Device capable of improving axial rigidity of main shaft of precision machine tool with adjustable bearing pre-tightening force

A technology of bearing pretightening force and precision machine tools, which is applied in metal processing equipment and other directions, and can solve problems such as weakening of axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

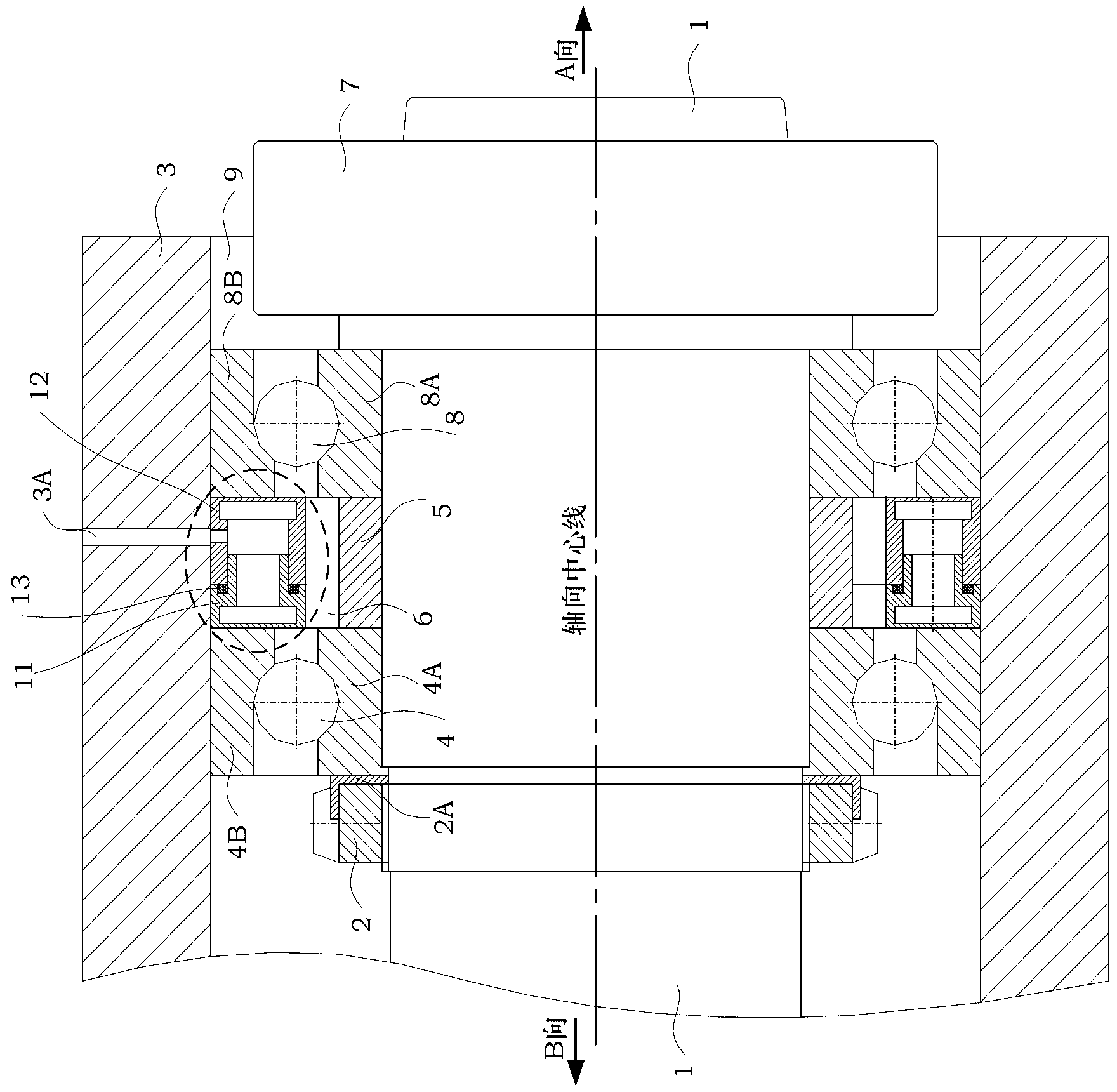

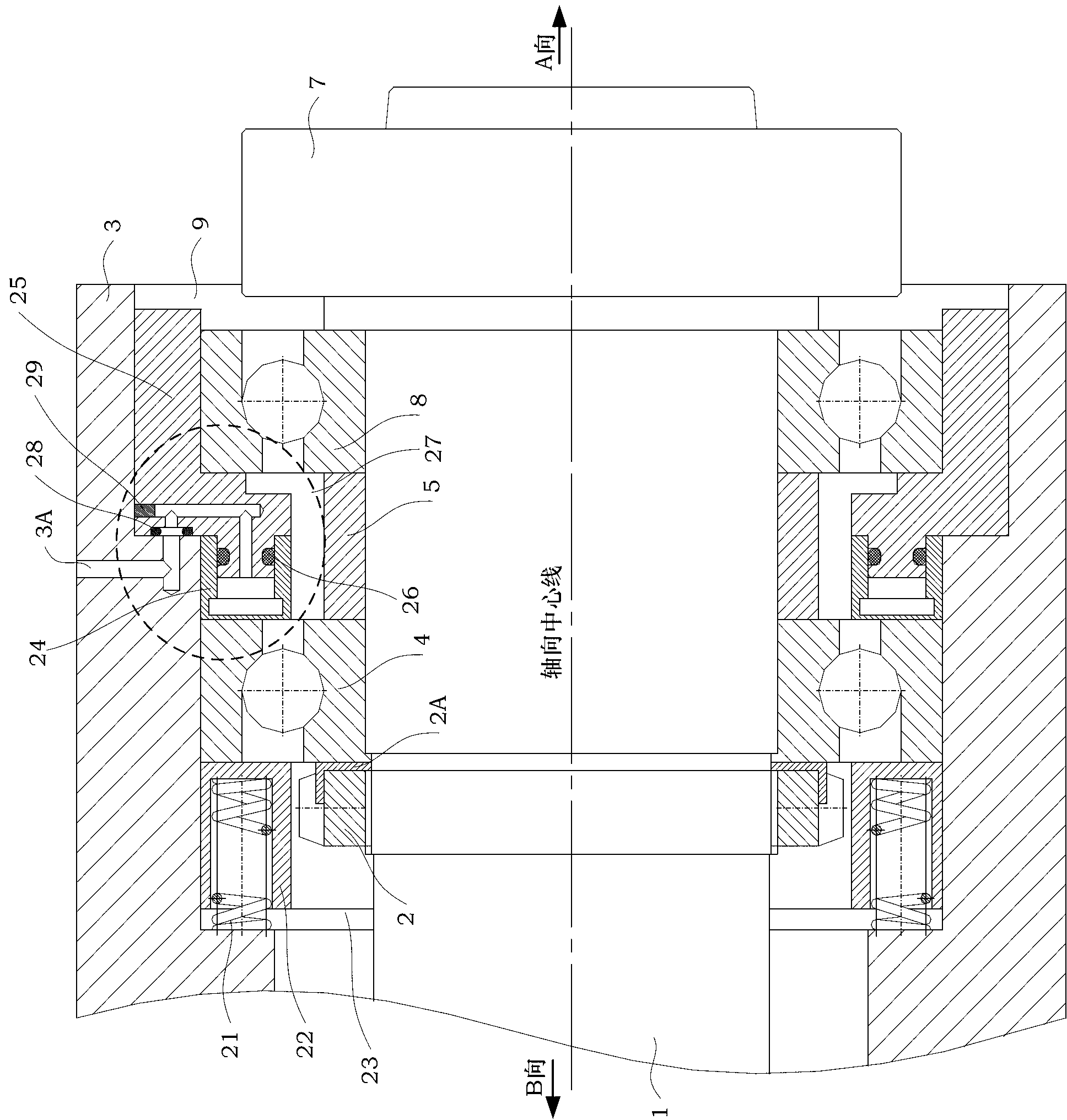

[0040] see figure 2 , Figure 2A , Figure 2B As shown, the present invention is a device for improving the axial stiffness of the spindle of a precision machine tool with adjustable bearing pretightening force. The device includes a spindle 1, a lock nut 2, a gasket 2A, a box seat 3, and an end cover 7. , a compression ring 9, a preload spring assembly and an improved bearing preload device;

[0041] The preloaded spring assembly includes a spring 21, a spring seat 22 and a pressing plate 23;

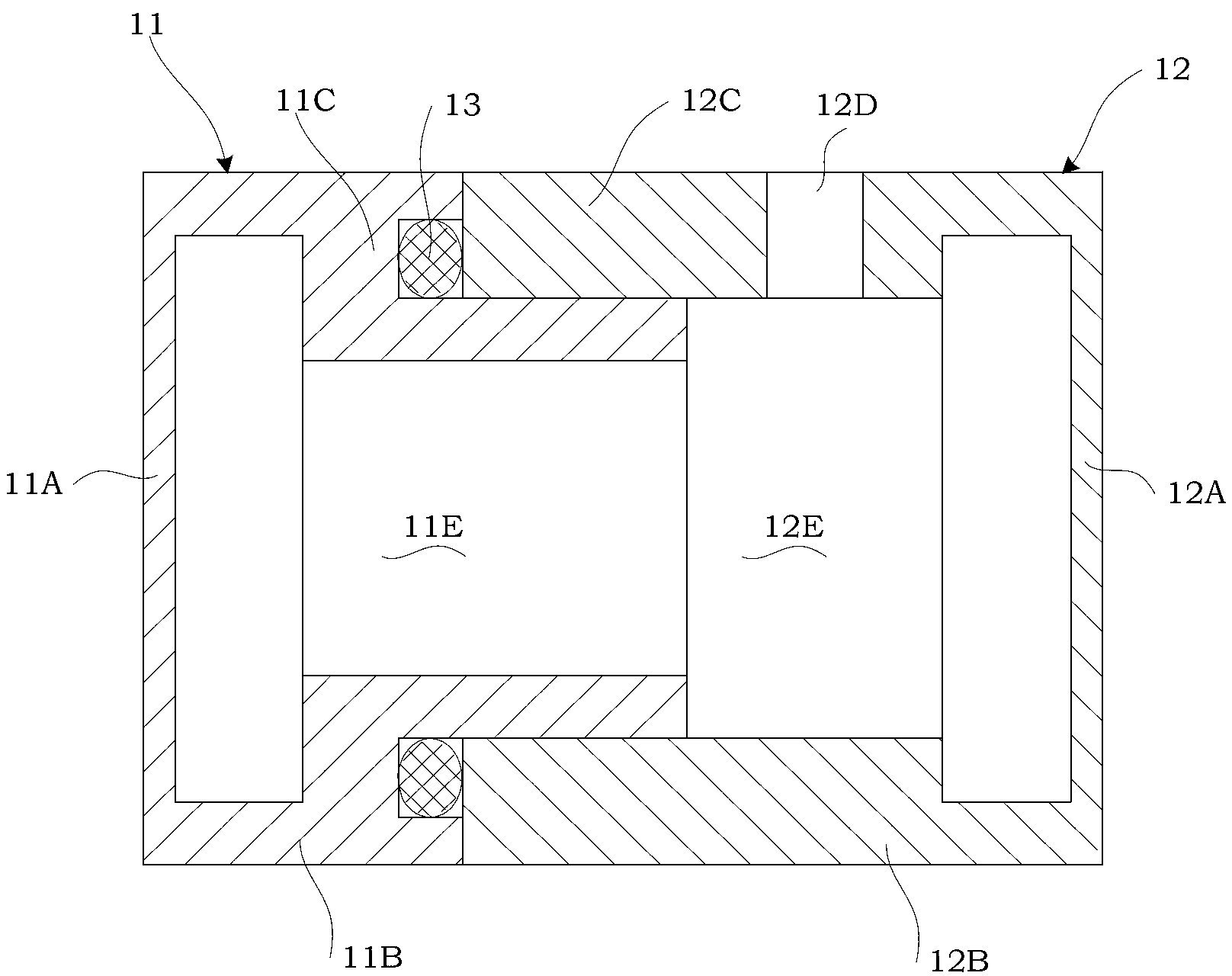

[0042] The improved bearing pretensioning device includes a C ring oil chamber 24 , a D ring oil chamber 25 , an A bearing 4 , a B bearing 8 , a shaft sleeve 5 and a second washer 27 .

[0043] In the present invention, the improved bearing pretensioning device is an annular oil chamber structure with one side thin-walled end surface deformed.

[0044] preloaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com