Manufacturing and forming process of HDPE geomembrane

A molding process and geomembrane technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem of affecting the winding quality of HDPE geomembrane, affecting the efficiency of winding work, the quality of use, and the inability to meet market demand, etc. problems, to achieve the effect of ensuring the quality of winding, reducing frictional resistance and reducing mechanical fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

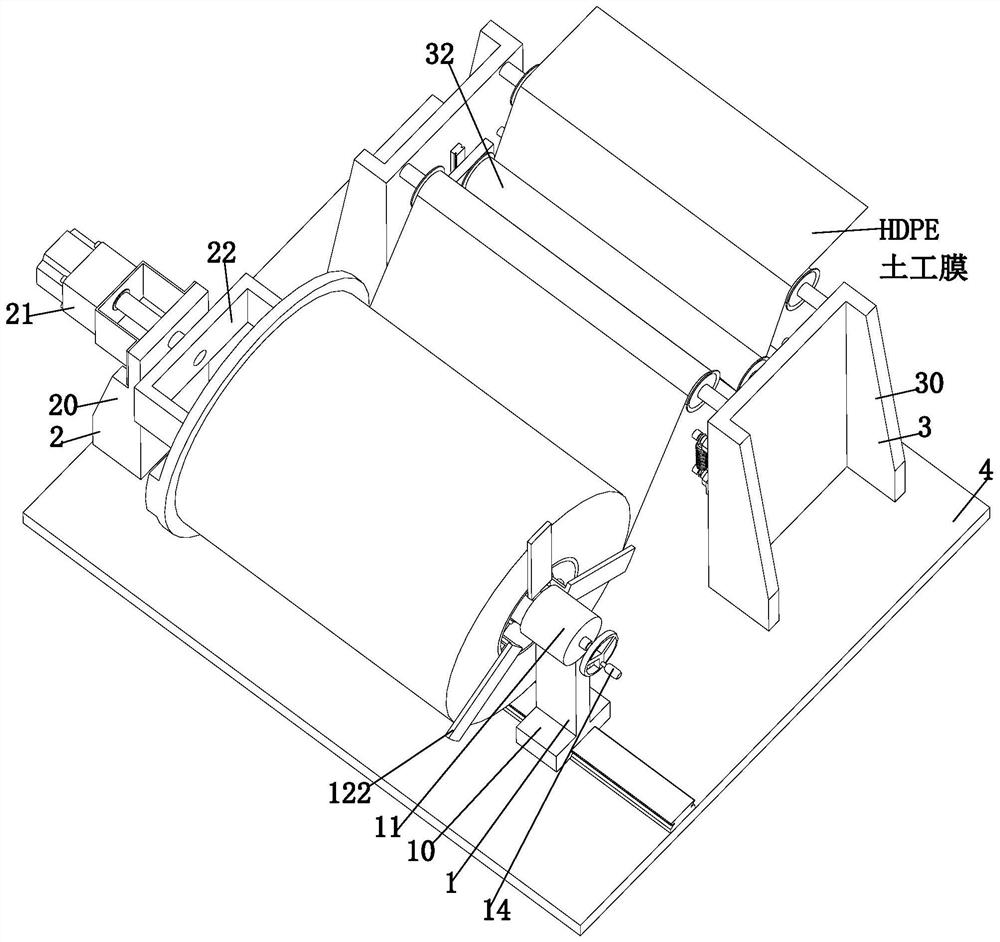

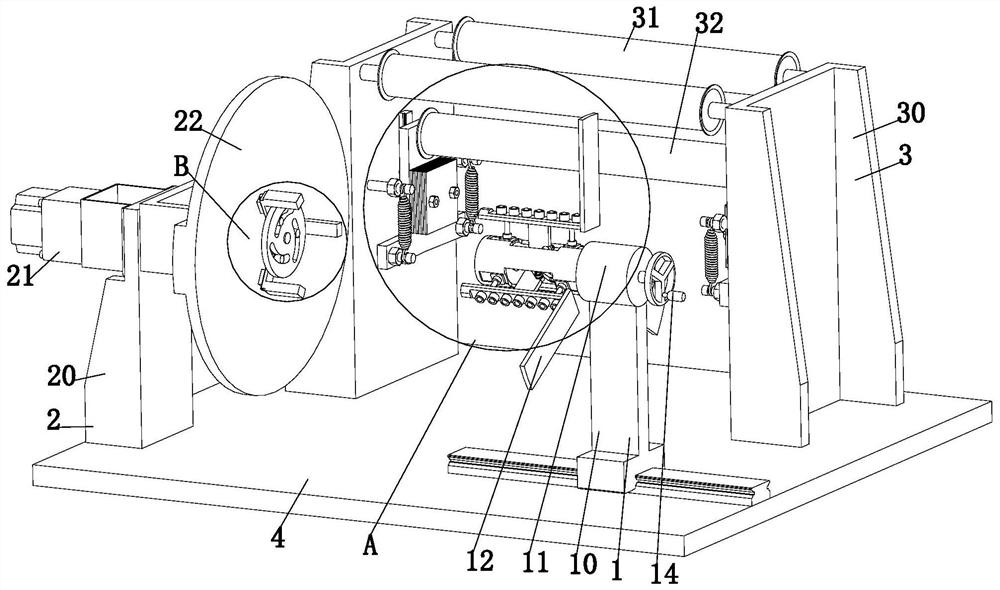

[0034]In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following will further illustrate the present invention in combination with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in this application and The features in the embodiments can be combined with each other.

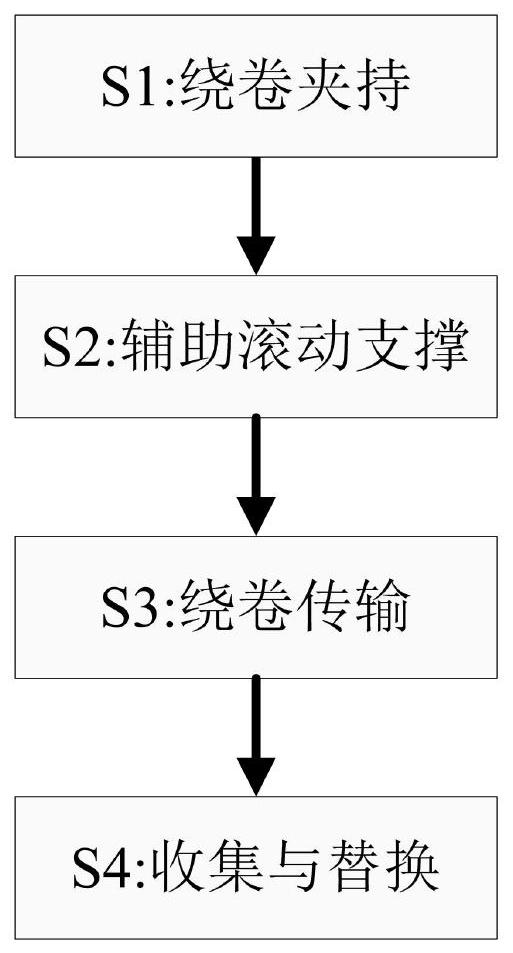

[0035]Such asFigure 1 to Figure 11As shown, a HDPE geomembrane manufacturing process, the specific HDPE geomembrane manufacturing process is as follows:

[0036]S1, winding and clamping: manually place the winding drum 5 into the winding mechanism 2, and perform positioning, clamping and fixing, and then realize the winding rotation;

[0037]S2. Auxiliary rolling support: Rolling support is performed on the winding drum 5 positioned and clamped in the above S1 through the guiding sliding mechanism 1;

[0038]S3. Rolling transmission: the HDPE geomembrane is rolled and transmitted through the transmission te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com