Pruning machine

A technology of a pruning machine and a casing is applied in the field of pruning machines, which can solve the problems of insufficient firmness and easy falling off, and achieve the effects of convenient manufacture, simple and reliable operation, and good work safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

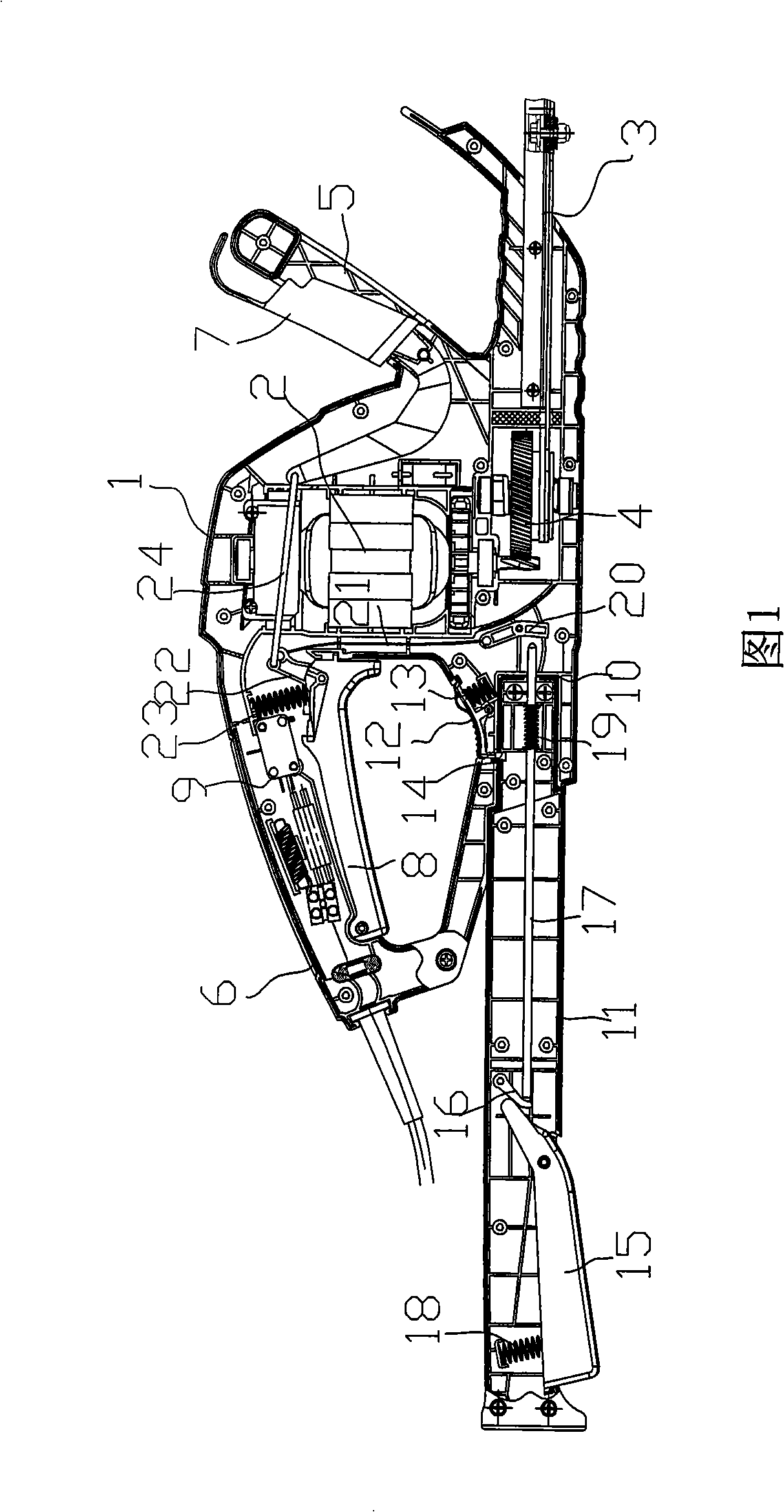

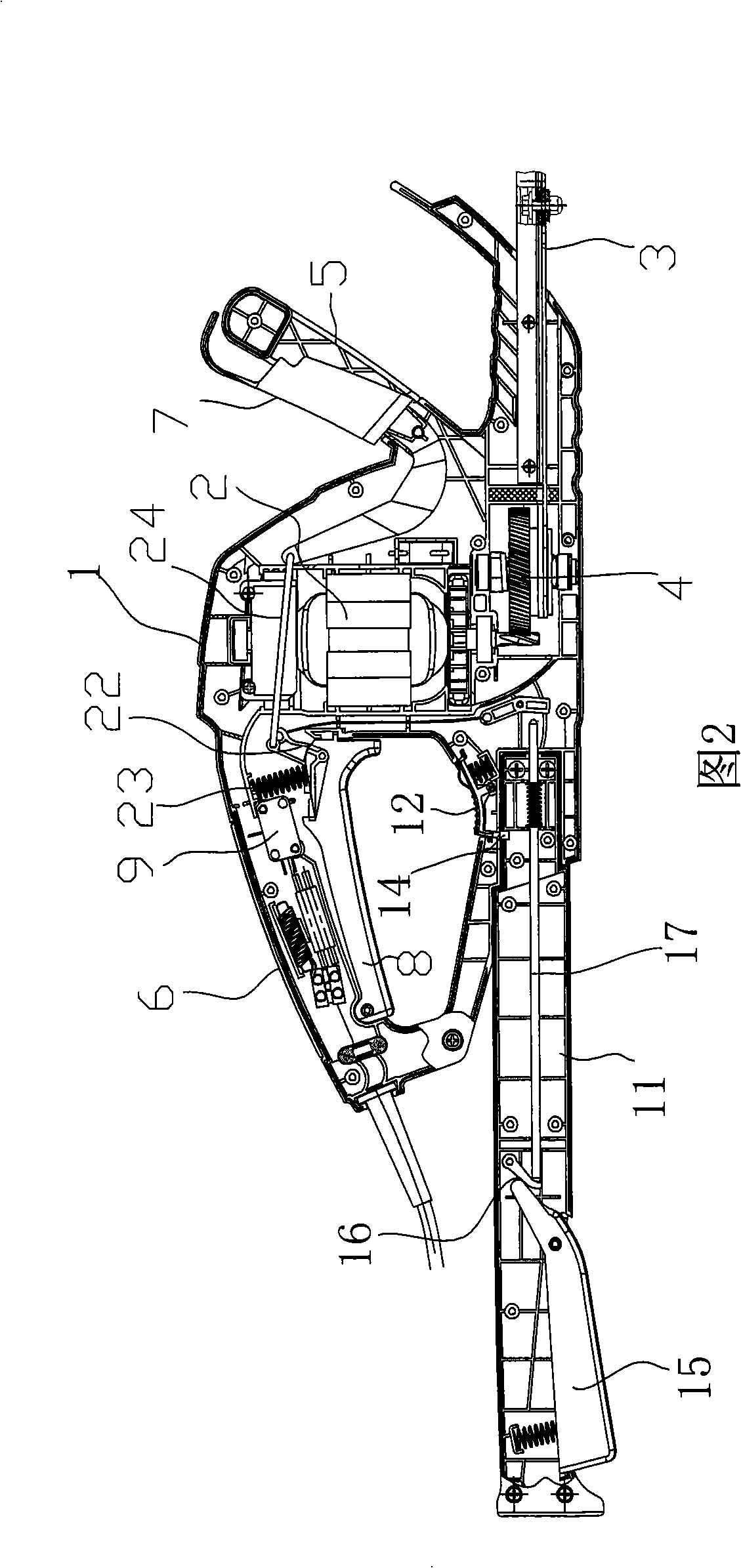

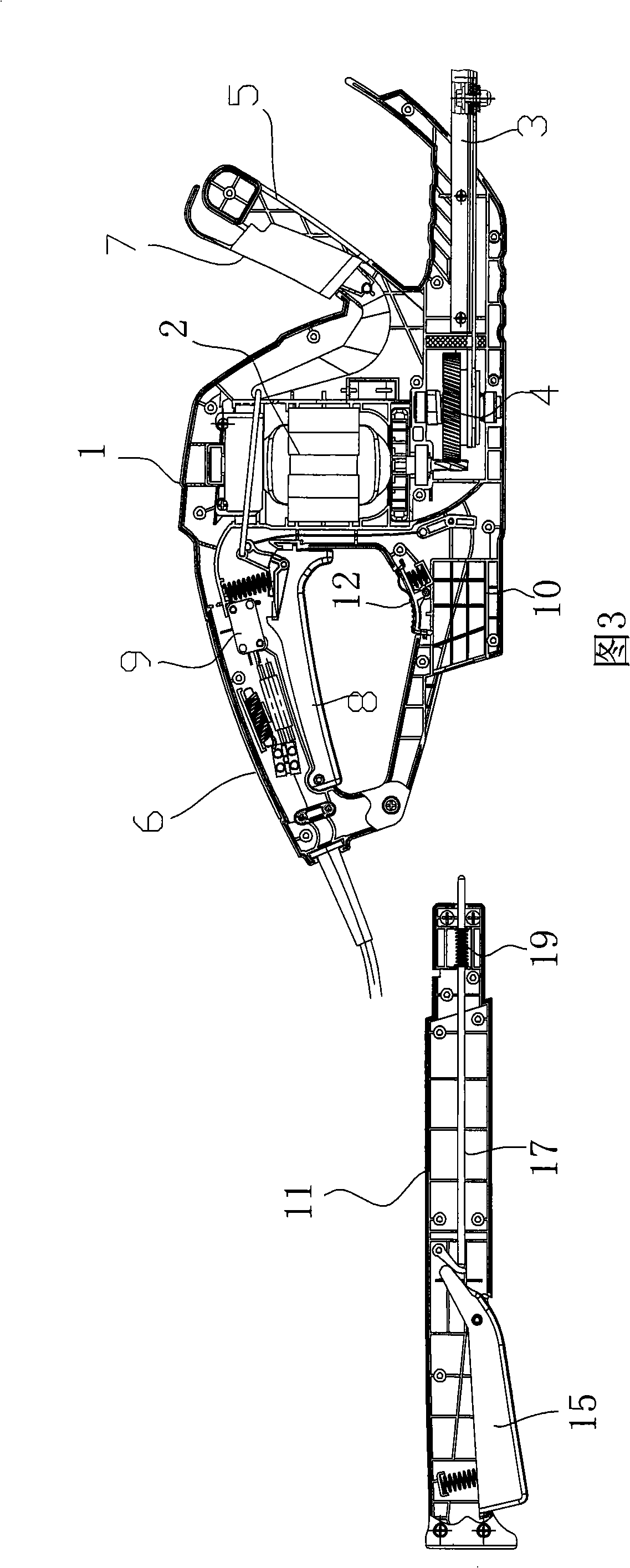

[0026] As shown in Figure 1-5, a pruning machine includes an organic casing 1. The casing 1 is usually assembled and connected with screws after the left and right casings are combined. The motor 2 is installed in the casing 1. The motor The output shaft of 2 is connected through the transmission mechanism 4 to drive the upper and lower blades 3 that reciprocate outside the casing 1. The rear and front of the casing 1 are usually connected with a rear handle 6 and a front handle 5, and in The rear handle 6 and the front handle 5 are respectively rotatably hingedly connected with a rear trigger 8 and a front trigger 7. Correspondingly, a micro switch 9 for controlling whether the motor works or not is installed in the casing 1 or the handle. Make the rear trigger 8 and the front trigger 7 cooperate with the contacts of the micro switch 9 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com