Plaster coating system

A plaster and coating technology, which is applied in the direction of making medicines into special physical or ingestible devices, etc. It can solve the problems of elastic cloth deformation, widening and elongation, affecting production efficiency, uneven coating, etc., and achieve production efficiency High, reasonable and practical structure, uniform glue coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

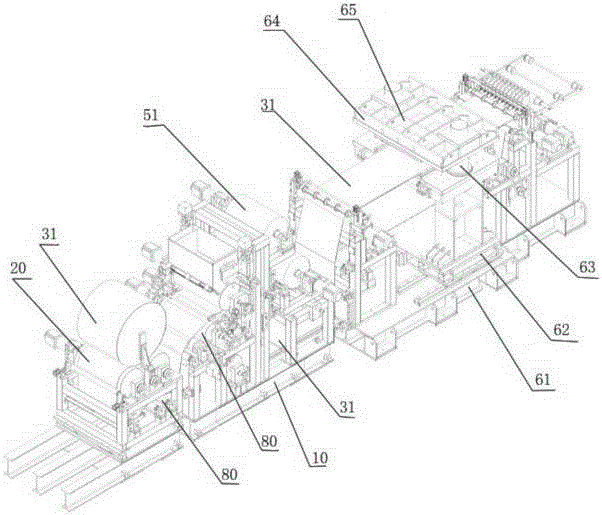

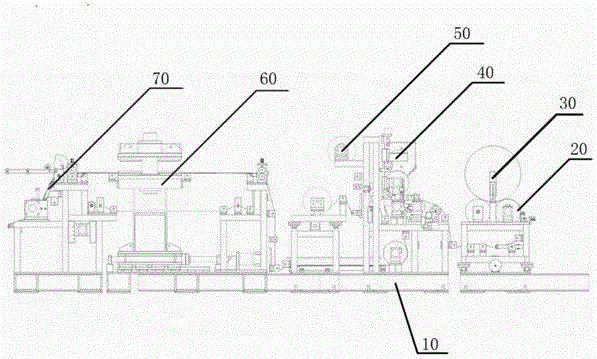

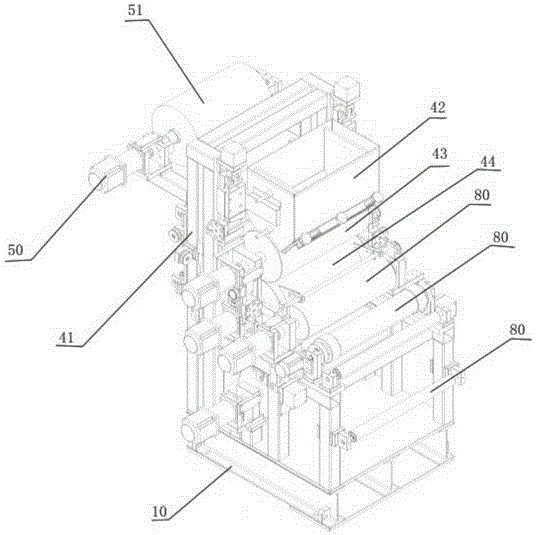

[0017] A plaster application system such as Figure 1 to Figure 4 In the shown embodiment, comprise frame, and the non-tension feeding mechanism that is arranged on the frame successively, the plaster bottom cloth cloth roll fixing device that is used to place elastic cloth cloth roll, plaster drug material coating mechanism, use The transfer film reel fixing device for placing the transfer film reel, the plaster base cloth parting mechanism and the plaster slicing mechanism, as well as the tensionless cloth feeding mechanism, the plaster material coating mechanism, the plaster base cloth parting mechanism and the plaster slicing mechanism The transmission mechanism used for elastic cloth transmission between the mechanisms, in this embodiment, the transmission mechanism is the transmission roller 80; the non-tension cloth feeding mechanism is arranged directly under the plaster base cloth roll fixing device and is connected with the elastic cloth roll Tangent to drive the ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com