Optical sensor for printer media motion detection

an optical sensor and motion detection technology, applied in printing, other printing apparatus, etc., can solve the problems of misidentification of print media type, inability to detect the slippage of the media with respect to the drive system, etc., to achieve accurate measurement of the motion of the print media, enabling accurate reading of the media markings, and greater accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

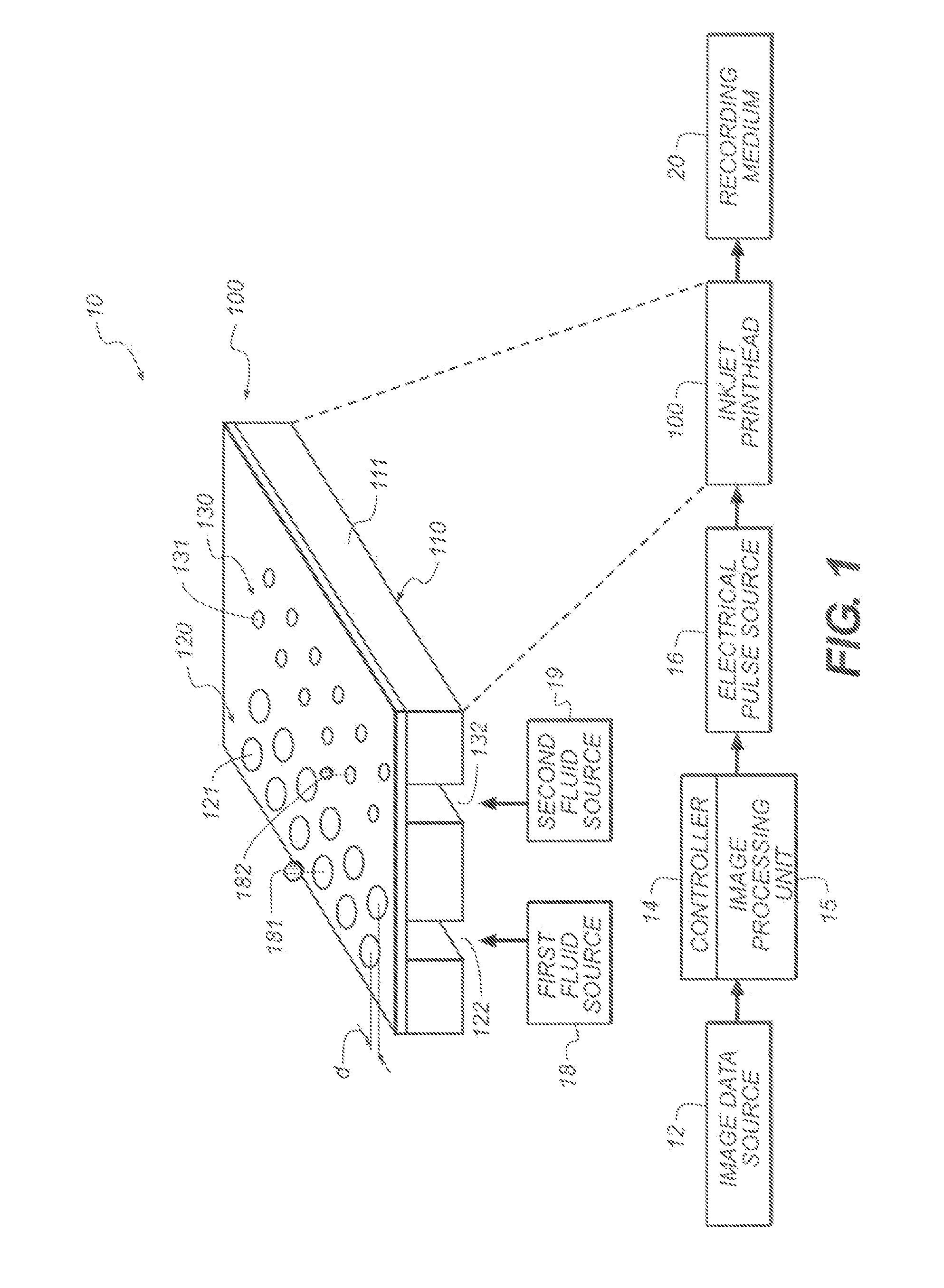

[0022]Referring to FIG. 1, a schematic representation of an inkjet printer system 10 is shown for its usefulness with the present invention and is fully described in U.S. Pat. No. 7,350,902, which is incorporated by reference herein in its entirety. Inkjet printer system 10 includes an image data source 12, which provides data signals that are interpreted by a controller 14 as being commands to eject drops. Controller 14 includes an image processing unit 15 for rendering images for printing, and the controller 14 outputs signals to an electrical pulse source 16 of electrical energy pulses that are inputted to an inkjet printhead 100, which includes at least one inkjet printhead die 110.

[0023]In the example shown in FIG. 1, there are two nozzle arrays. Nozzles 121 in the first nozzle array 120 have a larger opening area than nozzles 131 in the second nozzle array 130. In this example, each of the two nozzle arrays has two staggered rows of nozzles, each row having a nozzle density of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com