Y63-series special-type electric connector for high-speed rails

An electrical connector, Y63 technology, applied in the direction of connection, parts of the connection device, devices for reducing the stress at the connection of wires, etc., can solve the problems that the connection strength of electronic equipment is very high, and the connector cannot meet the use of trains, etc., to achieve Reduce the natural bearing weight, improve the safety of use, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

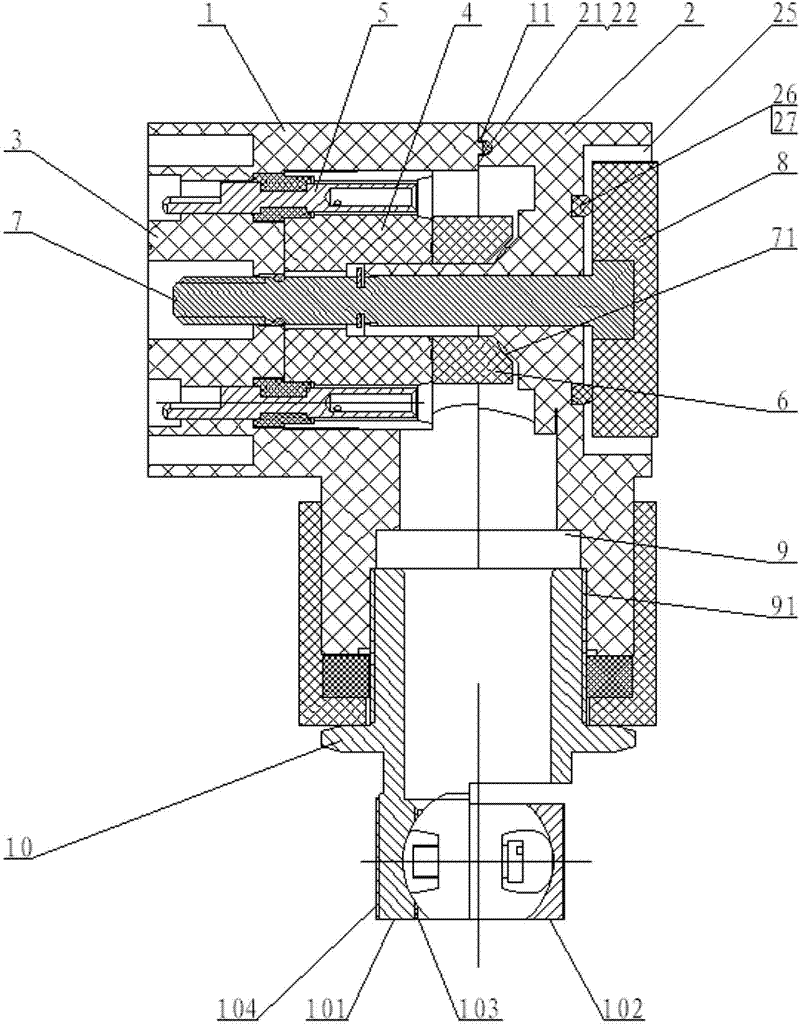

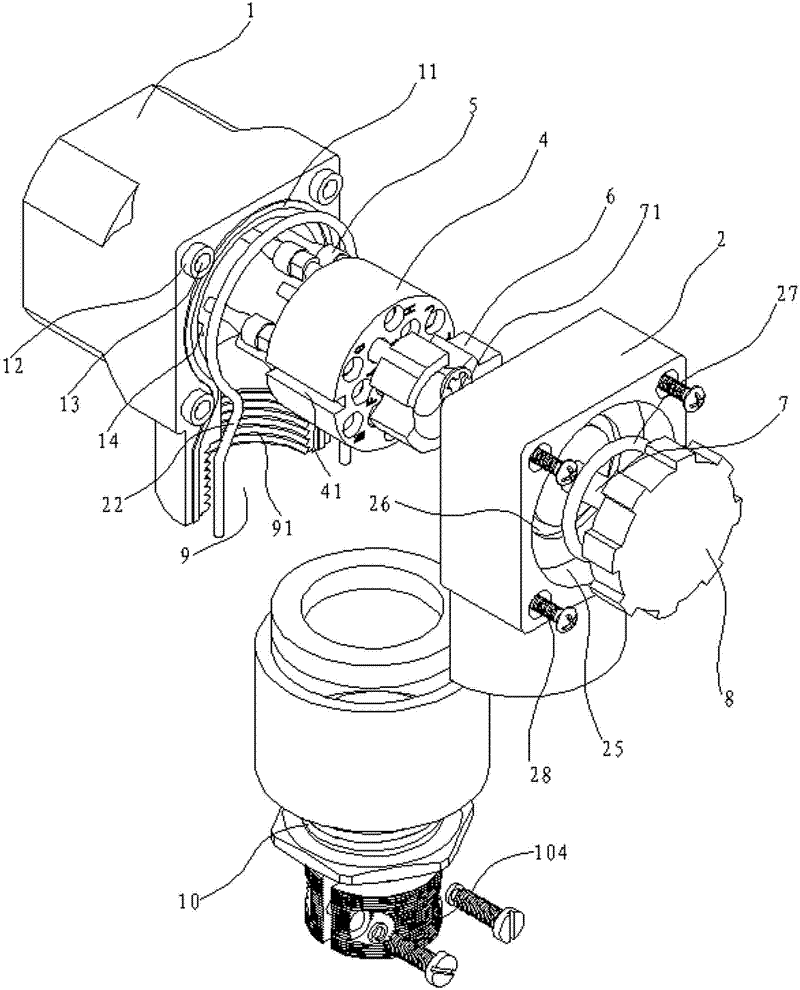

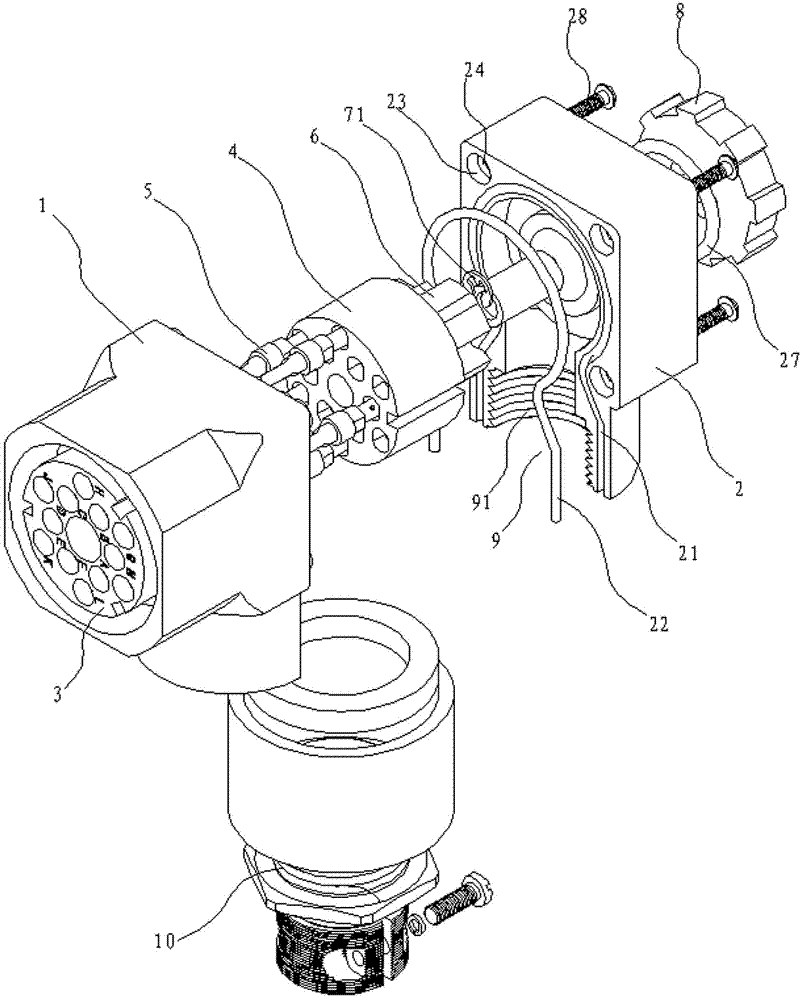

[0025] Figure 1-3 As shown, a Y63 series high-speed rail special electrical connector includes a front housing 1, a rear housing 2, a front insulator 3, a rear insulator 4, a circular contact piece 5, a spacer body 6, a screw 7, and a rotary pressure head 8 And cable end clip 10. The front insulator 3 is connected to the outer port of the front housing 1 by integral injection molding. The inner wall of the front housing 1 is provided with an axial anti-mis-insertion key 14, and the rear insulator 4 is matched with the anti-mis-insertion key through the anti-mis-insertion key groove 41 on its outer periphery. 14 is plugged into the front housing 1, the front end of the rear insulator 4 is connected with more than two circular contacts 5 passing through the front insulator 3, and the rear end of the rear insulator 4 is connected with a spacer connecting wires connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com