Prefabricated column, pier column structure and construction method

A construction method and prefabricated column technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of connection details and installation accuracy, the problem of positioning has not been better solved, and the service life of bridge piers is affected and other issues, to achieve the effect of rapid construction, improved durability and improved engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

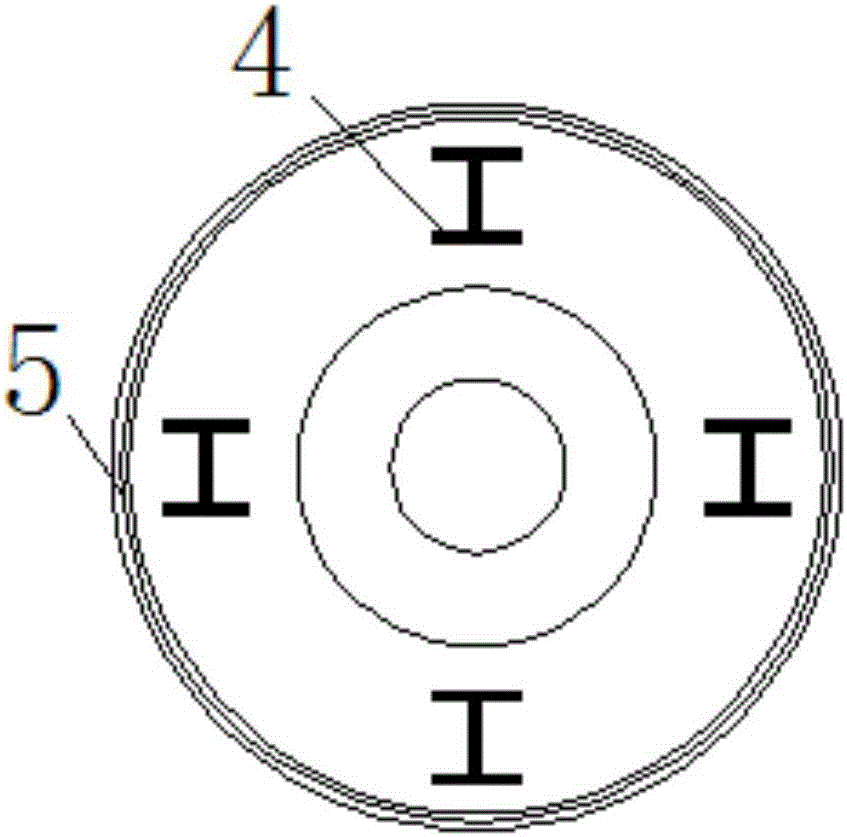

[0043] A prefabricated column, comprising a cylindrical or rectangular column with a cross-sectional shape, a protrusion or a groove is provided at one end of the column, and a steel plate protruding from the end of the column is arranged in the column along the longitudinal direction of the column , the steel plate and the protrusion or groove are arranged at the same end of the column, the cross section of the prefabricated column is square or circular, and the upper surface is flat to support the bridge.

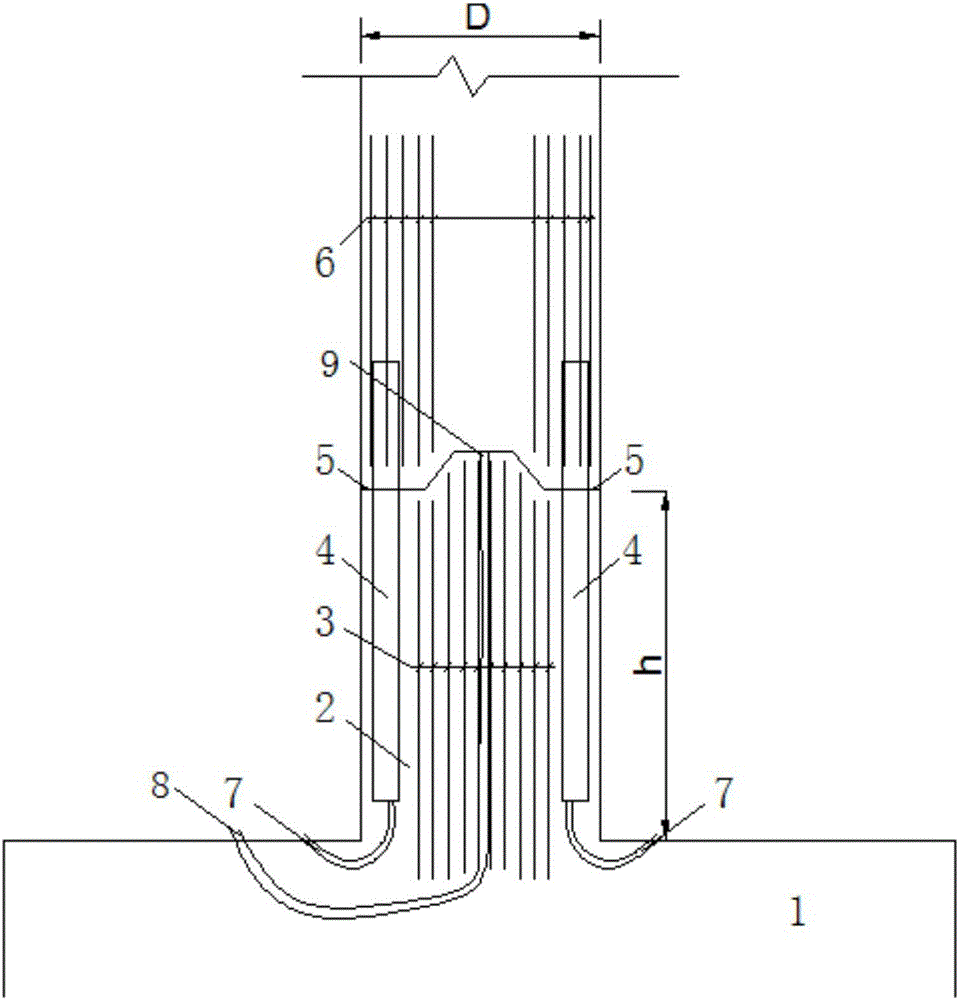

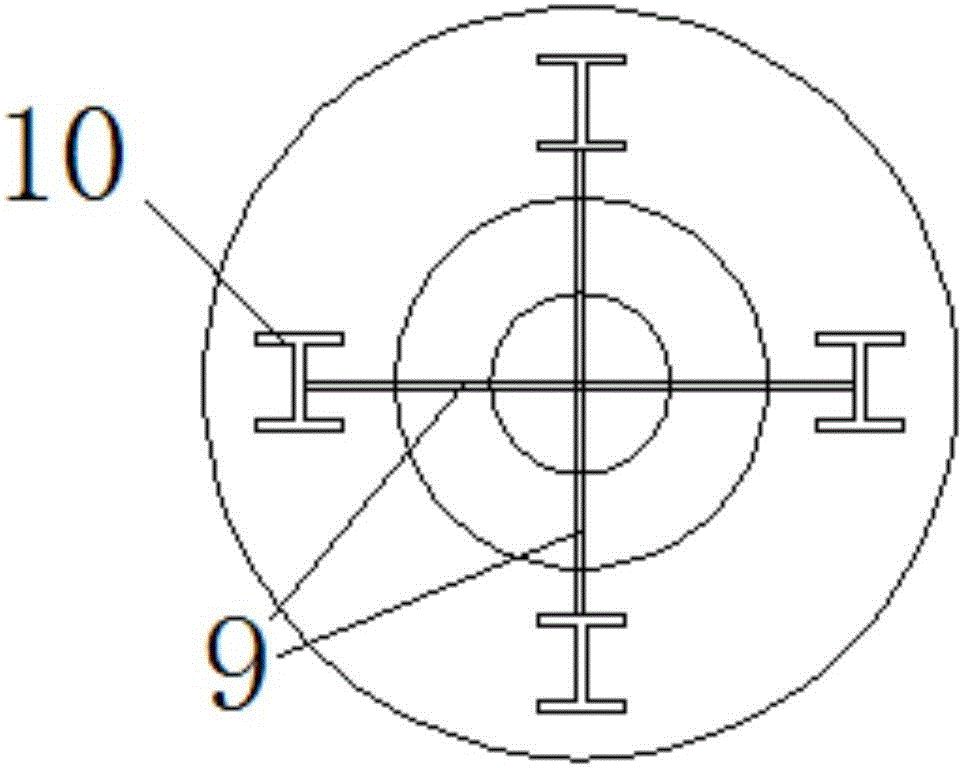

[0044] A prefabricated pier structure such as figure 1 As shown, including the above-mentioned prefabricated column, the prefabricated column is set on the platform 1 through the connecting column 2, the connecting column 2 and the platform 1 are constructed by cast-in-place concrete, and the connecting end faces of the prefabricated column and the connecting column 2 are matched with each other The protruding part is matched with the groove, and the protruding part is we...

Embodiment 2

[0061] A prefabricated column, which is characterized in that it includes a column with a cylindrical or rectangular cross-sectional shape, a protrusion or a groove is provided at one end of the column, and there is a hole in the column along the longitudinal direction of the column for connecting with a steel plate For the matching hole, the opening direction of the hole and the protrusion or the groove are arranged at the same end of the cylinder.

[0062] A prefabricated pier column structure, including prefabricated columns, the prefabricated columns are arranged on the caps through the connecting columns, the connecting columns and the caps are constructed by cast-in-place concrete, the bottom of the prefabricated columns is provided with convex parts or grooves, and the shape of the top of the connecting columns is To match the shape of the bottom of the prefabricated column, a steel plate partially protruding from the top of the connecting column is provided in the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com