Press key type switch valve core

A technology of switching valve core and button, applied in the direction of diaphragm valve, valve device, engine components, etc., can solve the problems of easy wear and tear of the valve core, shorten the service life of the valve core, and increase the cost, and achieve the simplified faucet structure, long service life, less wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

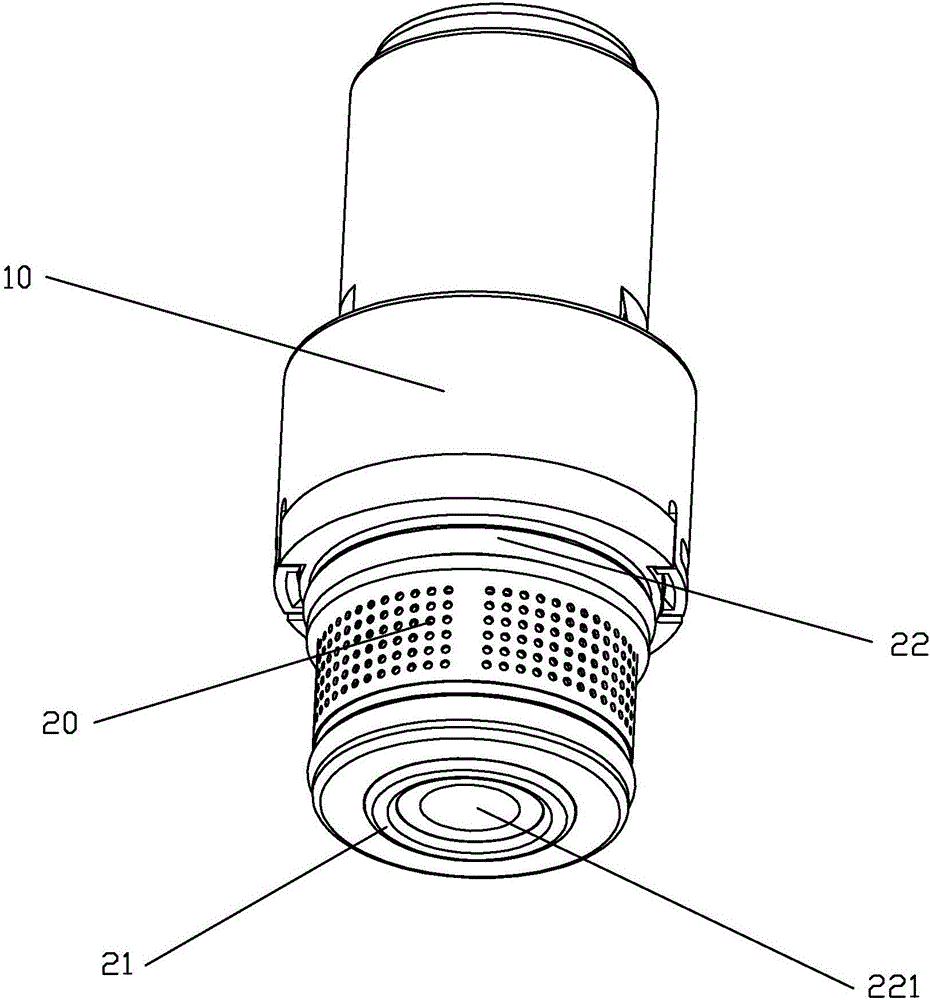

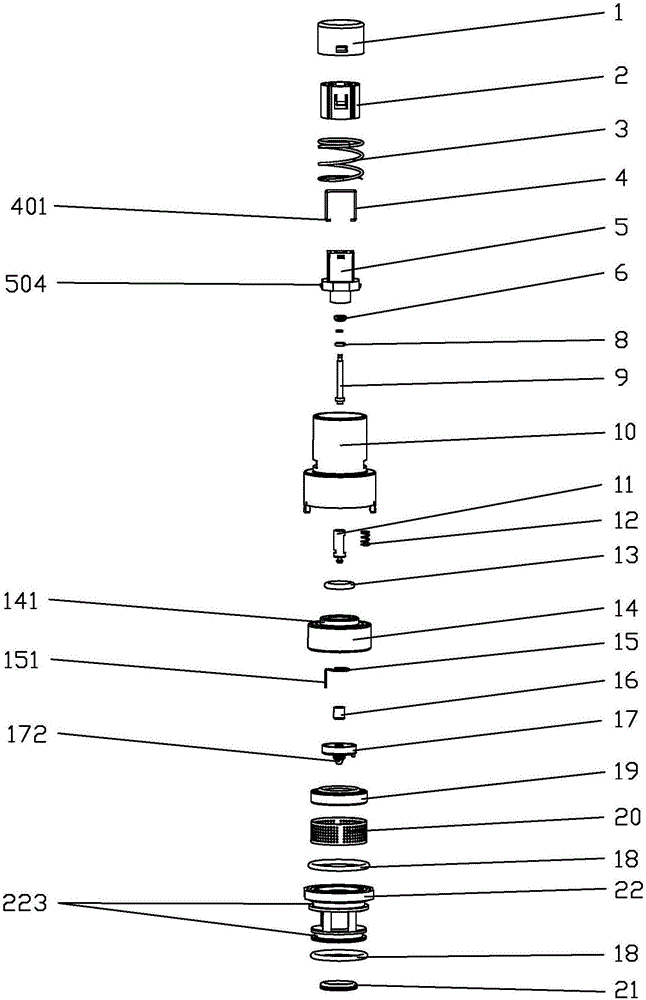

[0028] refer to Figure 1~Figure 9 , a push-button switch valve core, including a housing 10 and a base 22 installed at the bottom of the housing 10, a button 1 is arranged inside the housing 10, and a gear liner 2 is fixedly connected to the button 1, the A gear bracket 5 is arranged inside the gear liner 2, and a linkage small shaft 9 that can move up and down is pierced in the gear bracket 5, and the upper end of the linkage shaft 9 is fixedly connected with the gear liner 2. The lower end of the linkage small shaft 9 is connected with a water-stop spring seat 11, and the lower end of the water-stop spring seat 11 is connected with a water-stop pressure block 16, and the upper part of the housing 10 is provided with a return spring 3 that abuts against the lower end of the button 1. A compression spring 12 is arranged between the lower end of the linkage small shaft 9 and the water-stop spring seat 11, the gear bracket 5 is connected with a return spring 4, and the two side...

Embodiment 2

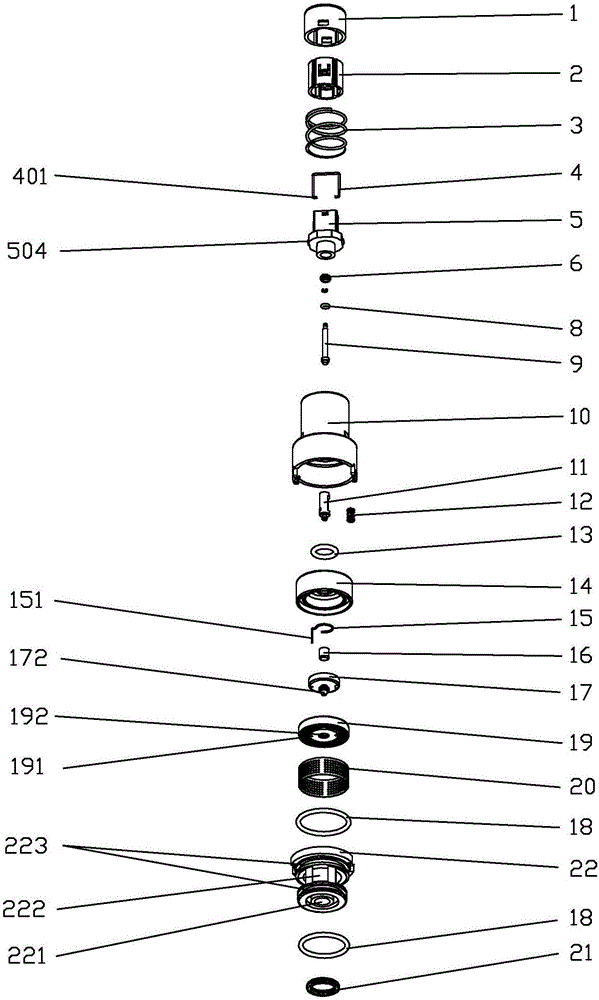

[0036] refer to Figure 10~Figure 13 , this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, a radially extending mounting ring 503 is provided at the lower end of the gear bracket 5, and the mounting ring 503 is fixed by the housing 10 and the seal Seat 14 clamps and locates gear support 5, adopts the mode of clamping, and processing, assembling are simpler, are convenient to disassembly and maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com