Collapsible container

a container and lid technology, applied in the field of collapsible containers, can solve the problem that the side walls cannot be easily collapsed during the washing process, and achieve the effect of preventing unintended collapsing walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

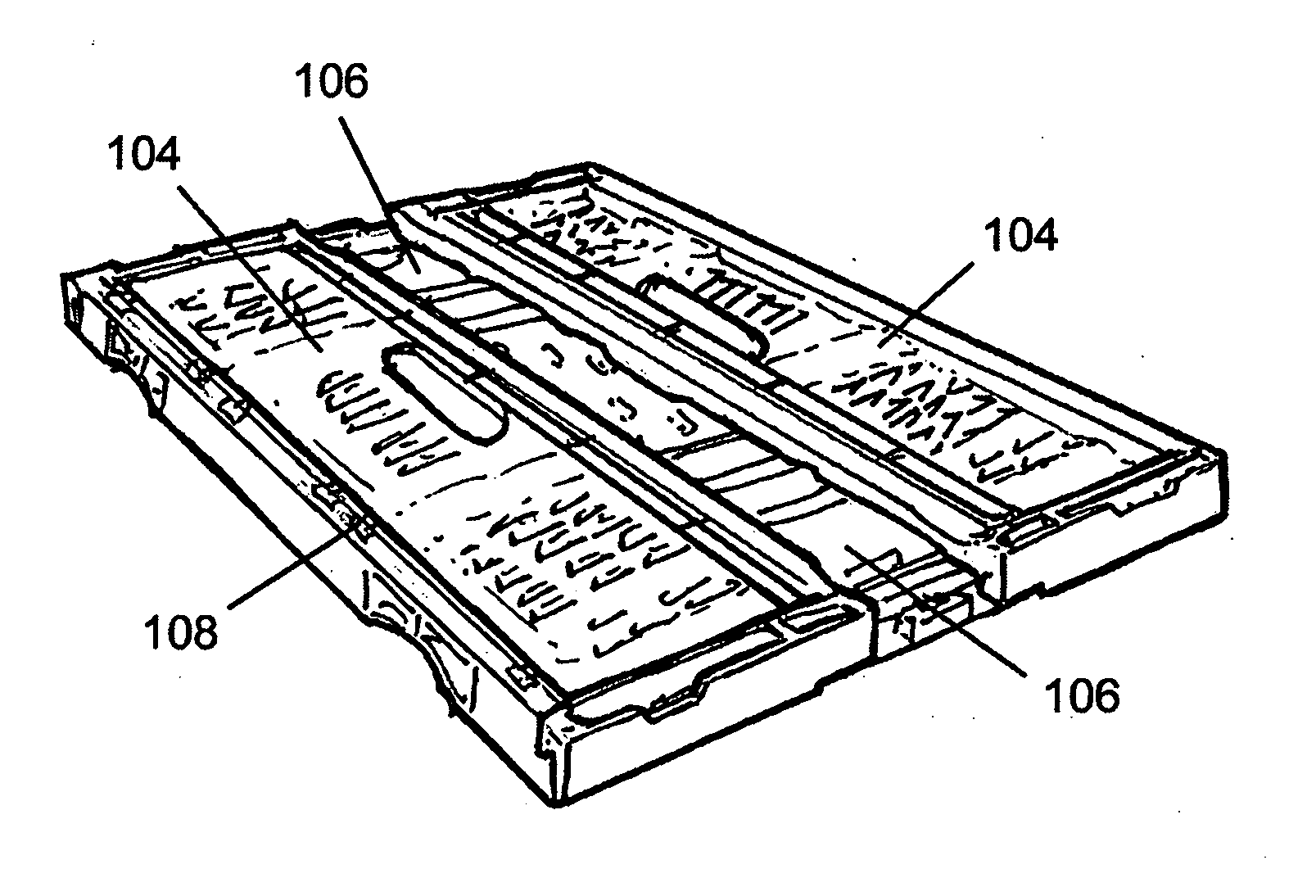

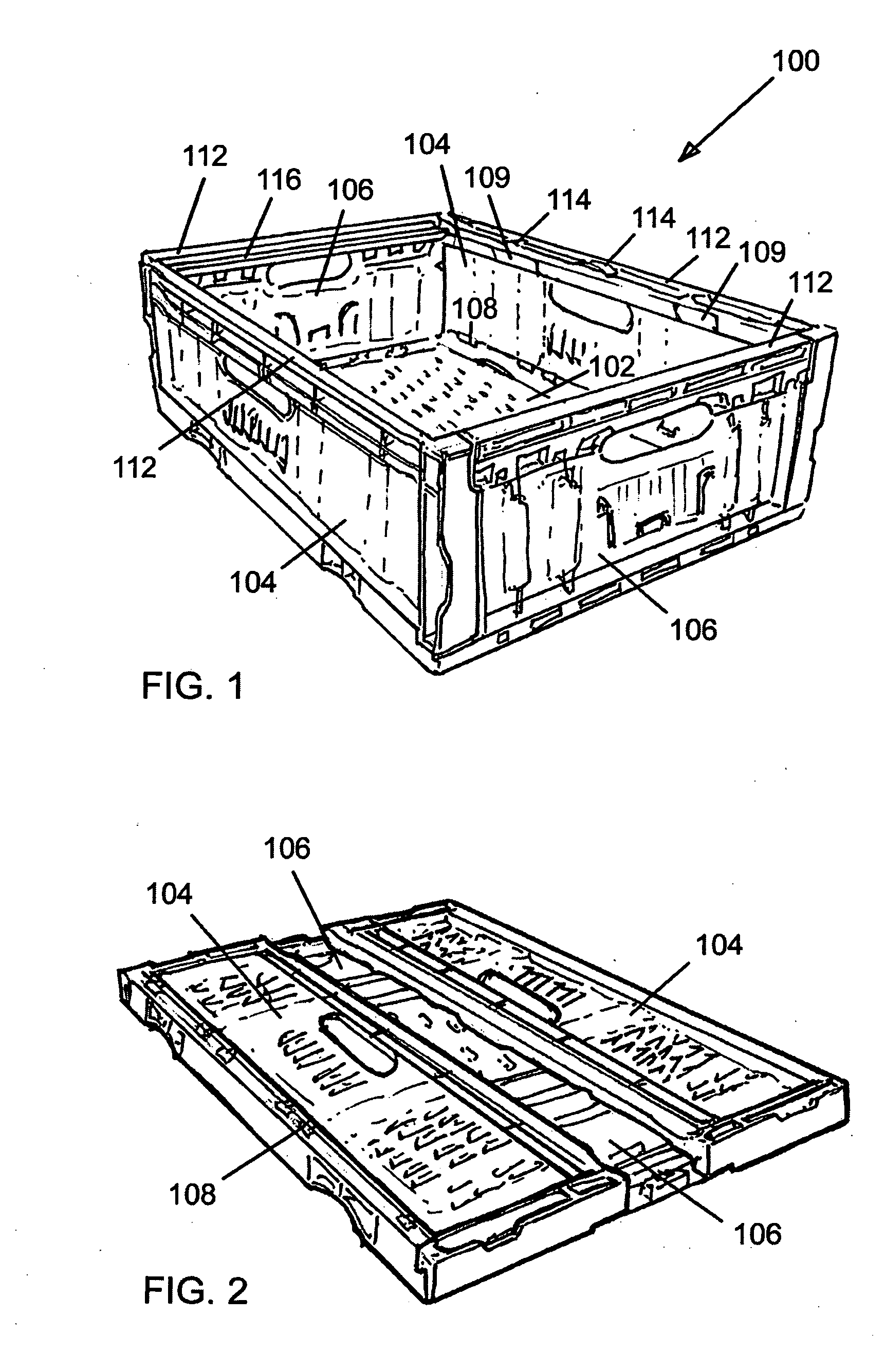

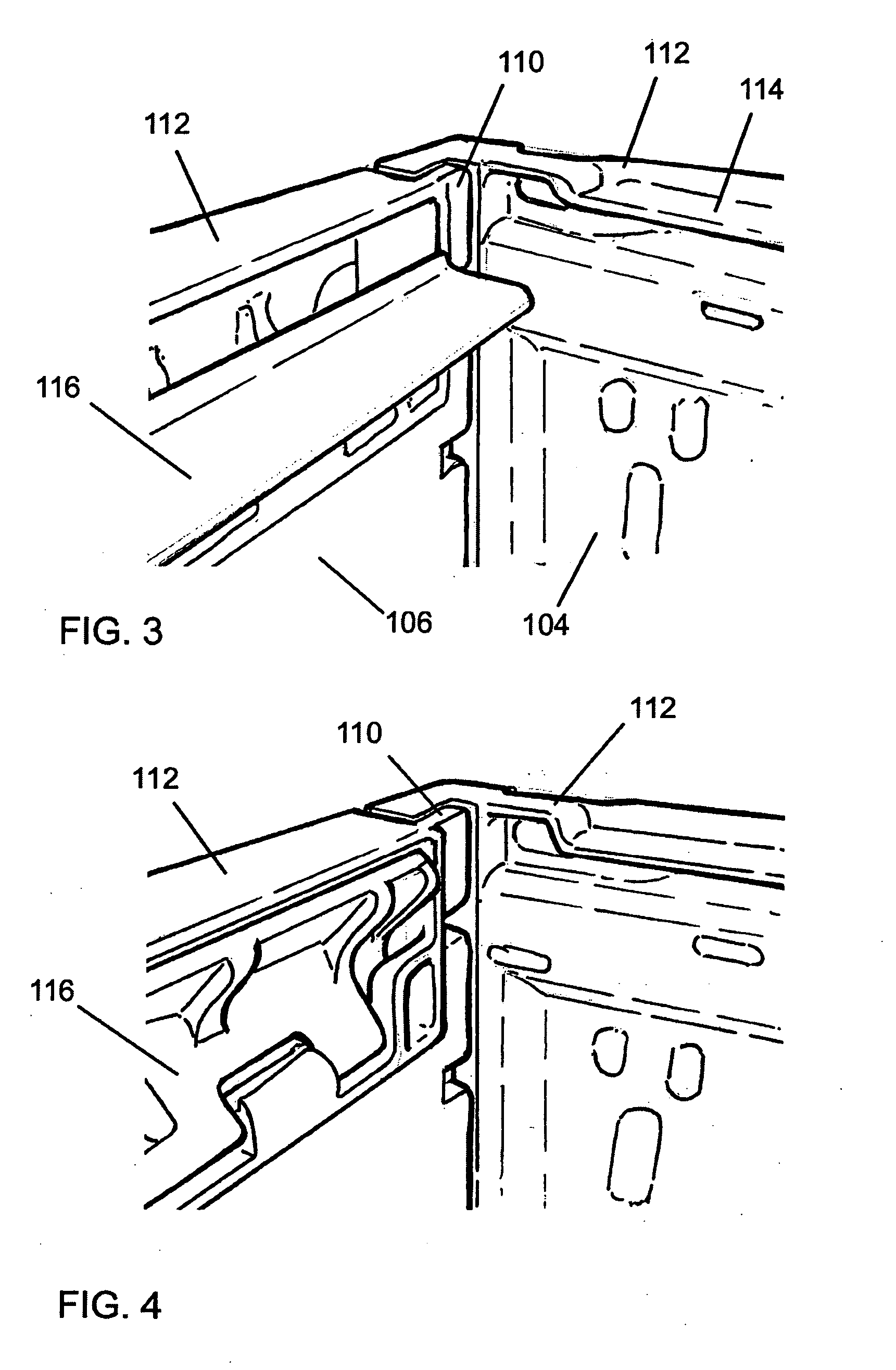

[0079] The first container 100 shown in FIGS. 1-6 comprises a substantially rectangular base 102, two longer side walls 104 and two shorter end walls 106. The side walls and the end walls are attached to the base 102 by means of hinges 108, which allow the walls to be folded flat onto the base 102 for storage or transportation in a collapsed condition, as shown in FIG. 2. It will be noted that the end walls 106 are folded first and that in the collapsed condition they lie adjacent to the base 102. The length of the end walls 106 is less than the separation of the erected side walls 104, so that the end walls can pivot between the side walls. The side walls 104 are collapsed after the end walls 106 and in the collapsed condition overlie the end walls 106. Recesses 109 are provided where necessary in the side walls to allow them to lie flat against the end walls.

[0080] Complementary locking formations 110 in the form of resilient detents are provided on the end walls and the side wal...

embodiment 2

[0088] The second container 200 shown in FIGS. 7-12 comprises a substantially rectangular base 202, two side walls 204 and two end walls 206. The side walls and the end walls are attached to the base 202 by means of hinges 208, which allow the walls to be folded flat onto the base 202 for storage or transportation in a collapsed condition, as shown in FIG. 8. It will be noted that the end walls 206 are folded first and that in the collapsed condition they lie adjacent to the base 202. The side walls 204 are collapsed after the end walls 206 and in the collapsed condition overlie the end walls 206.

[0089] Complementary locking formations 210 are provided on the end walls and the side walls, to lock the walls together when the container is in the erected condition as shown in FIG. 7. The locking formations 210 are conventional and will not be described in detail.

[0090] The upper edges 212 of the side walls 204 and the end walls 206 are designed to receive the edges of the base 202 of...

embodiment 3

[0098] The third container 300 shown in FIGS. 13-18 is similar in many respects to the second container and comprises a substantially rectangular base 302, two side walls 304 and two end walls 306. The side walls and the end walls are attached to the base 302 by means of hinges 308, which allow the walls to be folded flat onto the base 302 for storage or transportation in a collapsed condition, as shown in FIG. 14. It will be noted that the end walls 306 are folded first and that in the collapsed condition they lie adjacent to the base 302. The side walls 304 are collapsed after the end walls 306 and in the collapsed condition overlie the end walls 306.

[0099] Complementary locking formations are provided on the end walls and the side walls, to lock the walls together when the container is in the erected condition as shown in FIG. 13. The locking formations are conventional and will not be described in detail.

[0100] The upper edges 312 of the side walls 304 and the end walls 306 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com