Resistance memory an a method for fabricating integrated circuit with same

A technology of resistive memory and integrated circuit, applied in static memory, digital memory information, circuits, etc., can solve the problems of complex manufacturing process, affecting the performance of resistive memory, damage to the interface structure of storage medium 170, etc., to simplify the manufacturing process and process method. Flexible and controllable, good interface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a manufacturing method of an integrated circuit containing a resistive memory, refer to the attached Figure 12 shown, including:

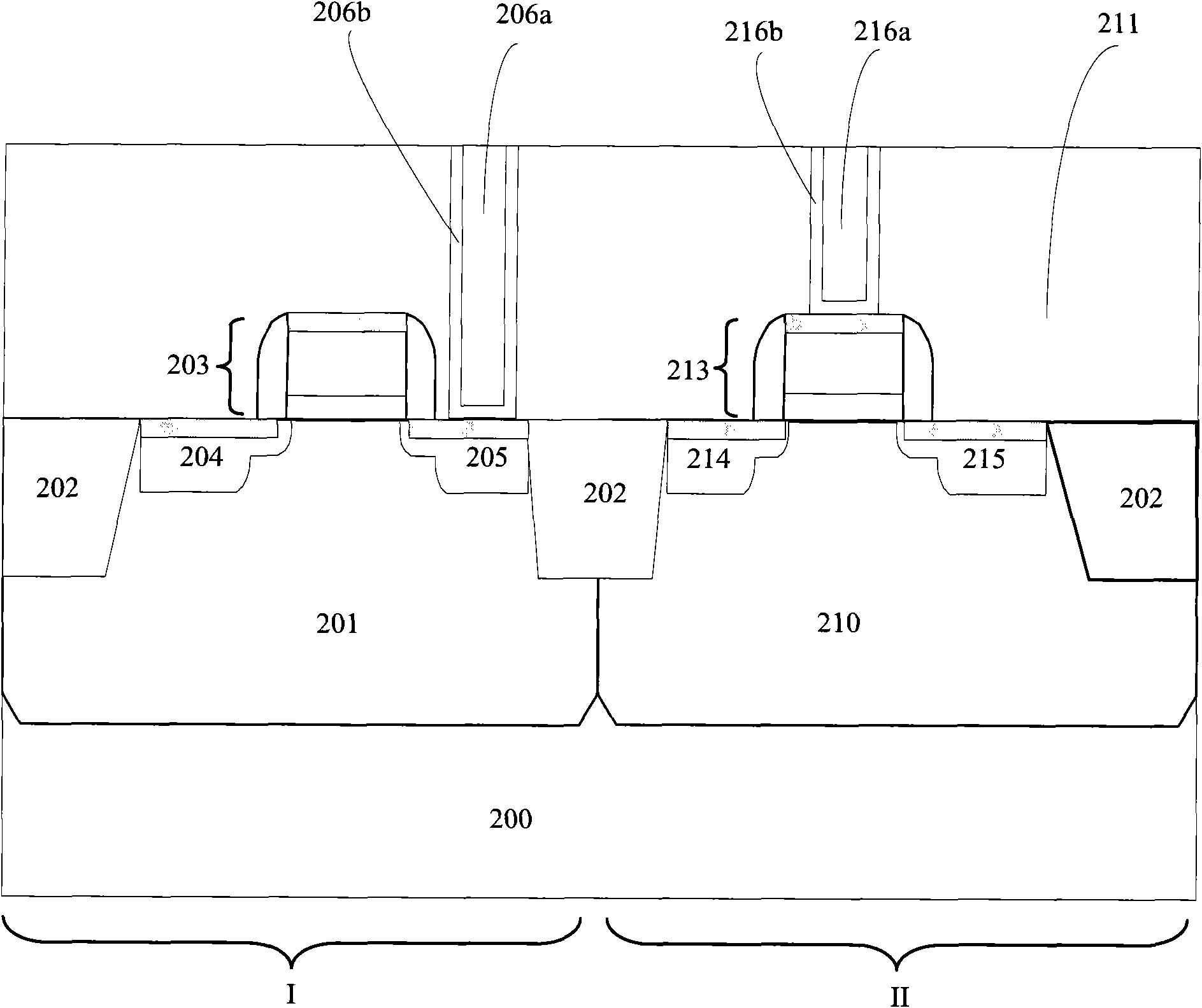

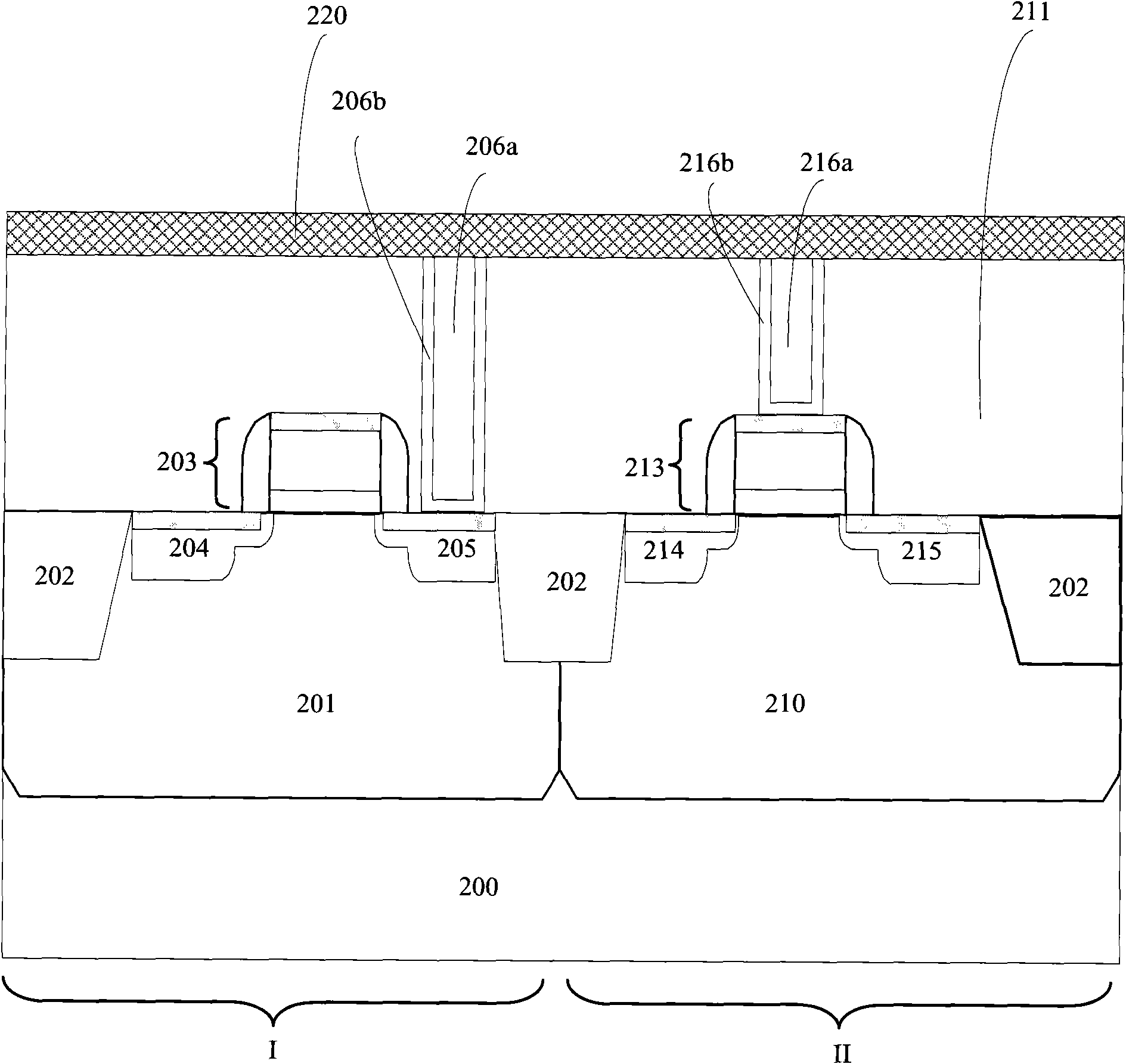

[0044] Provide a semiconductor substrate and an interlayer dielectric layer on the semiconductor substrate, the semiconductor substrate and the interlayer dielectric layer include a core device area and a peripheral circuit area;

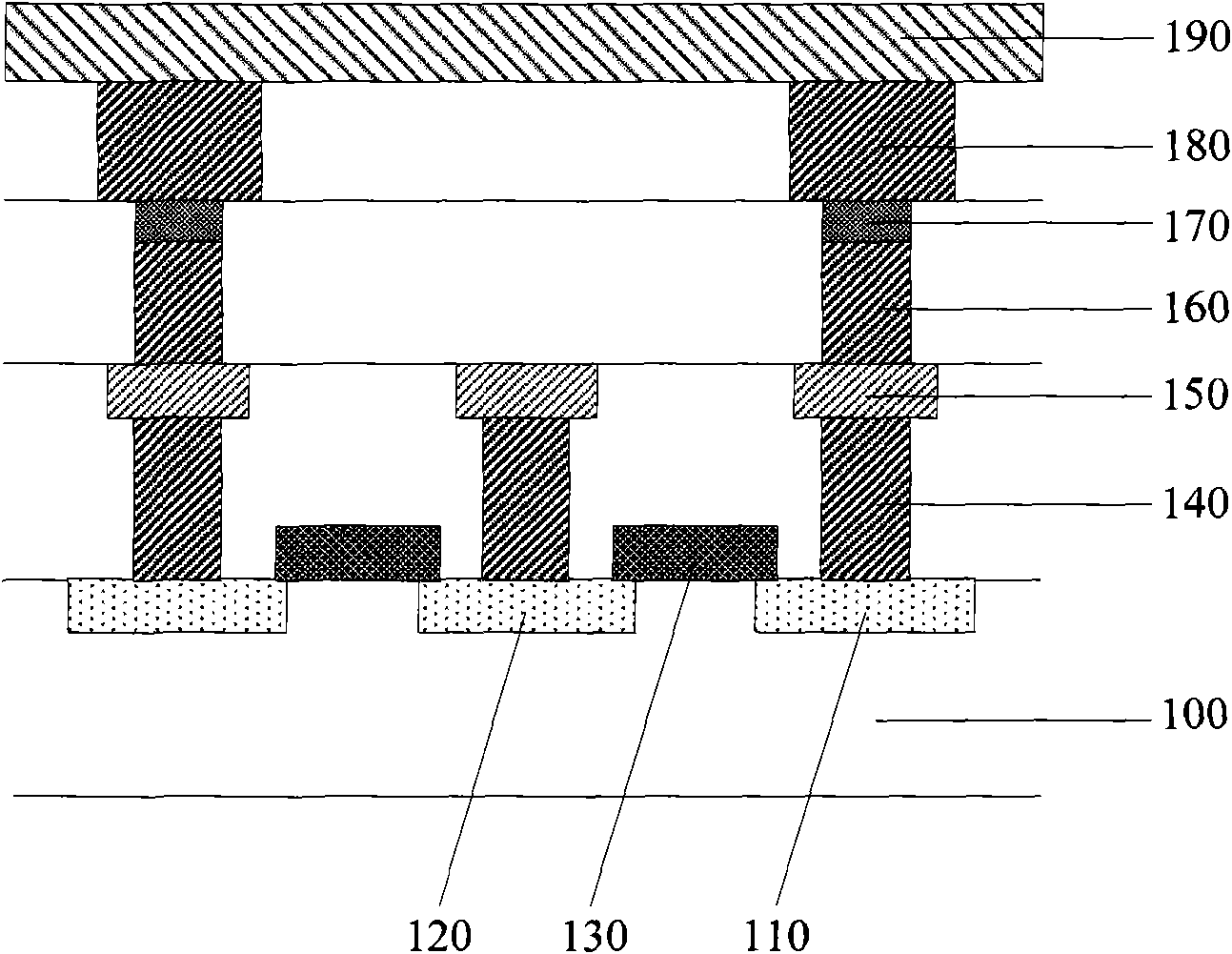

[0045]Openings are respectively formed in the interlayer dielectric layer of the core device area and the peripheral circuit area, and barrier layers and metal wiring are filled in the openings in order to form a first interconnection structure and a second interconnection structure. The first interconnection structure is used for The second interconnect structure is used to electrically connect the semiconductor devices in the core device area, and the second interconnection structure is used to electrically connect the semiconductor devices in the peripheral circuit area;

[0046] form...

Embodiment 2

[0091] This embodiment provides a resistance memory, refer to the attached Figure 11 As shown, it includes a first interconnection structure as a lower electrode, the first interconnection structure includes a metal wiring 206a and a barrier layer 206b located on the outer sidewall of the metal wiring, and a first dielectric layer on the metal wiring 206a as a storage medium layer layer 207, an etch barrier layer 220a on the barrier layer 206b, a first conductive layer 212a on the etch barrier layer 220a and the first dielectric layer 207, and a second conductive layer 209 on the first conductive layer 212a , the first conductive layer 212a and the second conductive layer 209 constitute the upper electrode of the resistive memory.

[0092] The blocking medium layer is silicon nitride or silicon oxide or a compound structure of silicon nitride and silicon oxide, and the thickness is 20nm-80nm.

[0093] Wherein, the first interconnection structure is located in the interlayer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com