Dry powder pump

A dry powder pump and bottle technology, applied in the direction of powder material distribution, unloading device, etc., can solve the problems that dry powder products cannot be directly applied, the structure cannot meet the requirements of dry powder, powder atomization and spraying can not be achieved, and the structure is reasonable Practical, easy to operate and use, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

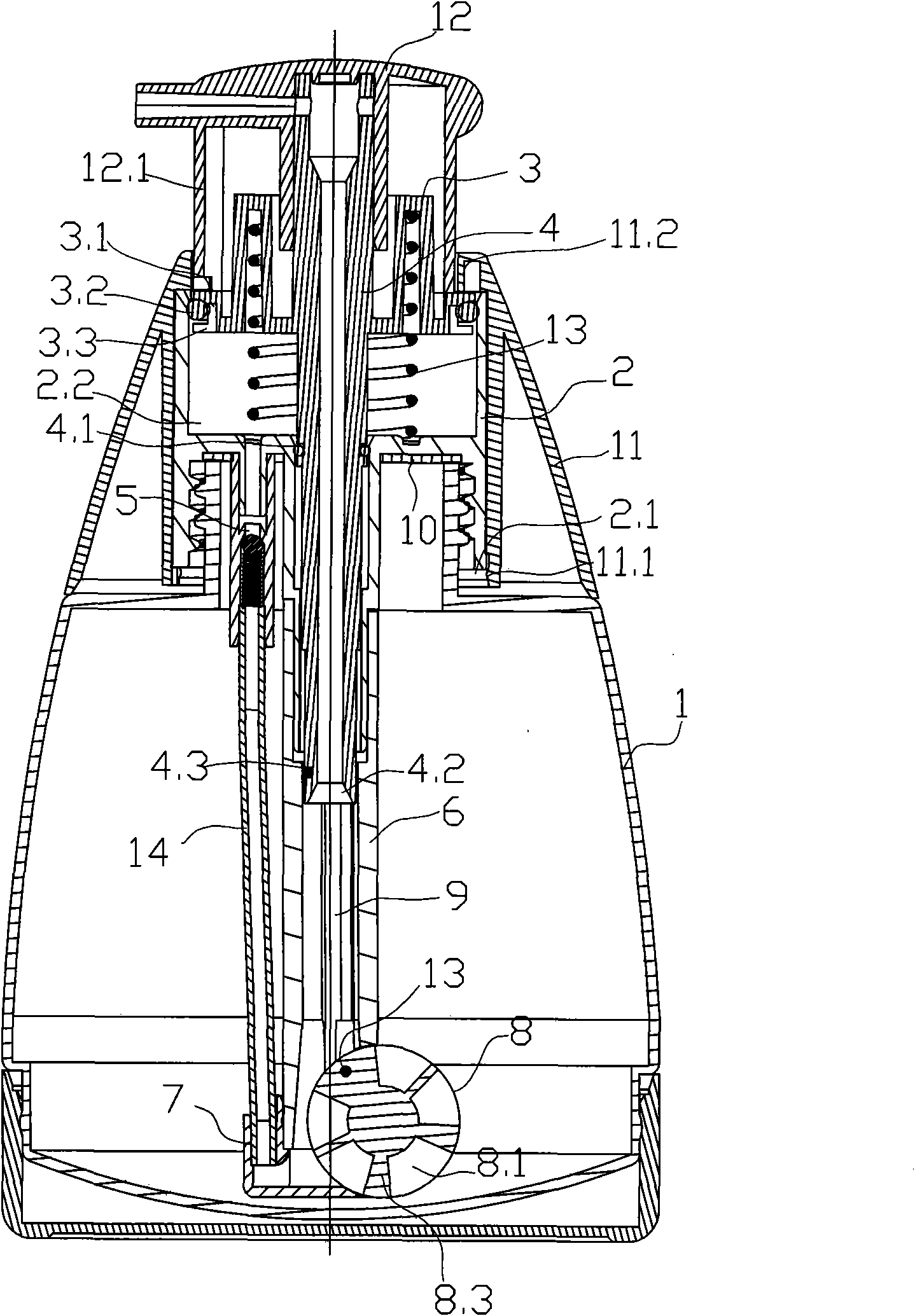

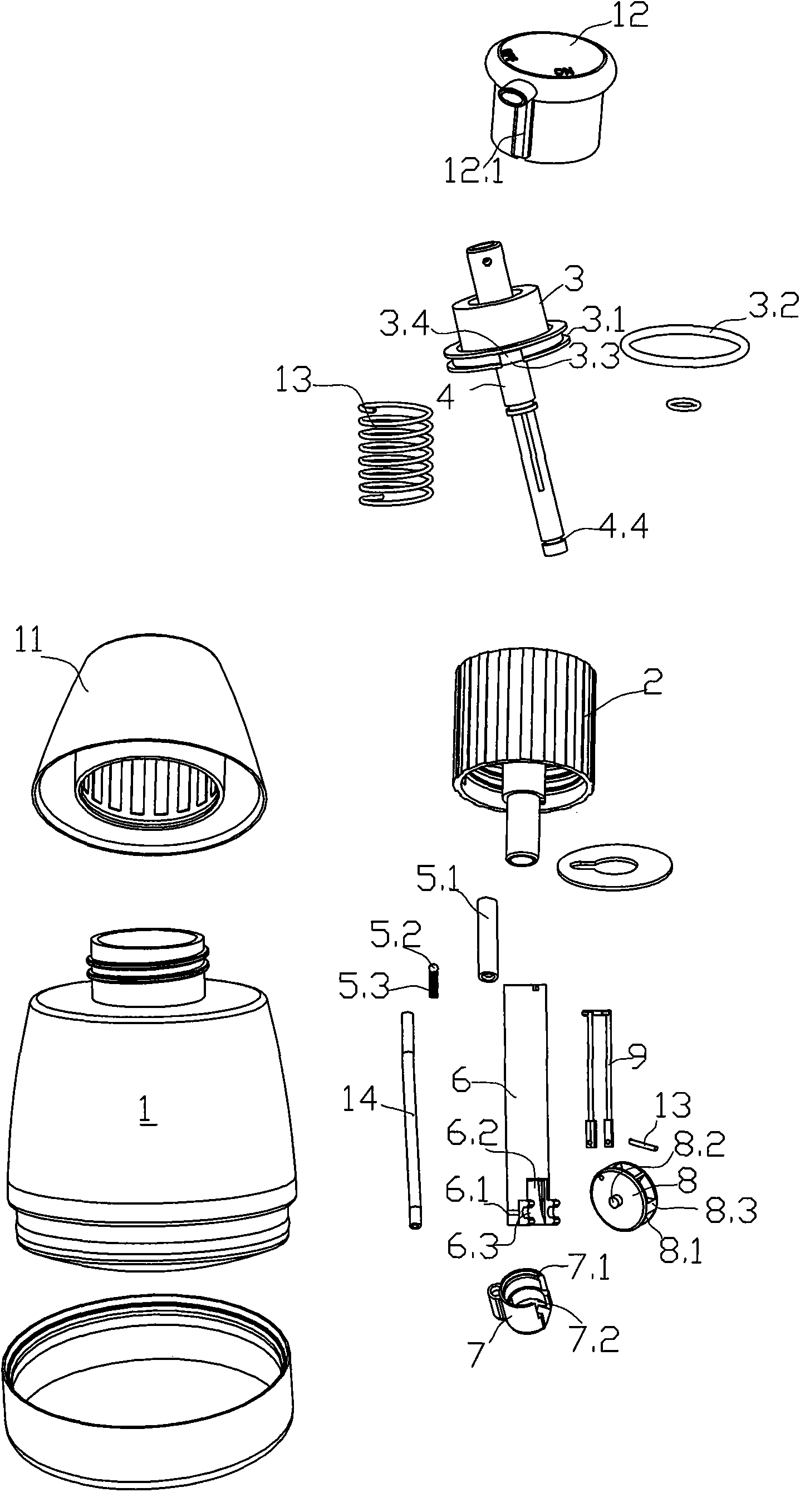

[0043] Implement Example 1, such as Figure 1-3Shown is a dry powder pump, which includes a bottle body 1, a cover 2, a piston 3, an elastic element, a piston rod 4, a one-way valve 5, a gear seat 6, a housing seat 7, a gear 8, a gear connecting rod 9, etc. The main parts, the bottle body 1 is hollow, and its inner cavity is used to hold powder such as talcum powder or prickly heat powder. Generally, the bottle body cannot hold all the powder, and some space needs to be reserved. In order to facilitate the dry powder in the bottle to be used up as much as possible, The bottom of the bottle body 1 is in a concave arc shape, the bottom of the bottle body 1 is socketed on the base of the bottle body, the cap 2 is installed on the upper part of the bottle body 1 through threaded connection, and a sealing ring 10 is lined between the cap 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com