Concrete mixing plant configured with vibration type mixing main engine

A technology of vibrating mixing and mixing stations, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve problems affecting measurement accuracy, vibration of the main building platform, and degradation of mixing quality, so as to improve mixing performance and reduce the impact of vibration , The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

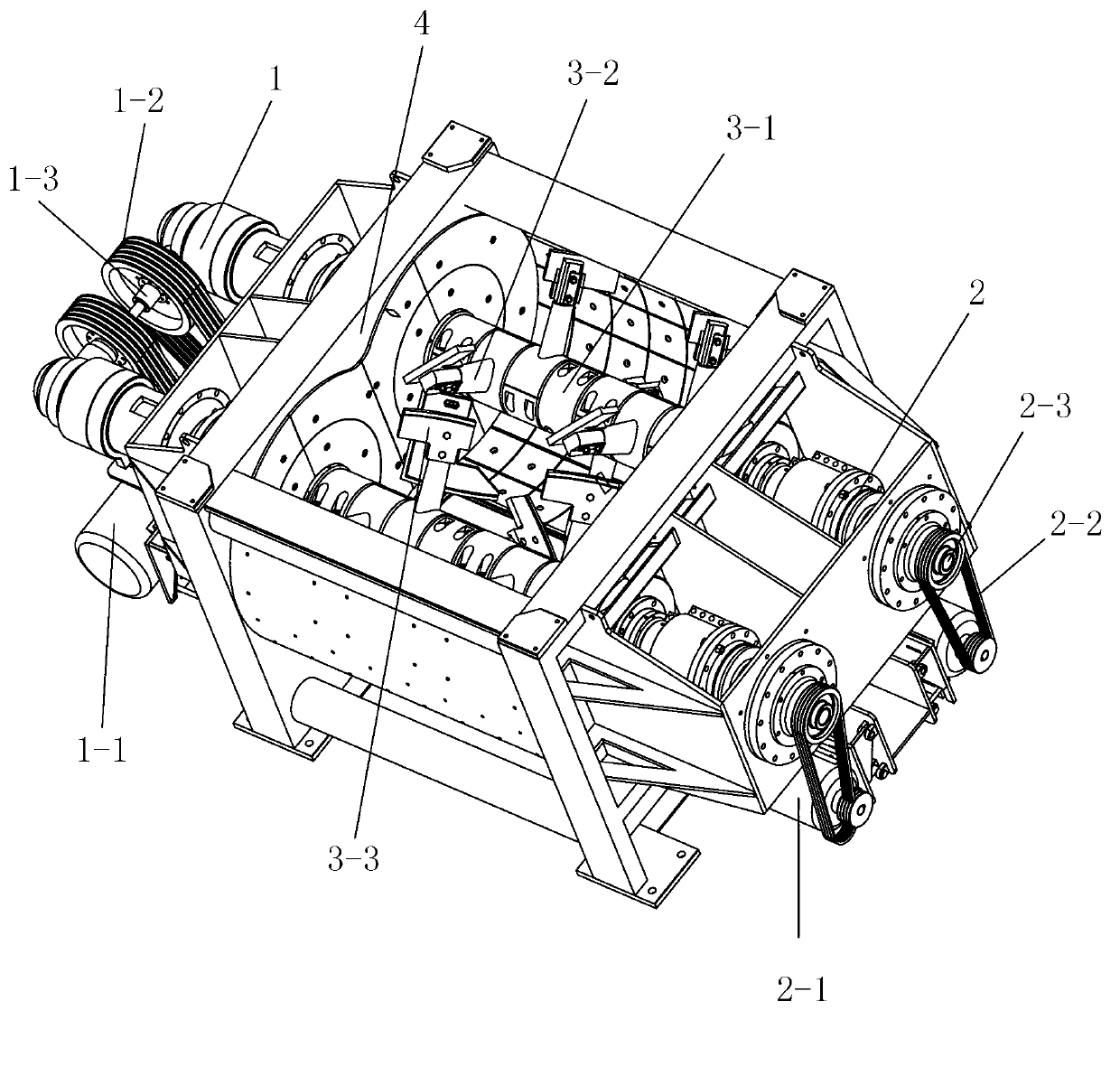

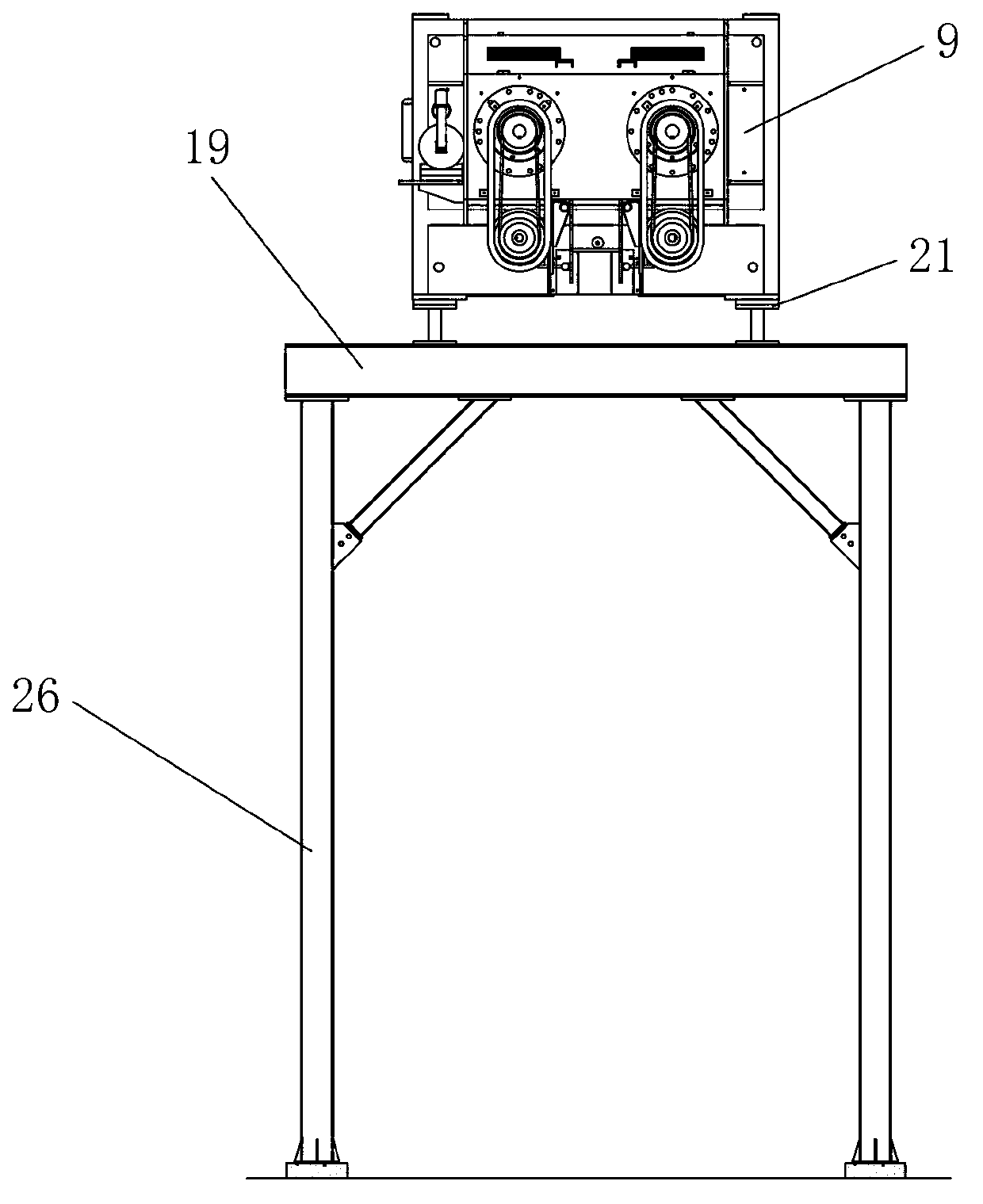

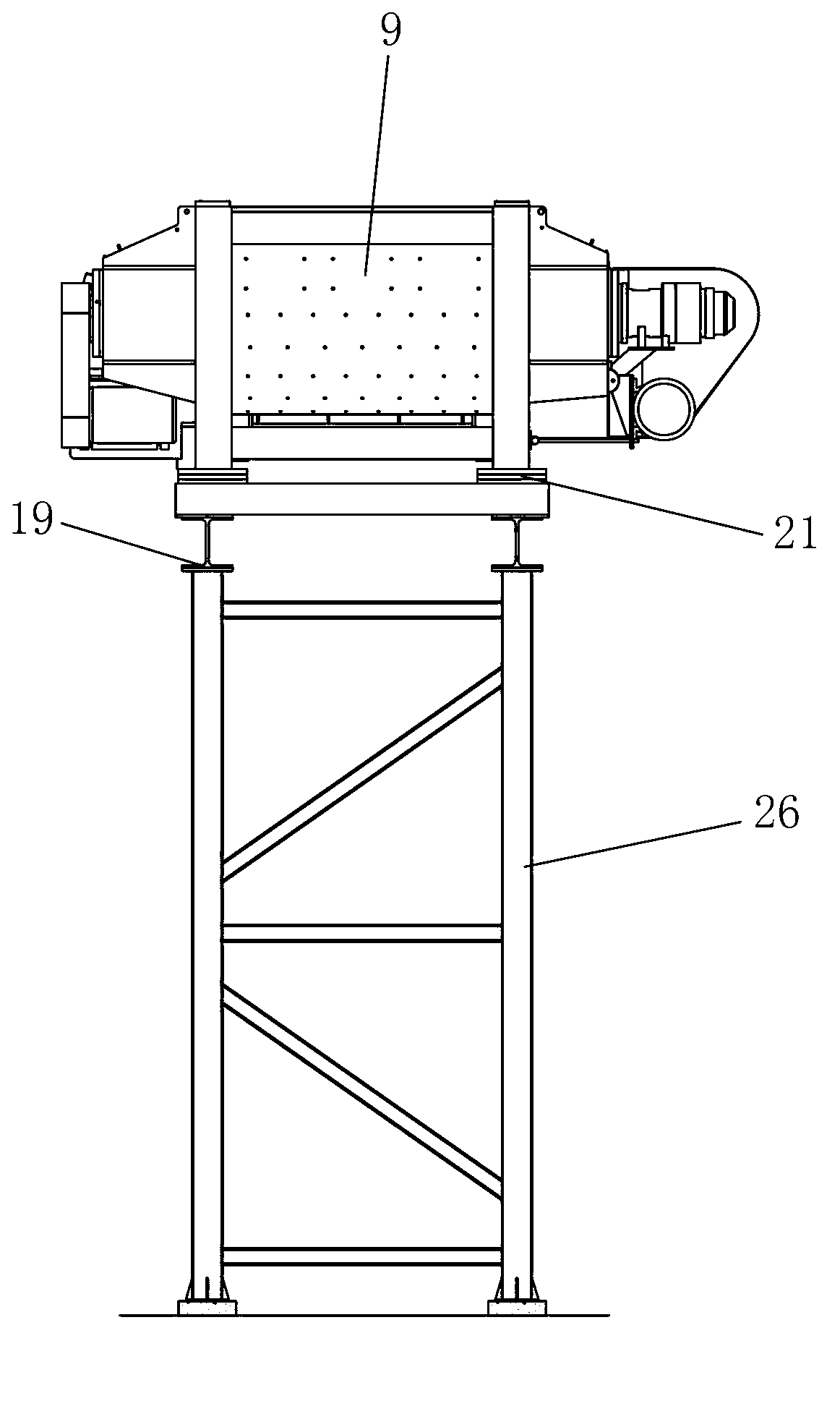

[0039] Such as Figure 1 to Figure 7As shown, a concrete mixing plant equipped with a vibrating mixing host includes an aggregate batching machine 5, an aggregate lifting mechanism, a main building platform 20, a cement silo 10, a fly ash silo 13, a cement screw conveyor 11, and a fly ash screw Conveyor 14, cement scale 12, fly ash scale 15, water scale 17, weighing main support 22, water tank 16, control room 18, host support platform 19 and vibration stirring host 9, the main building platform 20 is "back" font structure, the main building platform 20 is supported and fixed on the base surface by four main building legs 25, the four main building legs 25 are symmetrically arranged, and the weighing main bracket 22 is fixedly installed on the main building platform 20, so The main frame support platform 19 is arranged at the central opening of the main building platform 20 and is lower than the main building platform 20. The main frame support platform 19 is supported and fix...

Embodiment 2

[0046] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the aggregate lifting mechanism is a belt conveyor. In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

[0047] The working process of this embodiment is as follows: first, the loader transports the stones and sands of different grades from the stone pile and the sand pile to the corresponding bins of the aggregate batching machine 5, and then mixes the aggregate according to the required levels. The material is discharged and weighed. After the weighing is completed, the aggregate is transported to the belt conveyor 27 by the flat belt of the batching machine, and the motor drives the belt to rotate to drive the aggregate to move upward. When the aggregate is transported to the highest position, Aggregate is thrown into the hopper 29 fixedly installed above the vibrating mixing main machine 9 through the hopper bracket 31. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com