Pallet structure

A technology of pallets and sealing boards, which is applied in the field of pallet structure, and can solve problems such as unloadable items, high manufacturing costs, and heavy weight of finished pallets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

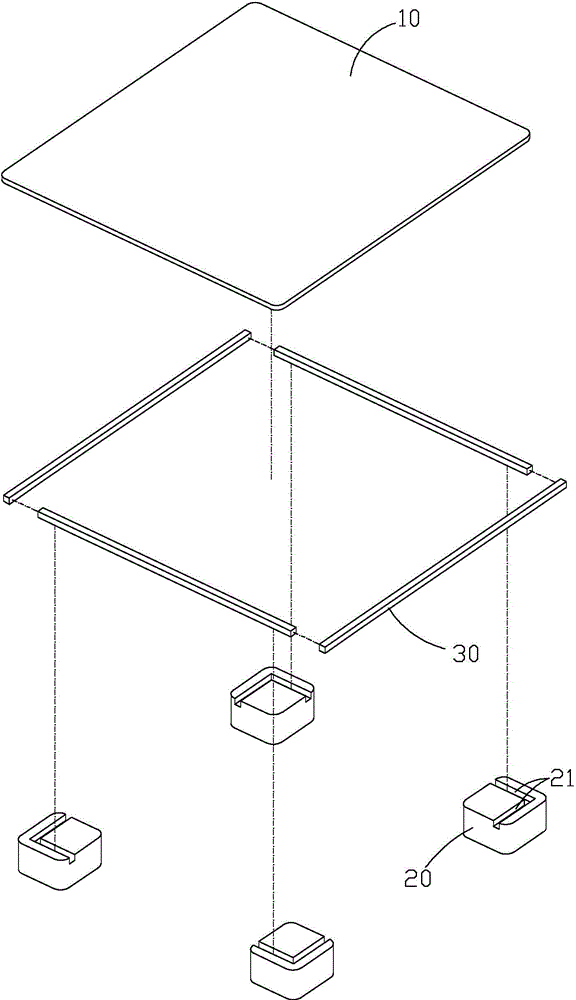

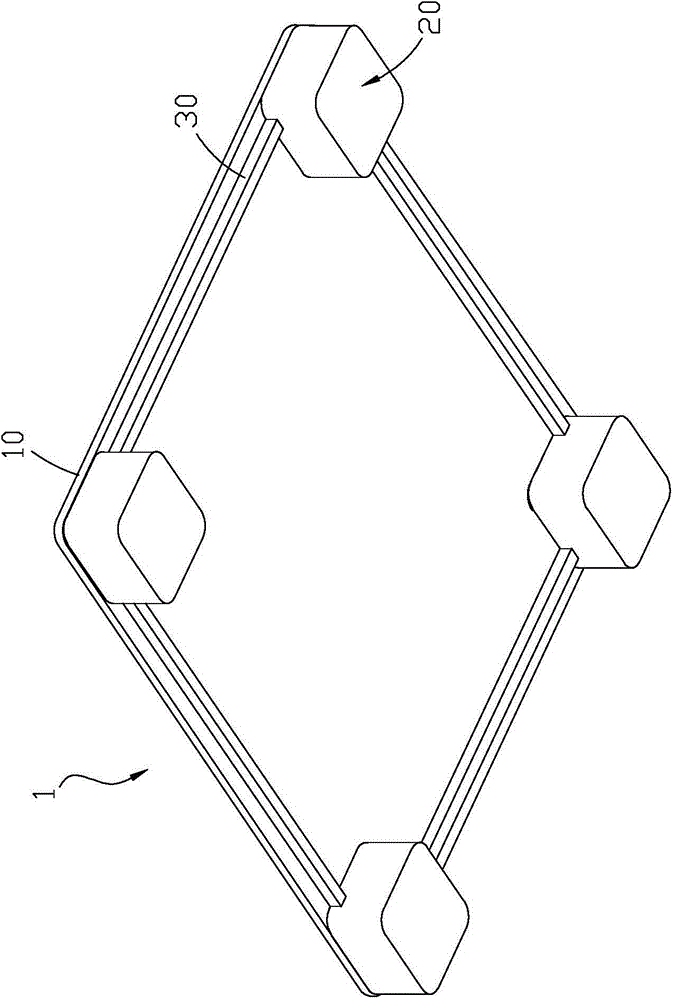

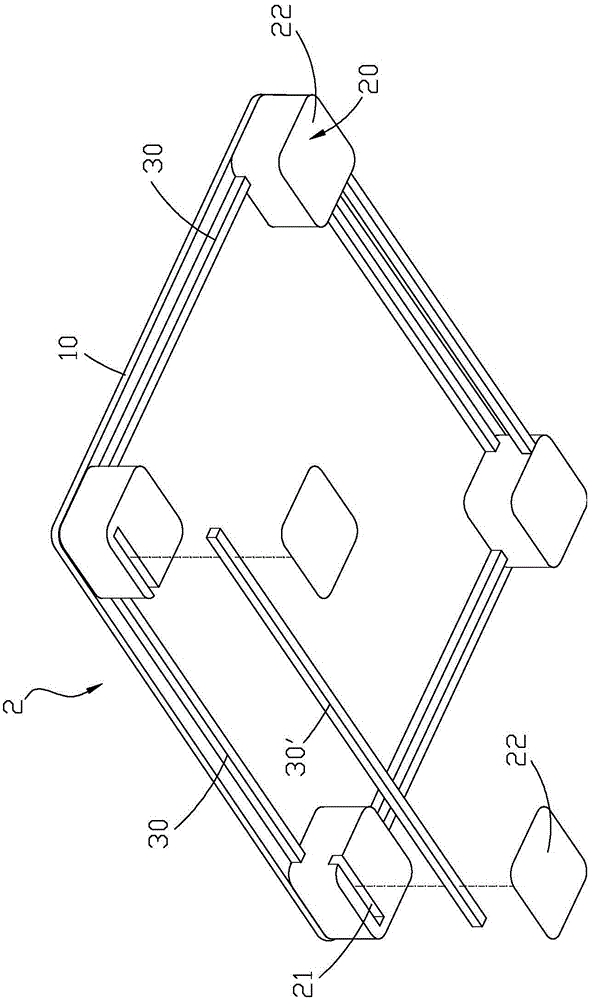

[0039] The present invention is about a "pallet structure", please refer to figure 1 , 2 As shown, it mainly includes: a carrier 10, several feet 20 and several support rods 30.

[0040] Wherein, the carrier 10 can be a carrier plate, a carrier plate with holes (such as Figure 19A shown), a load-carrying mesh body (such as Figure 19C shown), a plastic bearing plate or a plastic bearing mesh (such as Figure 19B shown) (it can also be a paper plate, but the strength will be poor); the load-bearing mesh and the plastic load-bearing mesh have several hollowed-out meshes, so their weight is lighter than that of a solid load-bearing plate (i.e. light weight), less material is used so the cost is low, and the load-bearing mesh body and the plastic load-bearing mesh body are composed of several horizontal and vertical support ribs intersecting, so the strength is stronger and can carry heavier loads, while The holes of the bearing plate body with holes can be perforations of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com