Regenerated concrete and production process thereof

A technology of recycled concrete and production process, which is applied in the field of building material production, can solve the problems of affecting strength and overall service life, high degree of dry shrinkage and creep, and affecting impermeability, so as to improve the effect of impermeability and improve Workability and the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

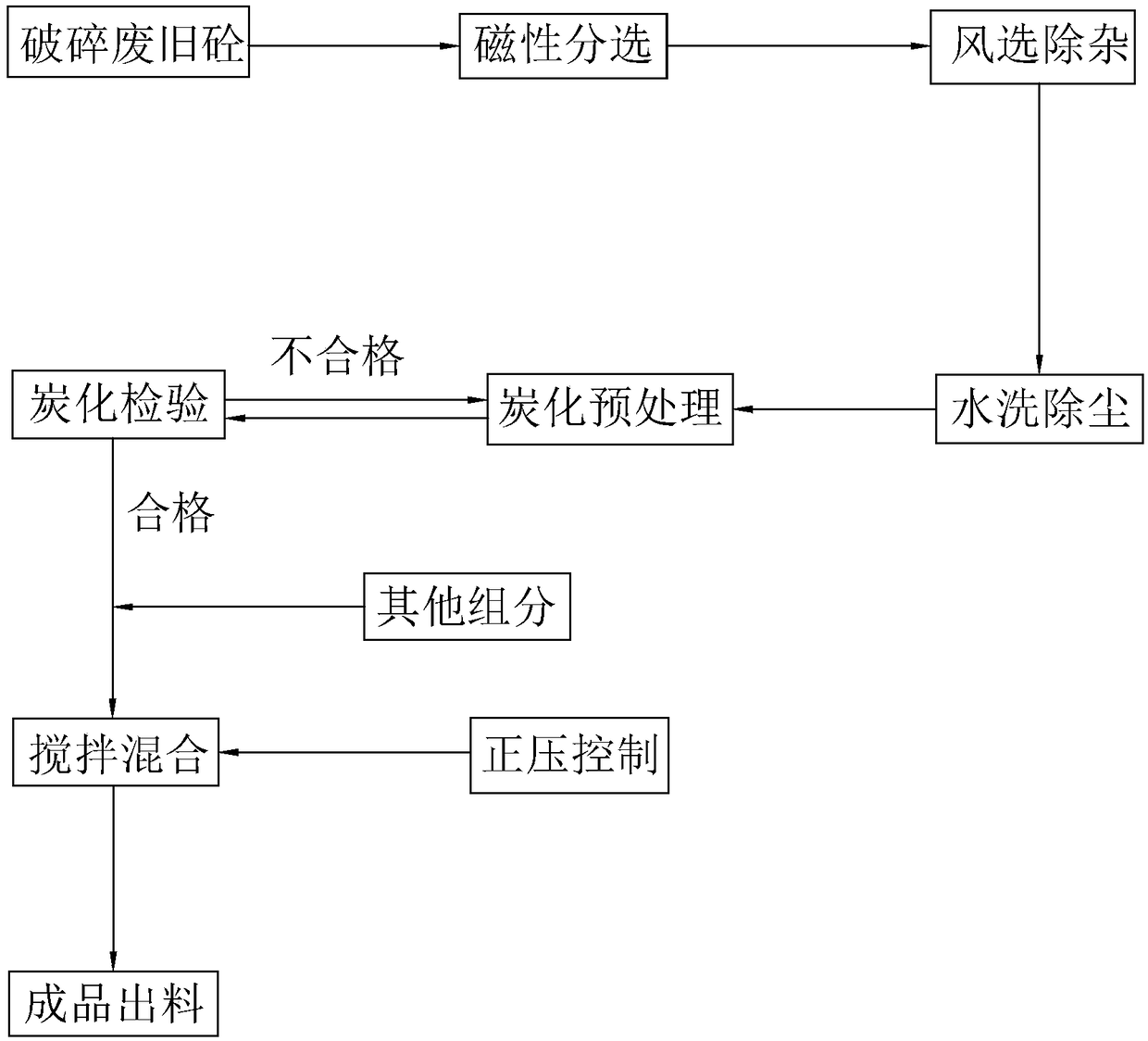

Method used

Image

Examples

Embodiment 1-5

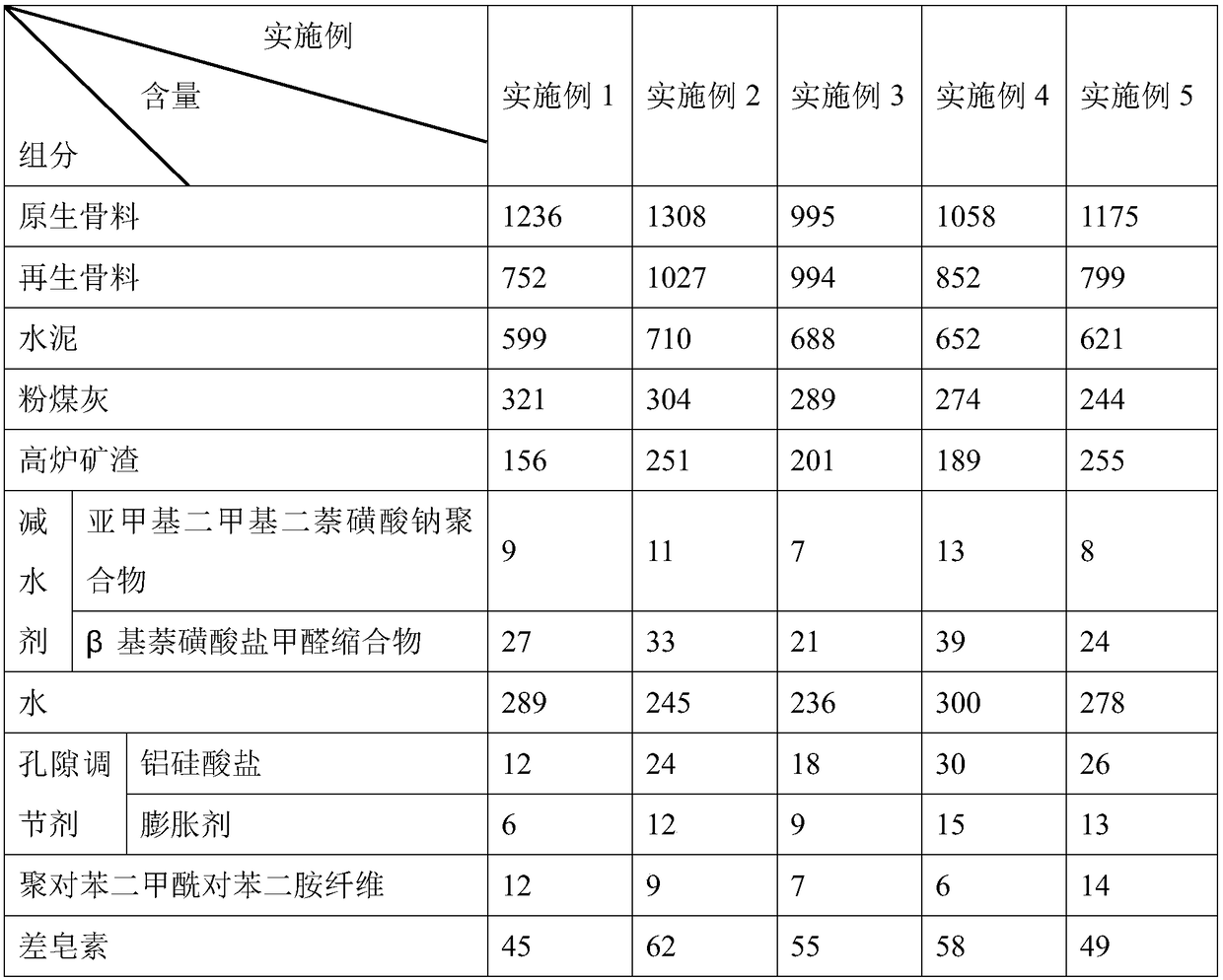

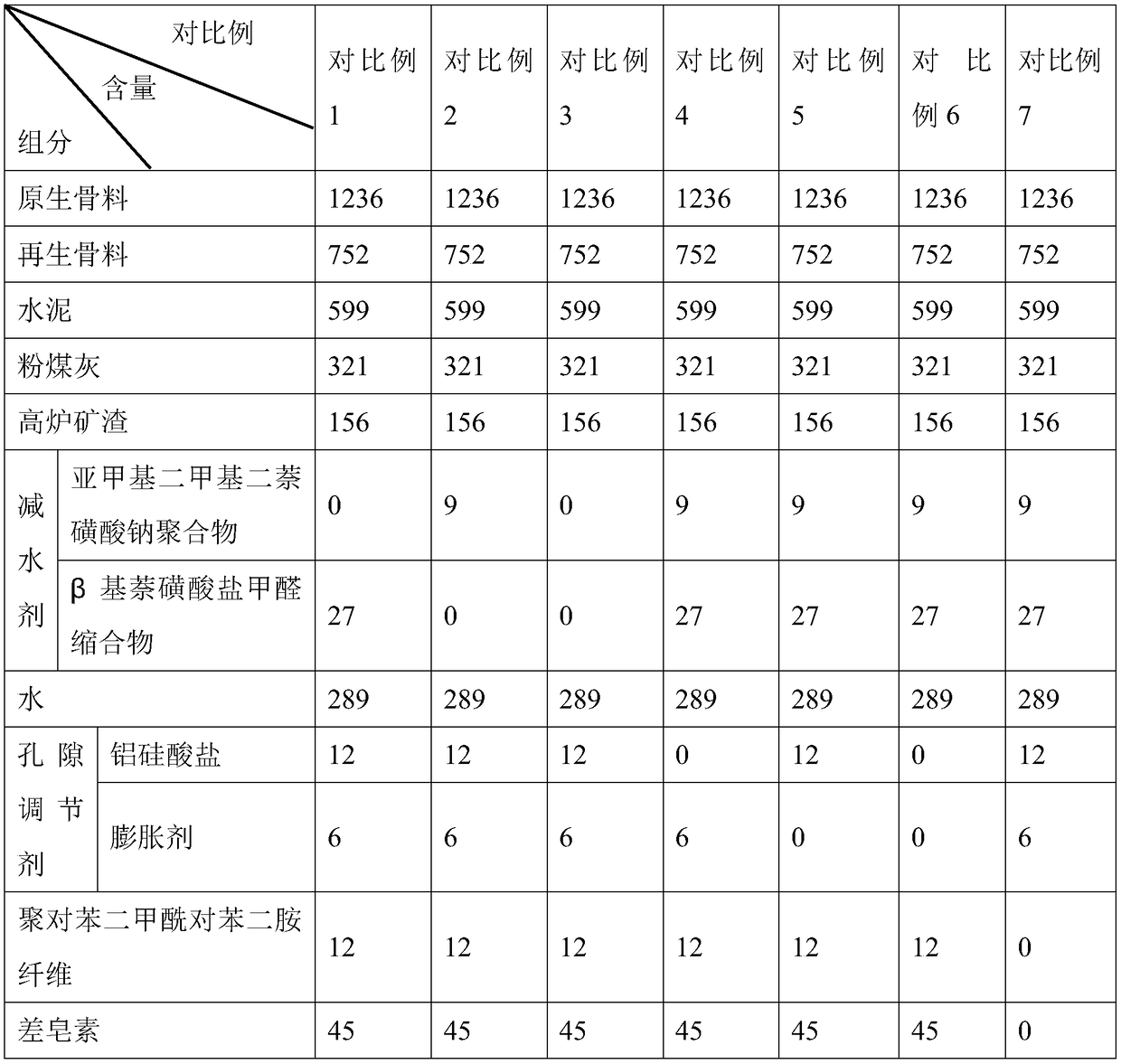

[0040]Examples 1-5, a recycled concrete, include components and corresponding contents as shown in Table 1. Among them, the cement is ordinary Portland cement with a strength grade of 32.5; the particle size of the recycled aggregate is 5-40mm; and β-naphthalene sulfonate formaldehyde condensate; the gap regulator includes a slow-release agent and an expansion agent with a weight ratio of 1:0.5, the slow-release agent is aluminosilicate treated by carbon dioxide immersion, and the expansion agent is composed of a weight ratio of It is composed of calcium oxide, calcium sulfoaluminate and magnesium oxide in a ratio of 1:2:2.

[0041] Each component and its corresponding content table (kg) in the embodiment 1-5 of table 1

[0042]

Embodiment 6

[0043] Embodiment 6, a recycled concrete, differs from Embodiment 1 in that it does not contain poly-p-phenylene terephthalamide fibers.

Embodiment 7

[0044] Embodiment 7, a recycled concrete, differs from Embodiment 1 in that it does not contain poor saponin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com