Vertical type wind power generation system provided with dual blades and multi-layer reinforced concrete frame

A wind power generation system and reinforced concrete technology, which are applied to wind turbines at right angles to the wind direction, wind turbine components, and configurations for installing/supporting wind turbines, etc. It can increase the power generation capacity and wind resource utilization efficiency, increase the integrity and system stability, and increase the wind-receiving area and wind power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

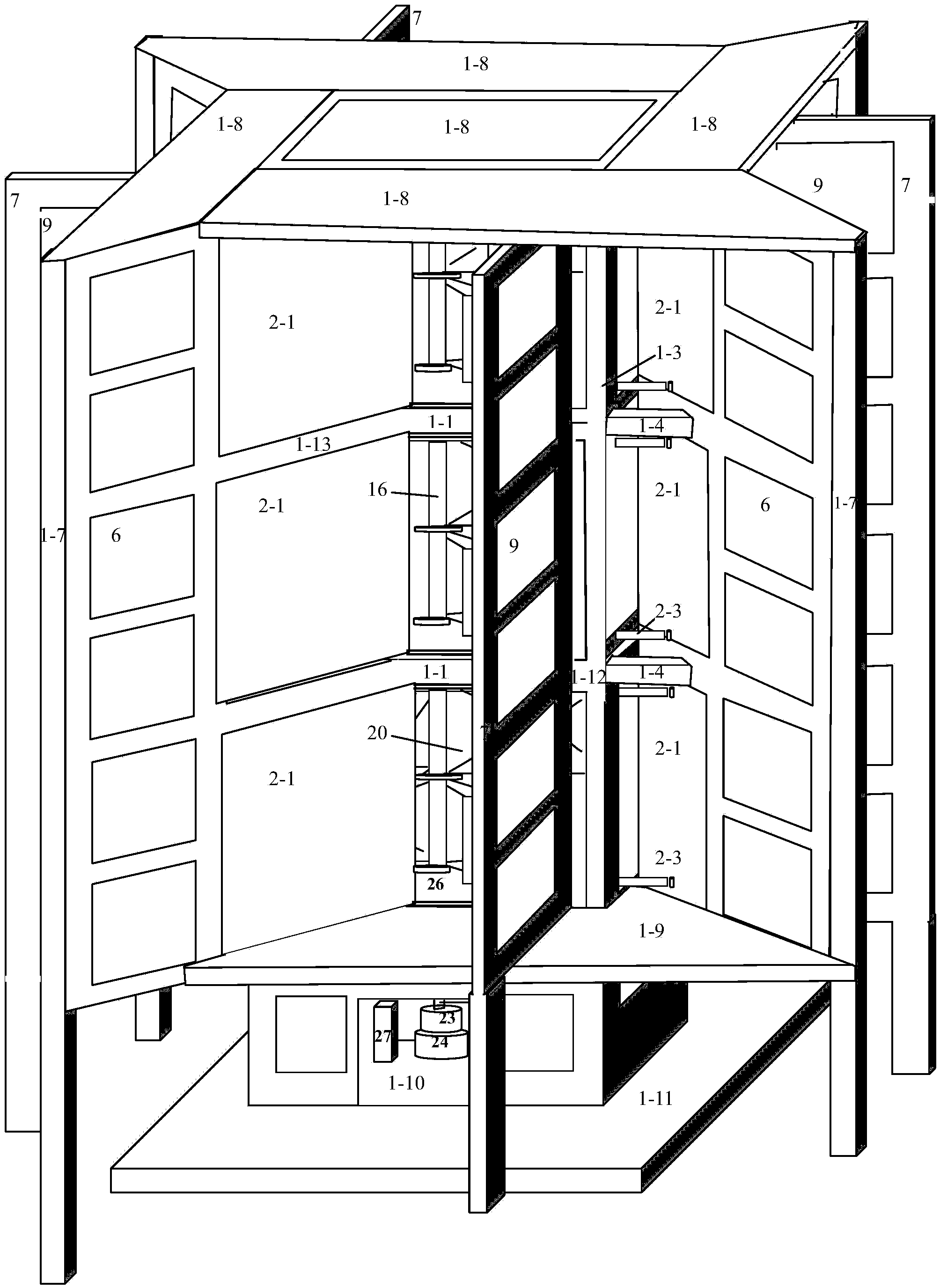

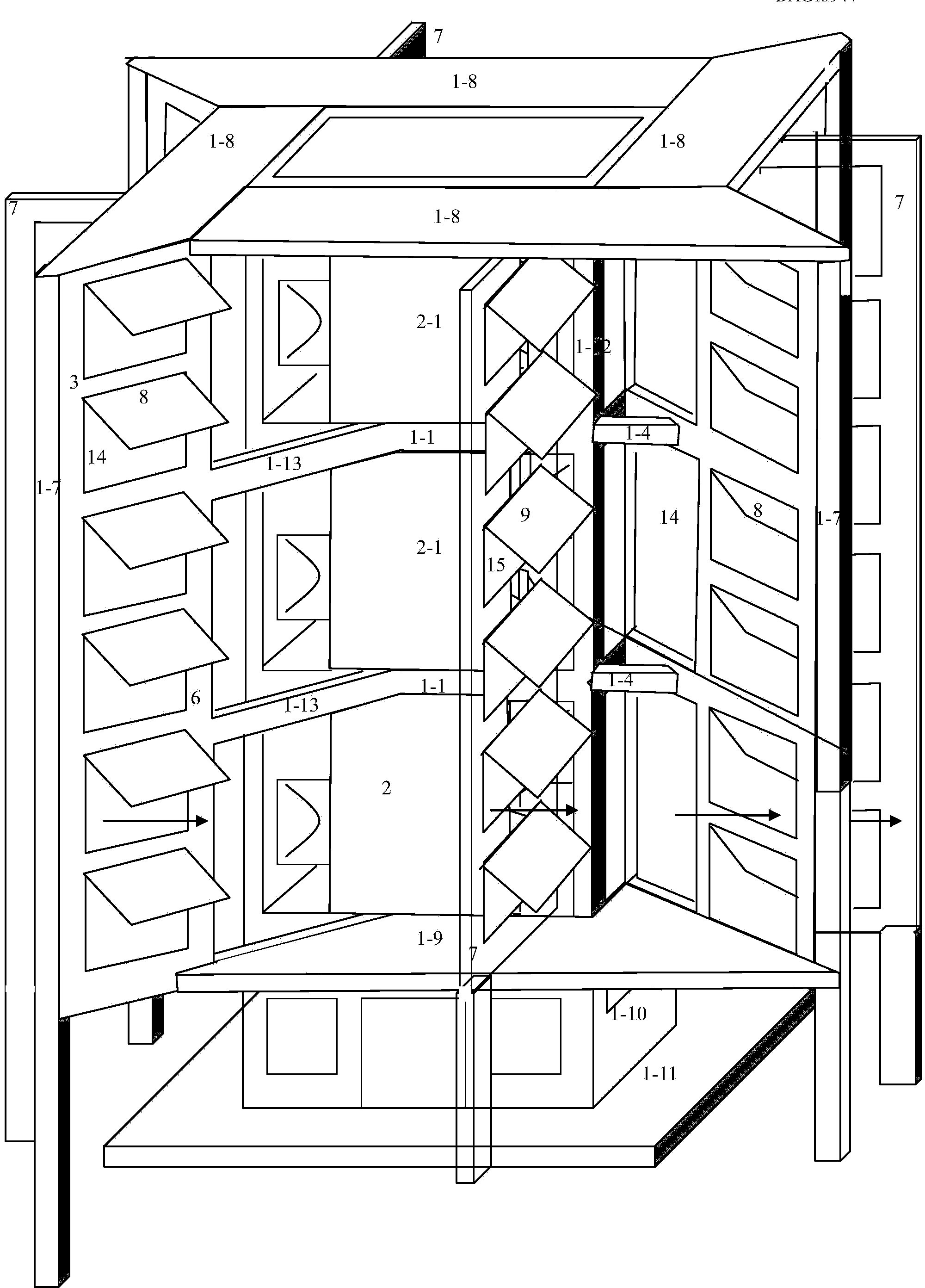

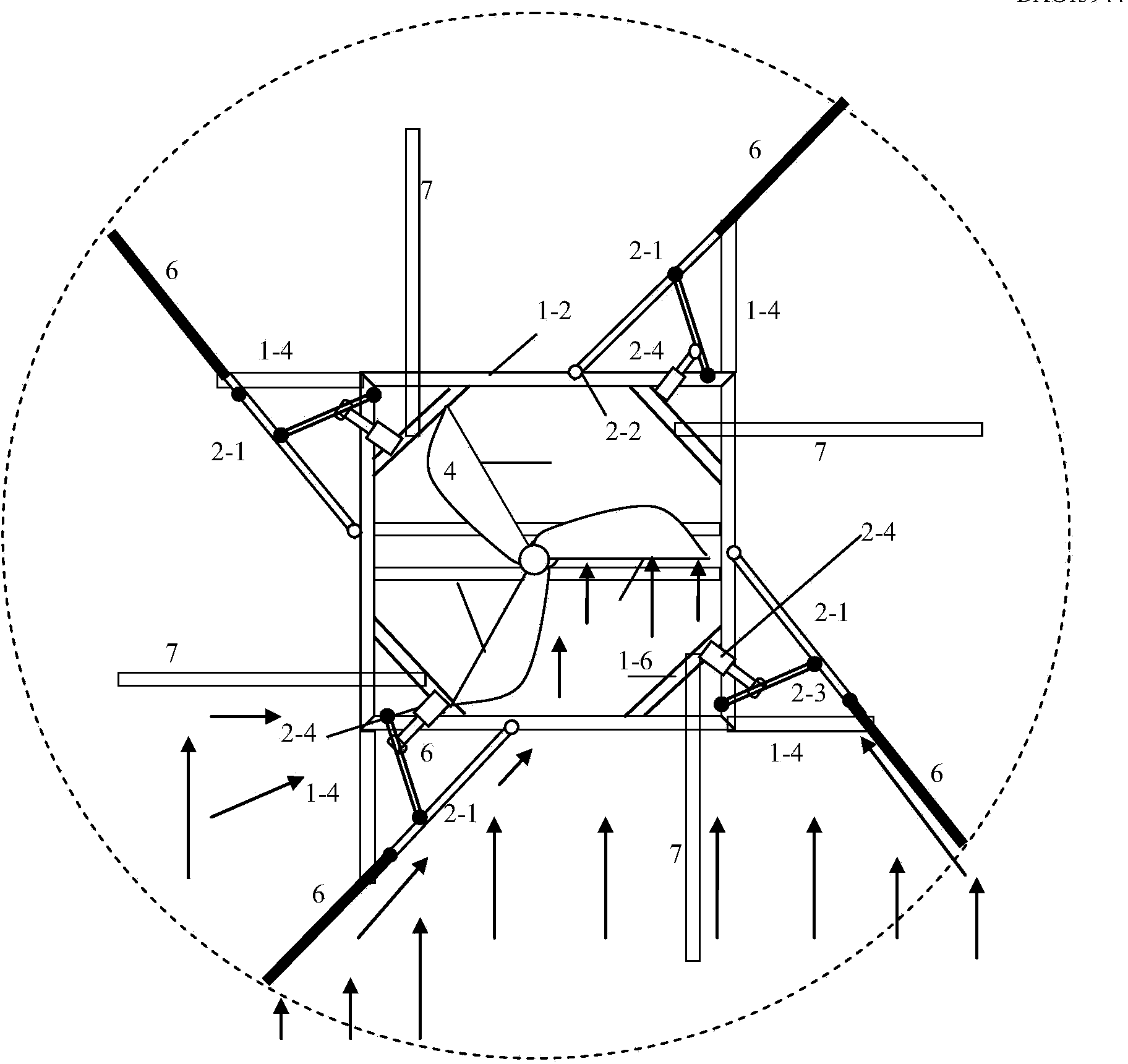

[0051] Specific implementation mode one: combine Figure 1 to Figure 12 Explain that the vertical wind power generation system equipped with dual combined wind blades and multi-layer reinforced concrete frame includes a multi-layer reinforced concrete frame 1, a mobile wind collection protection system 2, a fixed and extended wind collection system 3, a wind power system 4 and a power generation system. System 5;

[0052] The multi-layer reinforced concrete frame 1 is vertically arranged, and the multi-layer reinforced concrete frame 1 includes a plurality of reinforced beams 1-1, a plurality of slideways 1-2, a plurality of reinforced column square piers 1-3 and ground piles 1-3 -1, multiple steel bar cross beams 1-4, multiple machine bearing heavy steel bar beams 1-5, multiple supporting cable-stayed beams 1-6, multiple reinforcing columns 1-7, multiple upper wind gathering boards 1- 8. A plurality of lower wind collecting panels 1-9, a foundation base 1-10, a foundation pl...

specific Embodiment approach 2

[0058] Specific implementation mode two: combination Figure 4 and Figure 5Note that the fixed and extended air collection system 3 in this embodiment also includes a plurality of first rotating shafts 28 and a plurality of second rotating shafts 29, and each first air discharge door 8 is equipped with two first rotating shafts 28, two first rotating shafts The rotating shafts 28 are installed at 1 / 3 of the length of each first air discharge door 8 and the two first rotating shafts 28 are on the same straight line. The first air discharge door 8 is installed on the first air discharge port 14 through the two first rotating shafts 28 ; Two second rotating shafts 29 are installed on each second air discharge door 9, and the two second rotating shafts 29 are installed at 1 / 3 of the length of each second air discharge door 9 and the two second rotating shafts 29 are on the same line Above, the second air discharge door 9 is installed on the second air discharge port 15 through t...

specific Embodiment approach 3

[0059] Specific implementation mode three: combination figure 1 , figure 2 Note that the multi-layer reinforced concrete frame 1 in this embodiment is any one of a circle or a trigonal to an N-gonal shape. In this embodiment, the circular reinforced concrete frame 1, a plurality of fixed wind collecting panels 7, the ground pile 1-3-1 and the rock layer are integrated into one, and the ground pile 1-3-1 is driven into the rock layer for 1 to 5 meters. Below the depth, the wind turbine has the best stability. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com