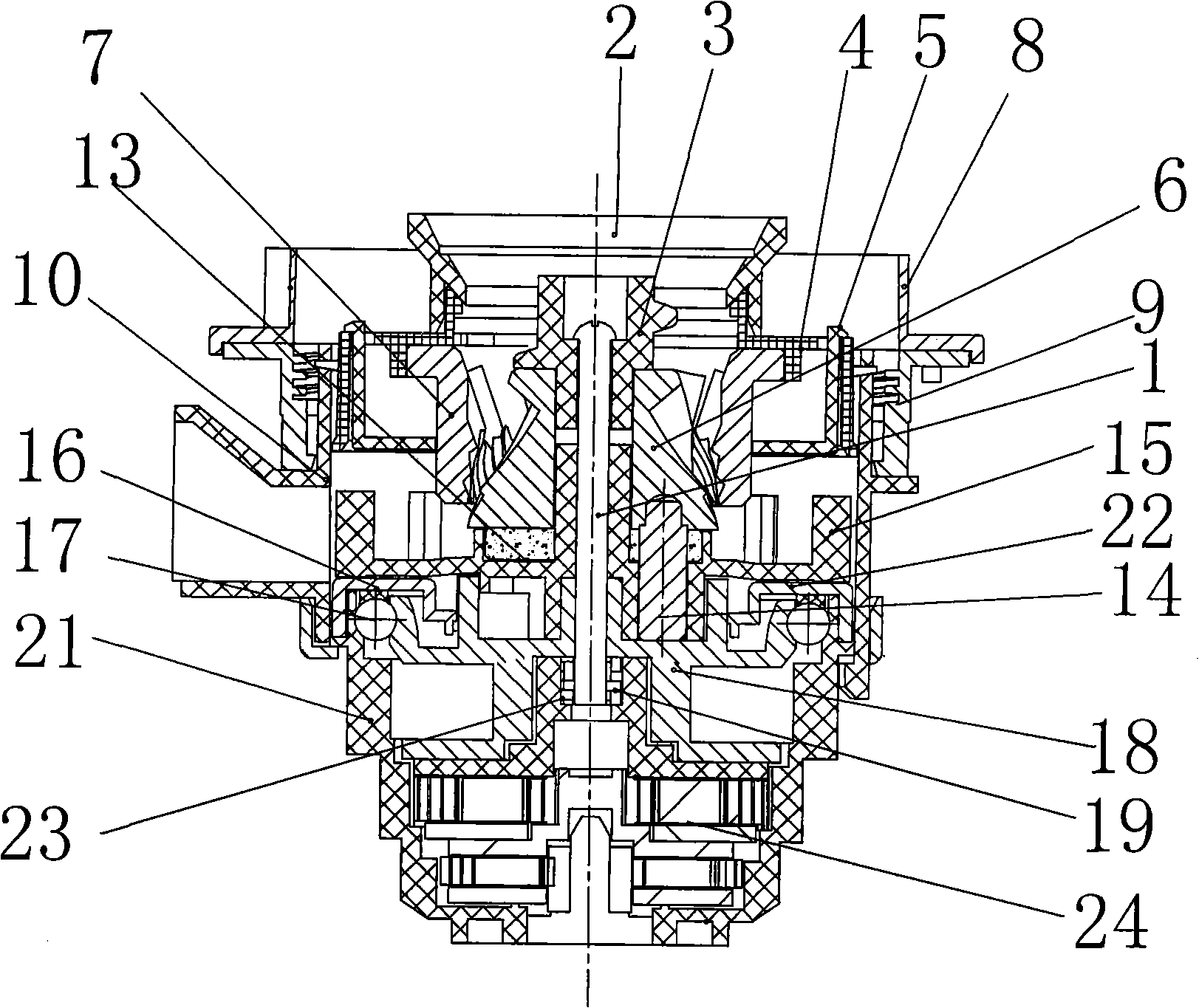

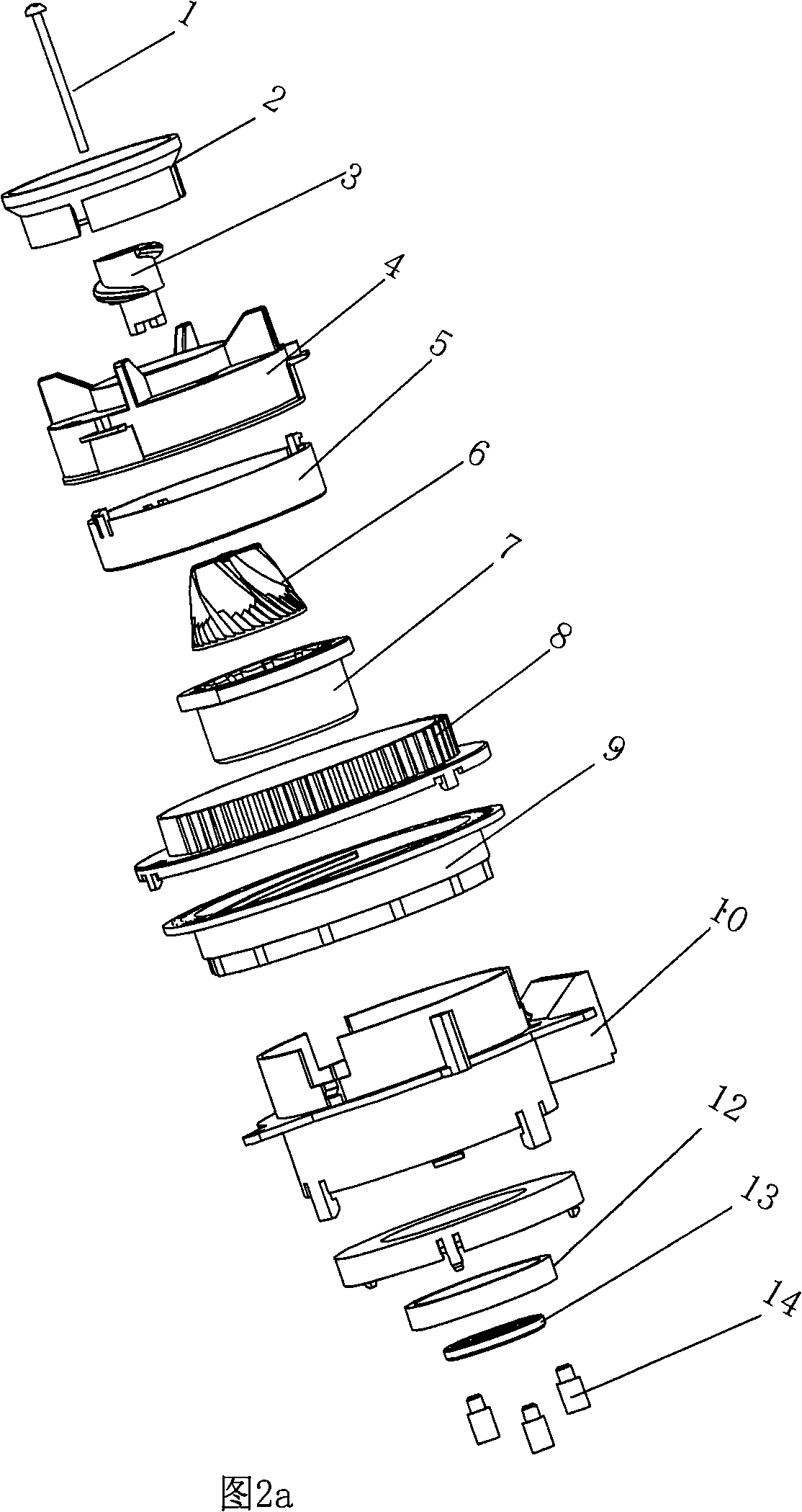

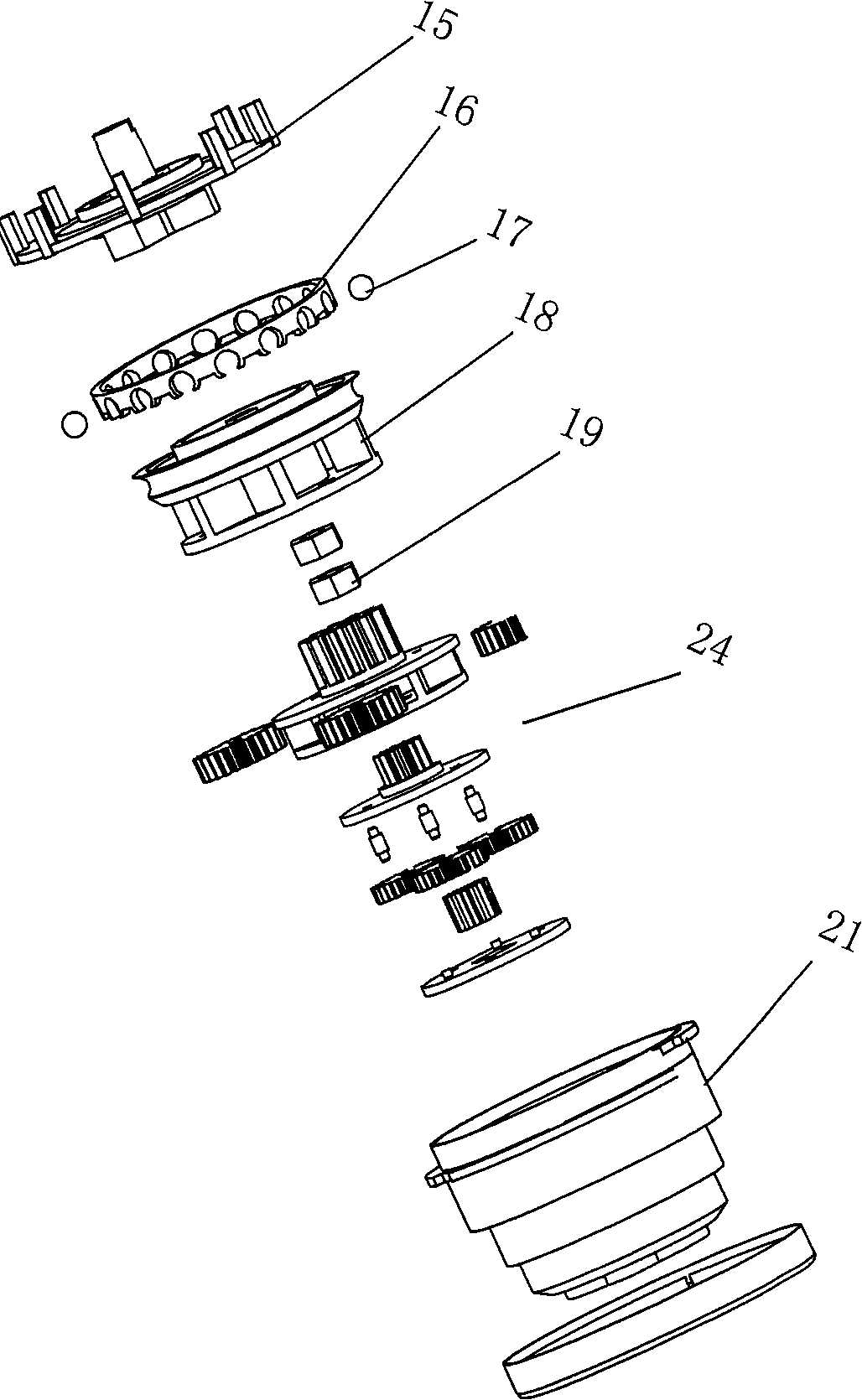

[0022] Such as figure 1 2a, 2b constitute a complete three-dimensional exploded view of the coffee machine grinder. A coffee machine grinder, which includes main components such as a grinding head 3, a cutter head 6, a cutter cover 7, and a transmission mechanism, wherein a long screw 1 is used for a vertical transmission shaft in the grinder, and a long screw 1 is inserted and fixed on the upper end of the grinder. Grinding head 3, coffee turntable 15 is fixed in the middle and lower part of long screw 1, and cutter head 6 is arranged between grinding head 3 and coffee turntable 15. At the same time, cutter head 6 is set on the vertical rotation axis of long screw 1, An elastic element 13 such as a spring or a rubber block is supported between the cutter head 3 and the opposite surface of the coffee turntable 15, and a wool felt 12 is lined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com