Engineering pile deviation preventing structure of soft soil foundation and pretreatment method

A technology of soft soil foundation and pretreatment method, which is applied in the direction of foundation structure engineering, sheet pile wall, excavation, etc., which can solve the problems of pile deviation, long time, poor water permeability, etc., and achieve the prevention of engineering pile deviation and reasonable structure Practical, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] 1. Determine the reinforcement plan.

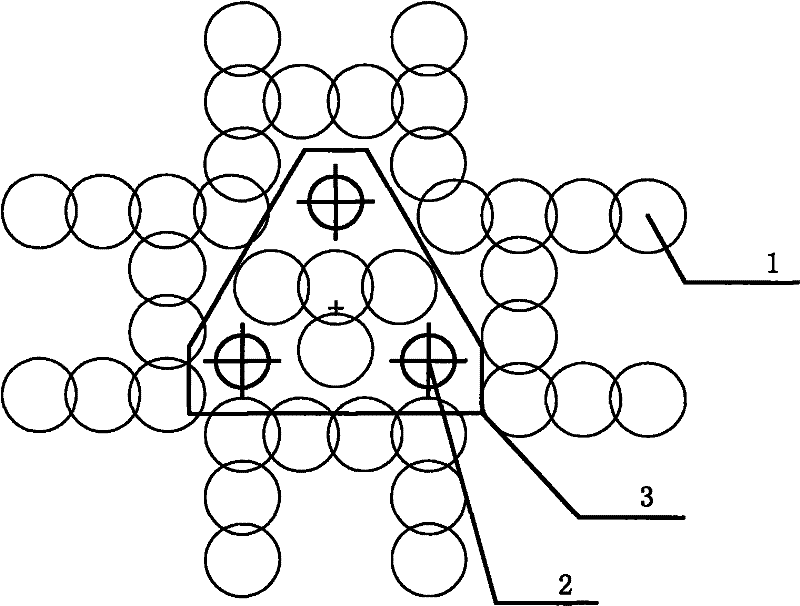

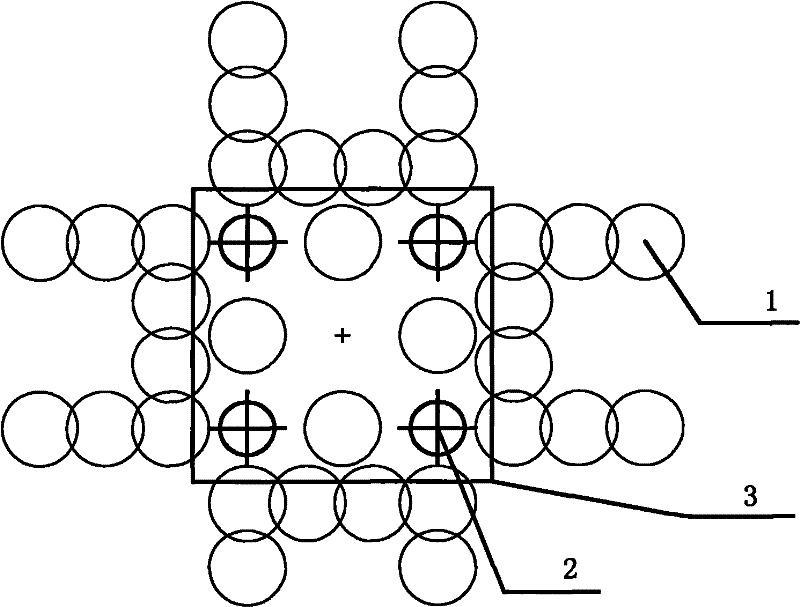

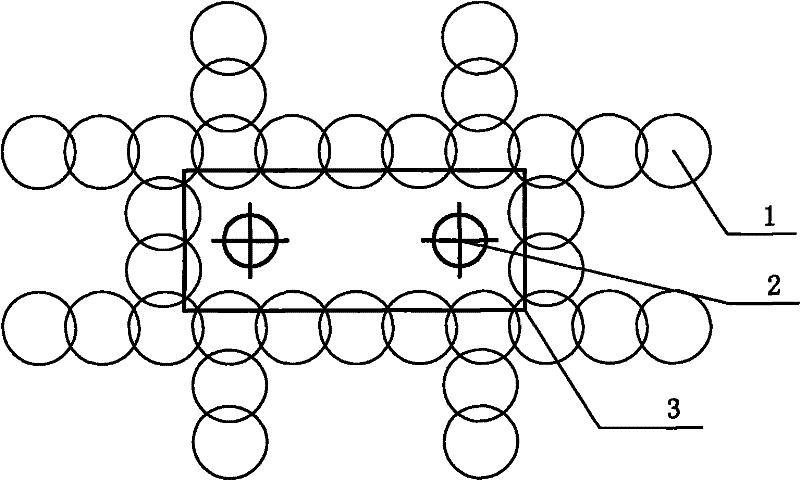

[0029] Such as Figure 1 to Figure 3 As shown, the reinforcement structure in the anti-engineering pile offset structure of the soft soil foundation is set within the range of about 2 / 3-3 / 4 of the foundation pit centered on the center of the foundation pit, including a plurality of mixing piles 1, and these stirring piles are basically It surrounds the cap 3 and is roughly arranged in a "well" shape with the cap as the wellhead to form a continuous grid-like reinforcement block. The engineering piles 2 are arranged on the corners corresponding to the cap 3. Reinforcement blocks corresponding to multiple caps can also be independent.

[0030] Such as figure 1 The cap is roughly triangular in shape, and there are three engineering piles, all of which are arranged at the corners of the cap, and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com