Method for batch machining of arc-shaped workpieces

A batch processing and workpiece technology, applied in metal processing equipment, manufacturing tools, components of boring machines/drilling machines, etc., can solve the problems of time-consuming and energy-consuming processing of drilling machine parts, and achieve the effect of optimizing complicated steps and avoiding errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

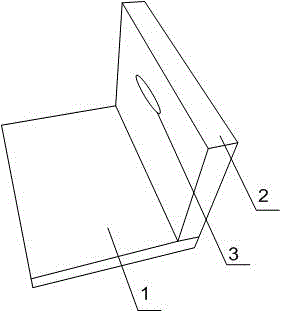

[0014] Such as figure 1 As shown, when workpieces are processed in batches, the workpieces to be drilled are stacked on the drilling machine to be close to the vertical surface formed by the baffle plate and the bottom plate, and the plane determined by three points is used to ensure the alignment of the stacked workpieces, and then the drilling The device performs a drilling procedure on it.

Embodiment 2

[0016] Such as figure 1 As shown, the anti-slip mechanism provided on the plane where the bottom plate is close to the drilling machine workbench can be a protruding anti-slip strip or a concave anti-slip groove.

Embodiment 3

[0018] Such as figure 1 As shown, the material of the bottom plate and the baffle plate in this embodiment is not cast iron, but aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com