Leg assembly for paper pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

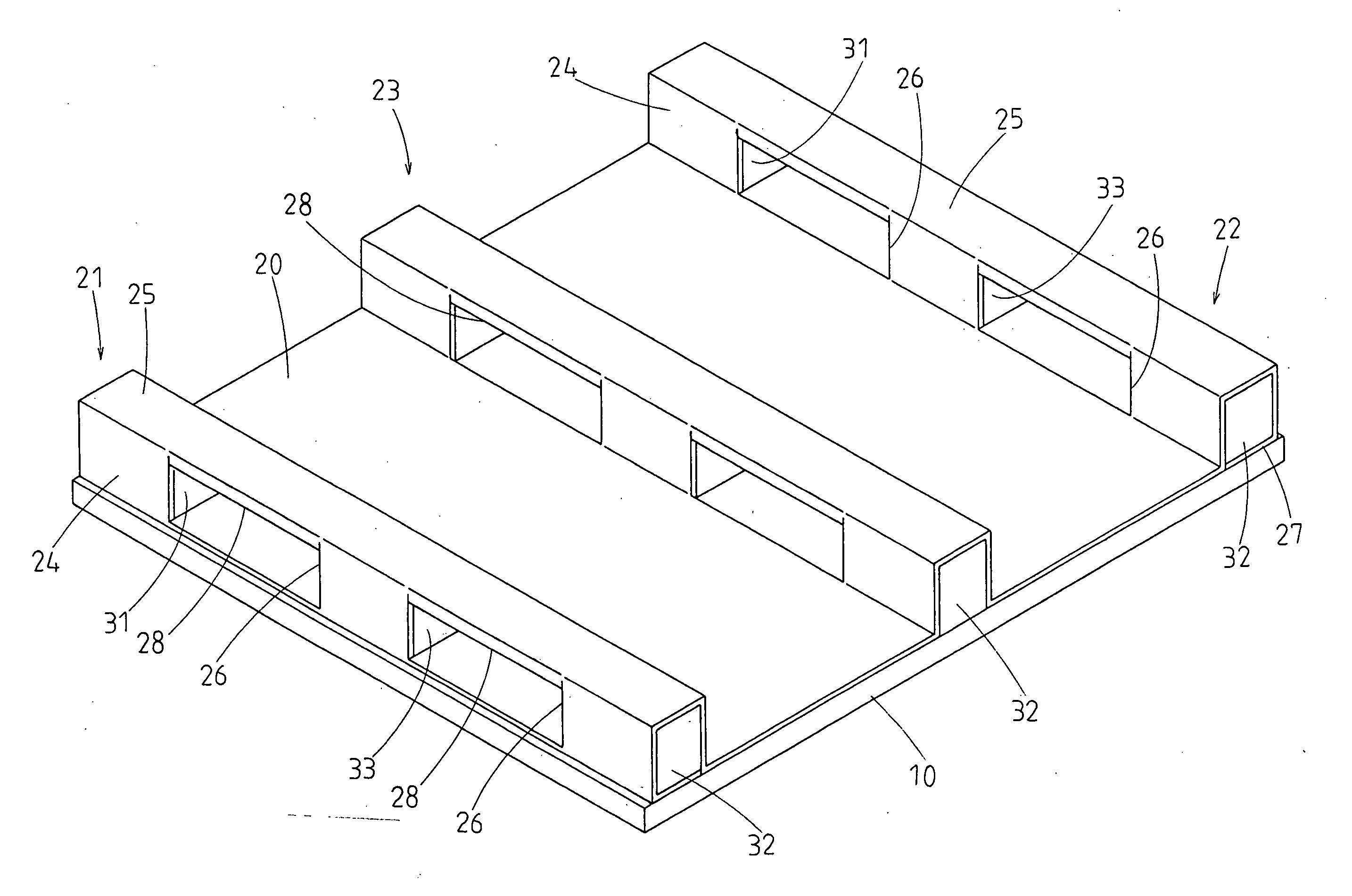

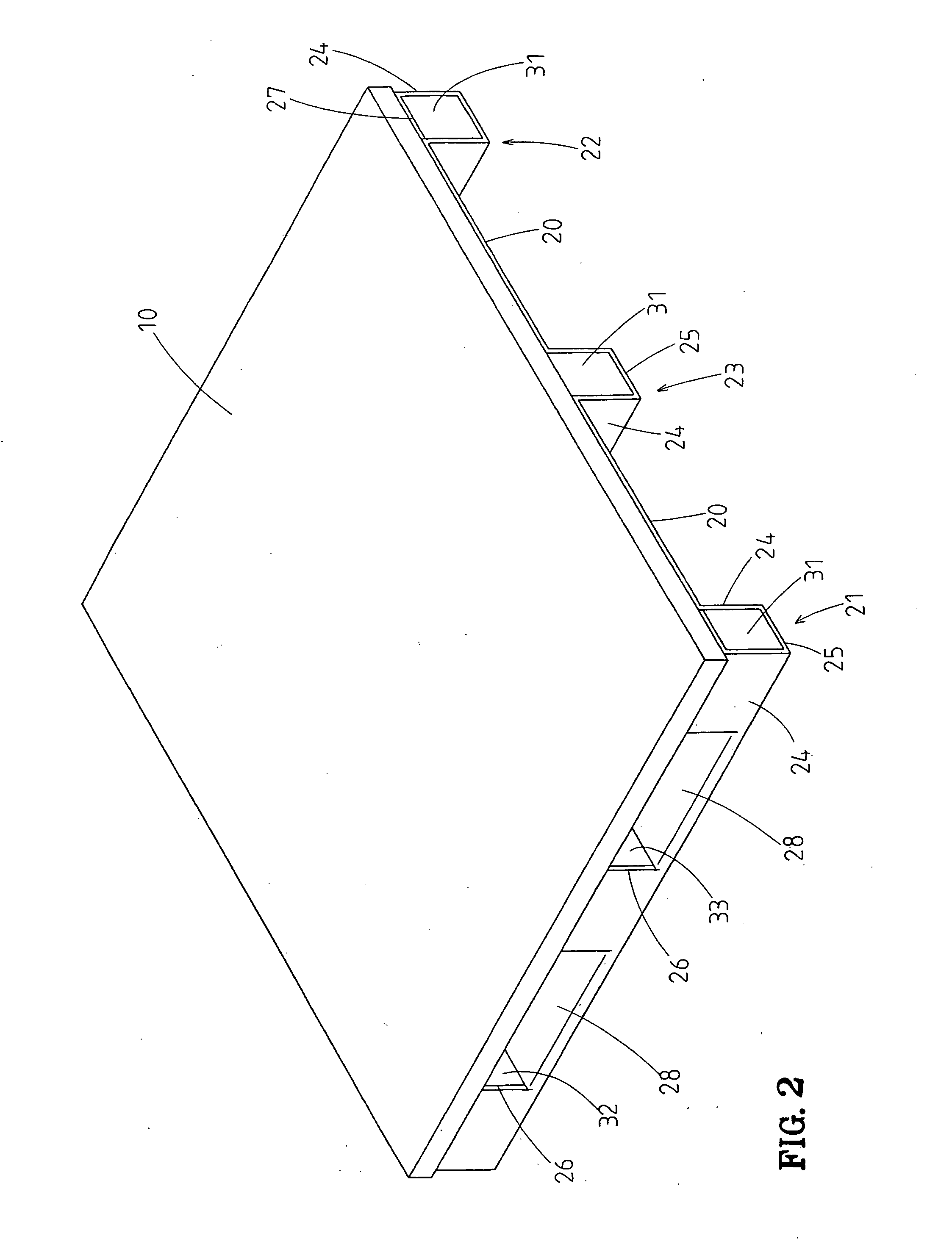

[0025]FIG. 2 illustrates an embodiment of a pallet in accordance with the present invention. The pallet comprises a top plate 10 and a leg assembly fixed below the top plate 10. The top plate 10 is substantially square or rectangular and may be formed by bonding a plurality of sheets of corrugated paper or thick paper. Cargo or the like is placed on a top side of the top plate 10. The leg assembly is also made of corrugated paper or thick paper. It is, however, noted that the top plate 10 and the leg assembly of the pallet can be made of any other suitable material.

[0026] Referring to FIGS. 2 through 4, the leg assembly comprises a bottom plate 20 and a plurality of supporting blocks 31, 32, and 33. The bottom plate 50 defines a plurality of compartments (not labeled) for receiving the supporting blocks 31, 32, and 33. In the illustrated embodiment, the bottom plate 20 comprises three receiving sections 21, 22, and 23 spaced from one another by a longitudinal space (not labeled). E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com