Vertical shaft multi-state dual-blade bidirectional rotation wind driven power generation device and power generation control method thereof

A wind power generation device, two-way rotation technology, applied to the control of wind power generators, wind power generators at right angles to the wind direction, wind power generators, etc., to achieve the effect of increasing the wind receiving area, the flexibility and convenience of speed regulation, and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and examples.

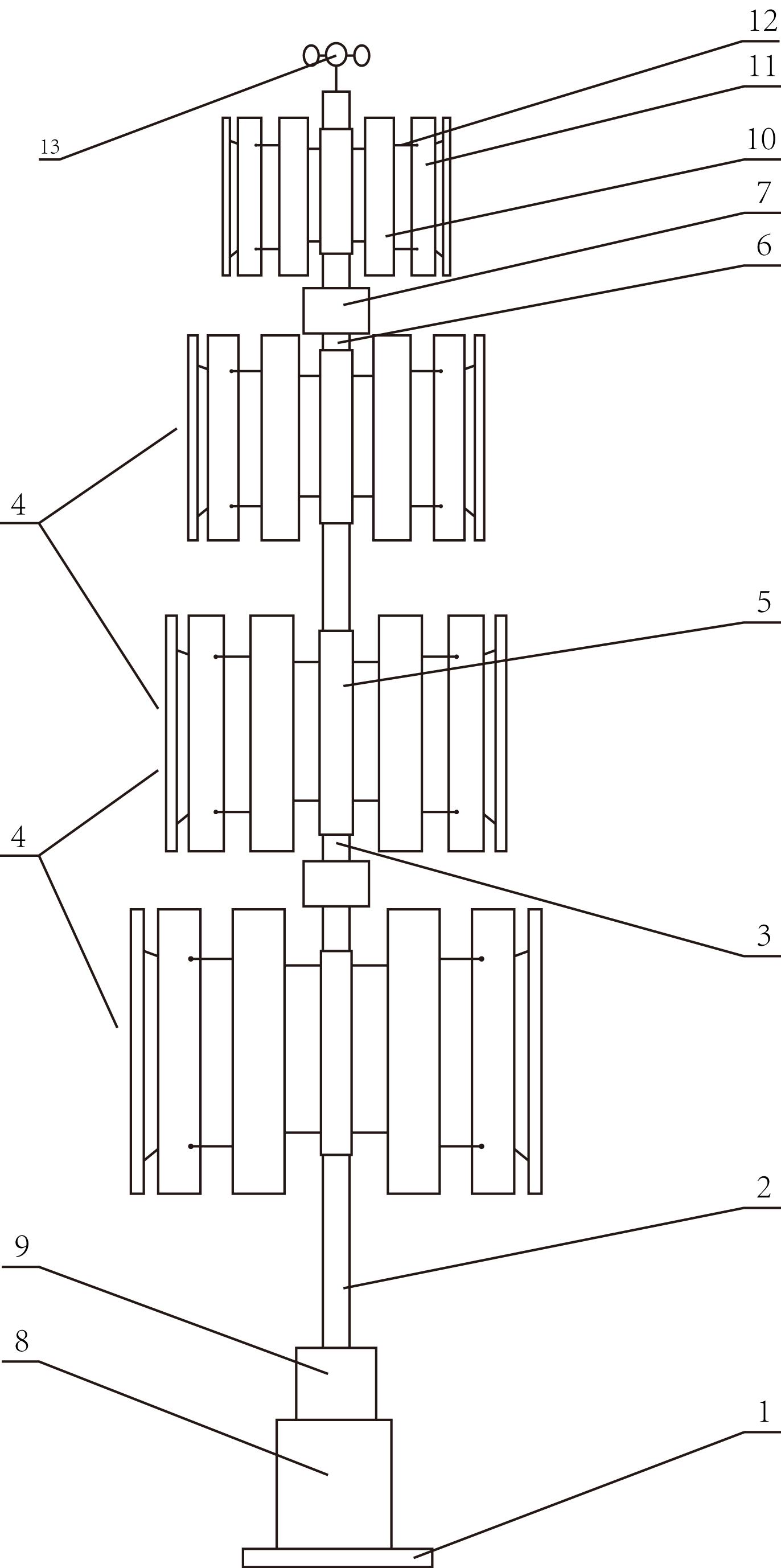

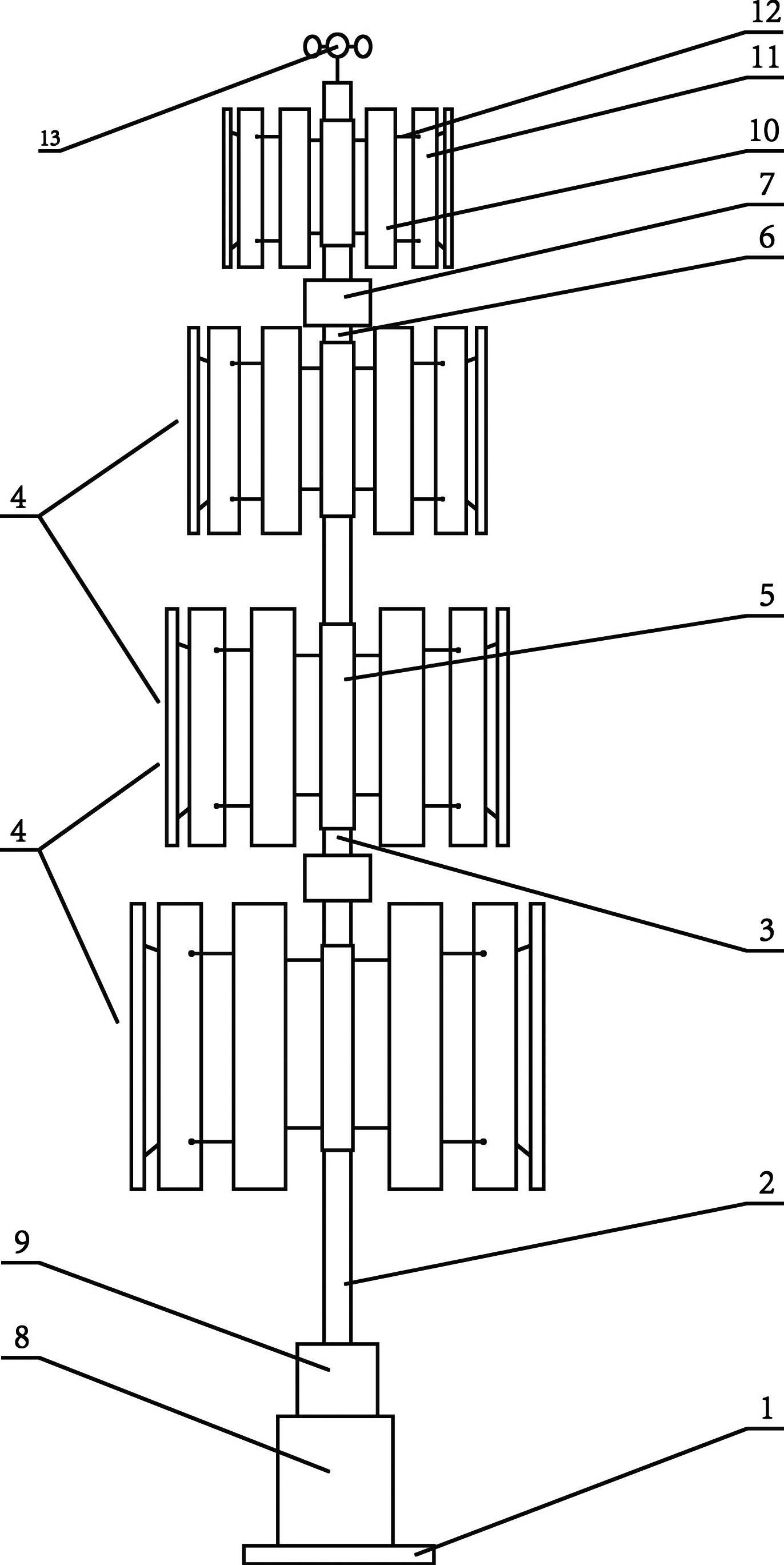

[0018] Such as figure 1 As shown, the present invention includes a tower column 2 perpendicular to the ground, and the bottom of the tower column 2 is connected to the ground through a support 1 . Two sets of power generation modules are arranged from top to bottom on the tower column 2, wherein each set of power generation modules includes a pair of wind rotor sets 4 arranged up and down, the upper wind wheel set 4-1 and the lower wind wheel set 4-2 A generator 7 is arranged between them. One of the wind rotor sets 4 includes a wind rotor hub 5 installed on the tower column 2, and also includes several main blades 10 installed on the wind rotor hub 5 uniformly distributed in the circumferential direction through support rods. Wherein the wind rotor hub of the upper wind turbine set 4-1 is connected with the rotor 3 of the generator 7, and the wind rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com