Winding machine

A bobbin winder and bobbin technology, applied in the field of bobbin winders, can solve the problems of bobbin spindle overload, single bobbin collapse, high load of bobbin spindle, etc., and achieve the effect of reducing overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

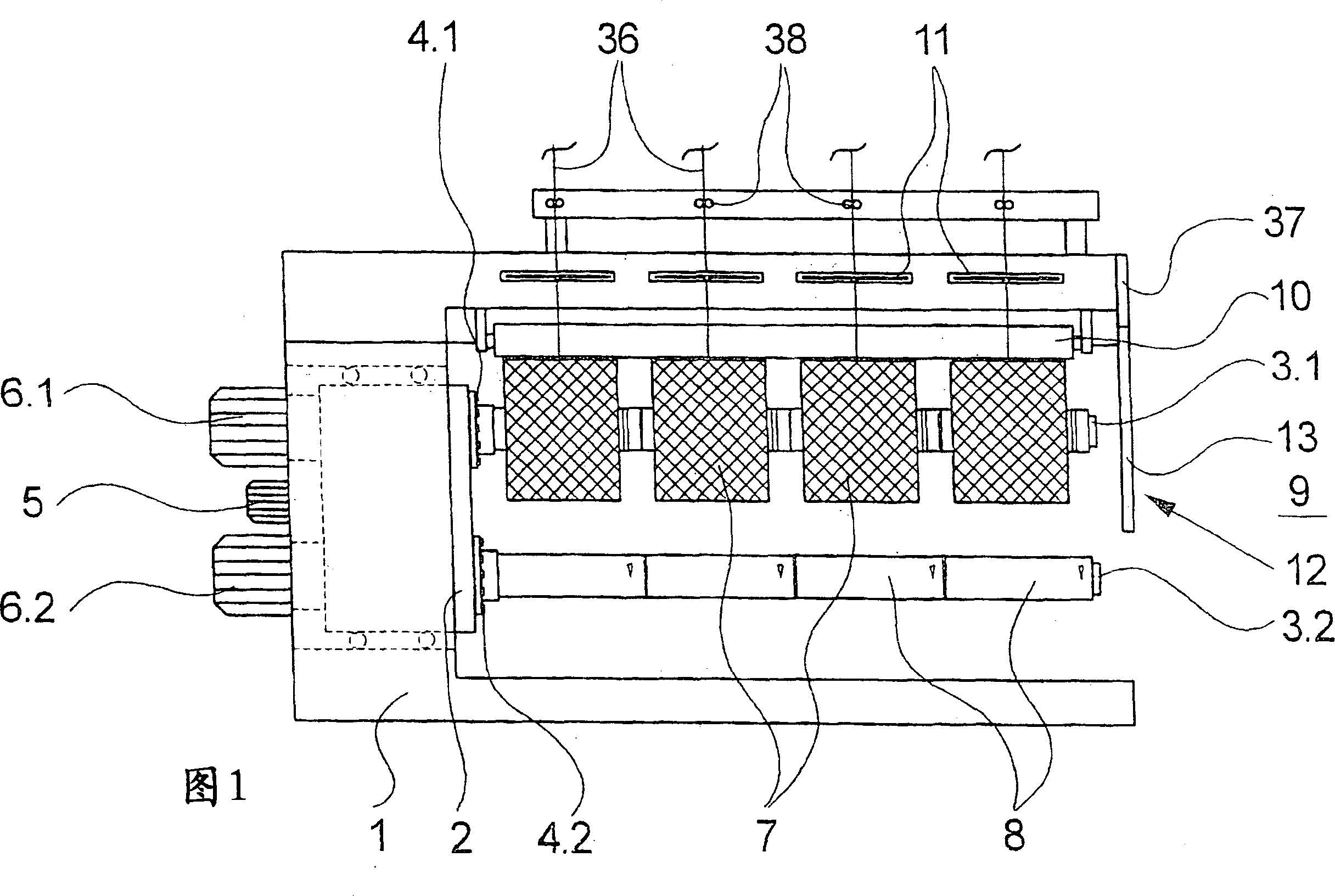

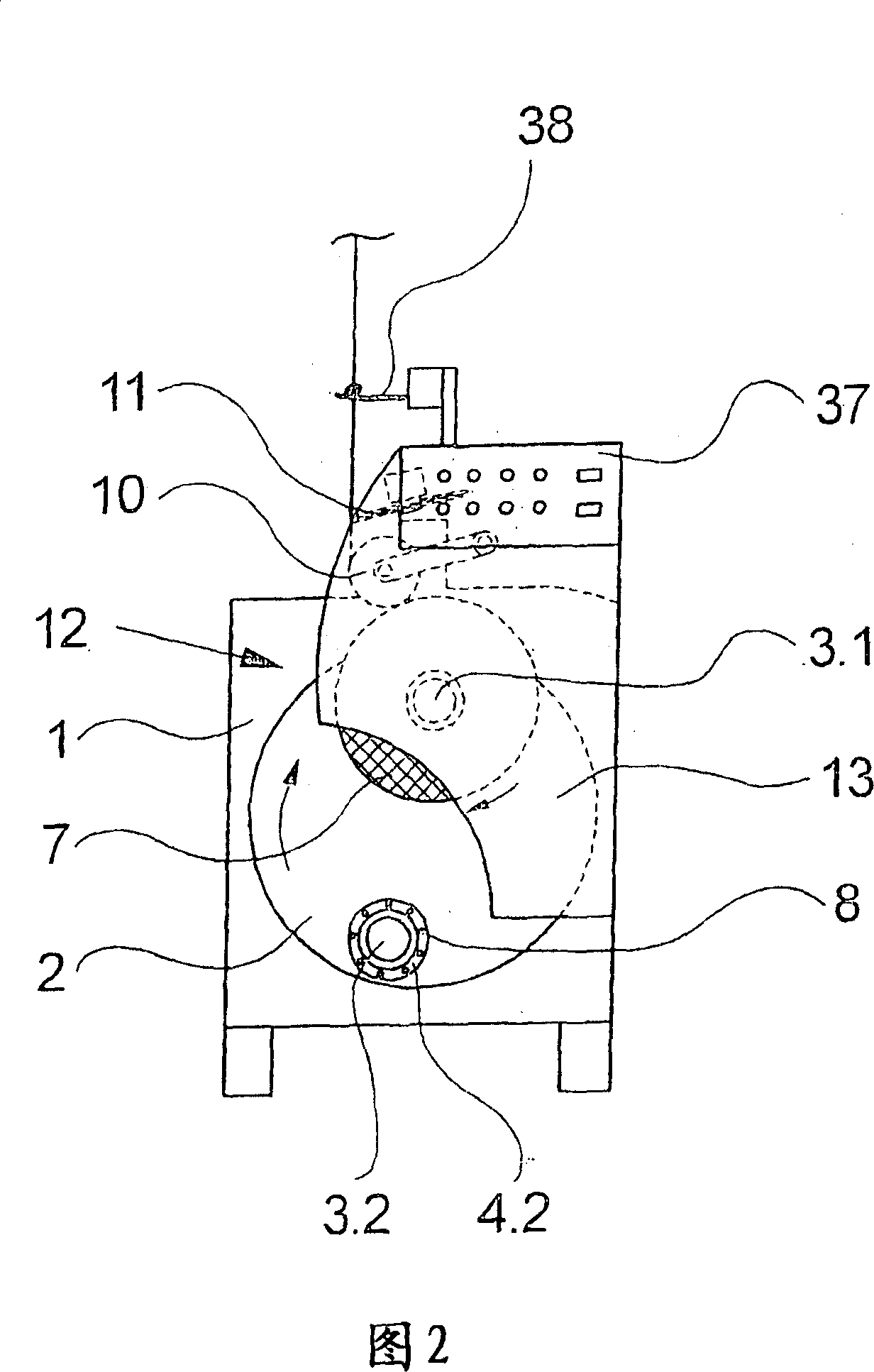

[0025] 1 and 2 schematically show several views of a first exemplary embodiment of a winding machine according to the invention. FIG. 1 shows a side view and FIG. 2 shows the embodiment in front view. The following description applies to both figures, if not explicitly for a figure.

[0026] The bobbin winder 1 has a bobbin gyrator 2 which is rotatably mounted on a machine frame 1 . Two bobbin spindles 3.1 and 3.2 are fixed to the bobbin gyrator 2, offset to one another by approximately 180°. The bobbin spindle 3.1 is connected to the bobbin gyrator 2 via a fastening mechanism 4.1 and the bobbin spindle 3.2 is connected via a fastening mechanism 4.2. The bobbin spindles 3.1 and 3.2 are each assigned a spindle drive 6.1 and 6.2 at their drive ends. The bobbin gyrator 2 is connected to a rotary drive 5 .

[0027] On the free-hanging bobbin spindles 3.1 and 3.2, a plurality of bobbin tubes 8 for receiving bobbins are fastened one behind the other. In the situation shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com