Transport and storage container for liquids and method for manufacturing an inner plastic container of the transport and storage container

A container and liner technology, used in chemical instruments and methods, containers, rigid containers, etc., can solve problems such as electrical grounding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

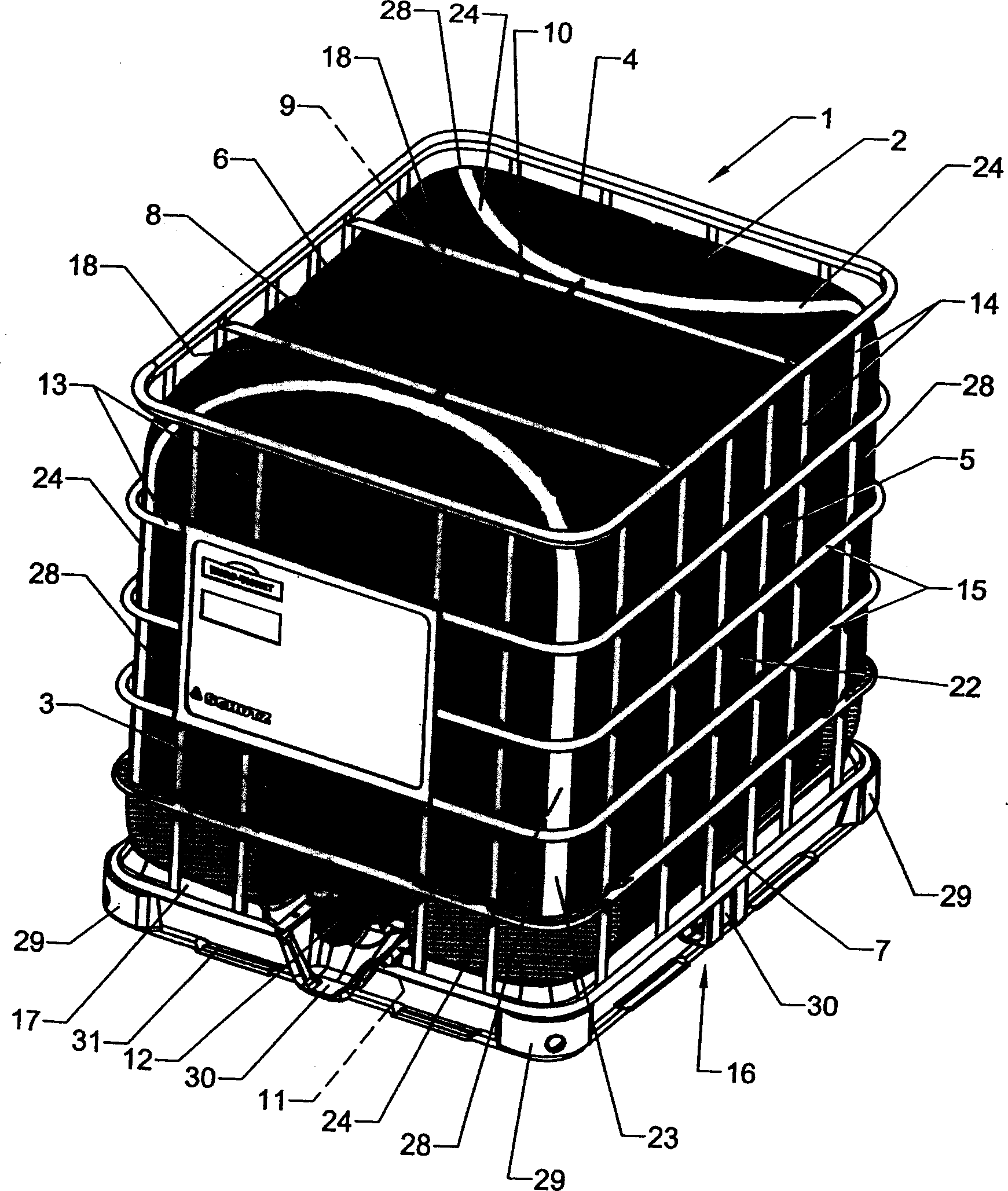

[0013] The main parts of the liquid storage and transportation container 1 that can be used as a disposable or reusable container: a replaceable, cubic polyethylene liner 2; a front wall 3, a rear wall 4 and two side walls 5 are housed, 6; the lower bottom 7 as the discharge bottom; the upper bottom 8 with a liquid injection port 9 that can be closed by a screw cap 10; the liquid discharge port 11 located at the lower half of the front wall 3 with the liquid taking valve 12; An outer jacket 13 composed of vertical and horizontal metal grid bars 14, 15; a tray-like underframe 16 for accommodating a plastic liner 2, a steel plate bottom groove 17, and two metal covers for protecting the liner 2 Article 18.

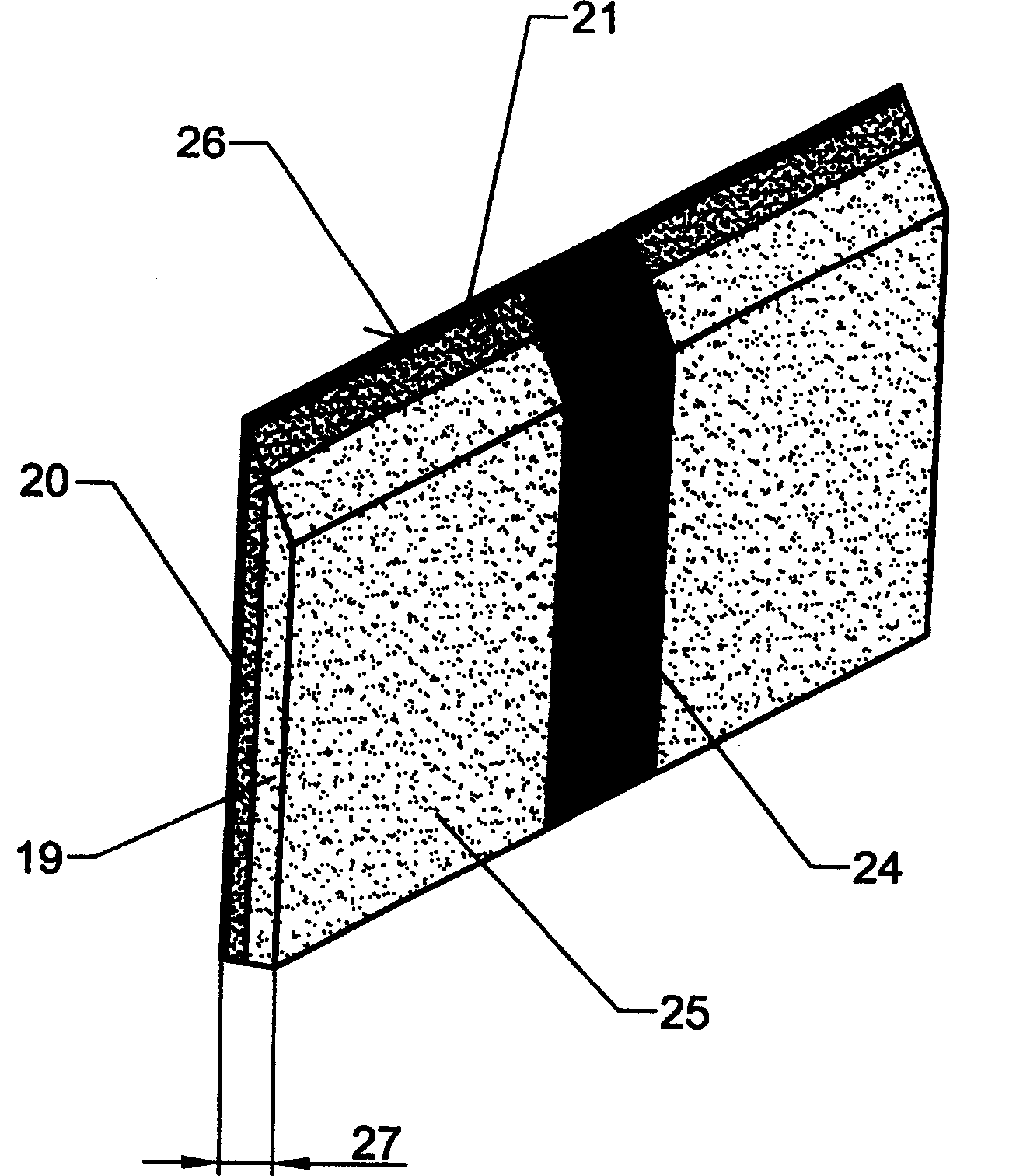

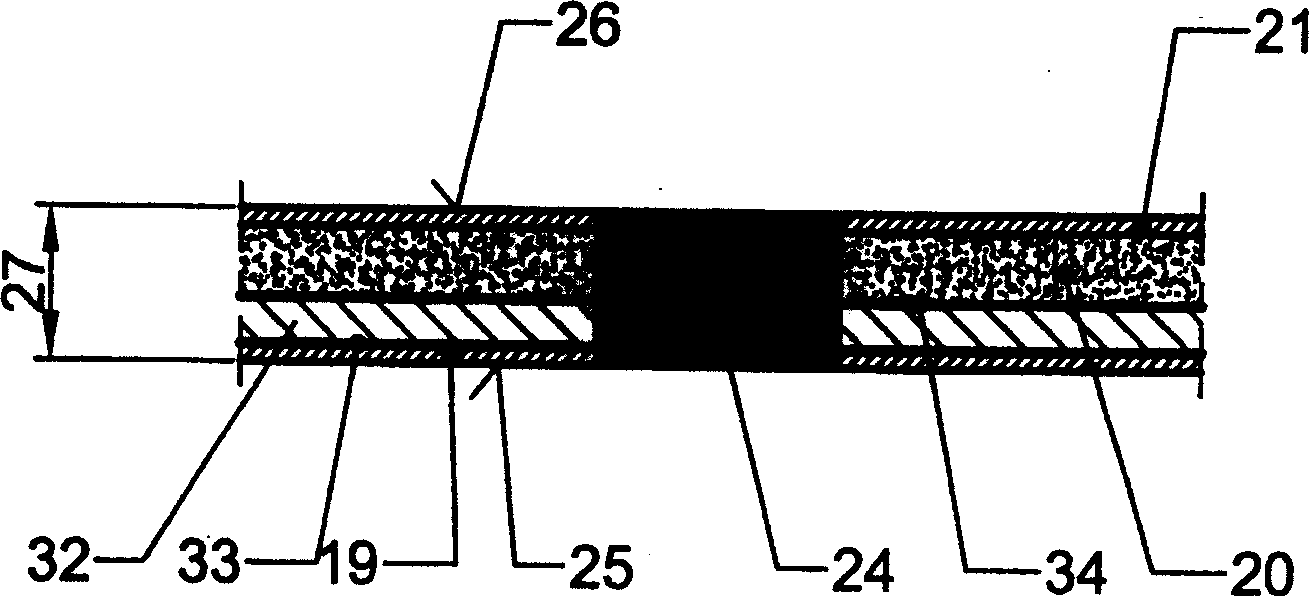

[0014] figure 2 The front wall 3, the rear wall 4, the side walls 5, 6 and the front wall 3, the rear wall 4, the side walls 5, 6 and the upper and lower bottom plates 7, 8 made of the plastic liner 2 by the extrusion blow molding process are specified. There is an inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com