Rapid cooling device used after fixation of tea leaves

A rapid cooling and tea technology, applied in the direction of tea treatment before extraction, can solve the problems of short cooling time of tea leaves, affecting the taste of tea leaves, unevenness, etc., and achieve the effects of controllable cooling time, high degree of automation, and sufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific implementations:

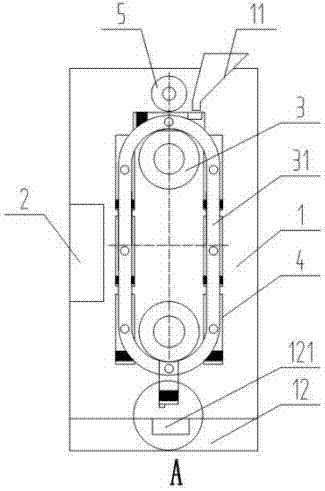

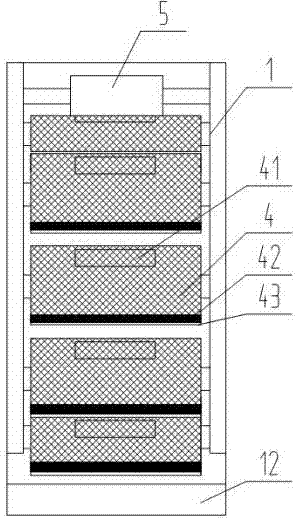

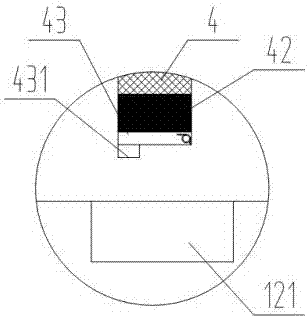

[0019] The reference signs in the drawings of the specification include: cooling box 1, feed box 11, batching box 12, electromagnet 121, air cooling mechanism 2, sprocket 3, chain 31, tea box 4, opening 41, gravity block 42, Cover 43, permanent magnet 431, and roller 5.

[0020] The embodiment is basically as attached figure 1 And figure 2 Shown:

[0021] The rapid cooling device for tea leaves after the greening process includes a cooling box 1, an air-cooling mechanism 2 and a transport mechanism for tea movement. A feed box 11 is installed above the cooling box 1. The feed box 11 is in the shape of a funnel, and the feed box 11 The upper end is provided with a feed opening and extends out of the cooling box 1, the lower end of the feed box 11 is processed with a discharge opening, and a discharge box is installed under the cooling box 1. The transport mechanism is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com