Patents

Literature

40results about How to "Avoid articulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

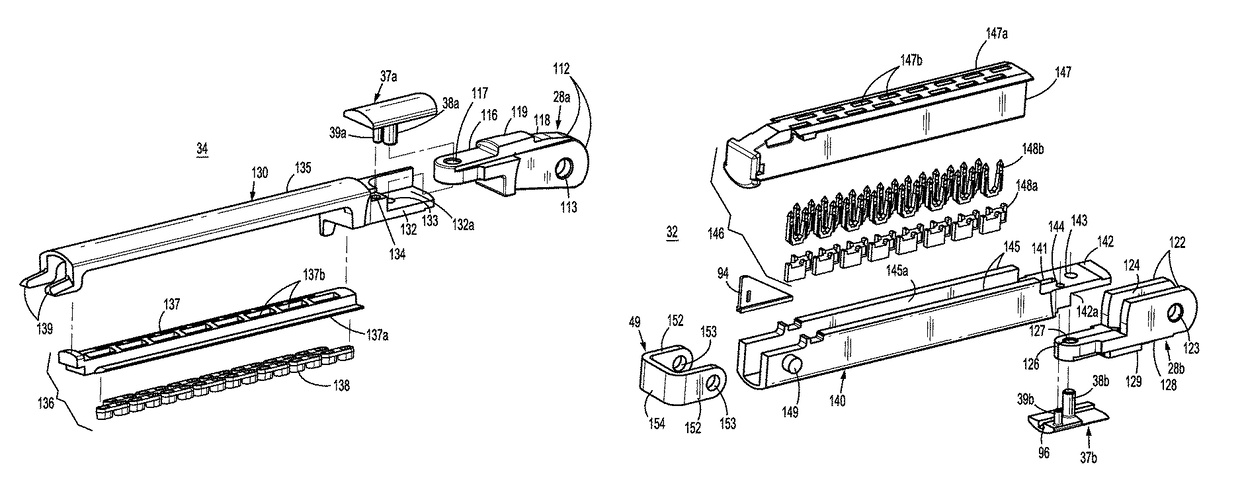

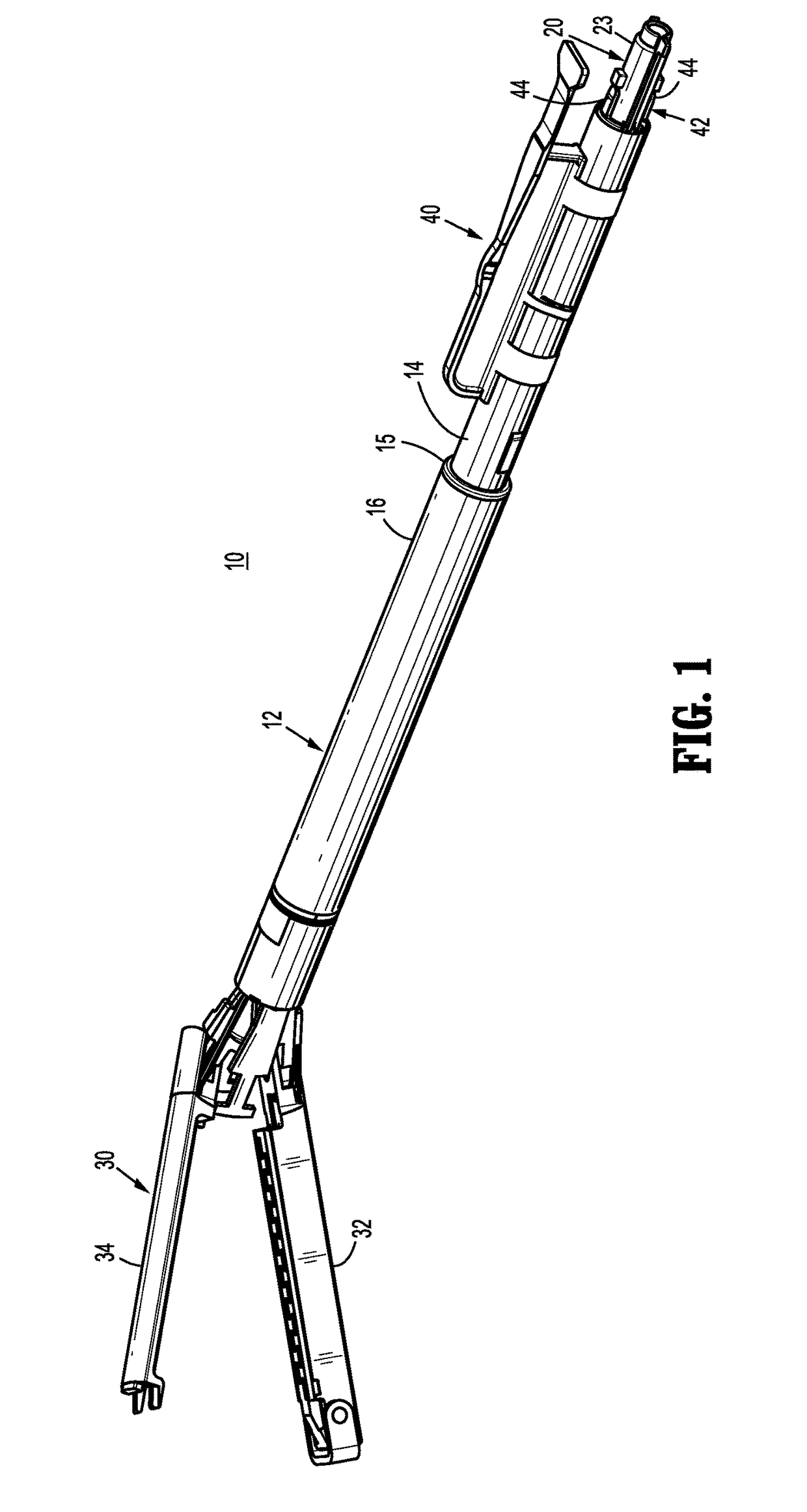

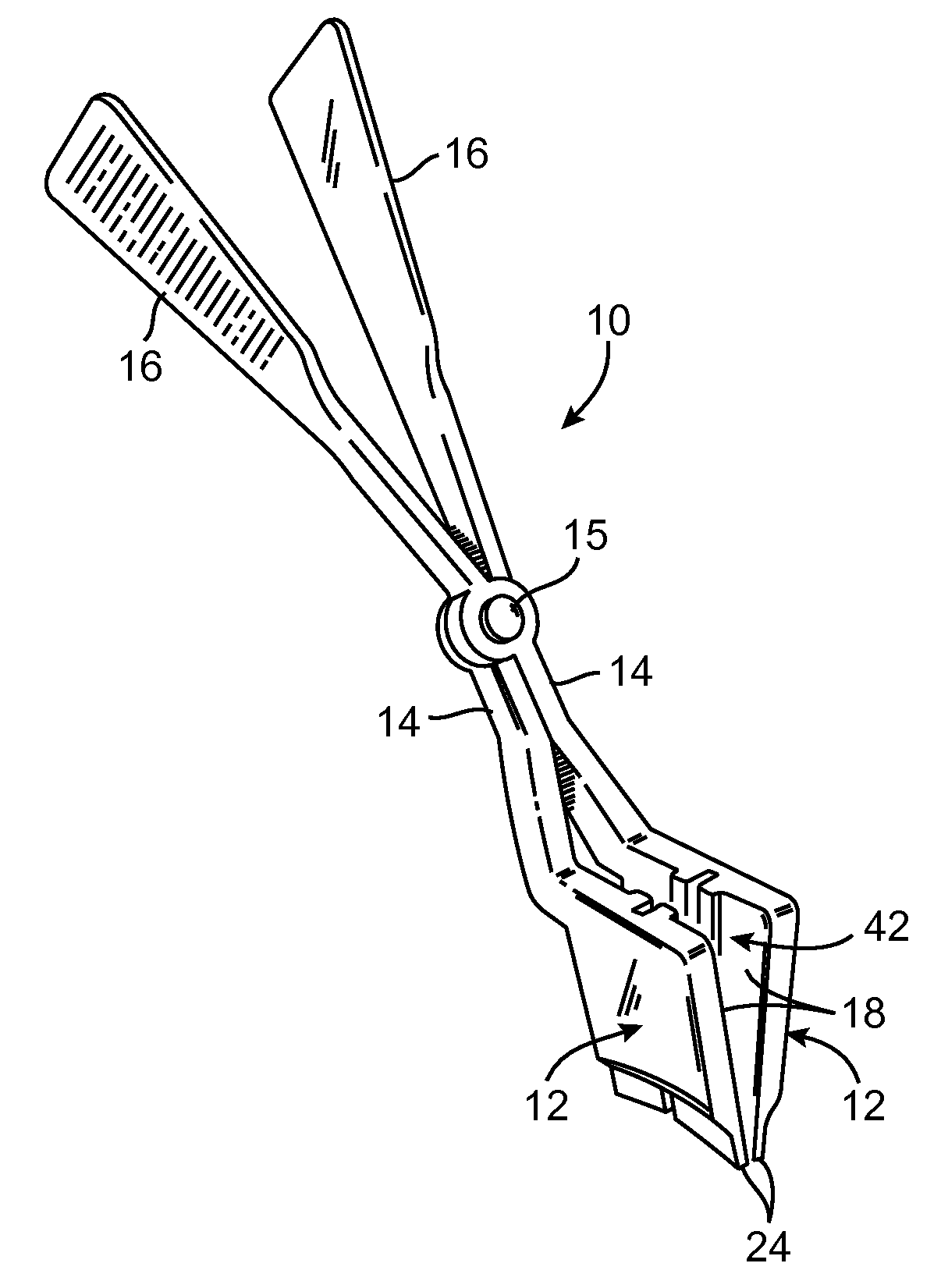

Surgical stapling loading unit having articulating jaws

An end effector includes first and second jaw members that are pivotable relative to one another between open and clamped configurations about a pivot axis. The first and second jaw members each define a pivot hole which defines the pivot axis. The first and second jaw members also each define an articulation axis that is orthogonal to the pivot axis and position distal of the pivot axis. The first and second jaw members are articulatable about the articulation axis between straight and fully articulated configurations.

Owner:TYCO HEALTHCARE GRP LP

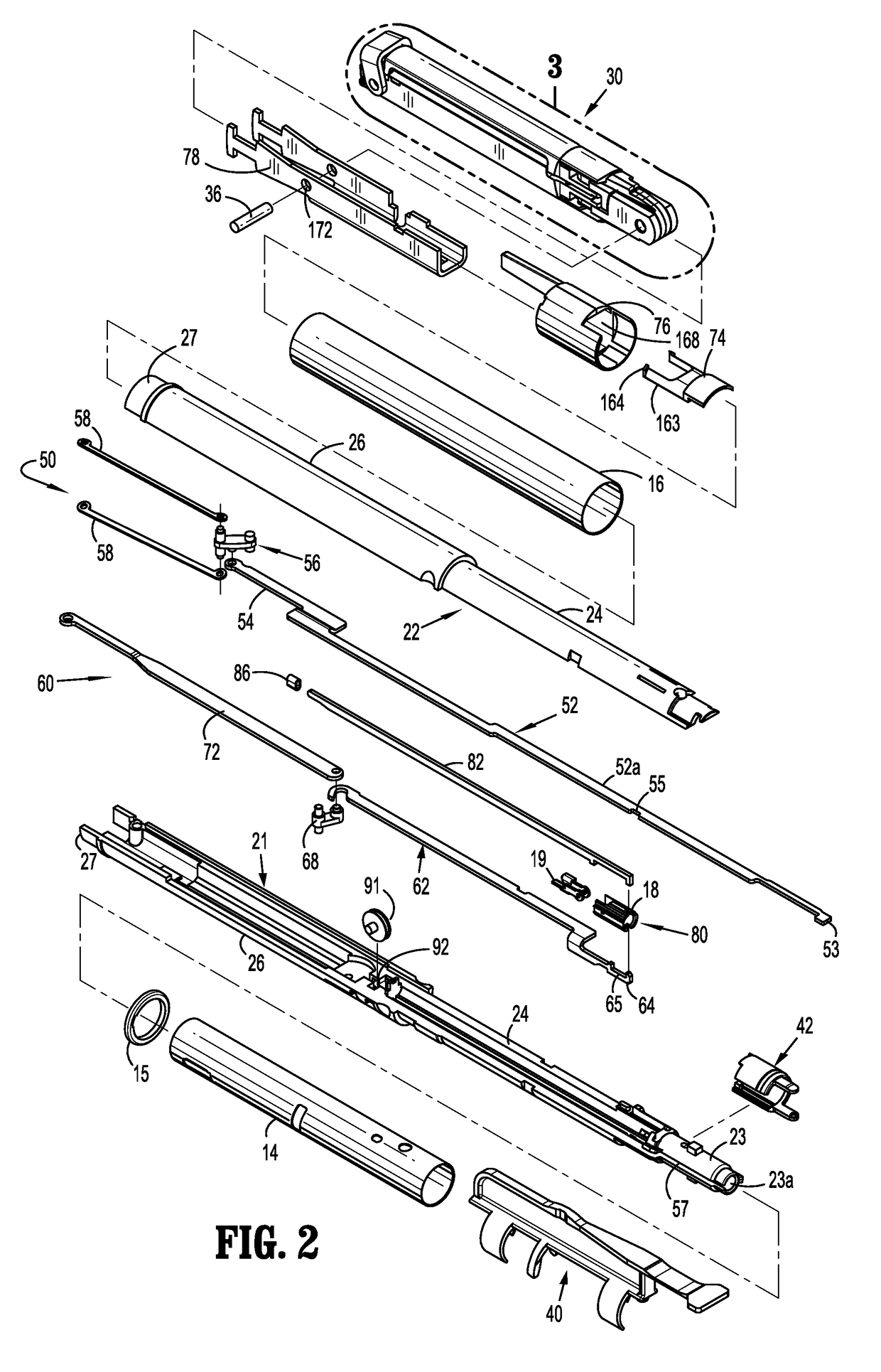

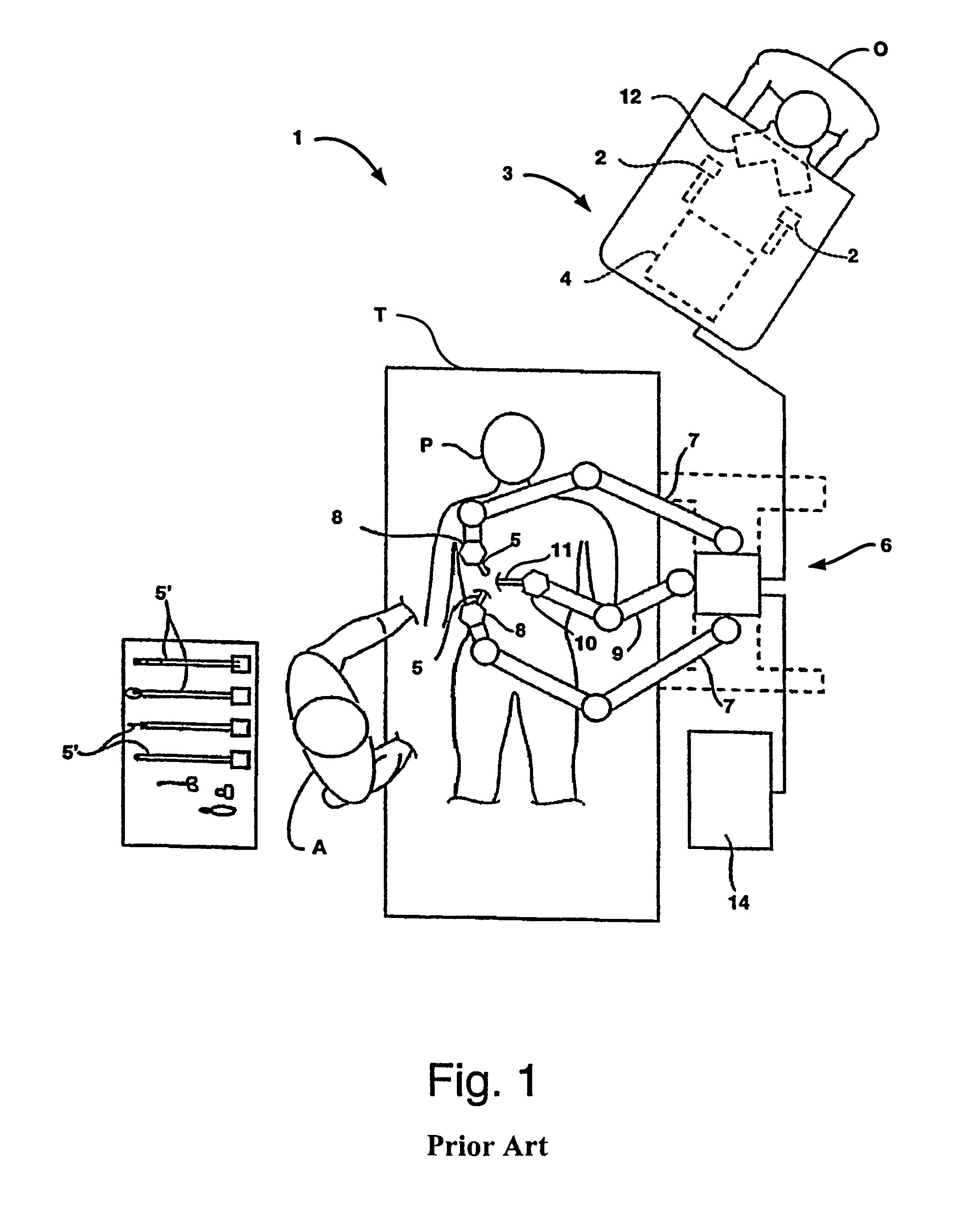

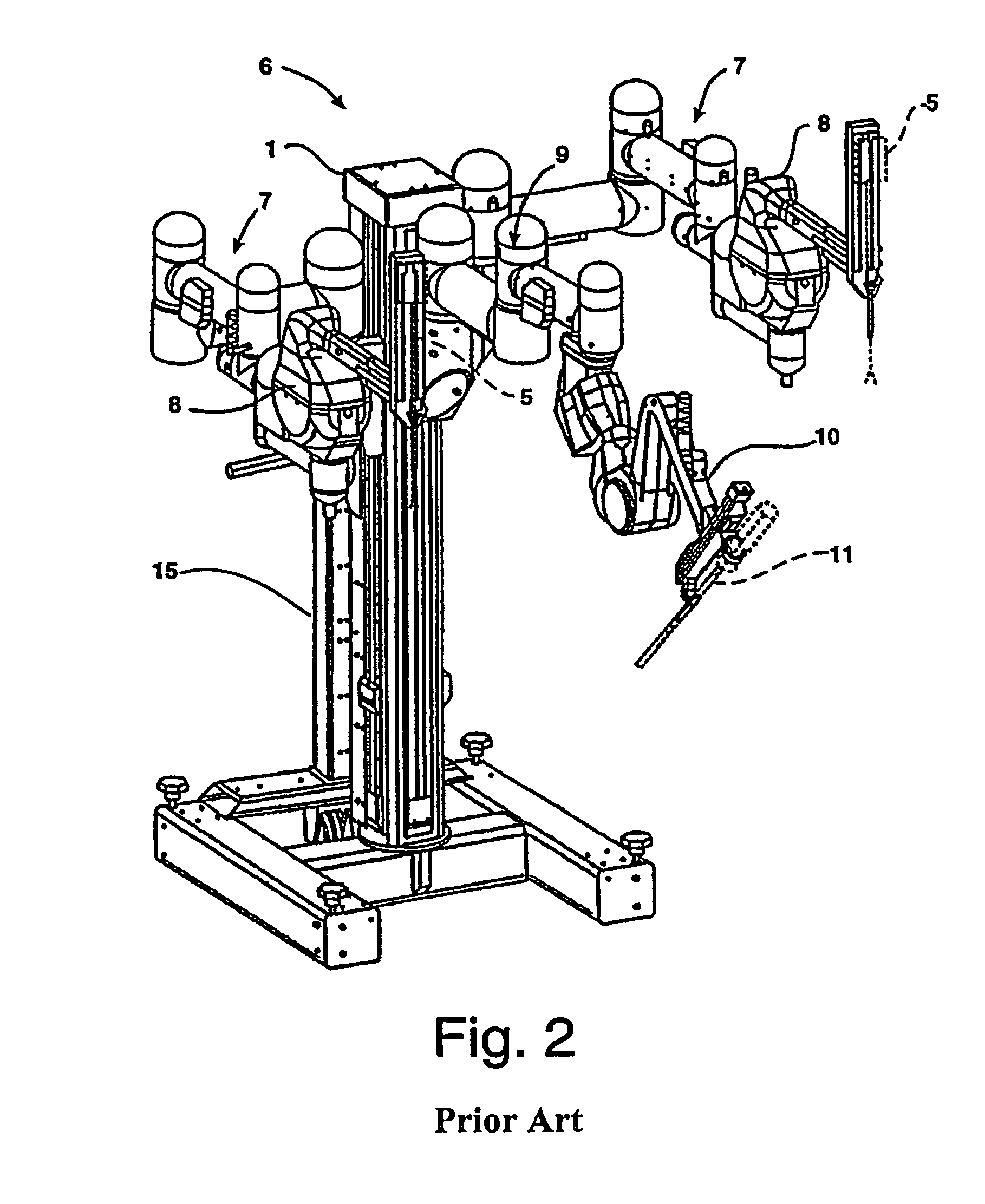

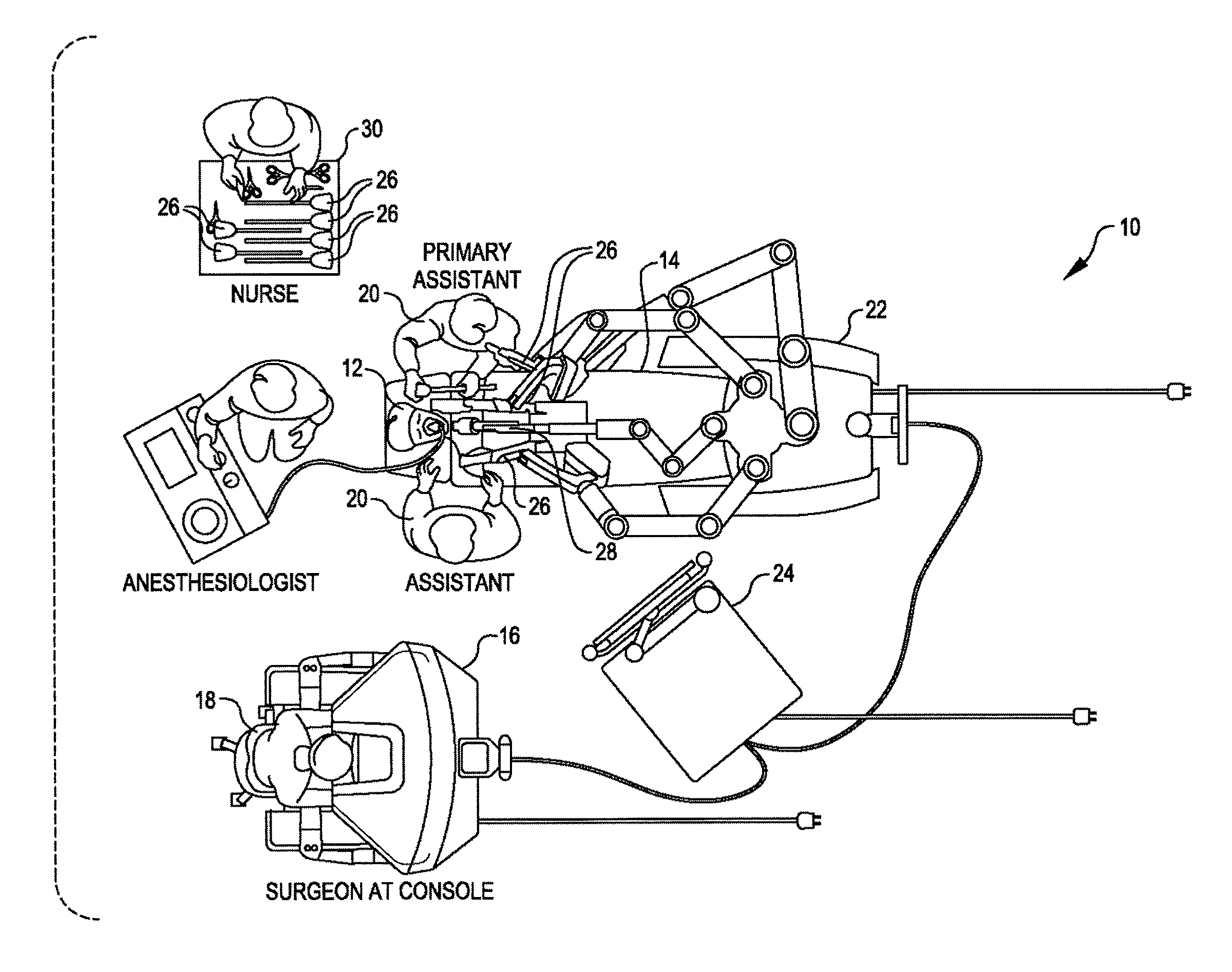

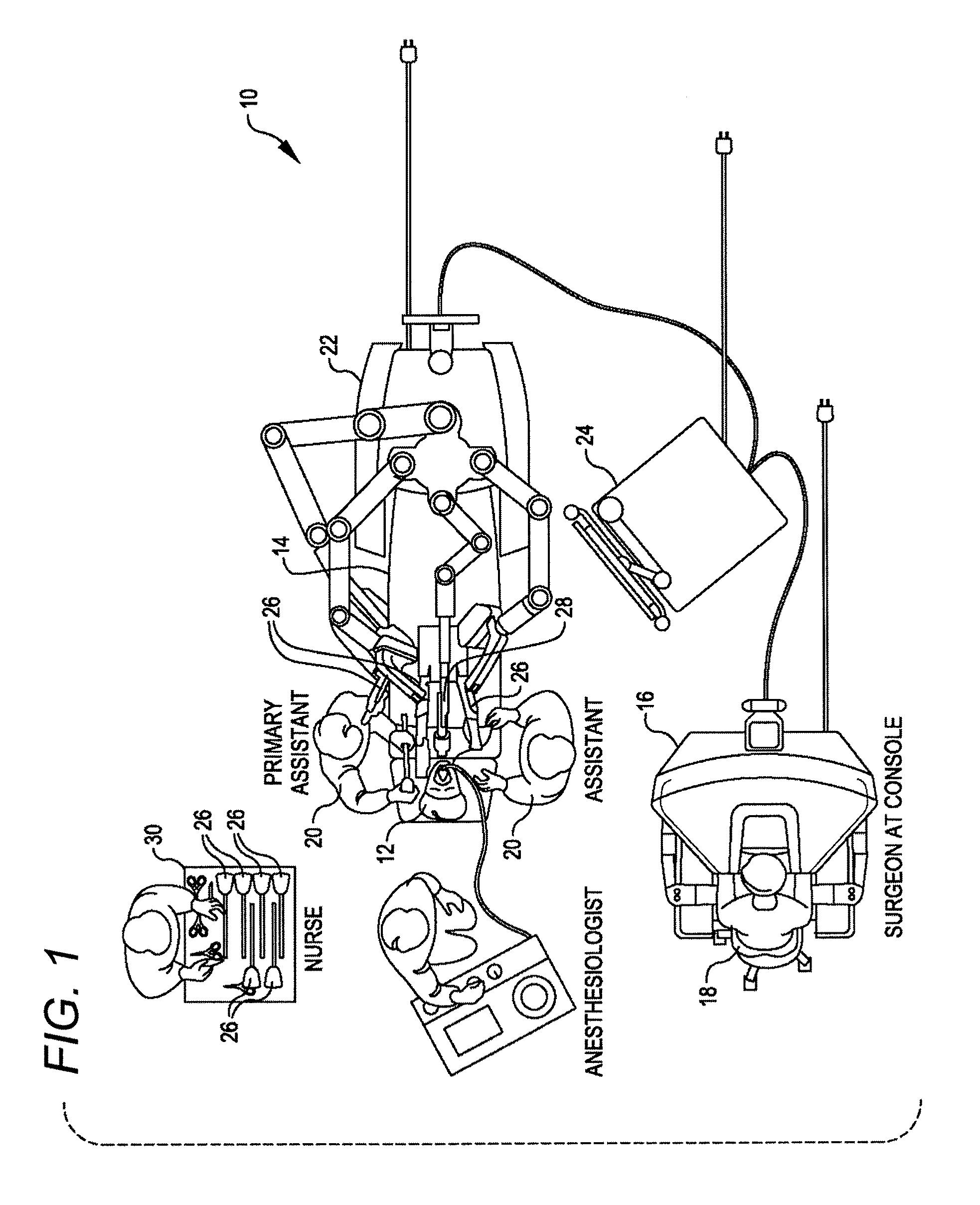

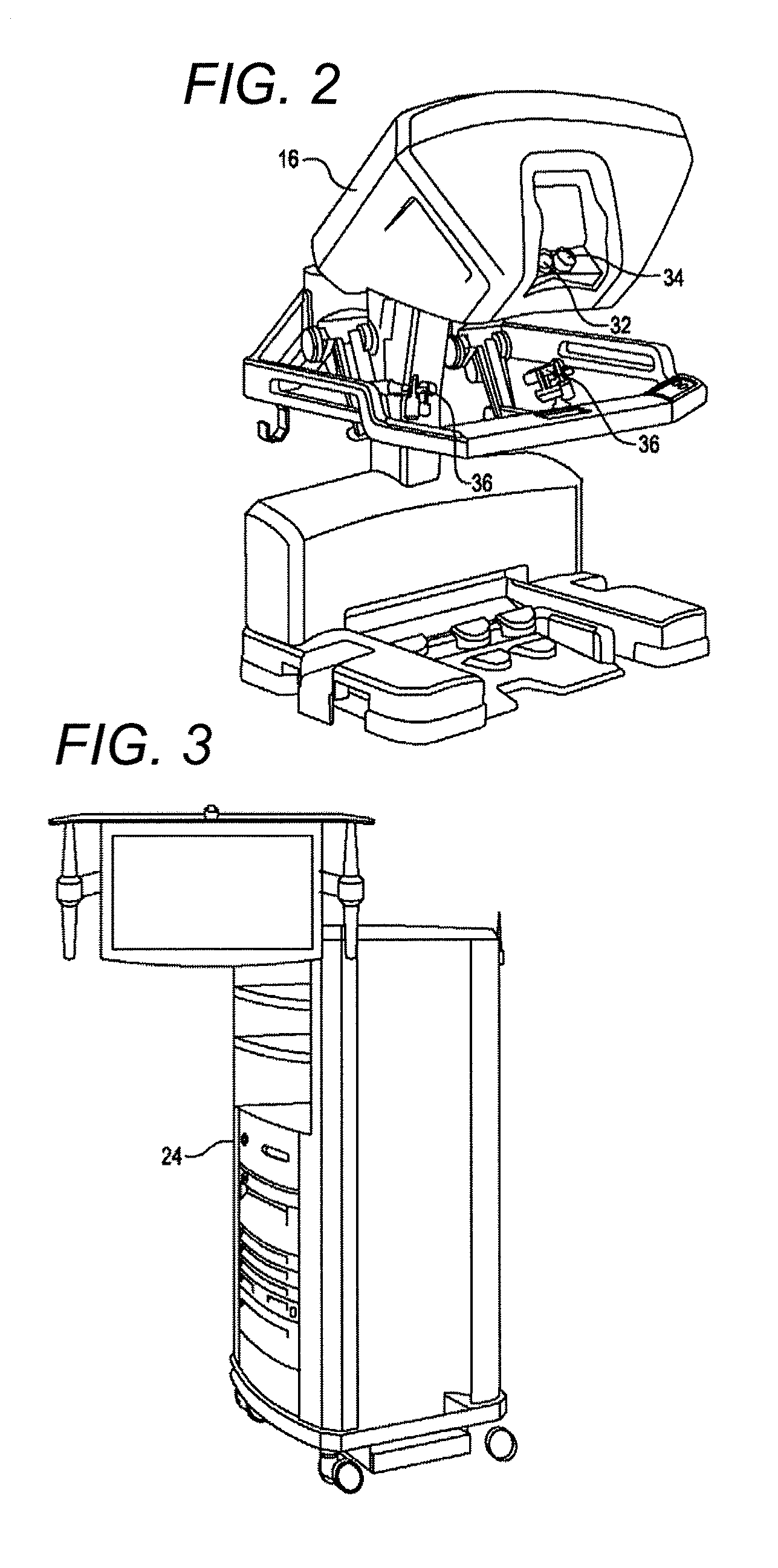

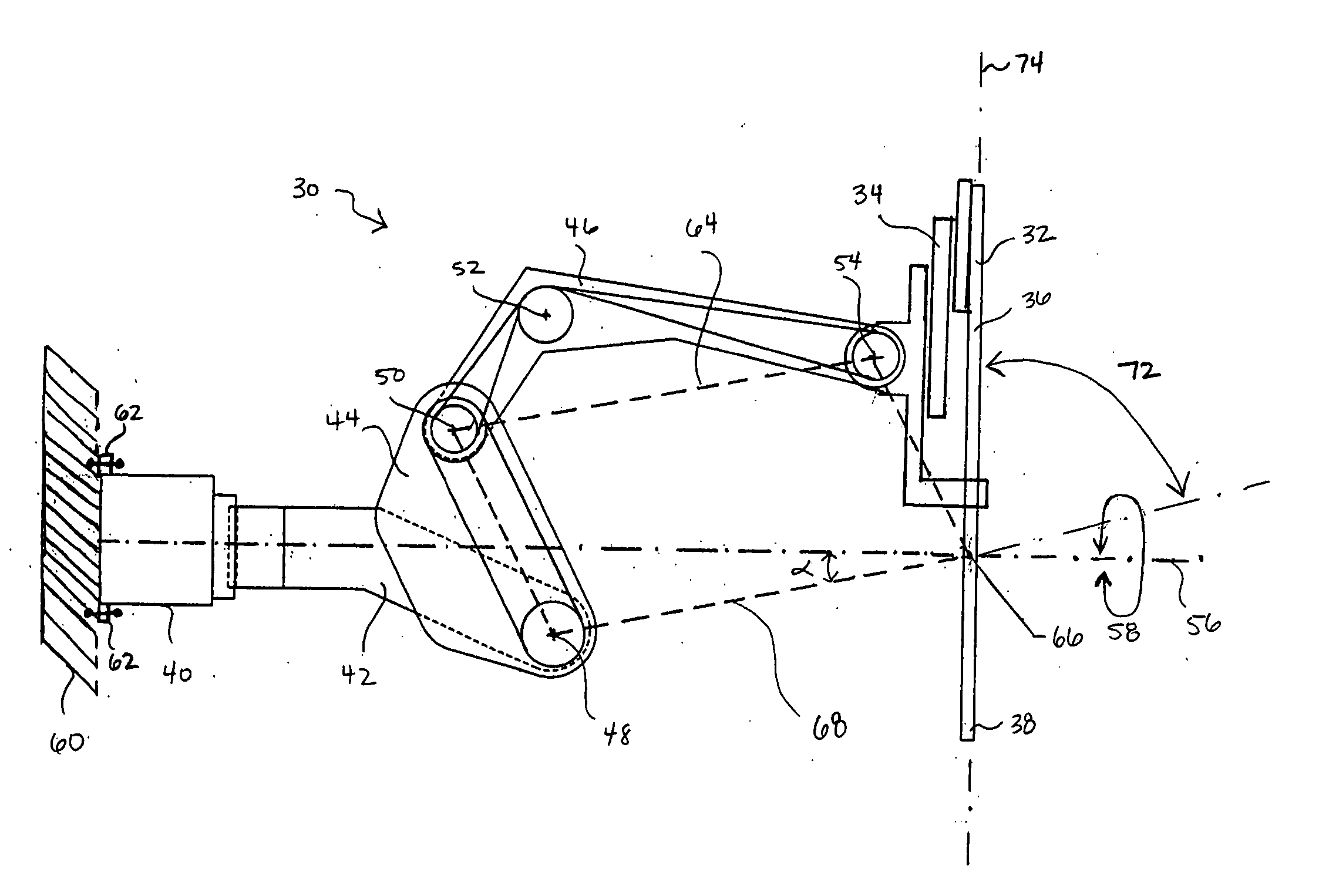

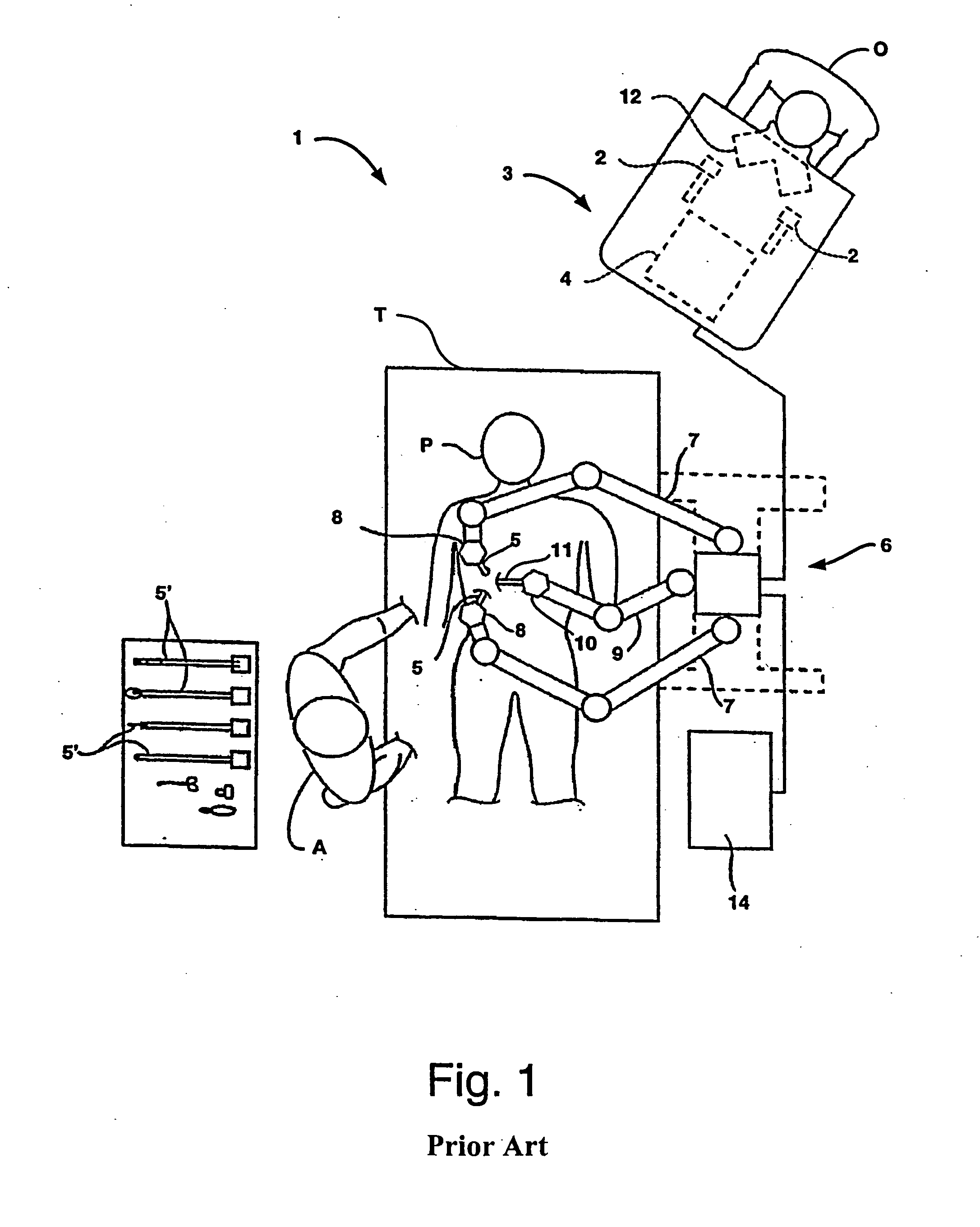

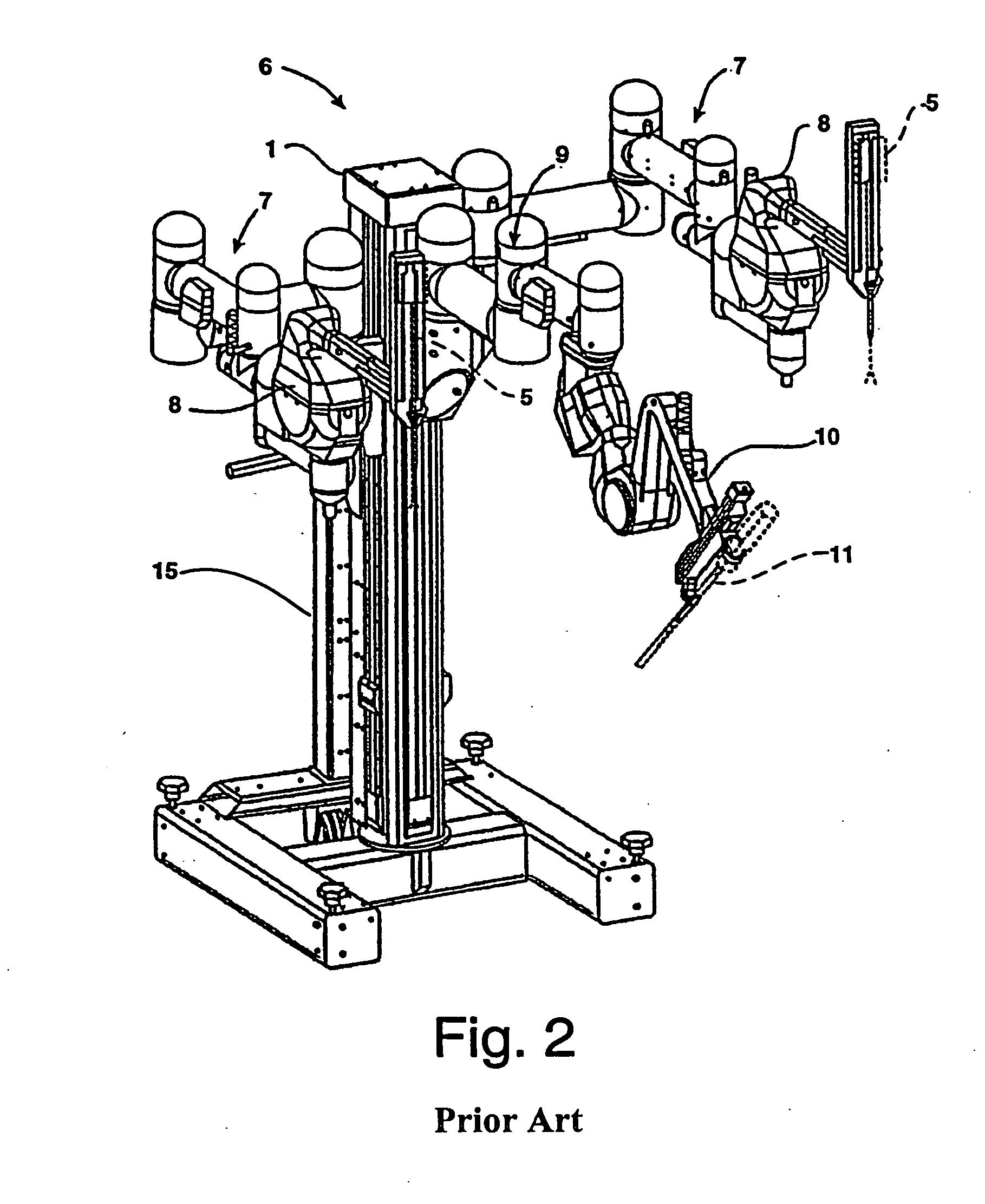

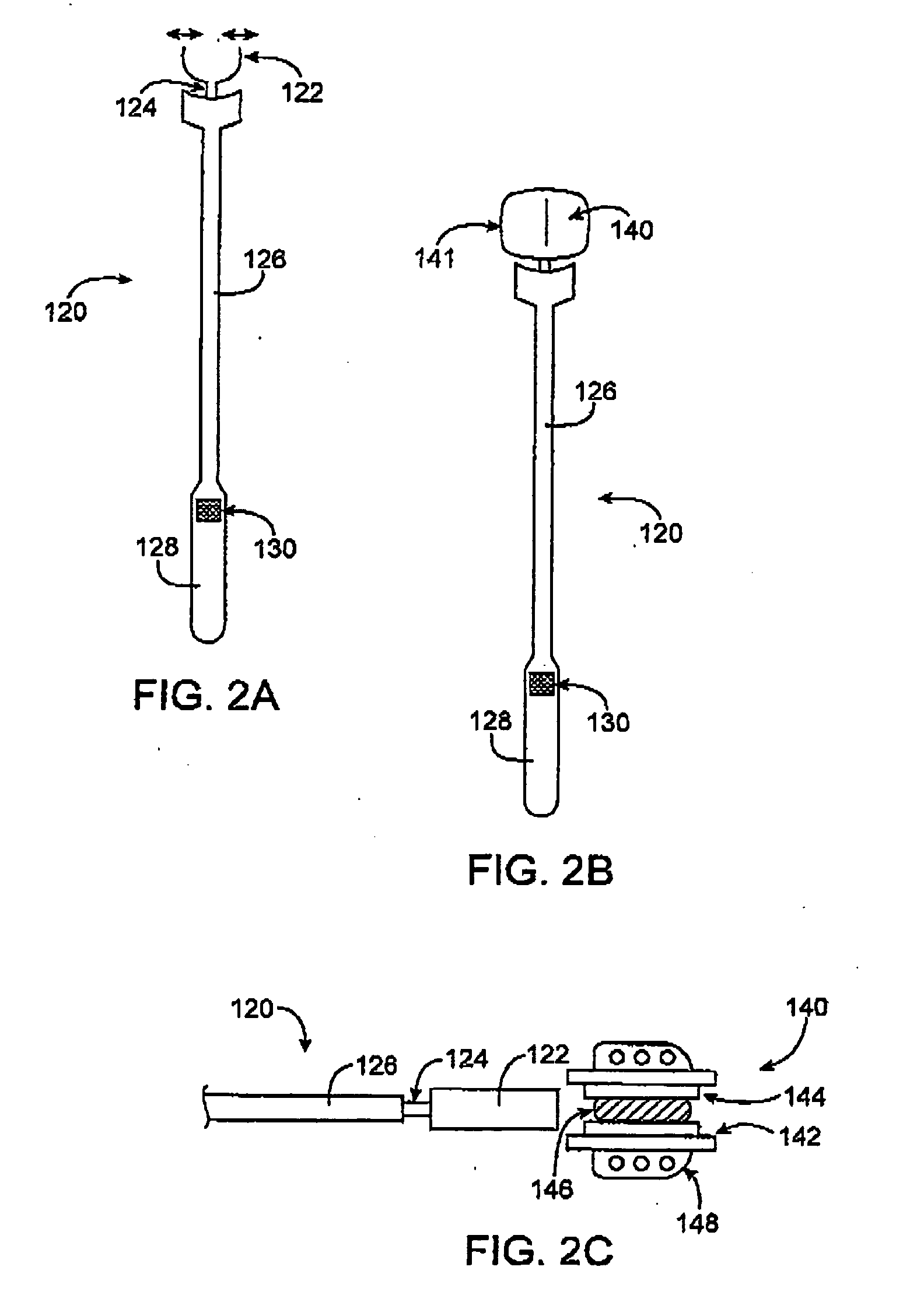

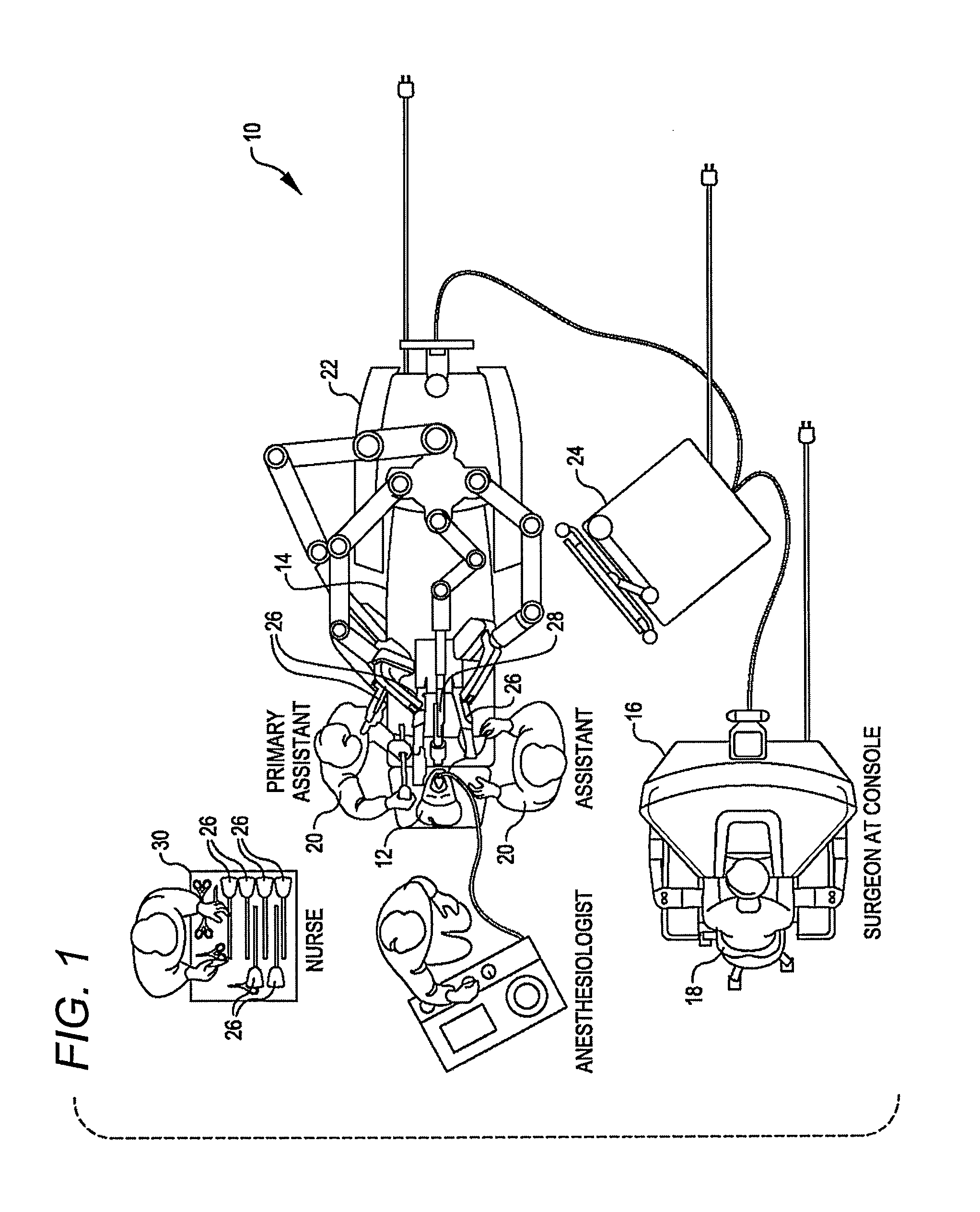

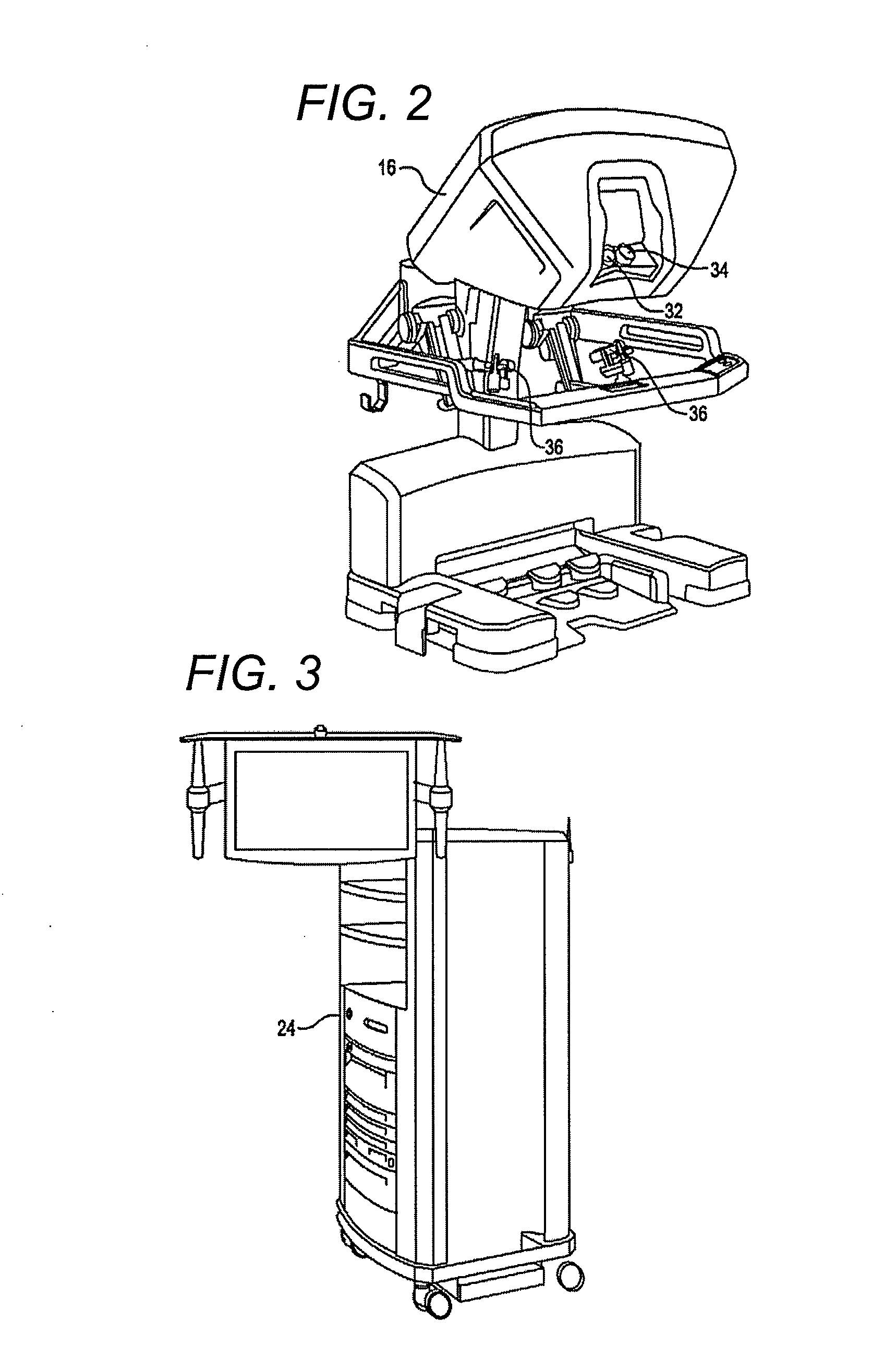

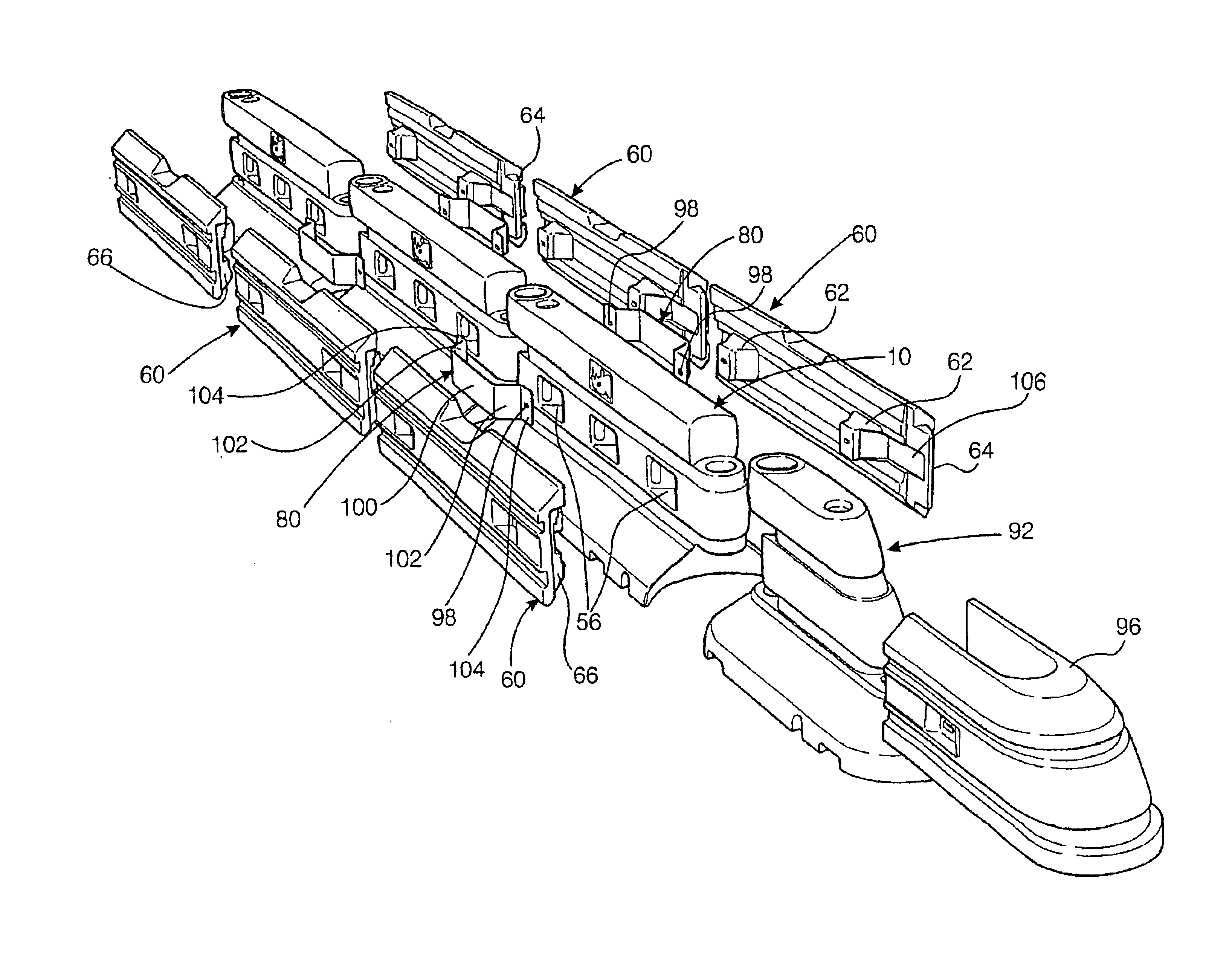

Offset remote center manipulator for robotic surgery

ActiveUS7594912B2Increase rangeReduces overall complexity and size and physical weightMechanical apparatusDiagnosticsEngineeringManipulator

Medical, surgical, and / or robotic devices and systems often including offset remote center parallelogram manipulator linkage assemblies which constrains a position of a surgical instrument during minimally invasive robotic surgery are disclosed. The improved remote center manipulator linkage assembly advantageously enhances the range of instrument motion while at the same time reduces the overall complexity, size, and physical weight of the robotic surgical system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

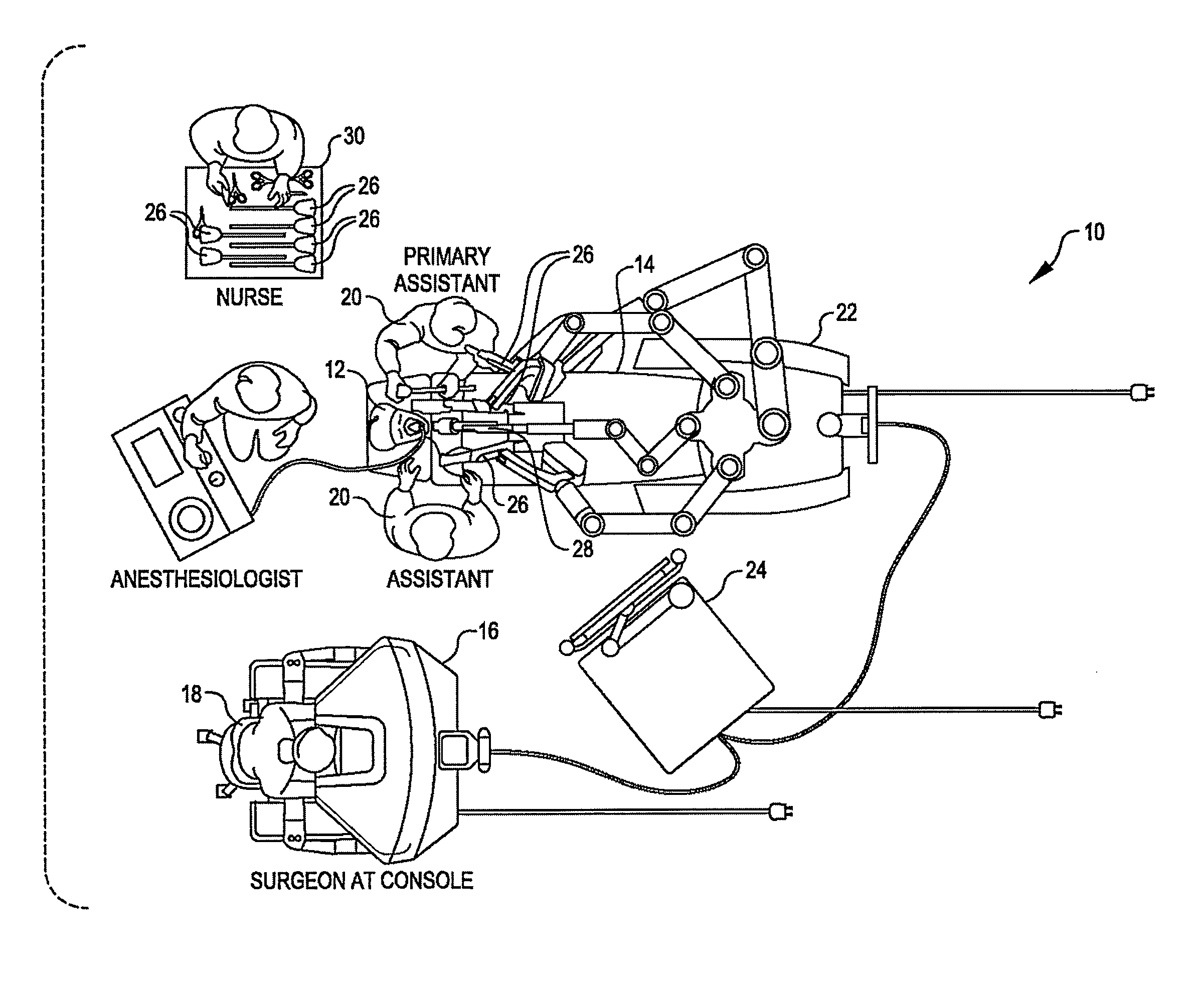

User initiated break-away clutching of a surgical mounting platform

ActiveUS9452020B2Improve pronunciationLess effortProgramme controlProgramme-controlled manipulatorDetentControl system

Owner:INTUITIVE SURGICAL OPERATIONS INC

Offset remote center manipulator for robotic surgery

ActiveUS20060074406A1Reduce in sizeEnhance rangeMechanical apparatusDiagnosticsManipulatorSurgical instrument

Medical, surgical, and / or robotic devices and systems often including offset remote center parallelogram manipulator linkage assemblies which constrains a position of a surgical instrument during minimally invasive robotic surgery are disclosed. The improved remote center manipulator linkage assembly advantageously enhances the range of instrument motion while at the same time reduces the overall complexity, size, and physical weight of the robotic surgical system.

Owner:INTUITIVE SURGICAL OPERATIONS INC

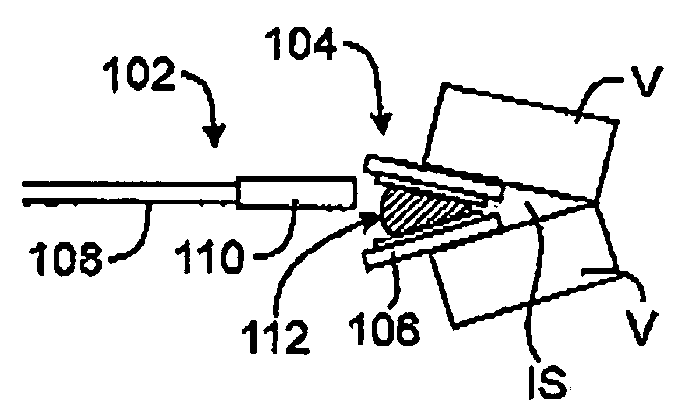

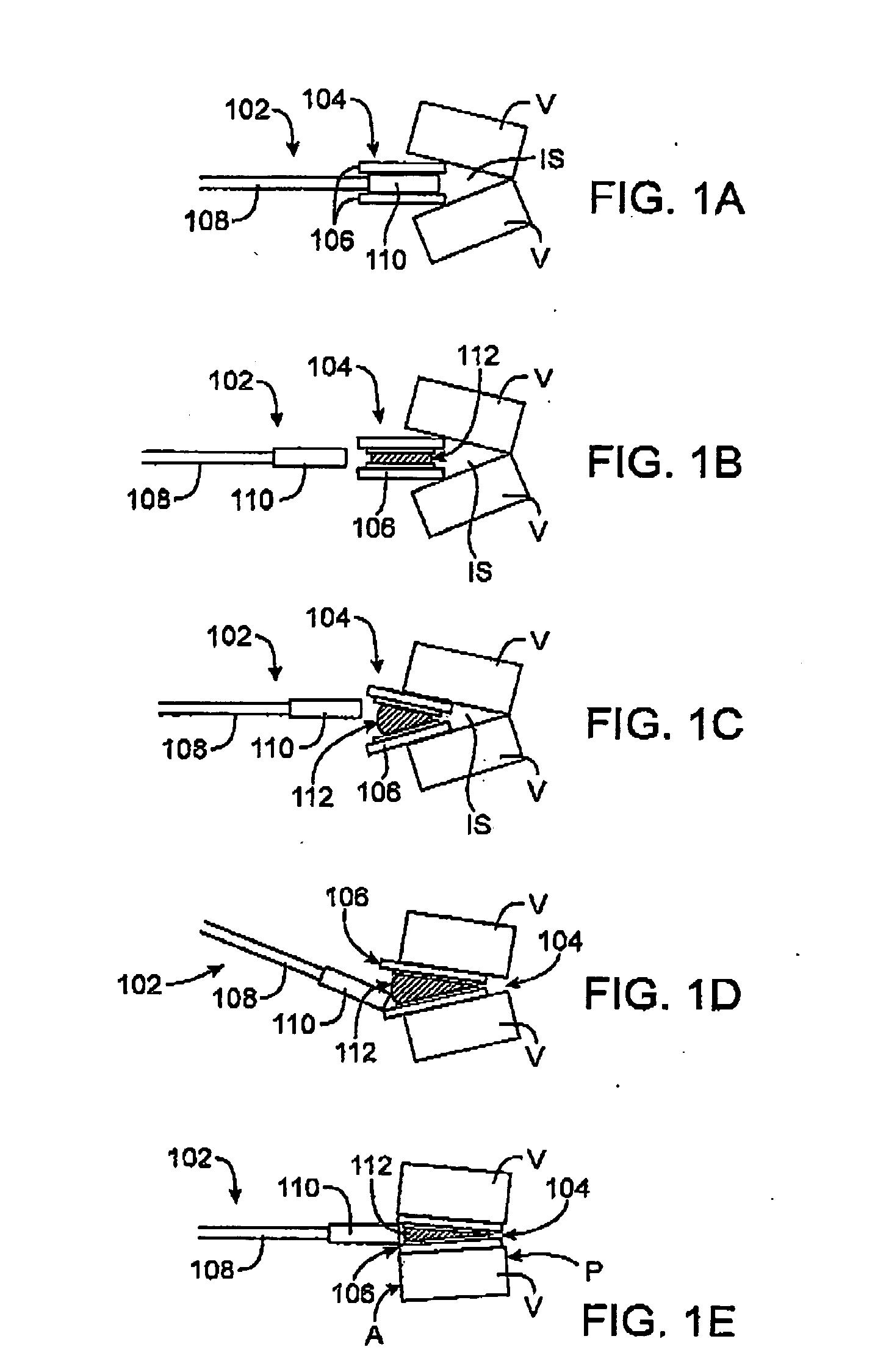

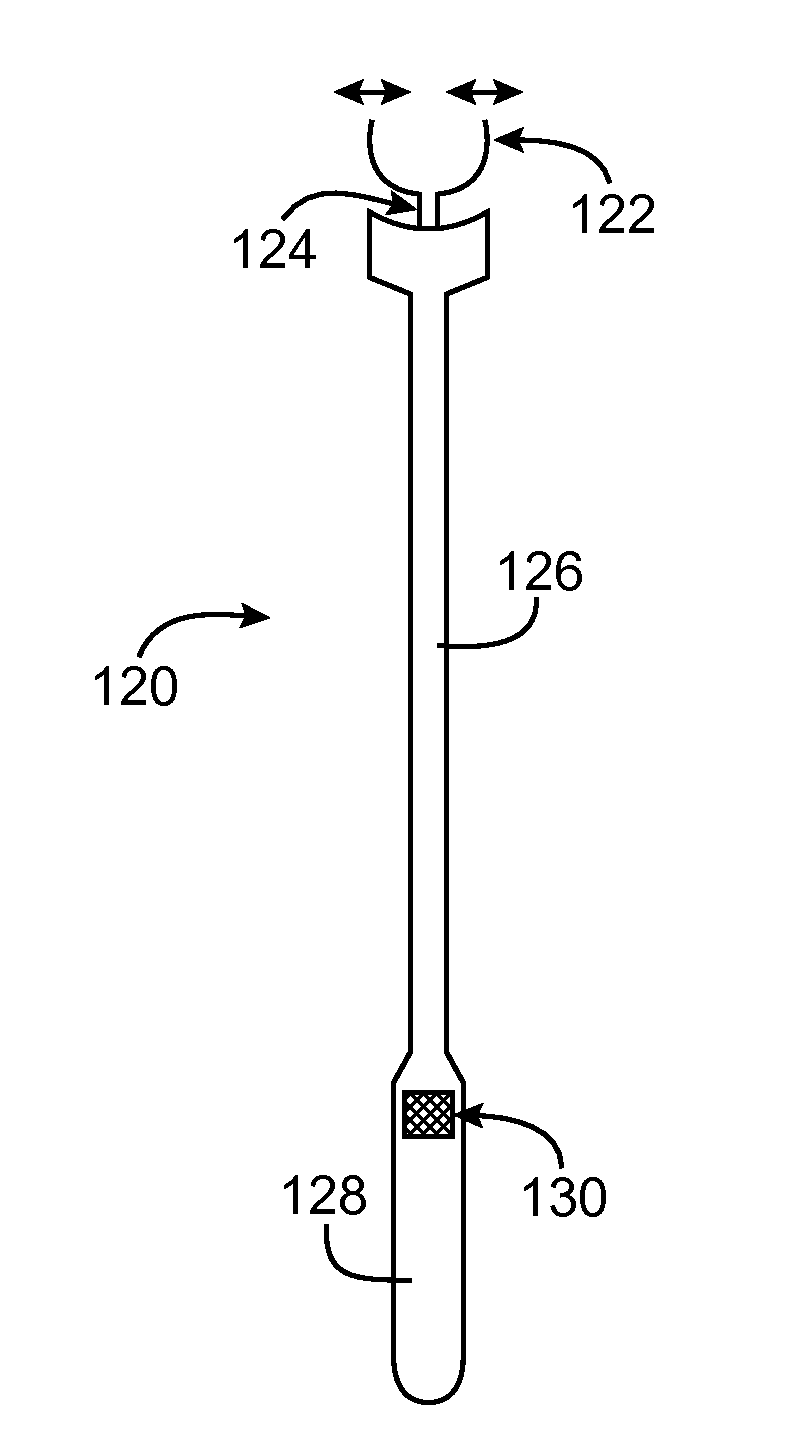

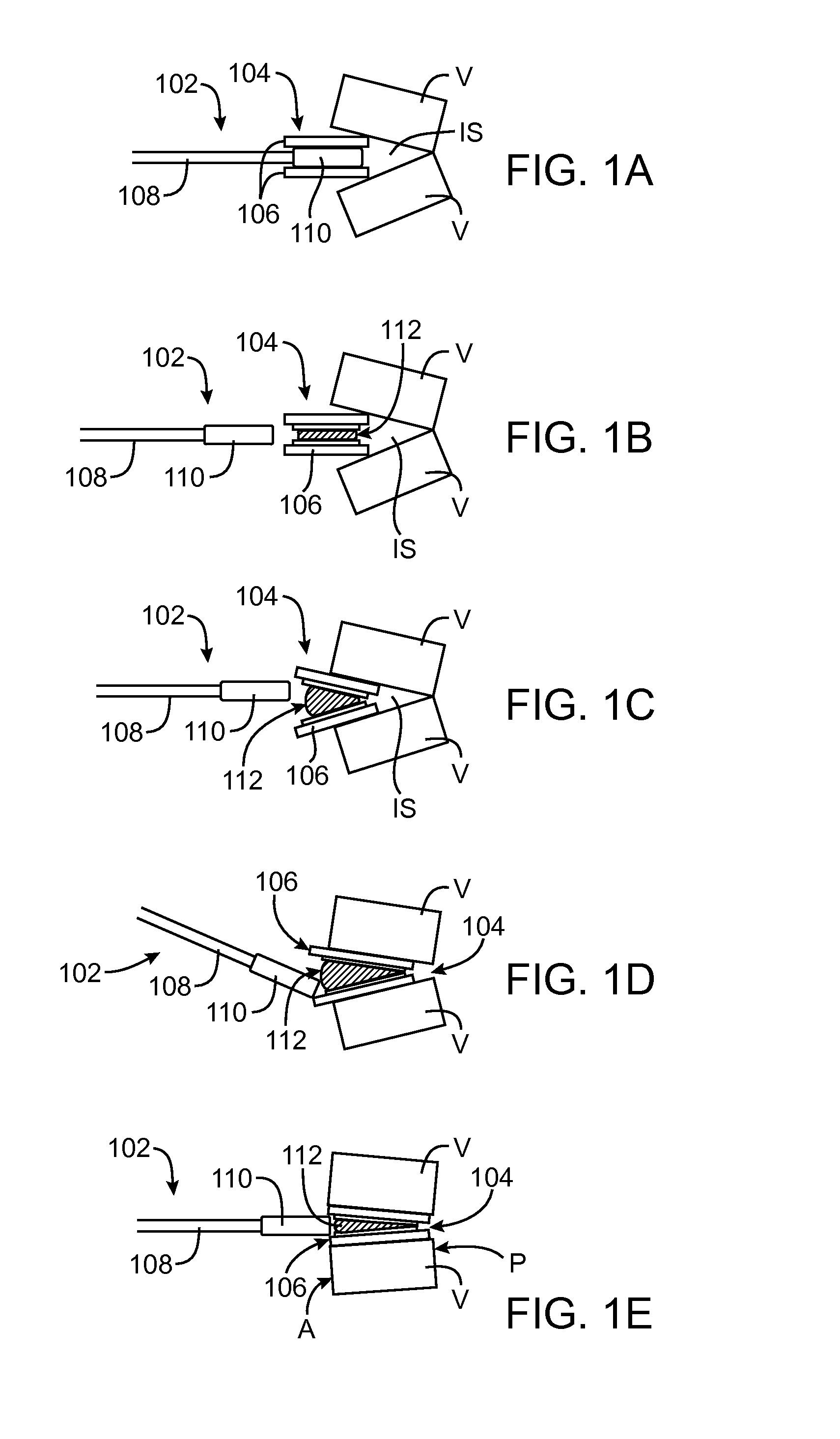

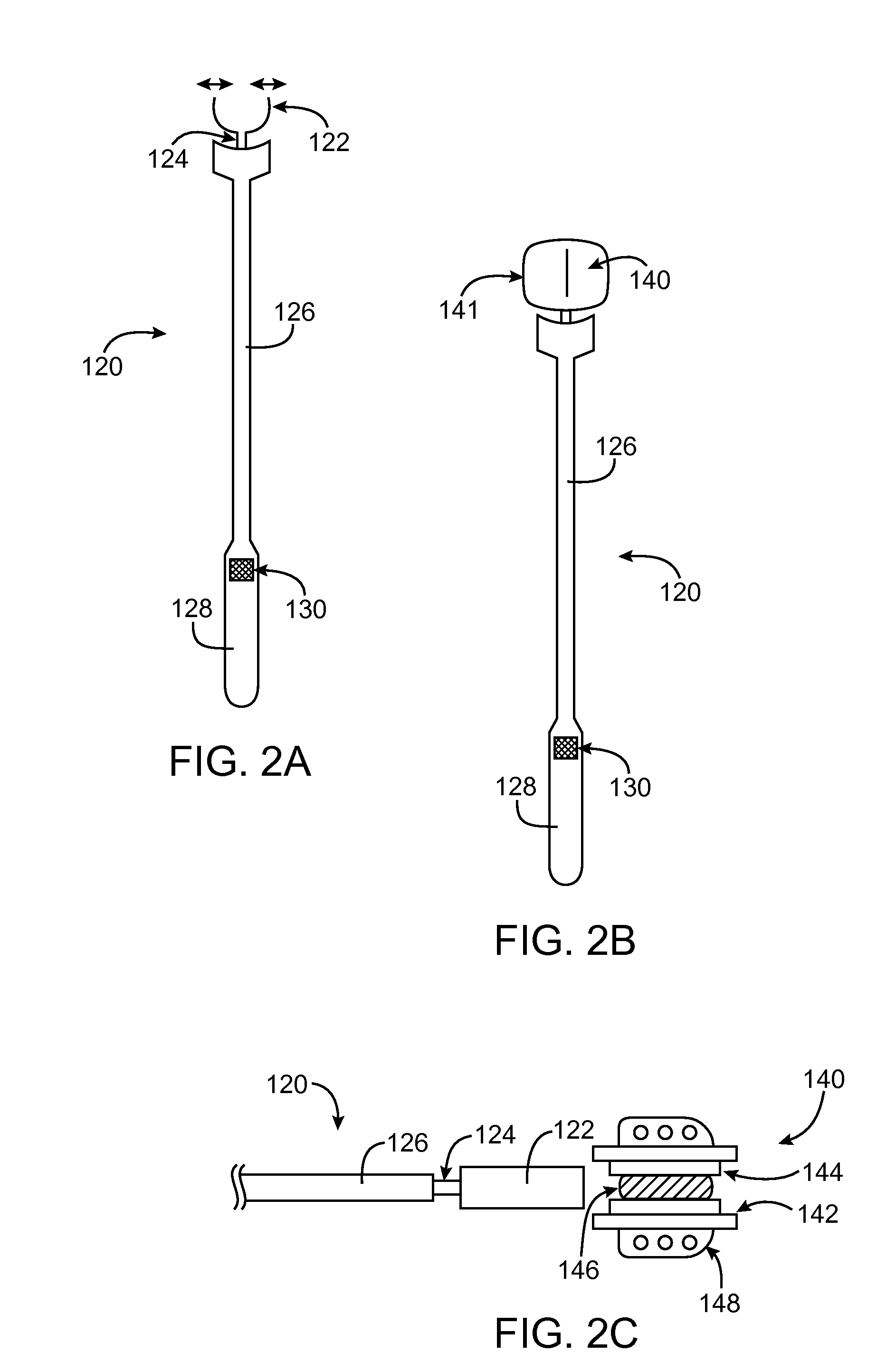

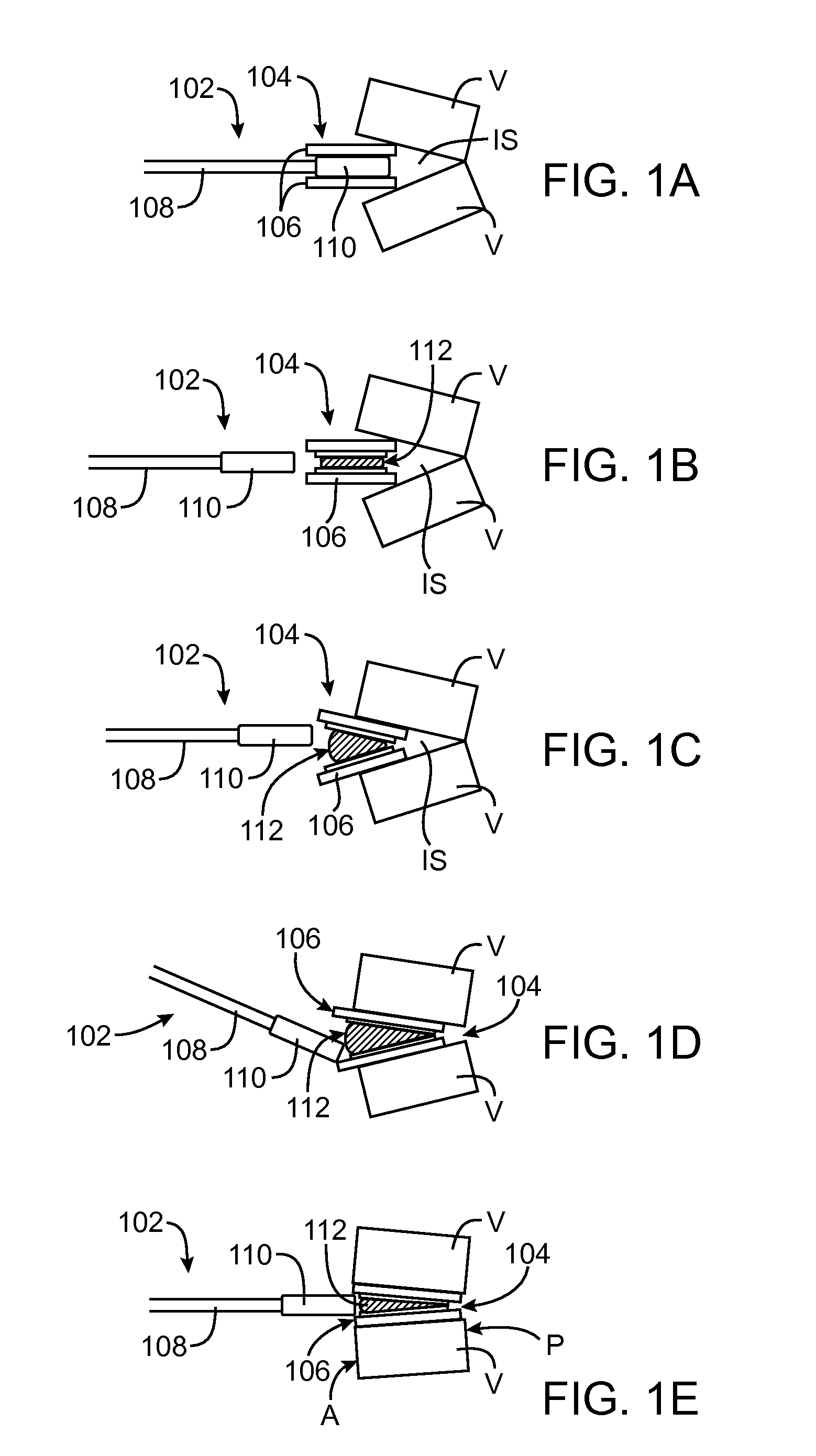

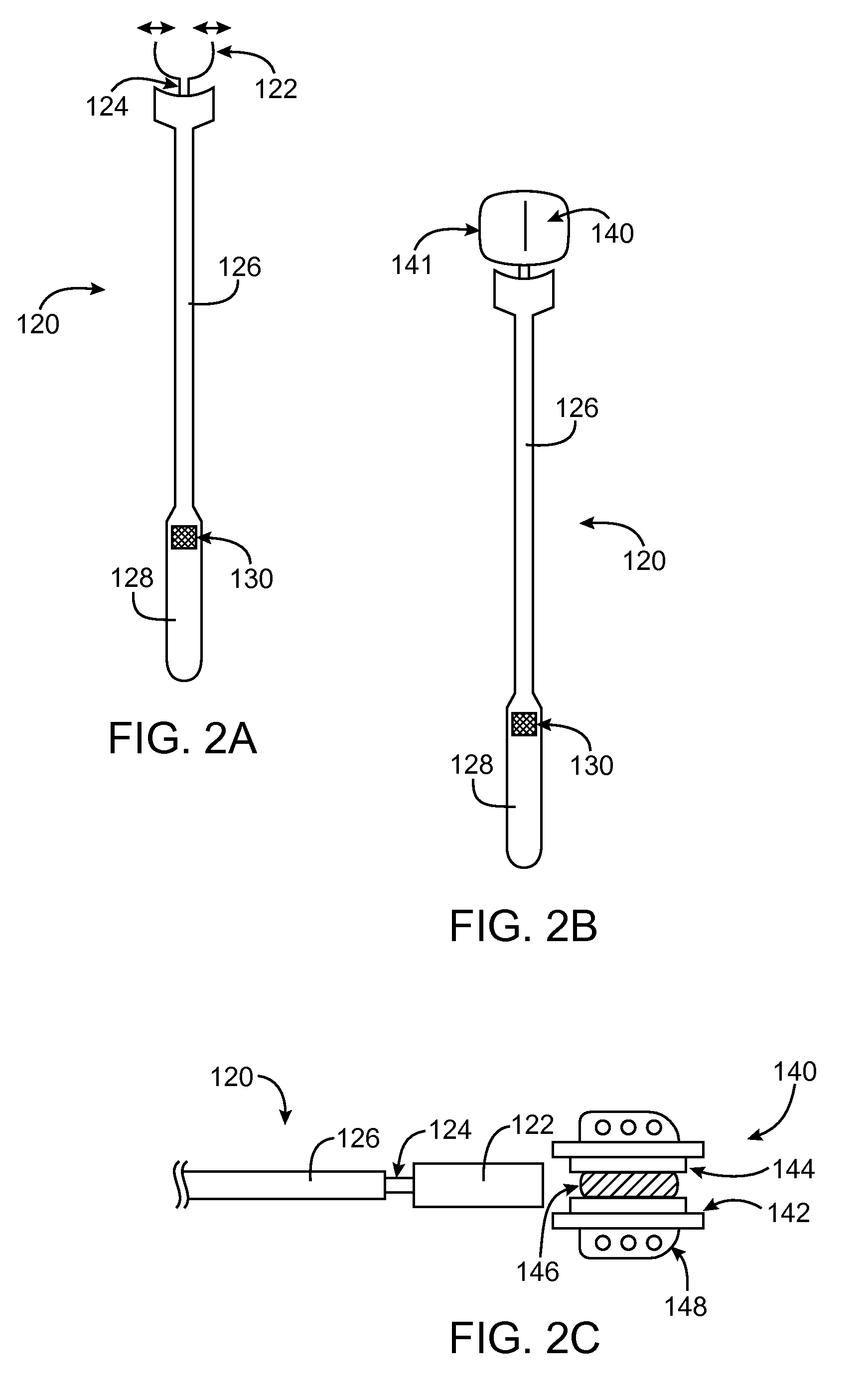

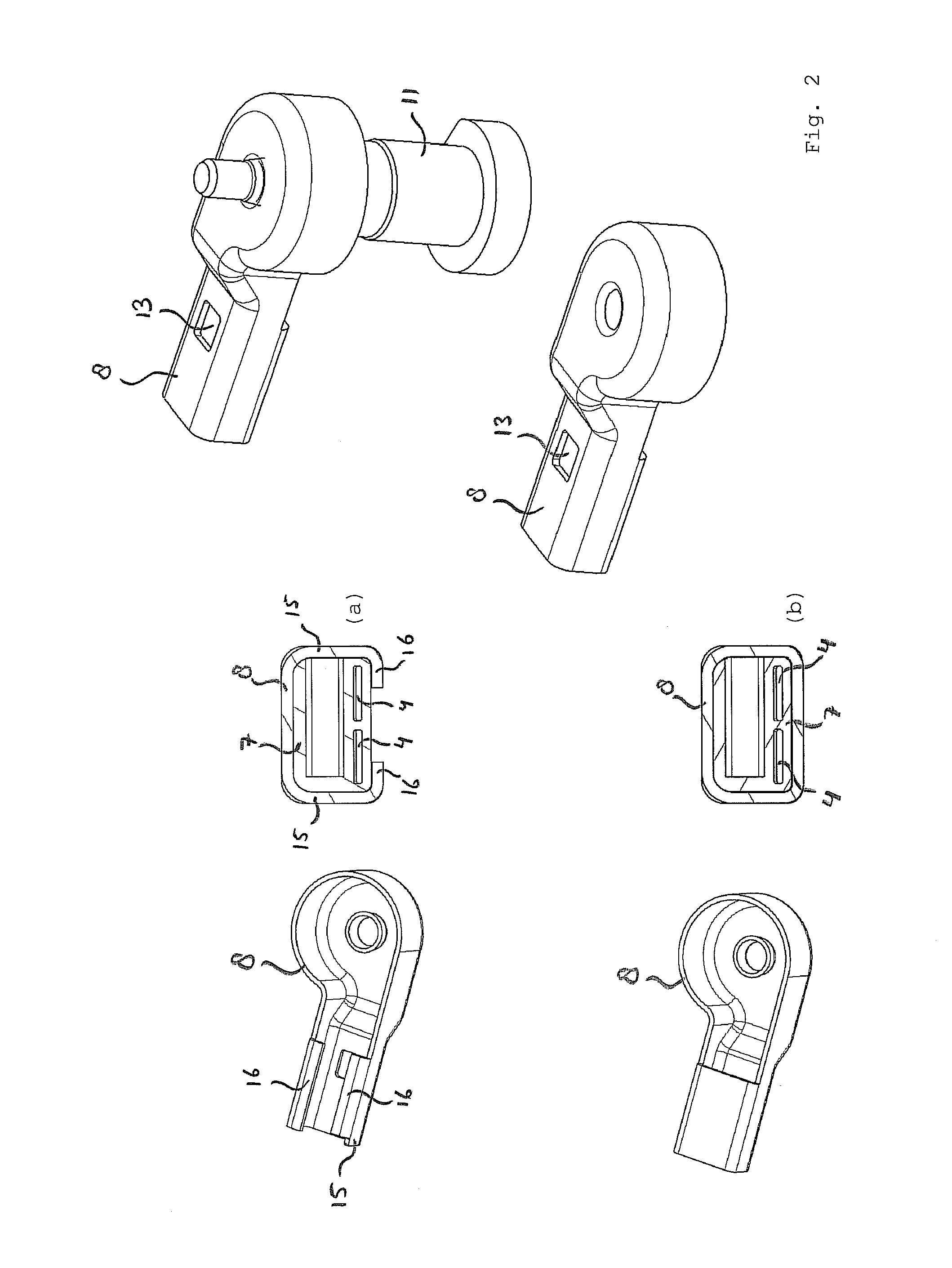

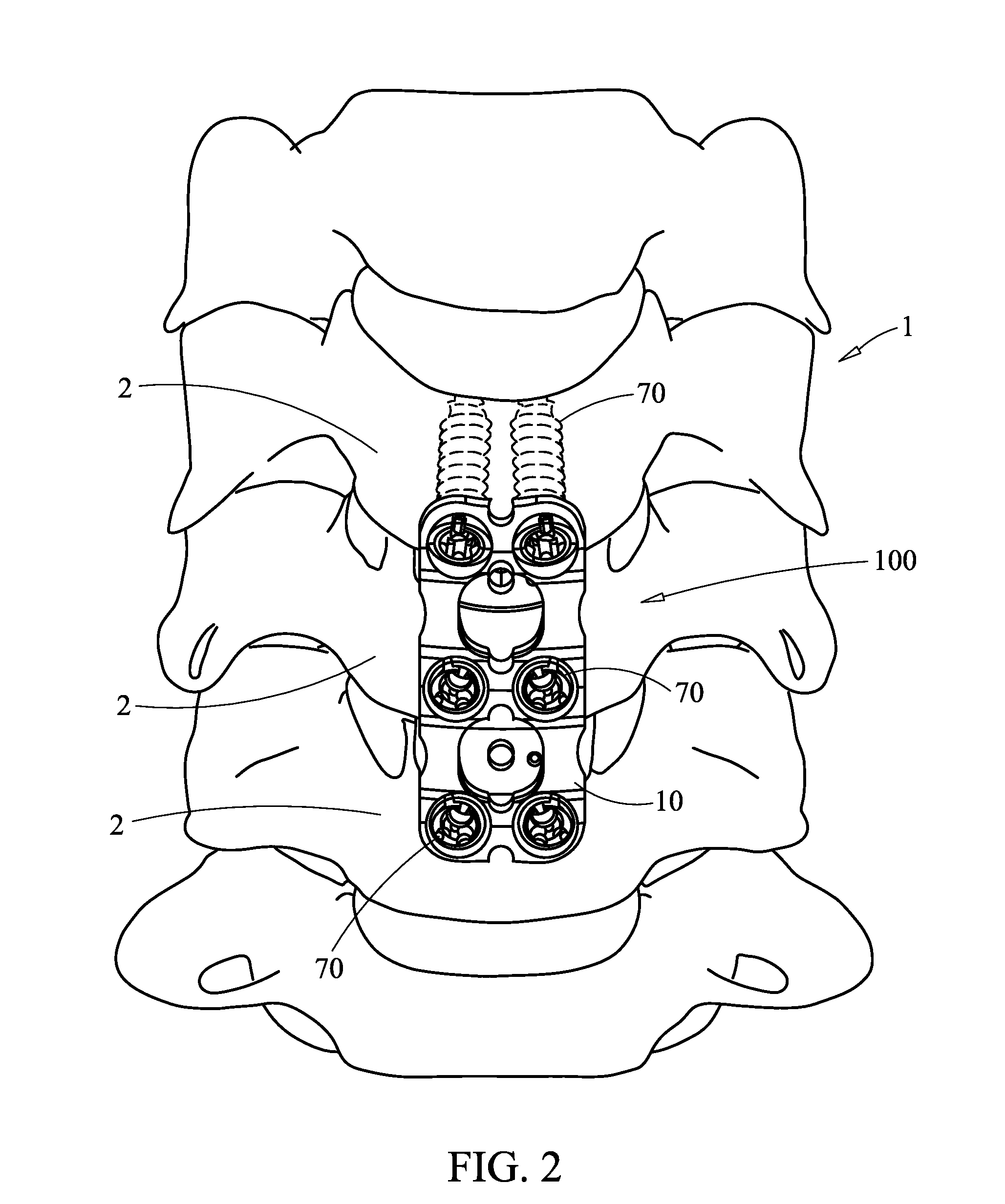

Methods and apparatus for intervertebral disc prosthesis insertion

ActiveUS20060030857A1Minimal distractionReduced distractionJoint implantsSpinal implantsVertebraBiomedical engineering

A method for inserting an intervertebral disc prosthesis into a space between two vertebrae involves inserting the prosthesis partway into the space under constraint to prevent endplates of the prosthesis from articulating, releasing the prosthesis from constraint, and inserting the unconstrained prosthesis farther into the space. In some embodiments, the method involves grasping the prosthesis with a grasping device to insert the prosthesis partway under constraint, loosing the grasping device to release the prosthesis from constraint, and pushing the prosthesis farther into the disc space using the grasping device and / or one or more separate pusher devices. A system includes a grasping device, at least one separate pushing device, and optionally a vertebral spreading device and / or a vertebral midline indicator device.

Owner:SIMPLIFY MEDICAL PTY LTD

User initiated break-away clutching of a surgical mounting platform

ActiveUS20140052154A1Improve pronunciationLess effortProgramme controlProgramme-controlled manipulatorDetentControl system

Robotic and / or surgical devices, systems, and methods include kinematic linkage structures and associated control systems configured to facilitate preparation of the system for use. One or more kinematic linkage sub-systems may include joints that are actively driven, passive, or a mix of both. A set-up mode employs an intuitive user interface in which one or more joints are initially held static by a brake or joint drive system. The user may articulate the joint(s) by manually pushing against the linkage with a force, torque, or the like that exceeds a manual articulation threshold. Articulation of the moving joints is facilitated by modifying the signals transmitted to the brake or drive system. The system may sense completion of the reconfiguration from a velocity of the joint(s) falling below a threshold, optionally for a desired dwell time. The system may provide a detent-like manual articulation that is not limited to mechanically pre-defined detent joint configurations. Embodiments of the invention provide, and can be particularly well-suited for manual movement of a platform supporting a plurality of surgical manipulators in a robotic surgical system or the like without having to add additional input devices.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Methods and Apparatus for Intervertebral Disc Prosthesis Insertion

ActiveUS20080154382A1Minimal and reduced intervertebral distractionAvoid traumaDiagnosticsJoint implantsIntervertebral diskBiomedical engineering

A method for inserting an intervertebral disc prosthesis into a space between two vertebrae involves inserting the prosthesis partway into the space under constraint to prevent endplates of the prosthesis from articulating, releasing the prosthesis from constraint, and inserting the unconstrained prosthesis farther into the space. In some embodiments, the method involves grasping the prosthesis with a grasping device to insert the prosthesis partway under constraint, loosing the grasping device to release the prosthesis from constraint, and pushing the prosthesis farther into the disc space using the grasping device and / or one or more separate pusher devices. A system includes a grasping device, at least one separate pushing device, and optionally a vertebral spreading device and / or a vertebral midline indicator device.

Owner:SIMPLIFY MEDICAL PTY LTD

Methods and Apparatus for Intervertebral Disc Prosthesis Insertion

InactiveUS20080154301A1Minimal and reduced intervertebral distractionAvoid traumaJoint implantsSpinal implantsIntervertebral discBiomedical engineering

Owner:SIMPLIFY MEDICAL PTY LTD

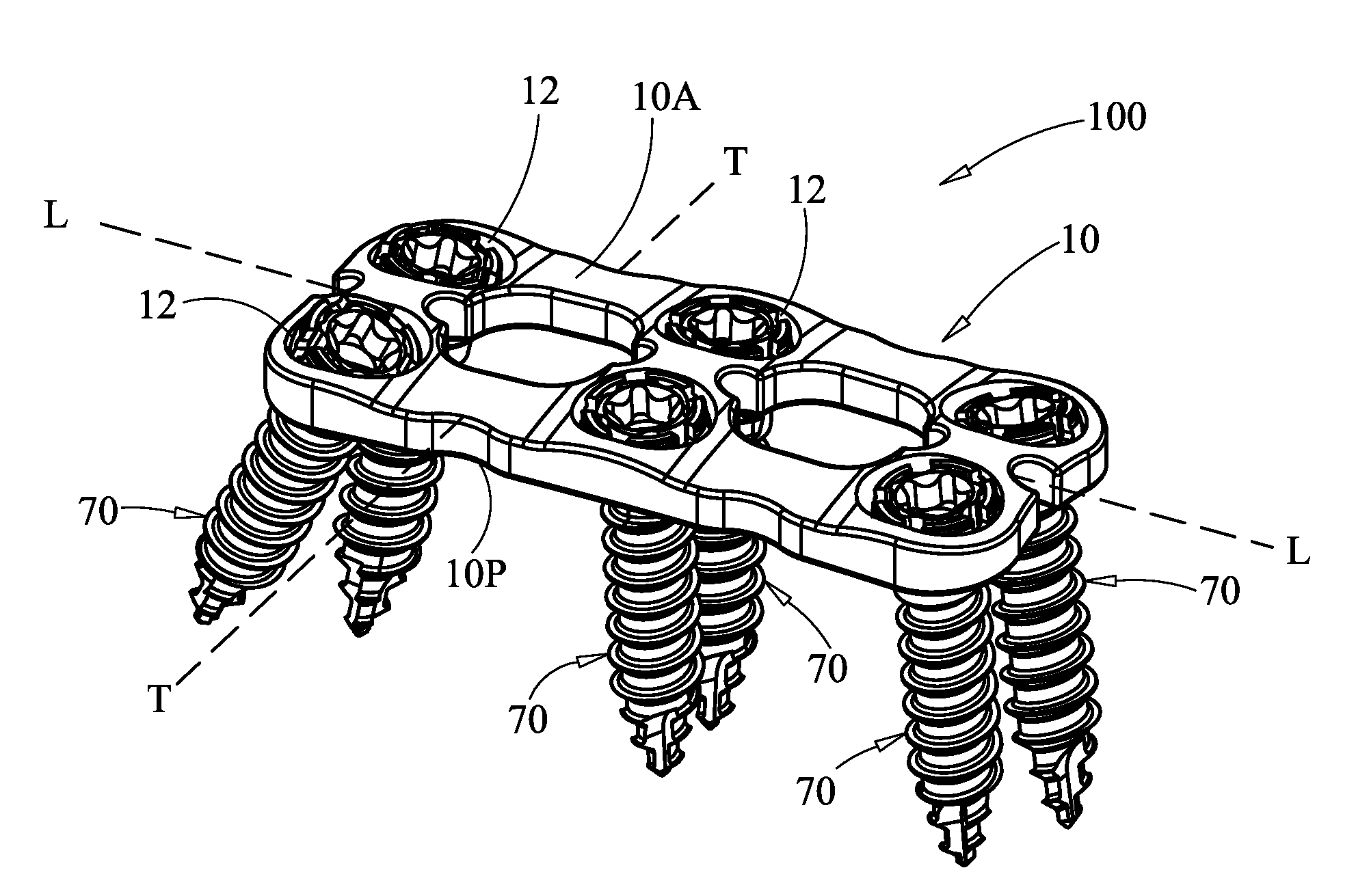

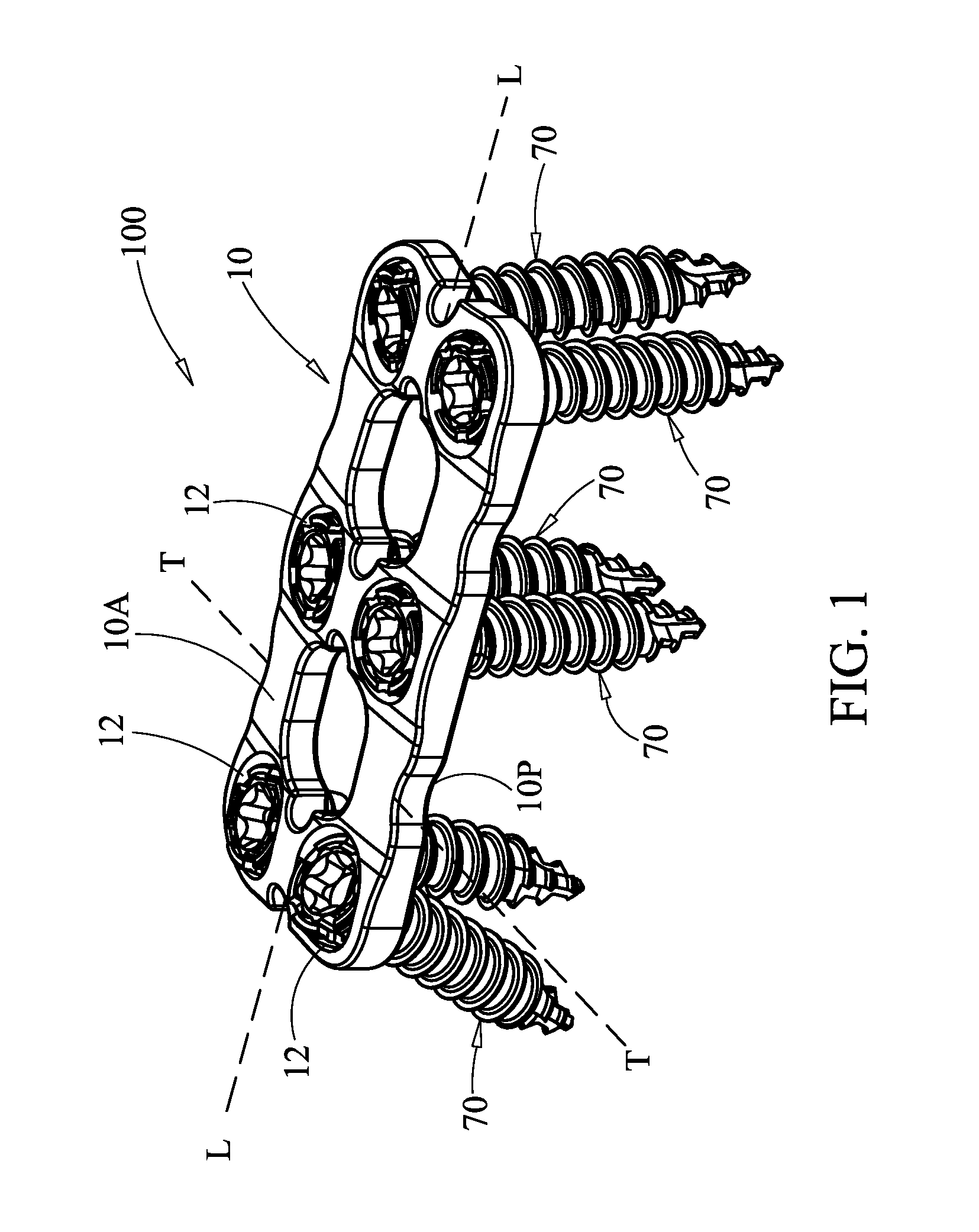

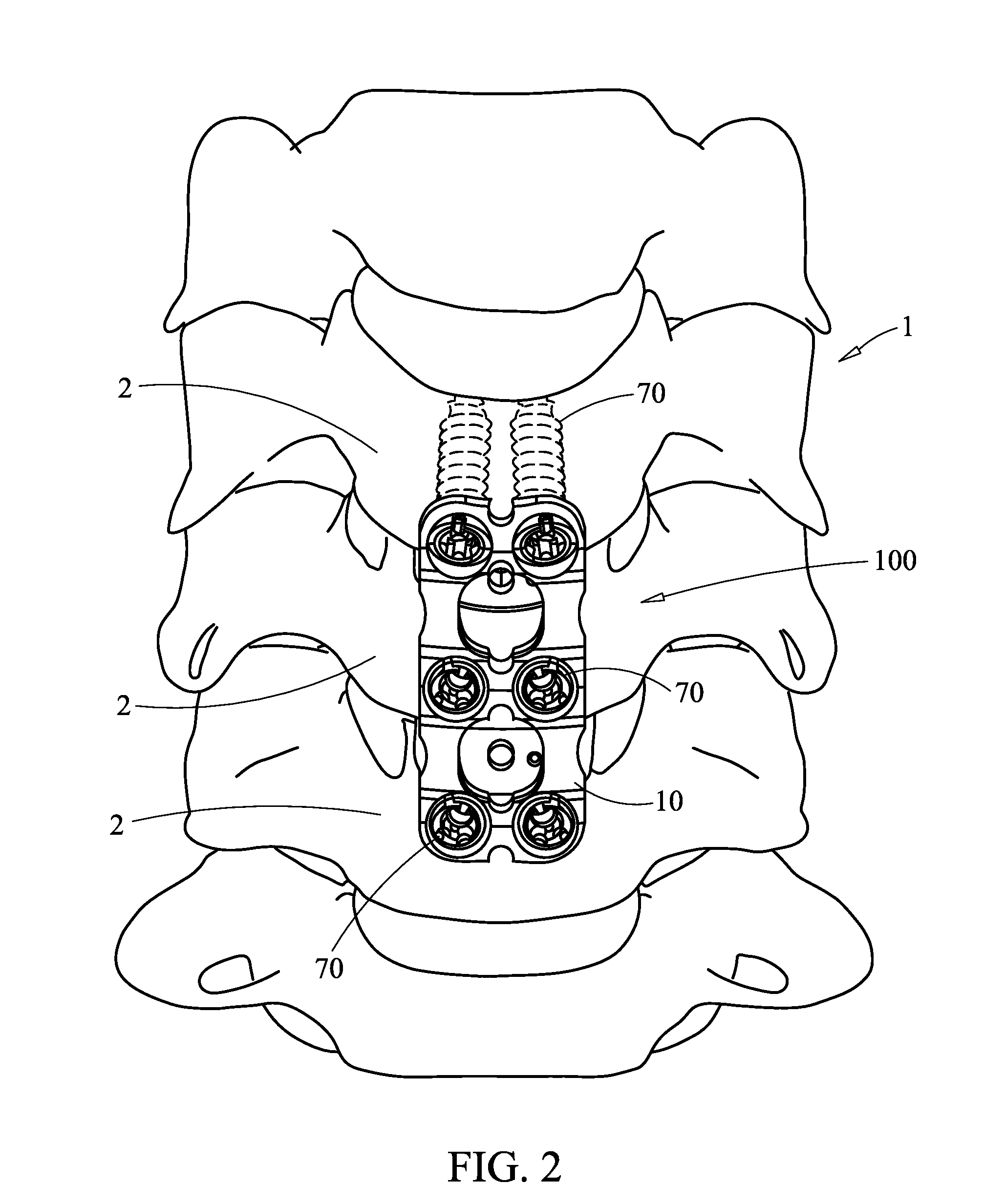

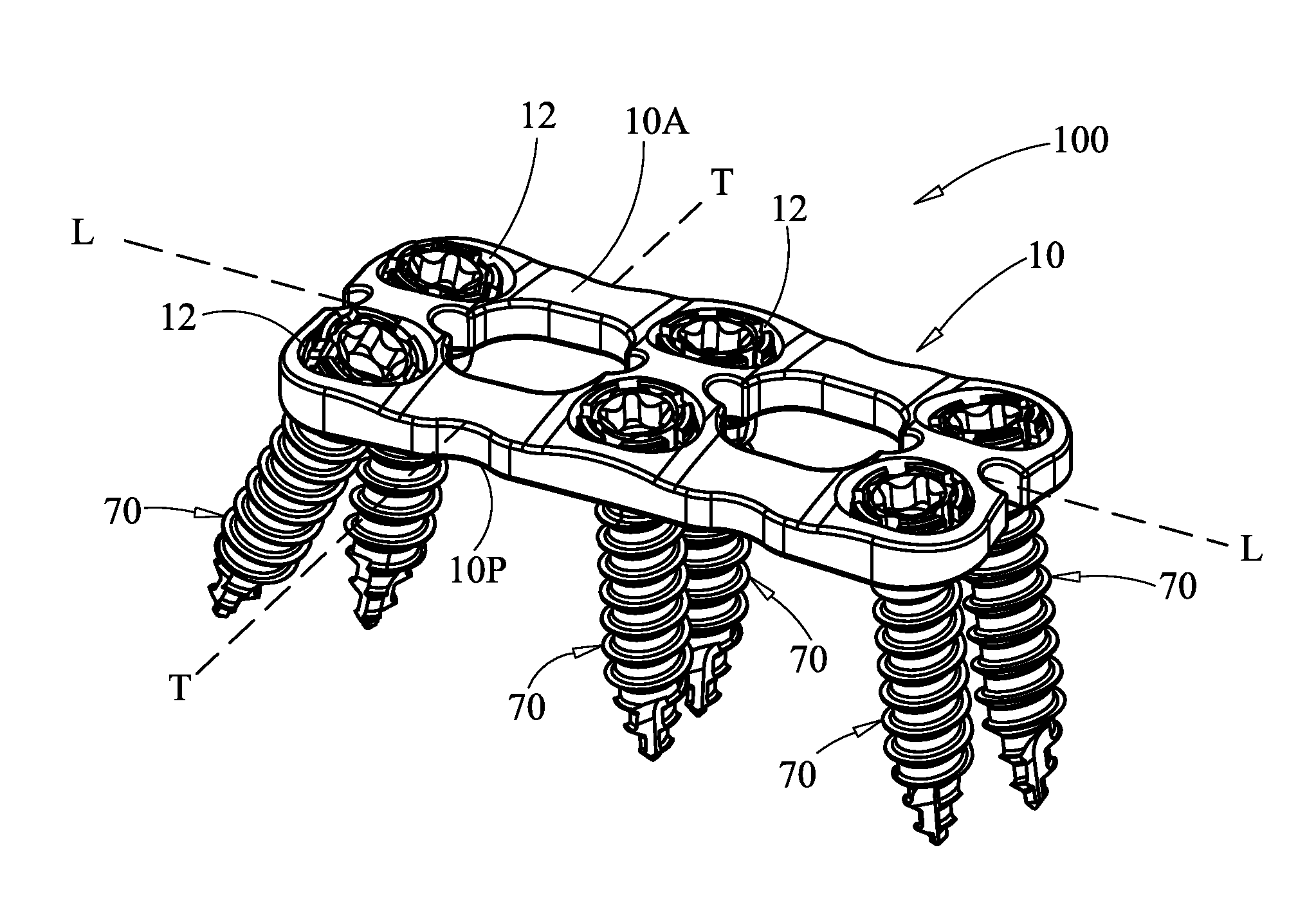

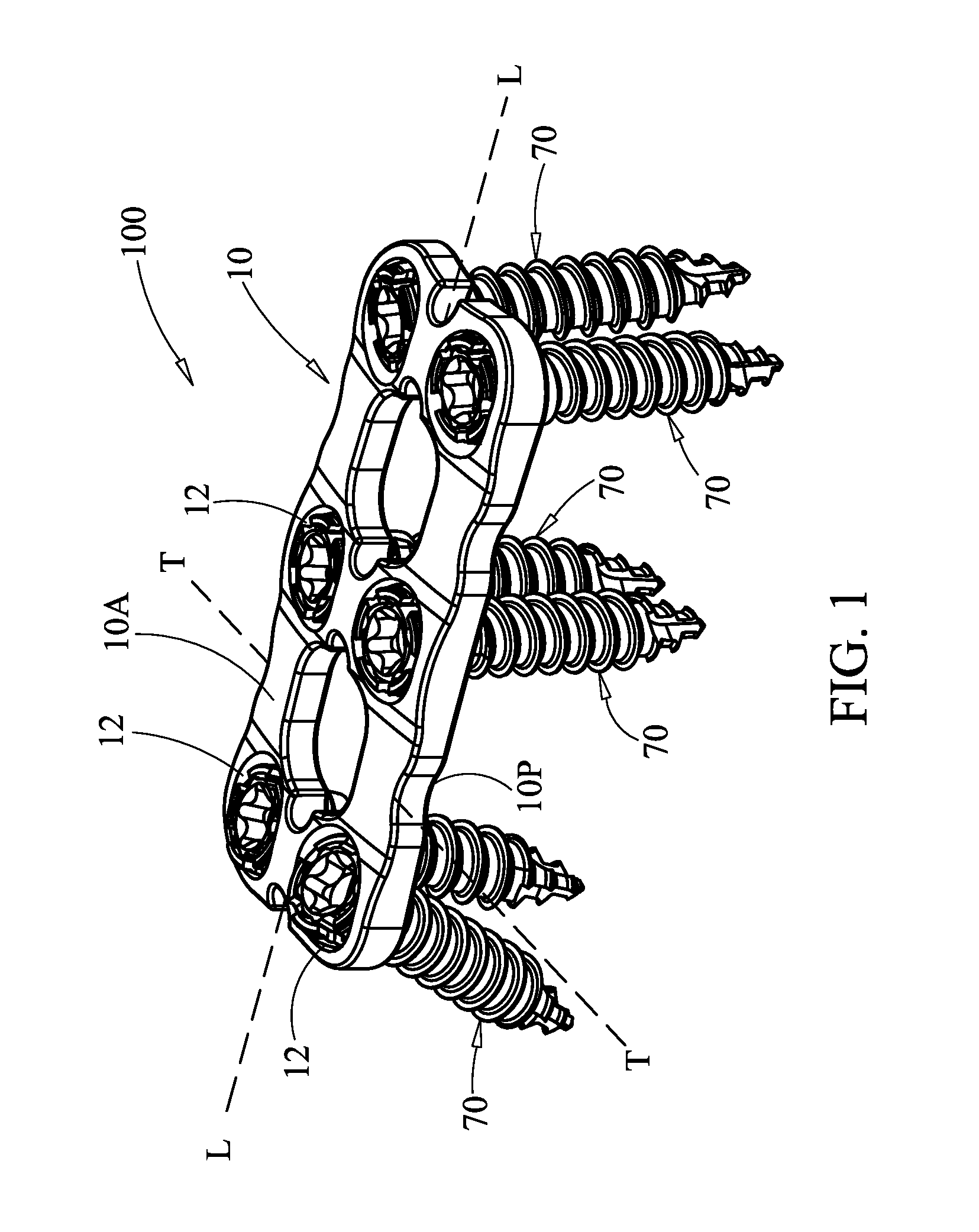

Surgical plate system and method

ActiveUS20120179207A1Reduce diameter of headReduce the overall diameterInternal osteosythesisProsthesisTransverse axisAnterior surface

A surgical plate system, components and methods of using are described. A surgical plate system includes a plate having an anterior surface, a posterior surface, a longitudinal axis, a transverse axis and a through hole passing through the anterior and posterior surfaces. A variable fastener is configured and dimensioned to connect to the plate, the variable fastener having a head and a shaft extending distally from the head. The head is configured to assume different proximal end diameters. The head, in a first configuration allows inward flexing to reduce a diameter of the head to allow the head to pass through an entrance opening of the through hole. In a second configuration, the head is prevented from flexing inwardly thereby preventing the head from backing out of the entrance opening, while allowing articulation of the head, within the through hole, relative to the plate.

Owner:SPINECRAFT

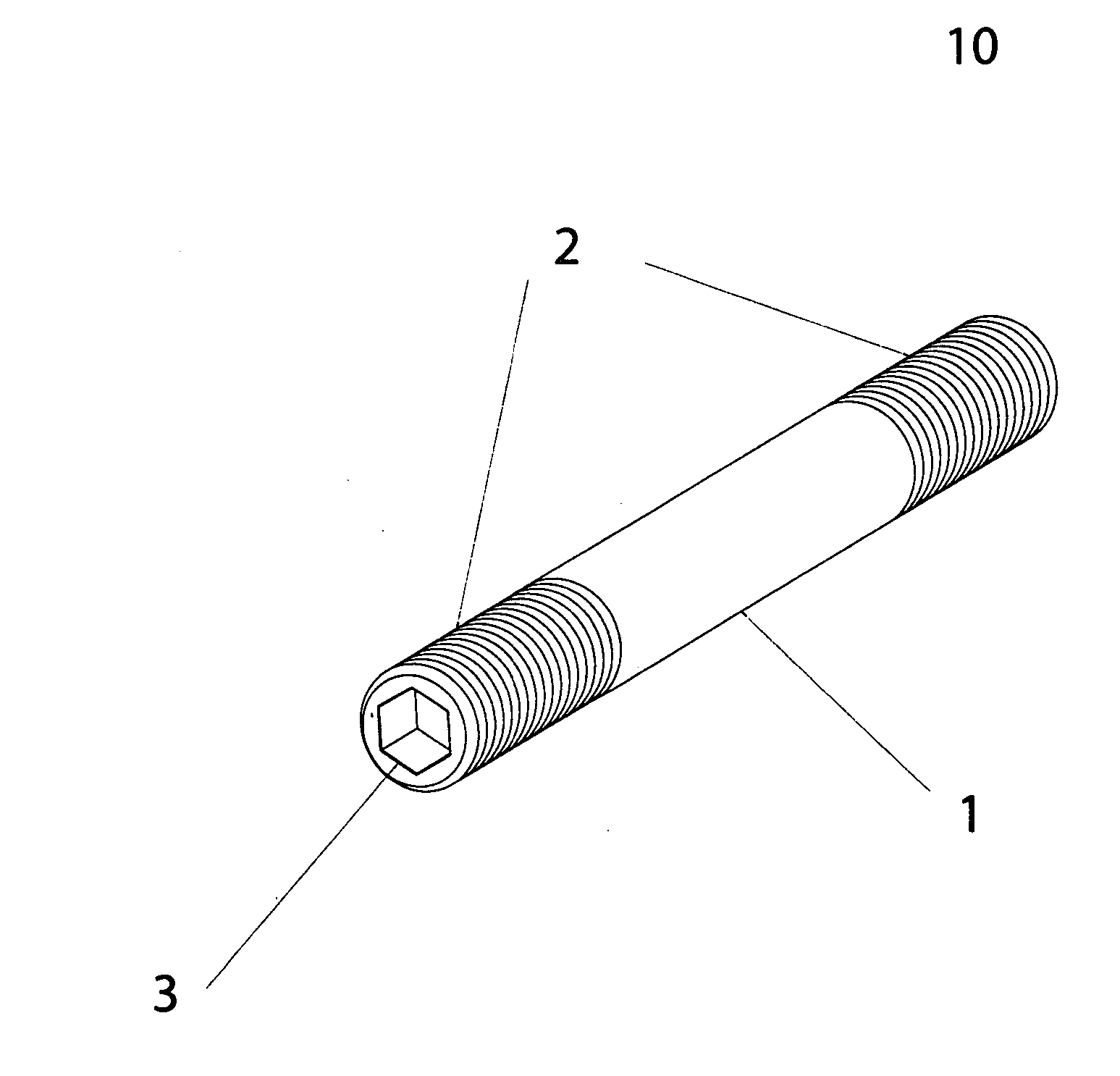

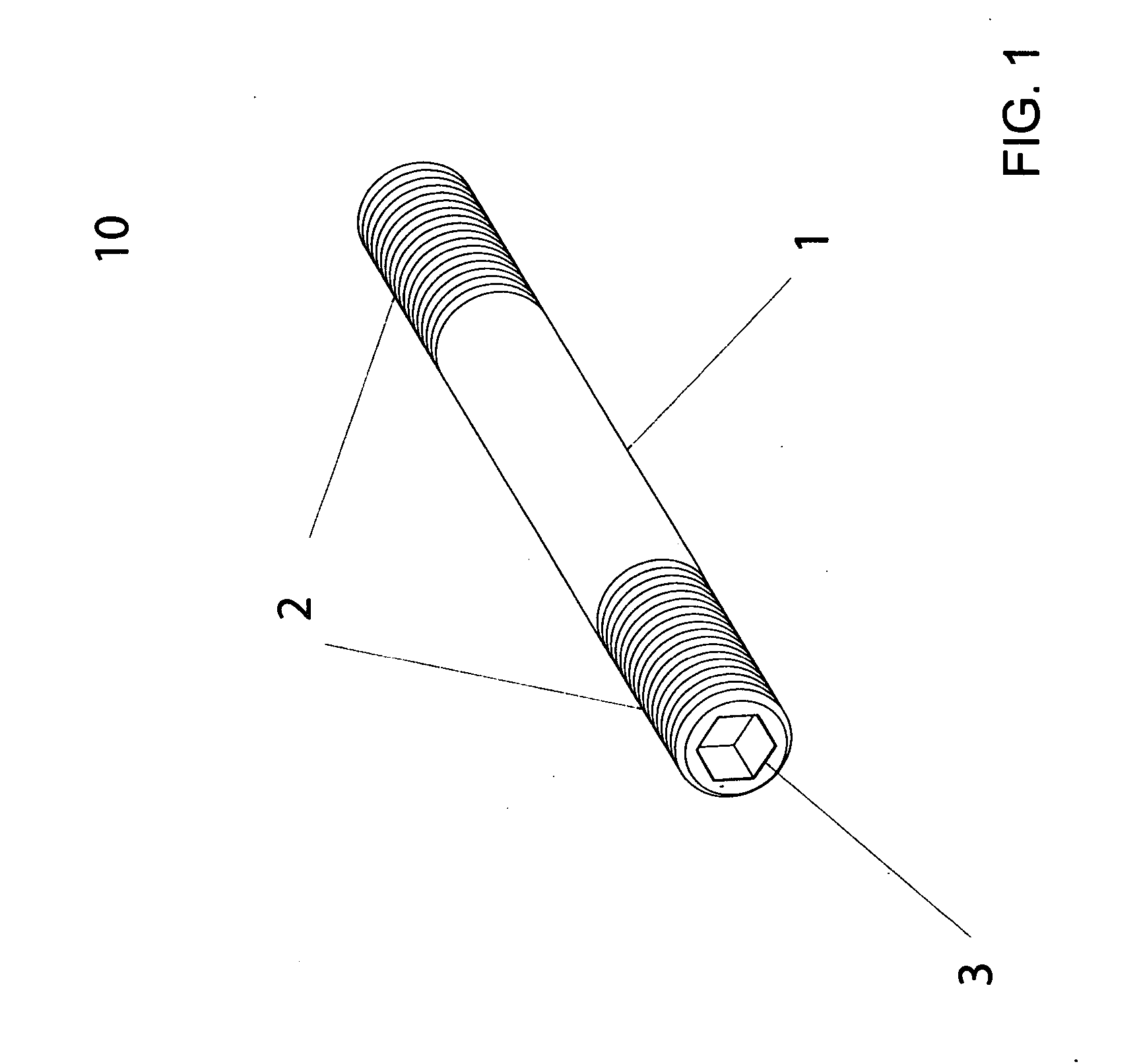

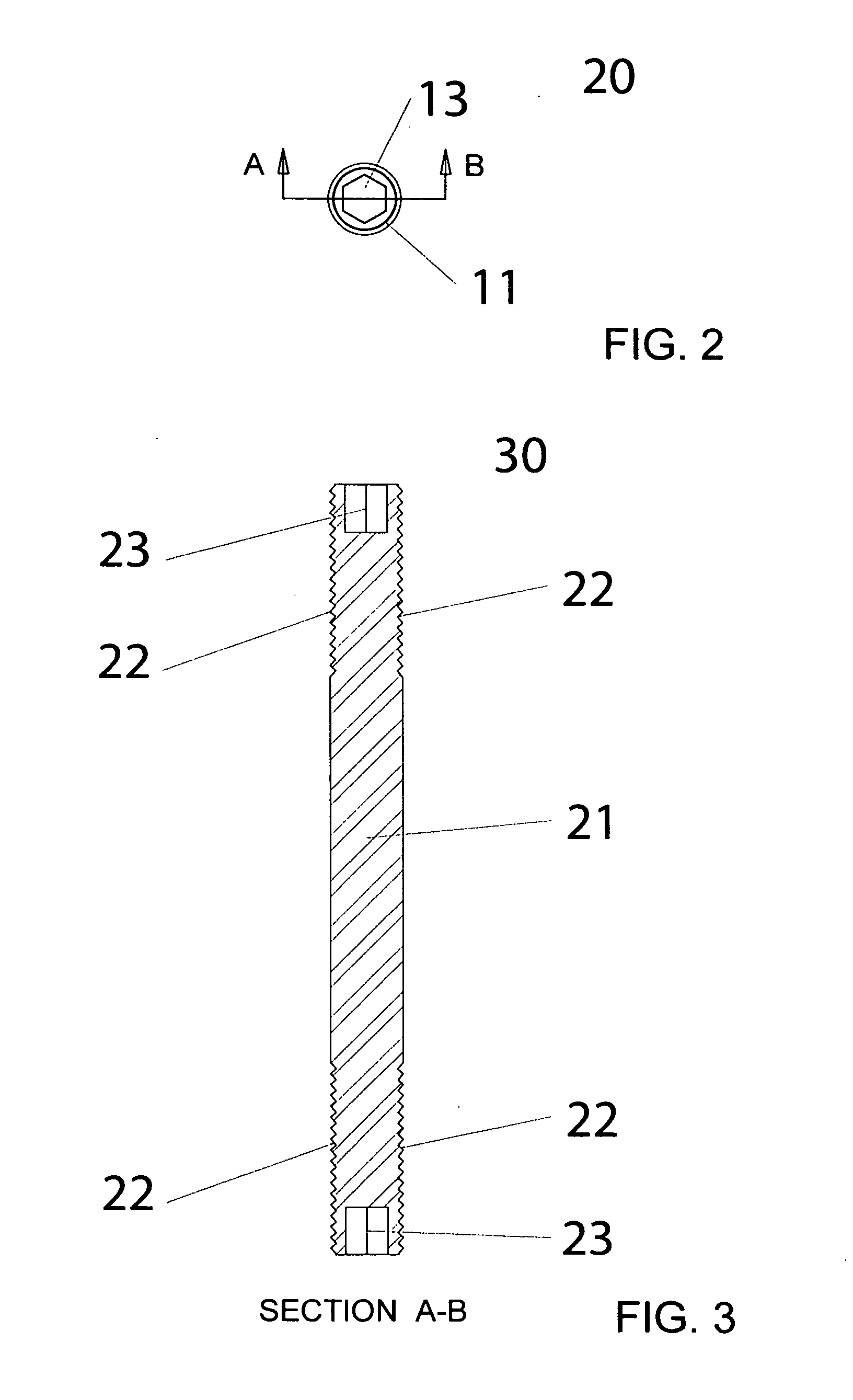

Stud for parts assembly

An improved stud for assembling an engine valve cover or other mechanical parts together comprised of an elongated shaft having two end portions and at least one intermediate threaded portion therebetween. At least one end portion of the stud has a drive receiving recess formed therein. The intermediate threaded portion may be a single continuous thread or two distinct threads. The pitch and spacing on the thread or threads need not be identical and are ideally matched to the receiving threads of an orafice. The drive pocket in the head of the stud allows the shaft to be installed and removed by applying torque to the end and not to the body of the stud along the shaft. The stud may also be securely held so as not to be loosened or removed from one set of receiving threads into which it is installed while an object is installed or removed from the threads on the opposing end.

Owner:FLEMING DAVID THOMAS

Modular barrier

InactiveUS6837647B2Prevent continued articulationImpart strengthPasturing equipmentTraffic restrictionsNoseModularity

A modular barrier includes a plurality of substantially identical barrier sections each section having a base portion surmounted by an upright portion. The upright portion has projections with substantially semi-cylindrical outer surfaces at its ends. Correspondingly shaped recesses are also provided. At a femal end, the base portion includes a nose. The surface of the nose is a surface of rotation of the profile of the base portion. At the male end, the base portion includes a correspondingly shaped cavity. The first and second projections and the nose are provided with bores. When the female end of the barrier section is brought up to a male end of a similar, adjacent barrier section, the projections mate with one another and the nose is received in the cavity of the adjacent barrier section. A hinge pin may then be passed through the bores for allowing one barrier section to be articulated to an adjacent barrier section with the joint between the two portions of adjacent barrier sections presenting an essentially smooth profile irrespective of the angle between the two adjacent barrier sections.

Owner:RLT DESIGN

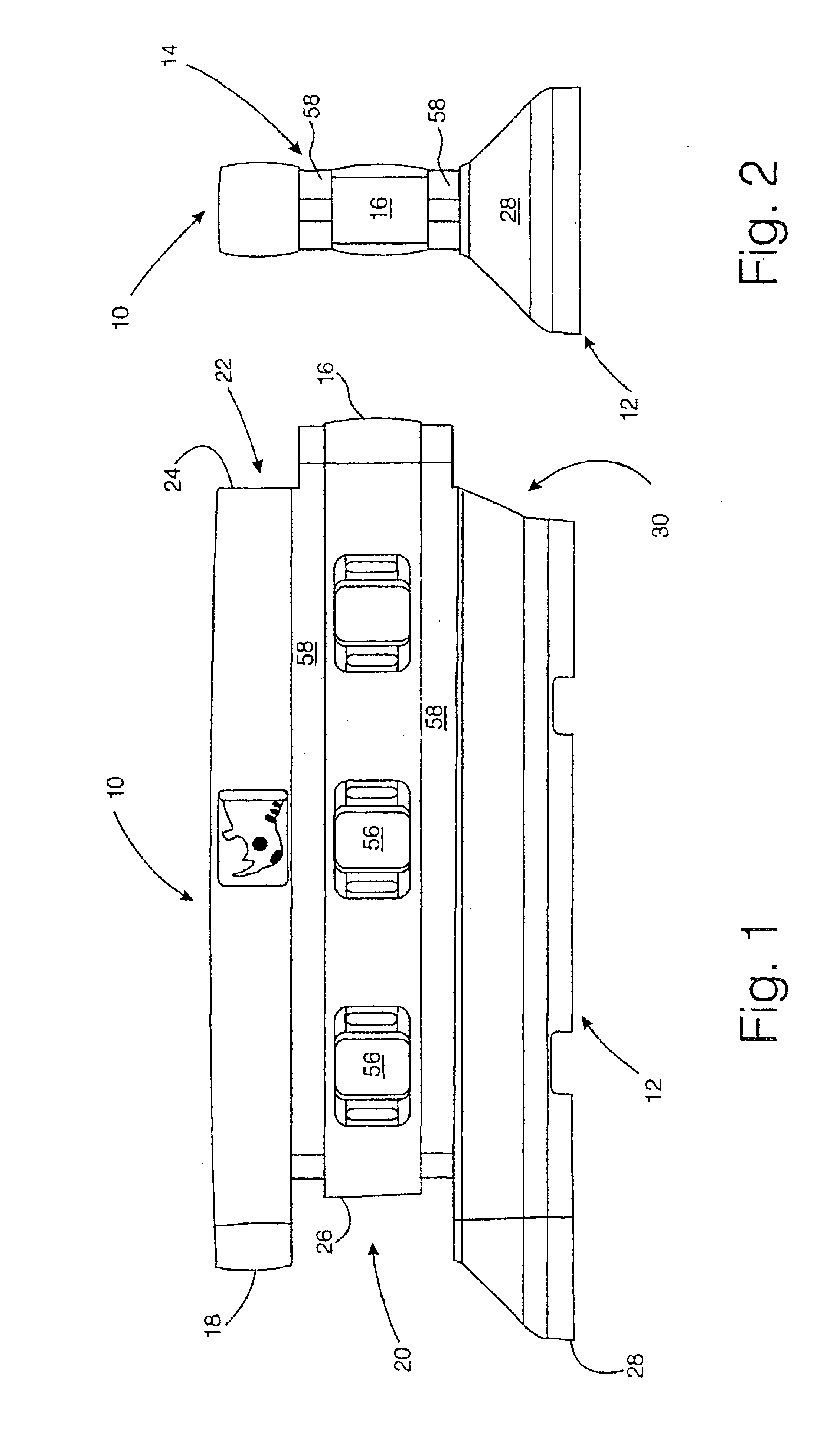

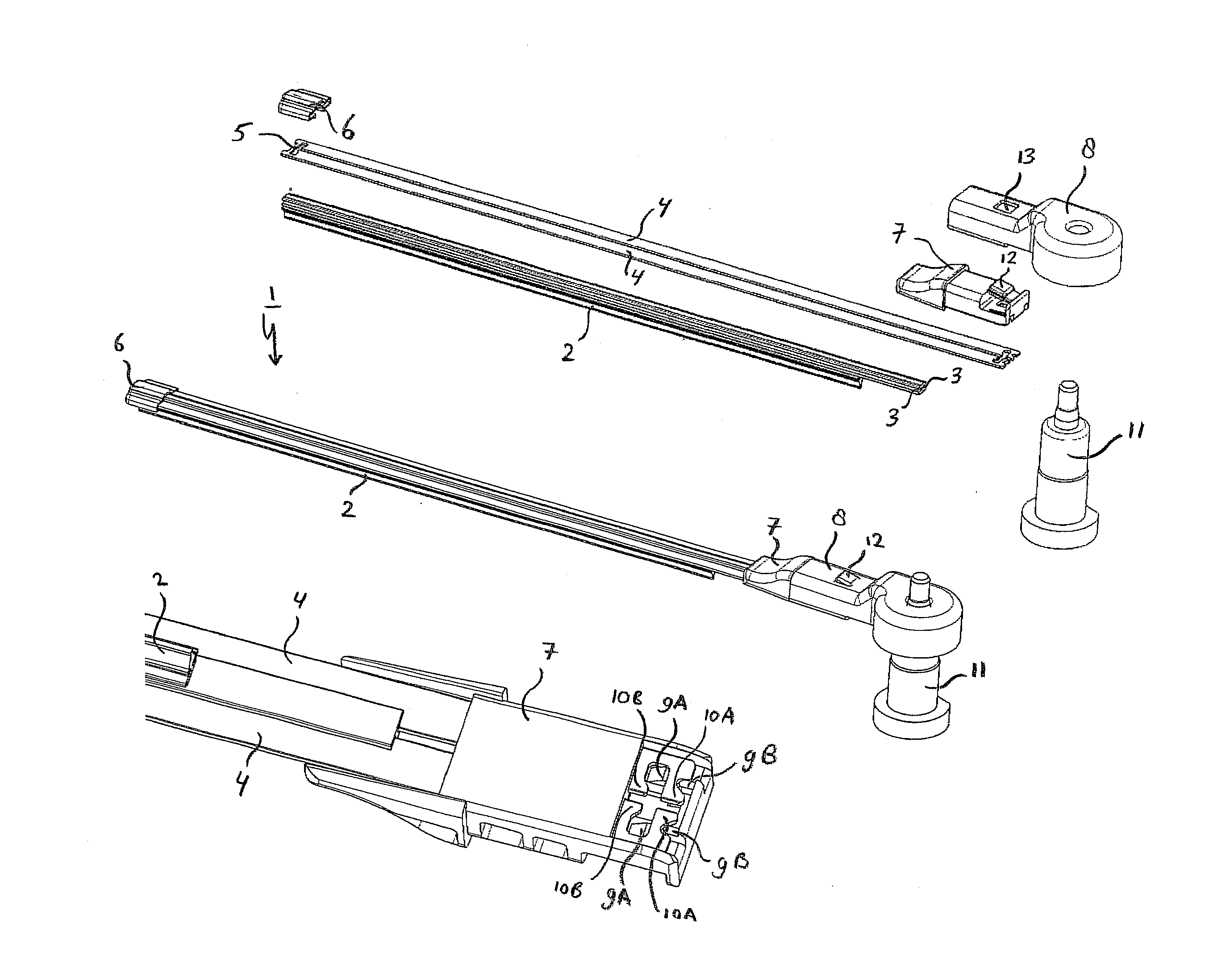

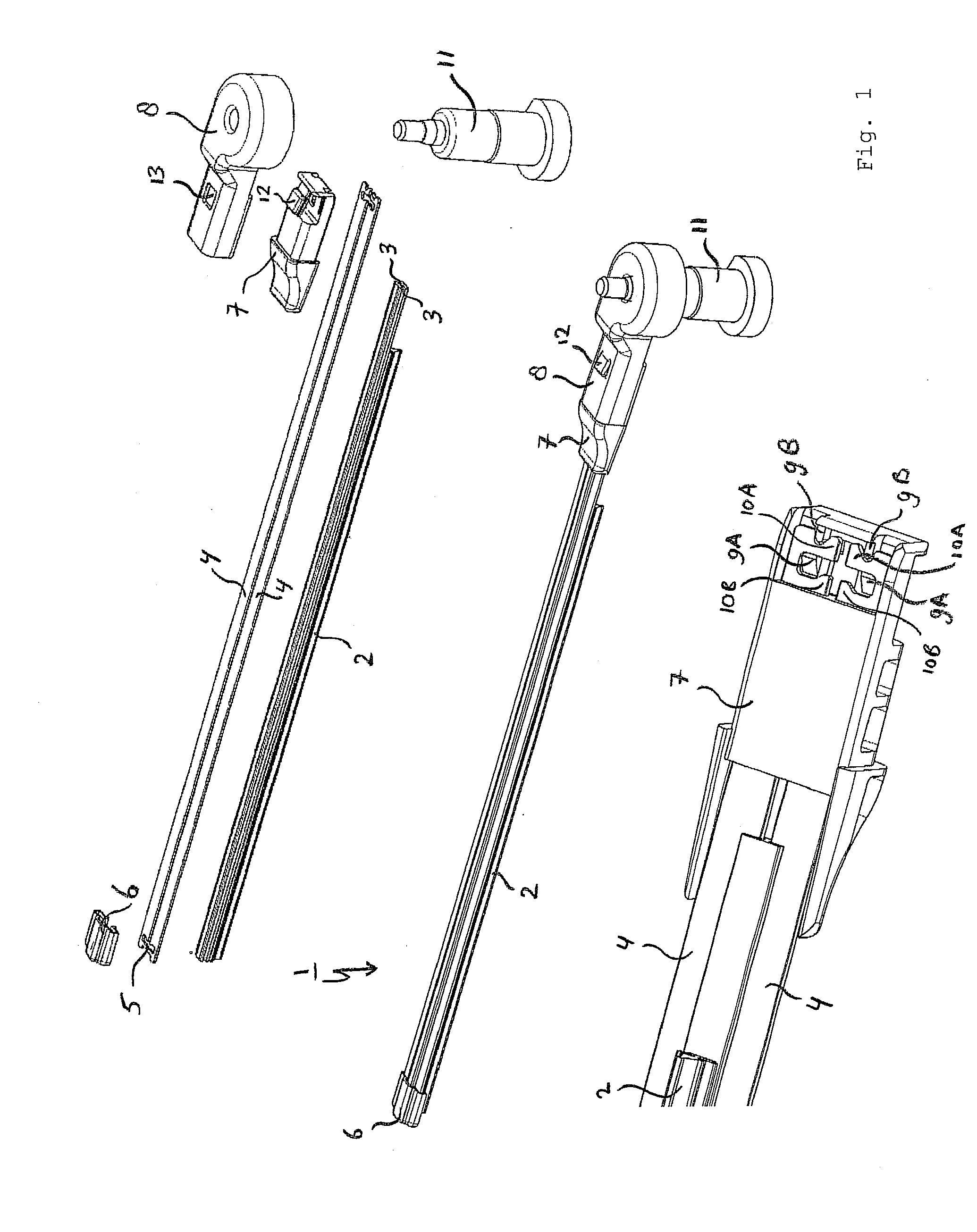

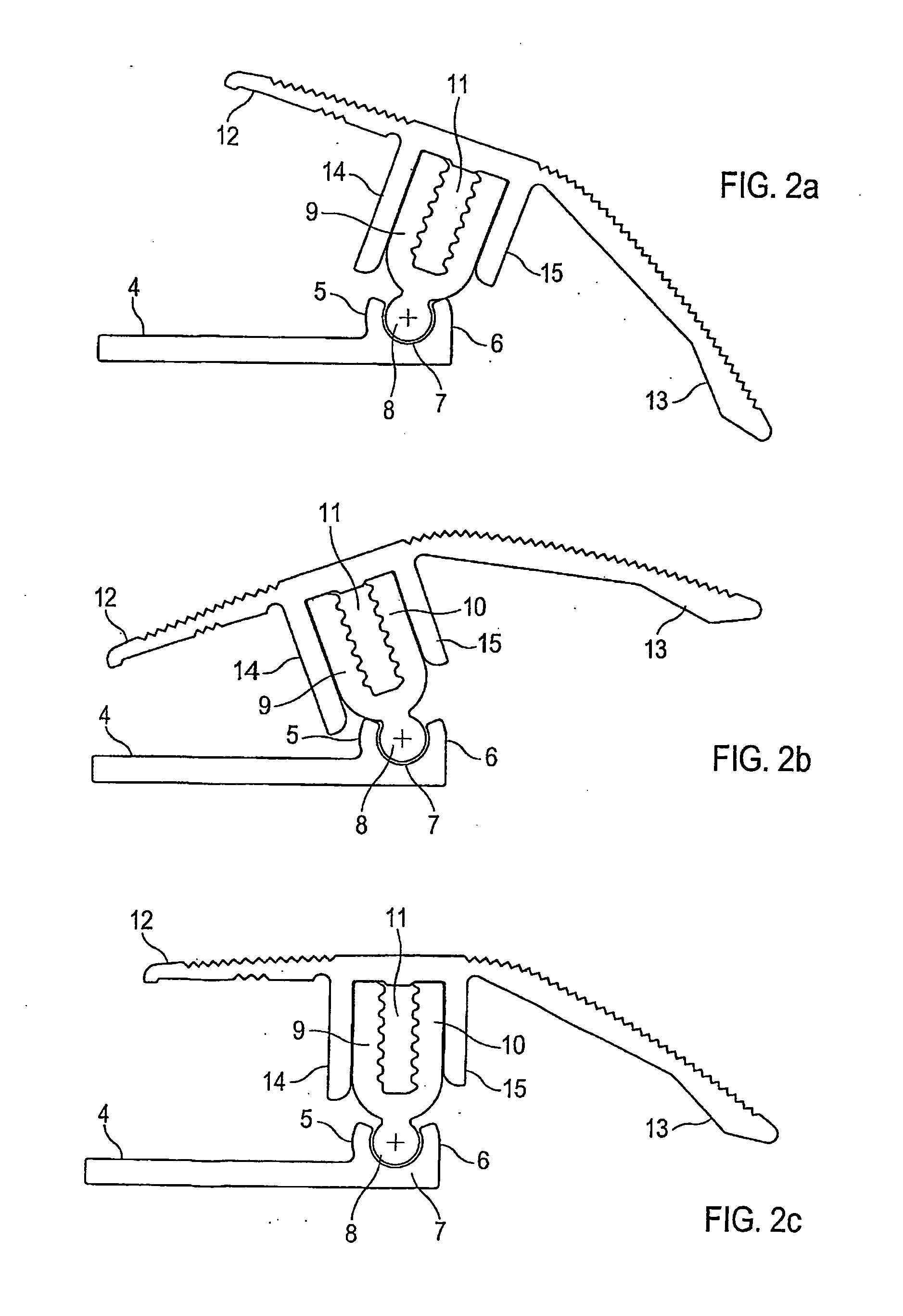

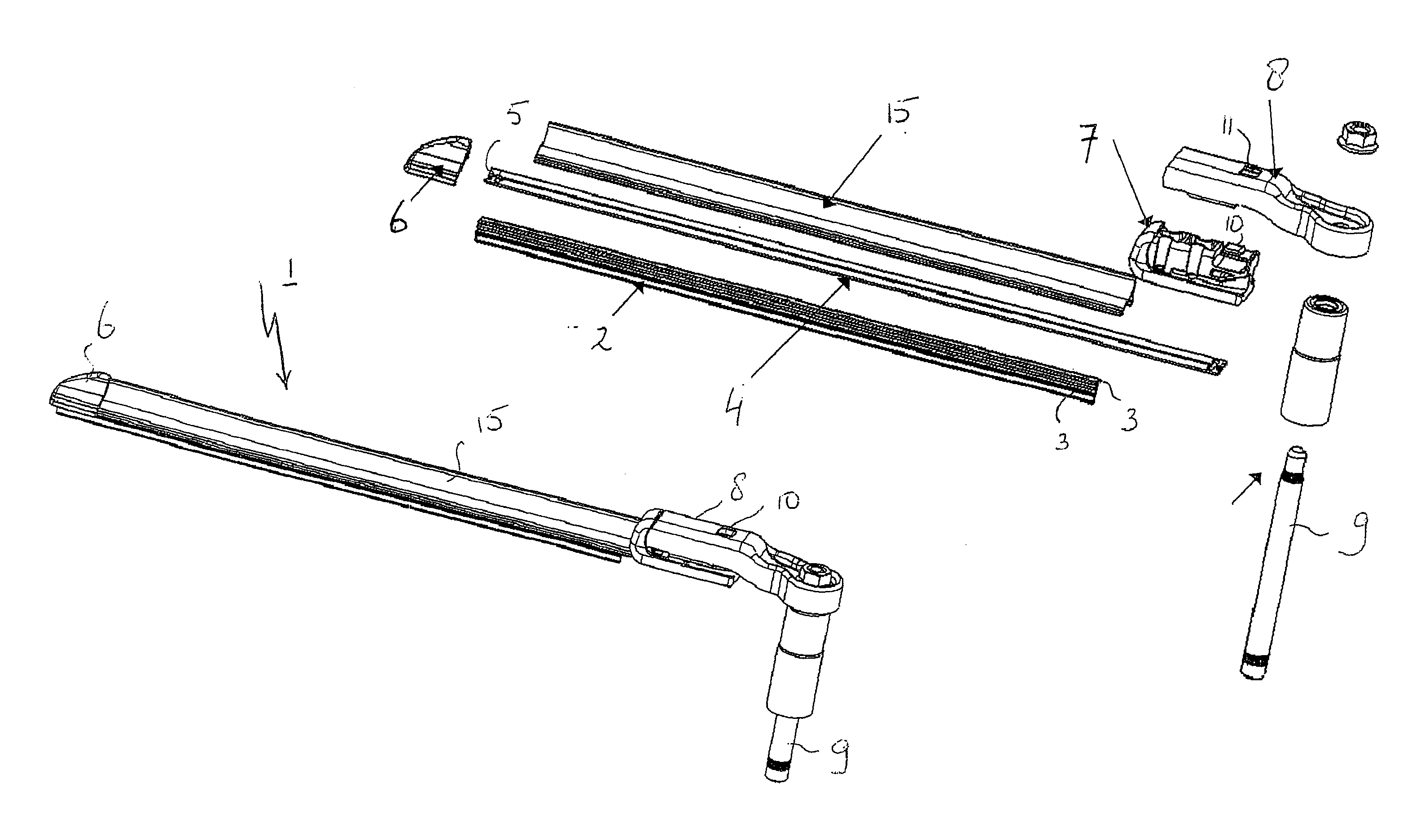

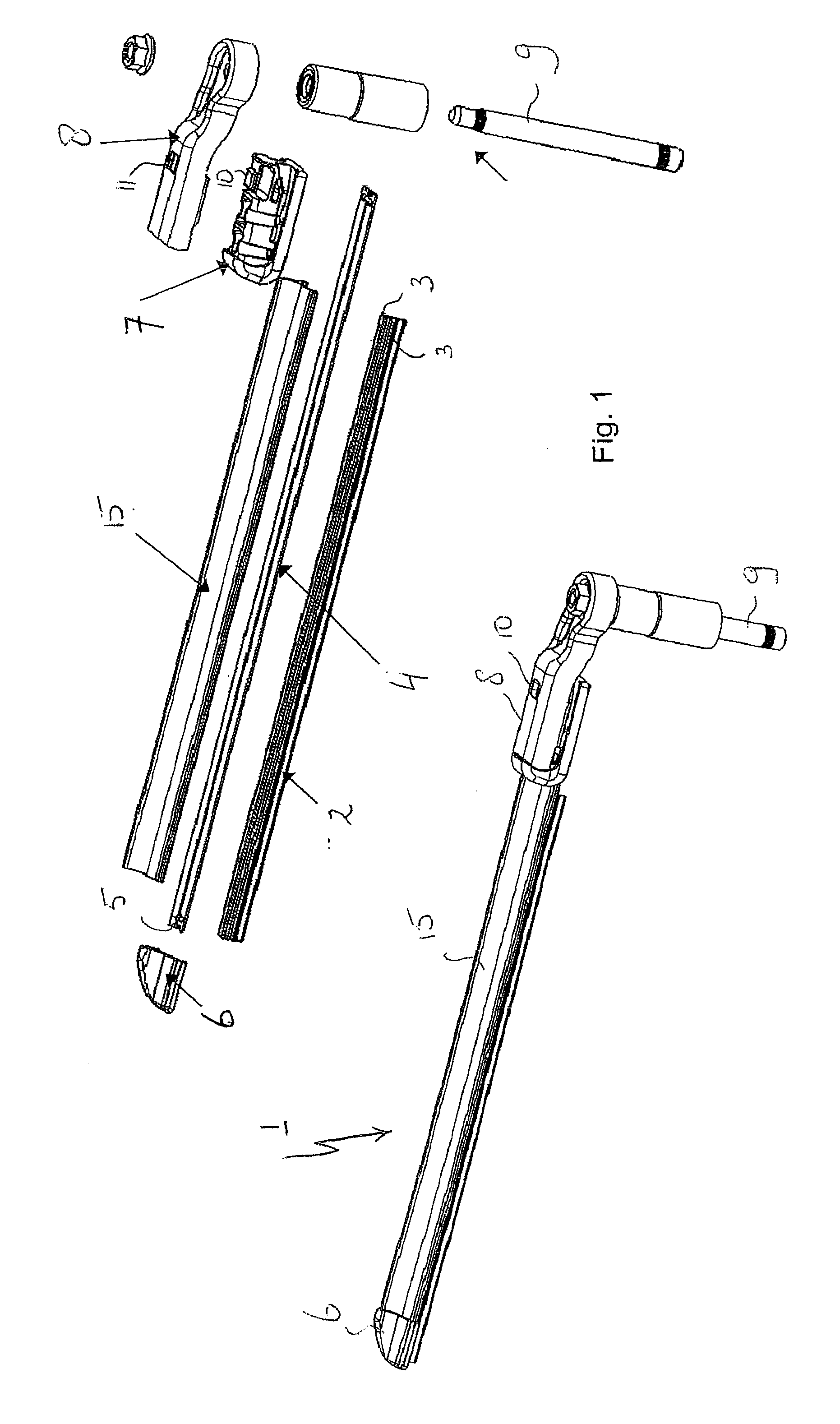

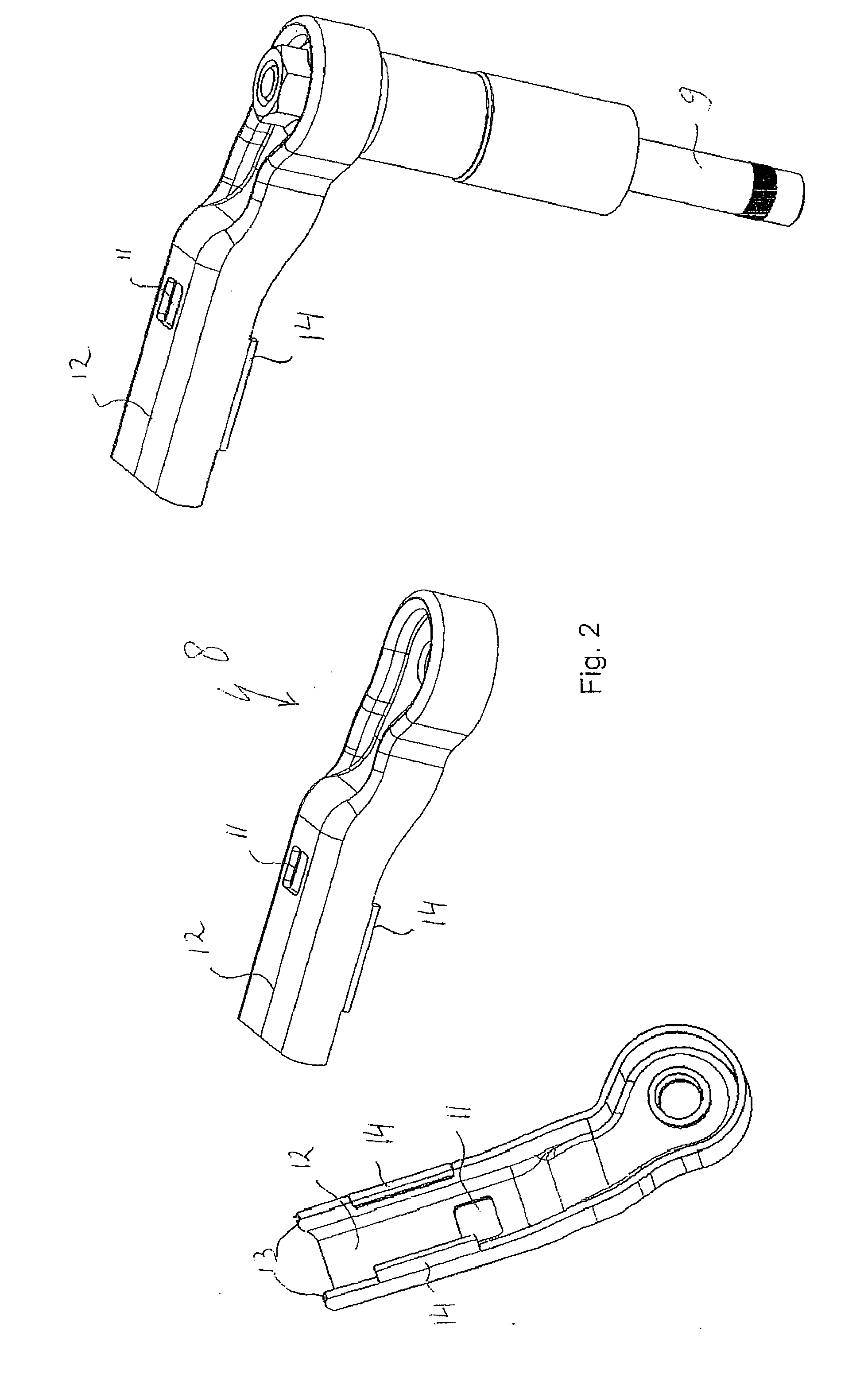

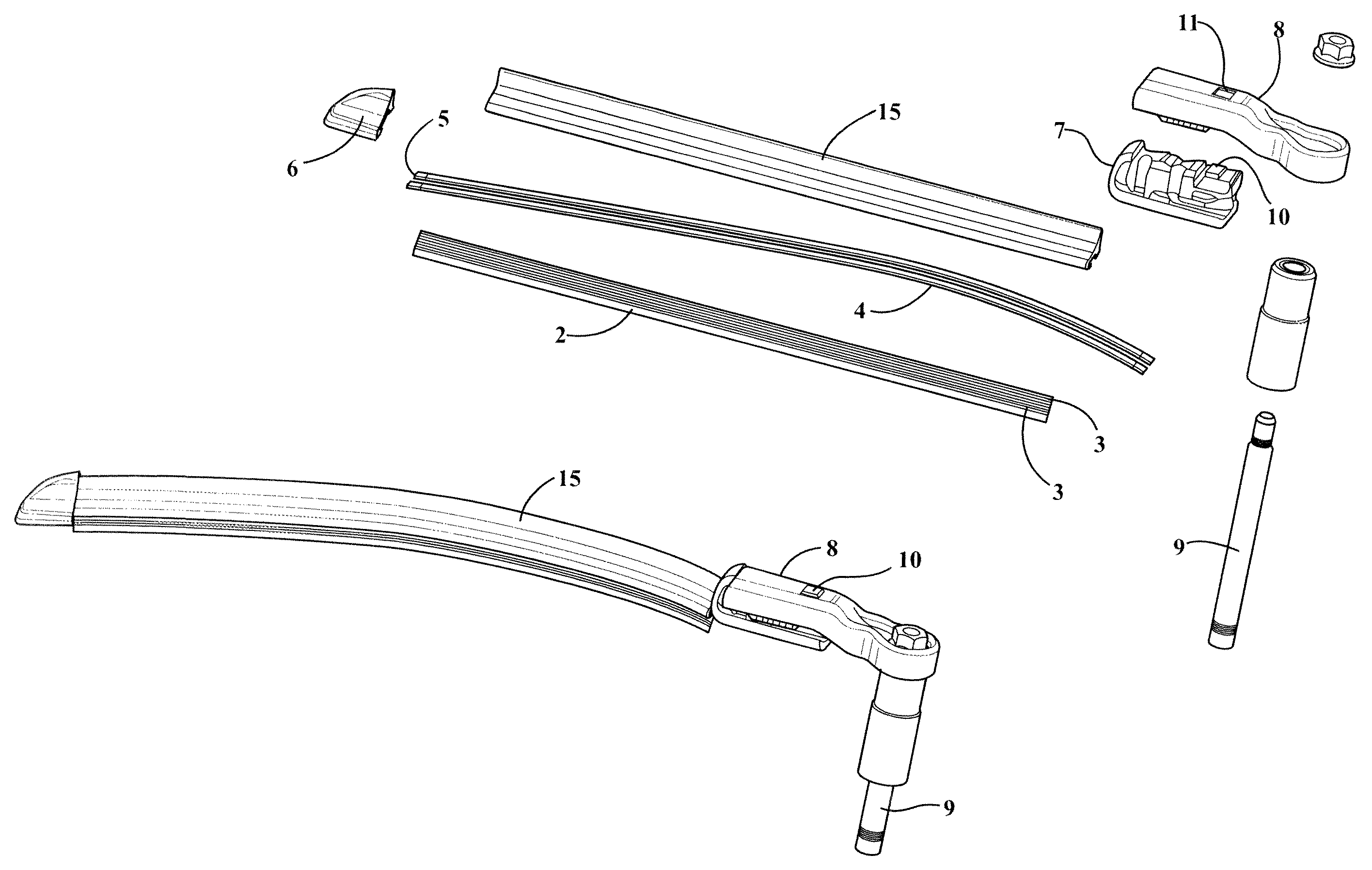

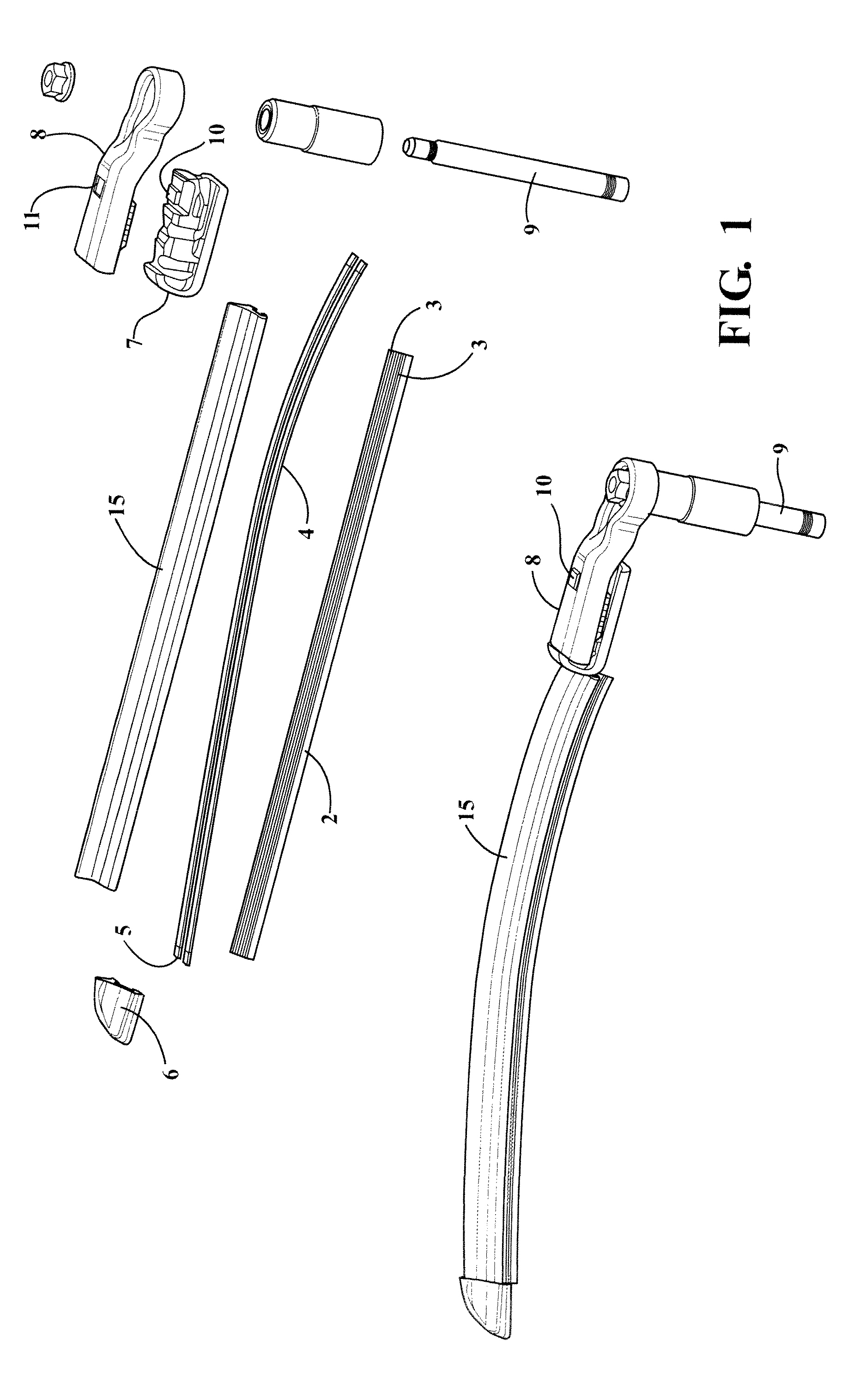

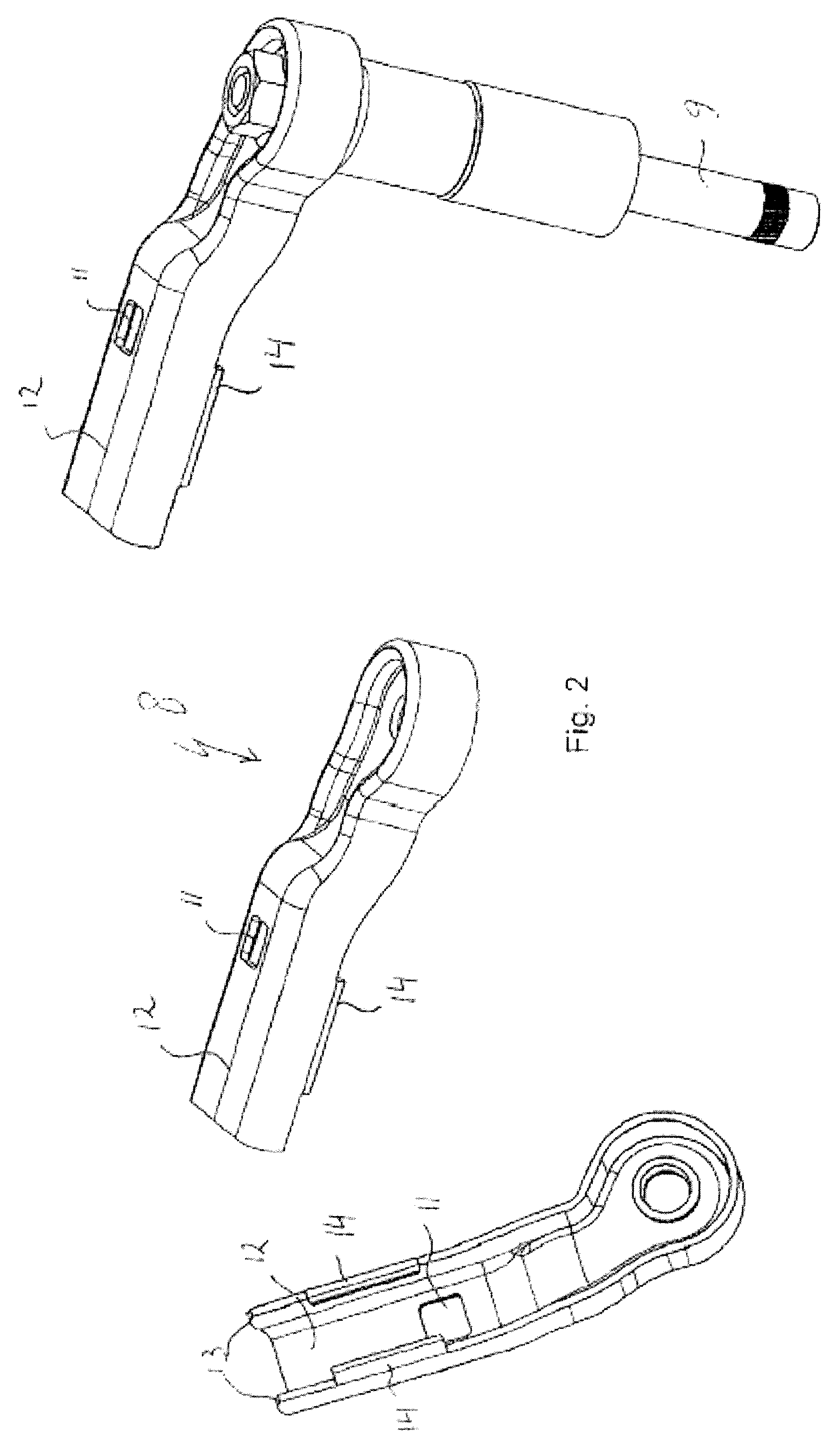

Windscreen wiper device

InactiveUS20120036671A1Less materialAvoid articulationWindow cleanersVehicle cleaningWindscreen wiperAbutment

A windscreen wiper device, particularly for automobiles, comprising an elastic, elongated carrier element, as well as an elongated wiper blade of a flexible material, which can be placed in abutment with a windscreen to be wiped, which wiper blade is of the flat blade type and includes at least one groove, in which groove a longitudinal strip of the carrier element is disposed, wherein the windscreen wiper device further comprises a mounting head for transferring a reciprocal movement to the wiper blade, with the special feature that the windscreen wiper device further comprises a connecting device for detachably connecting the wiper blade directly to the mounting head, wherein the connecting device is positioned near one end of the wiper blade, and wherein the connecting device, at the location of its attachment to the mounting head, is located in its entirety inside the mounting head.

Owner:FEDERAL MOGUL SA

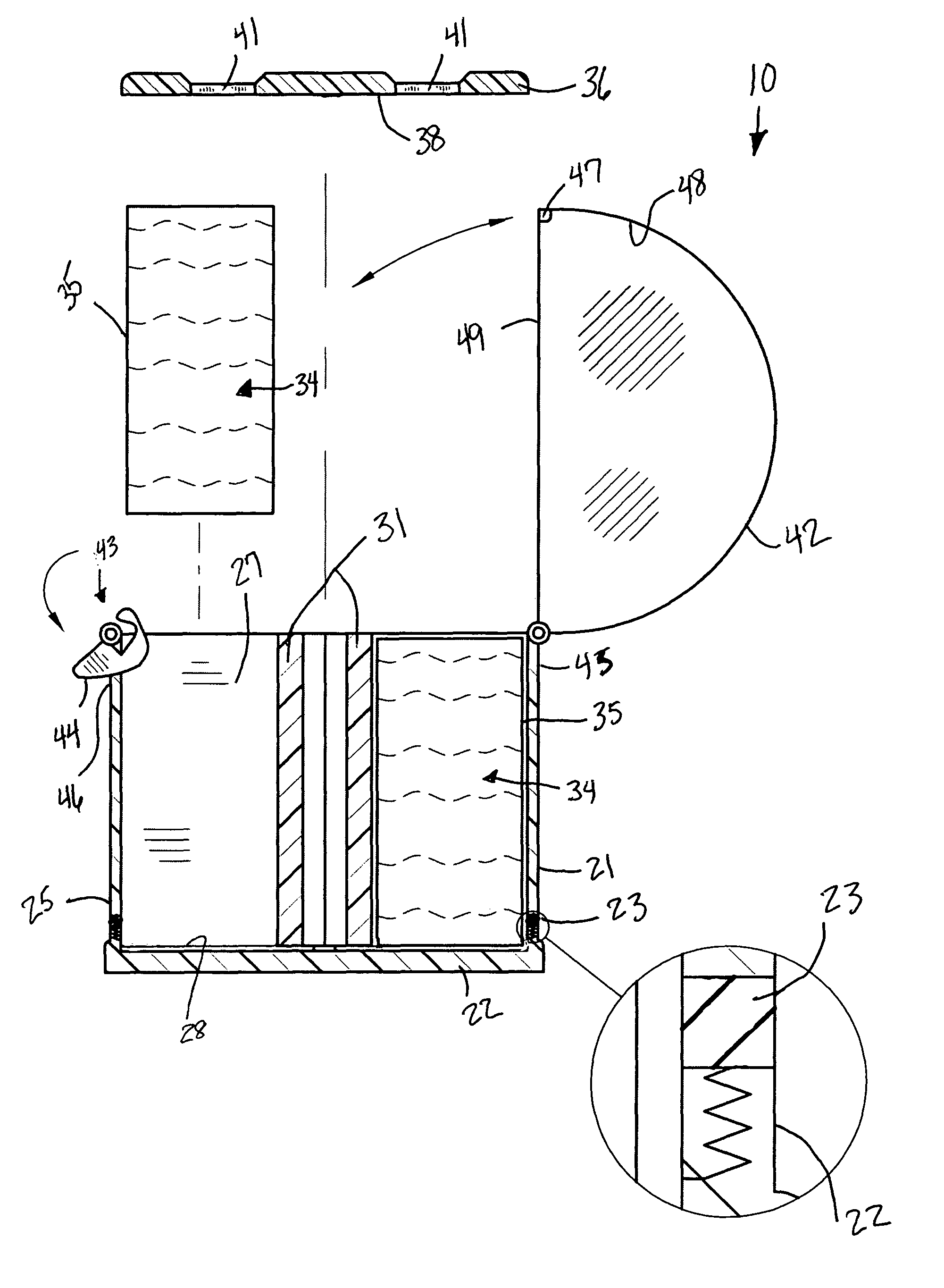

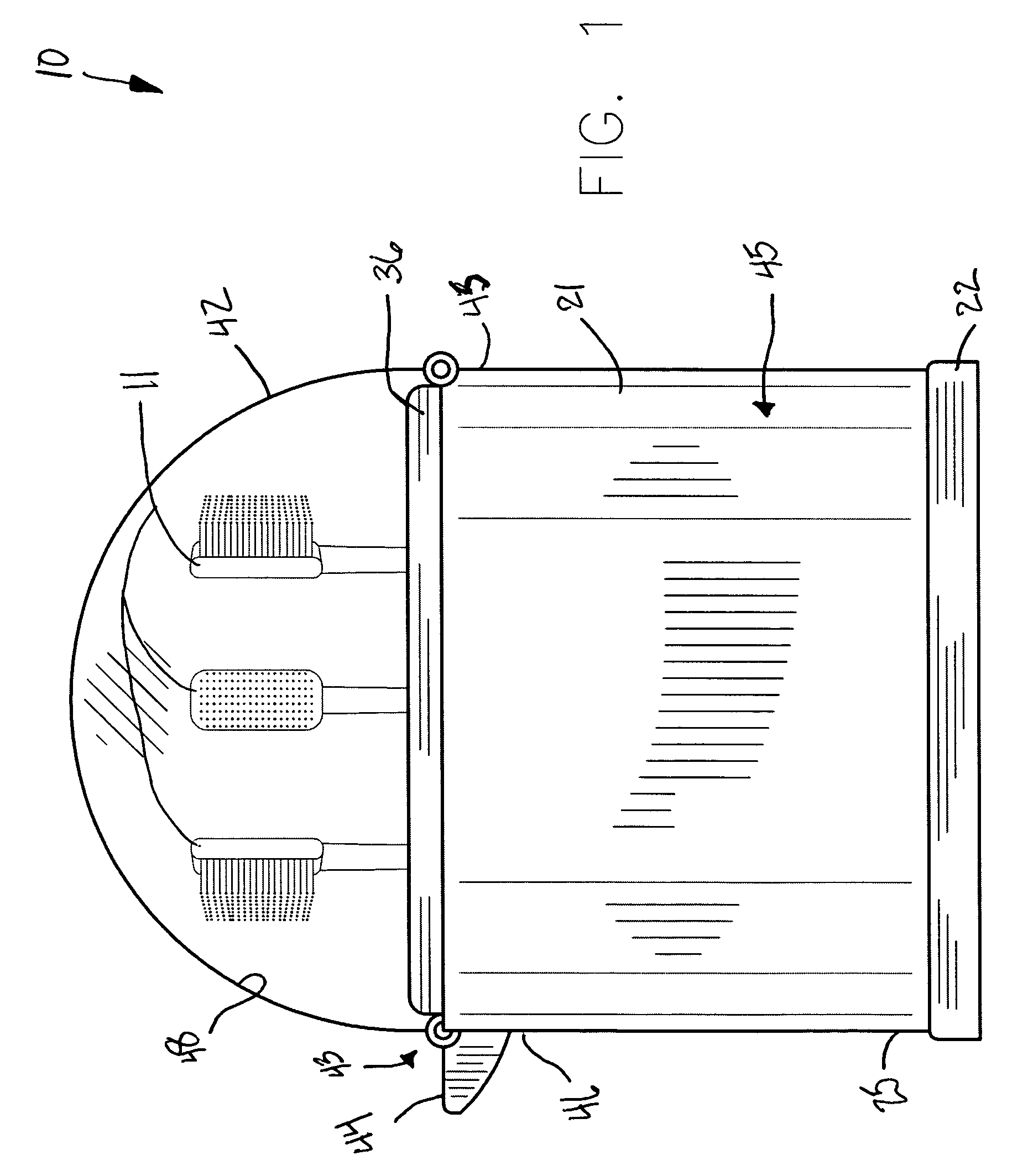

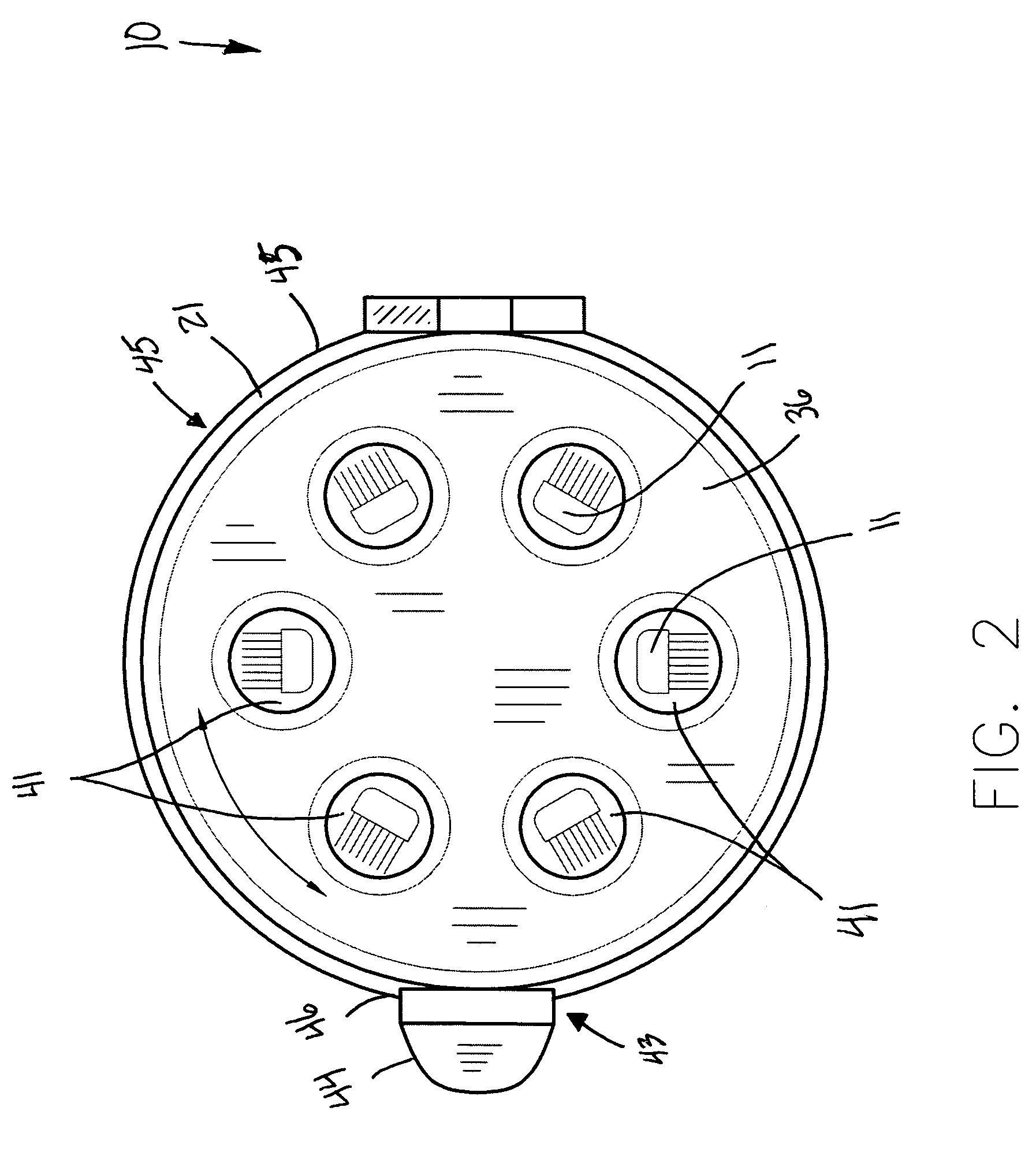

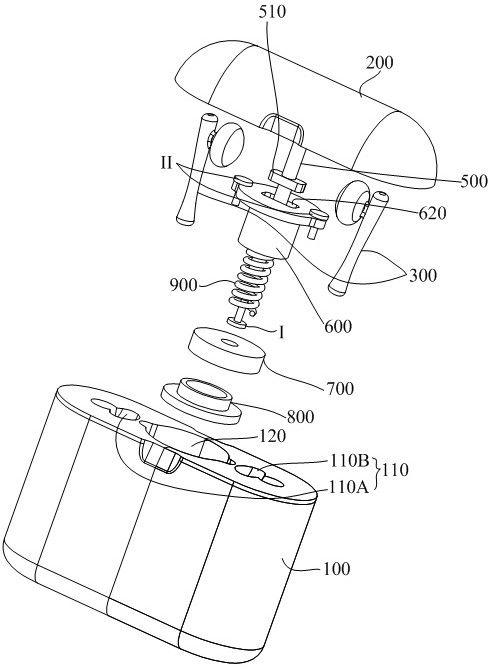

Toothbrush holder and sanitizer

InactiveUS7951343B1Avoid premature releaseEffective expansionLavatory sanitoryContainer/bottle contructionMechanical engineeringDome shape

A toothbrush holder includes an outer body with a bottom section coupled thereto. A seal is intercalated therebetween and extends along the circumference of the outer body. An inner body is seated within the outer body and includes a plurality of chambers equidistantly aligned with a center thereof. The inner body has a diameter less than a diameter of the outer body and has a vertically oriented central shaft formed with the chambers. A top plate is attached to the chambers and is provided with a plurality of apertures counter-sunk therein and vertically aligned above the chambers. A dome-shaped lid is connected to an outer perimeter of the outer body, and disposed adjacent to the top plate. The apparatus includes a mechanism for automatically locking the lid to the outer body after the lid is adapted to a closed position.

Owner:DAVIS ANNIE

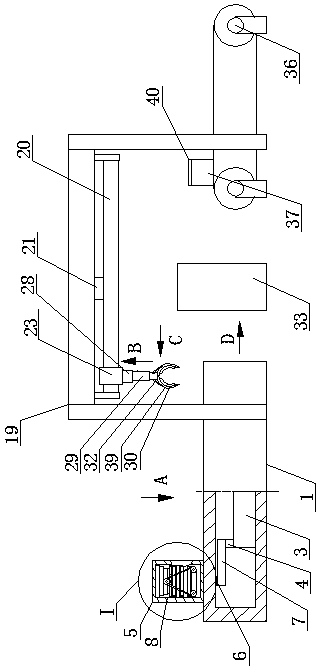

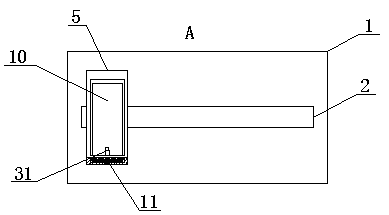

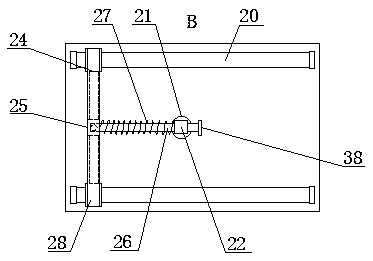

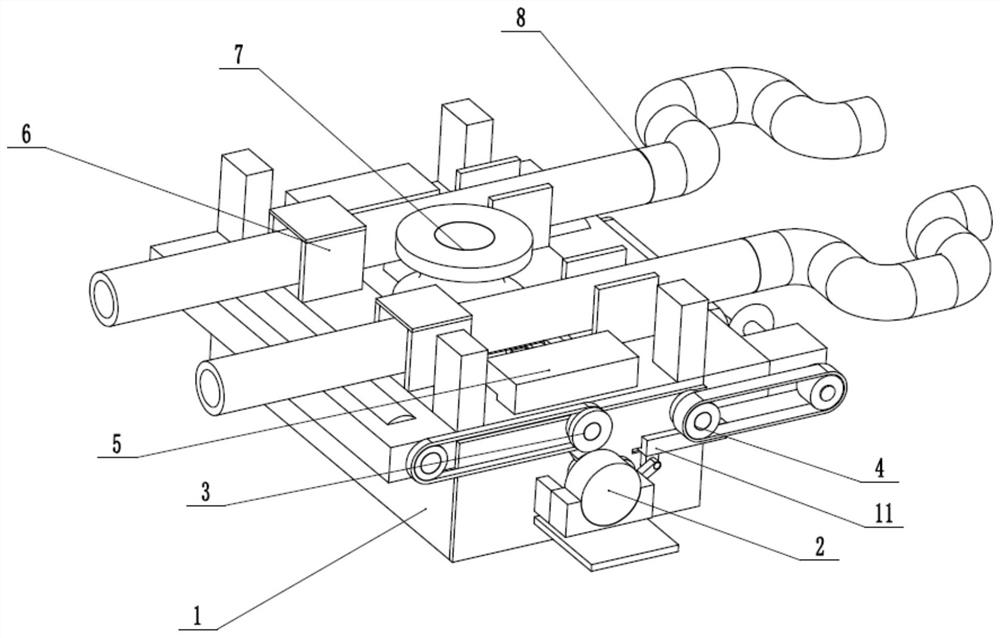

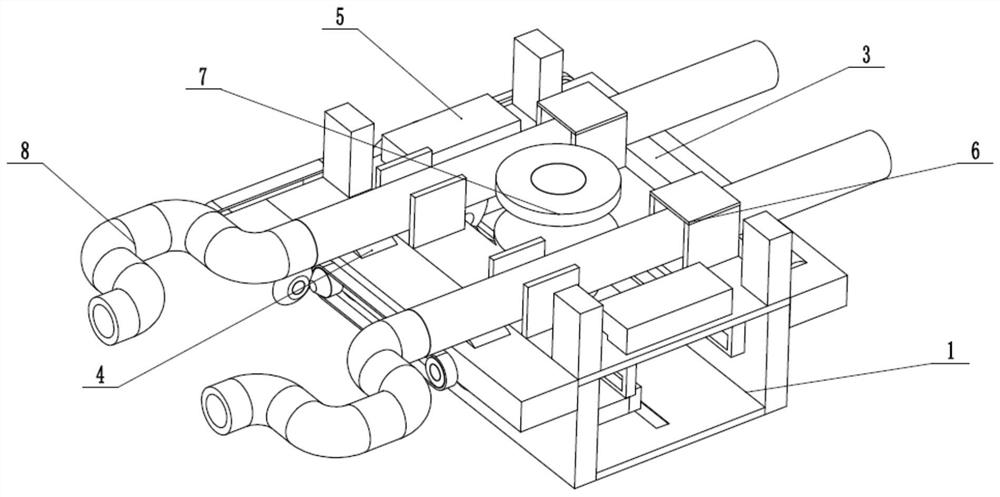

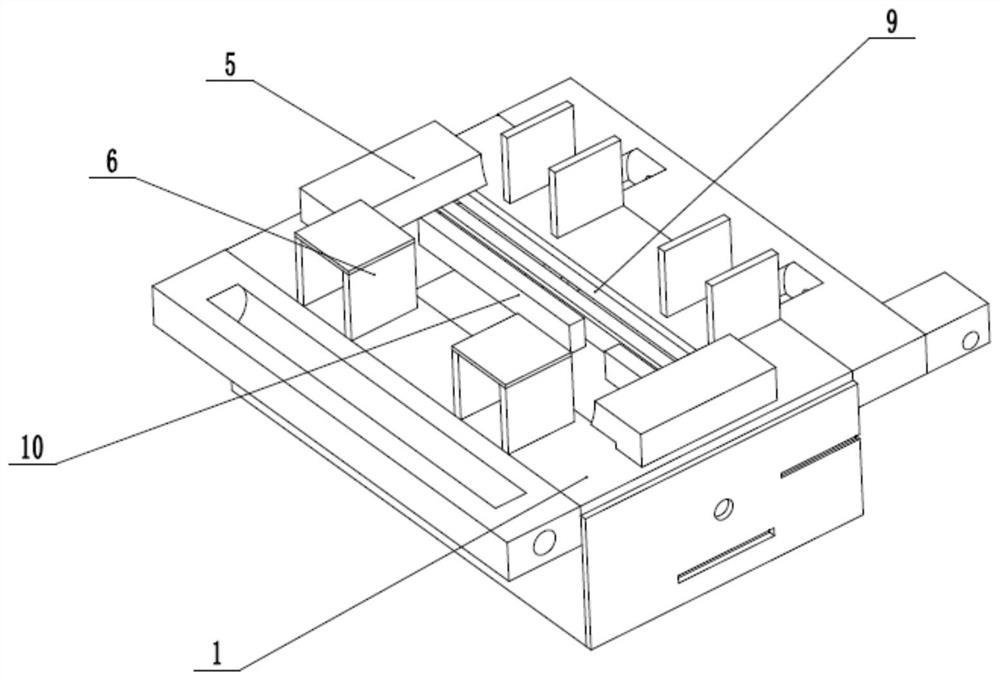

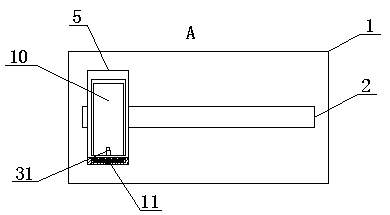

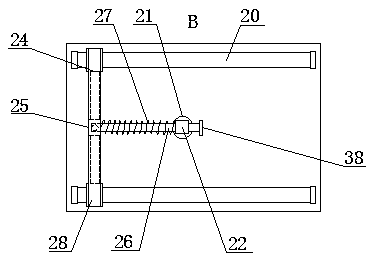

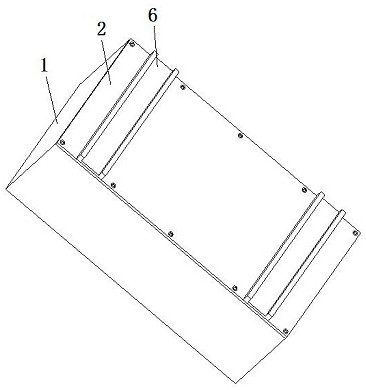

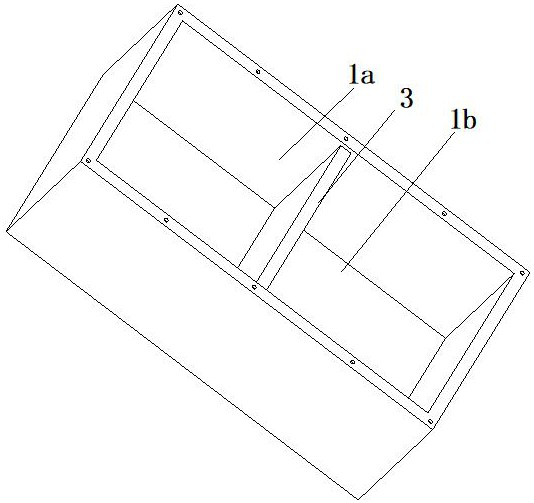

Garment production and machining conveyance device

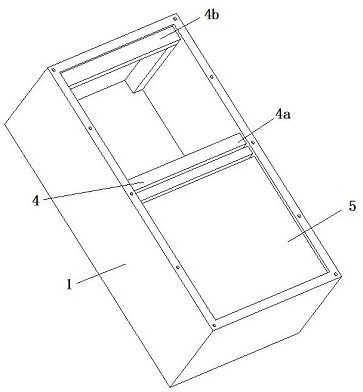

ActiveCN107600480AAvoid damageAvoid articulationIndividual articlesEngineeringMechanical engineering

A garment production and machining conveyance device comprises a first box. A long strip groove is formed at the top end of the first box. The bottom end of the long strip groove communicates with theinner portion of the first box. The inner wall of the bottom end of the first box is fixedly provided with a rotating disk provided with a power device. A convex block is fixedly installed at the eccentric position of the top face of the rotating disk. A holding box with an open top is arranged above the first box. A sliding block is fixedly installed at the bottom end of the holding box and located in the long strip groove. The bottom end of the sliding block is hinged to the convex block through a horizontal connection rod. A cavity is formed at the front end of the holding box. The inner wall of the back end of the cavity is sequentially provided with multiple grooves from top to bottom. The grooves communicate with the inner portion of the holding box. By the adoption of the garment production and machining conveyance device, the situations that garment makes machines get stuck in the conveying process, and then the machines and the garment are damaged are avoided, the garment isironed through steam, and the garment becomes flat.

Owner:CHANGCHUN INST OF TECH

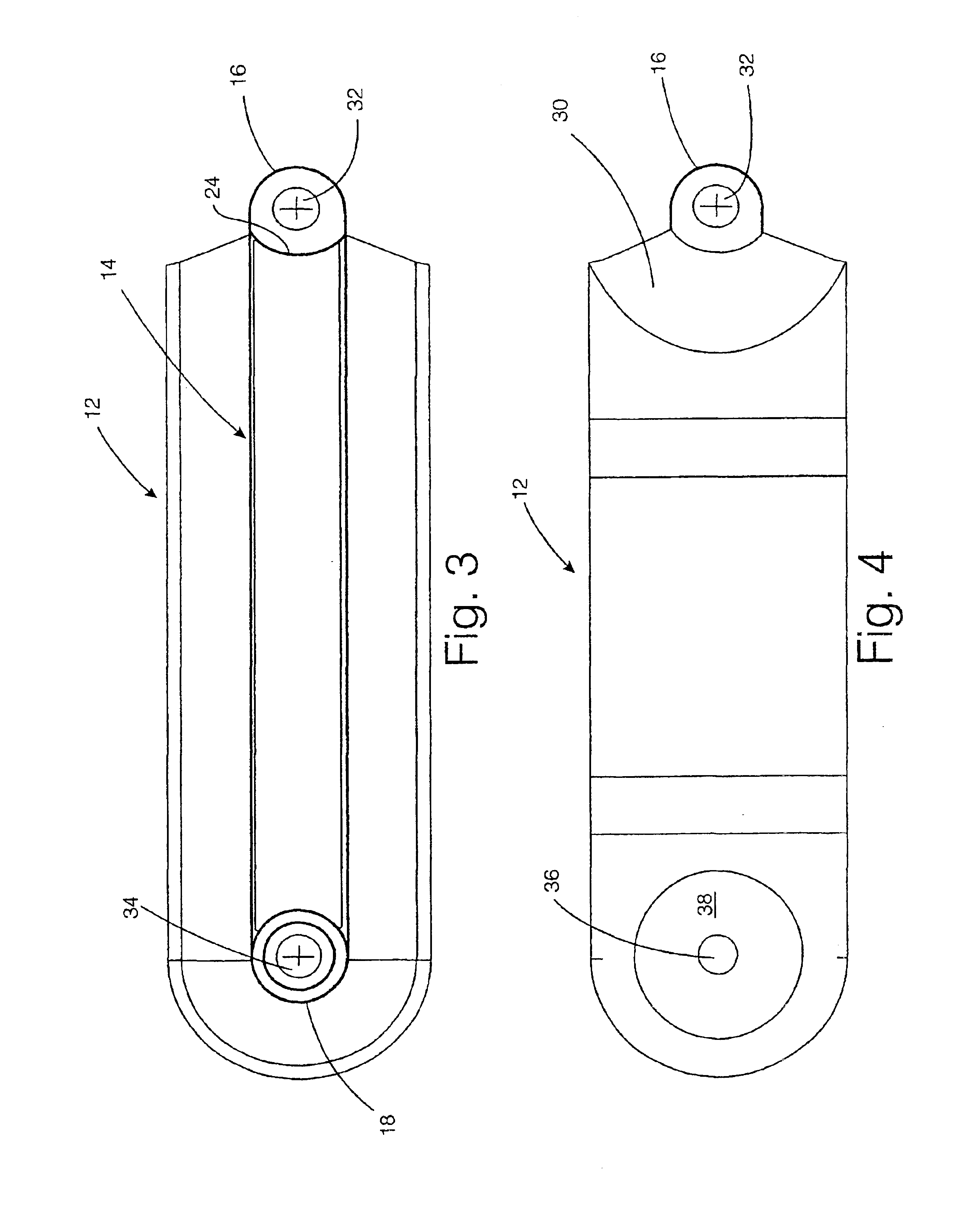

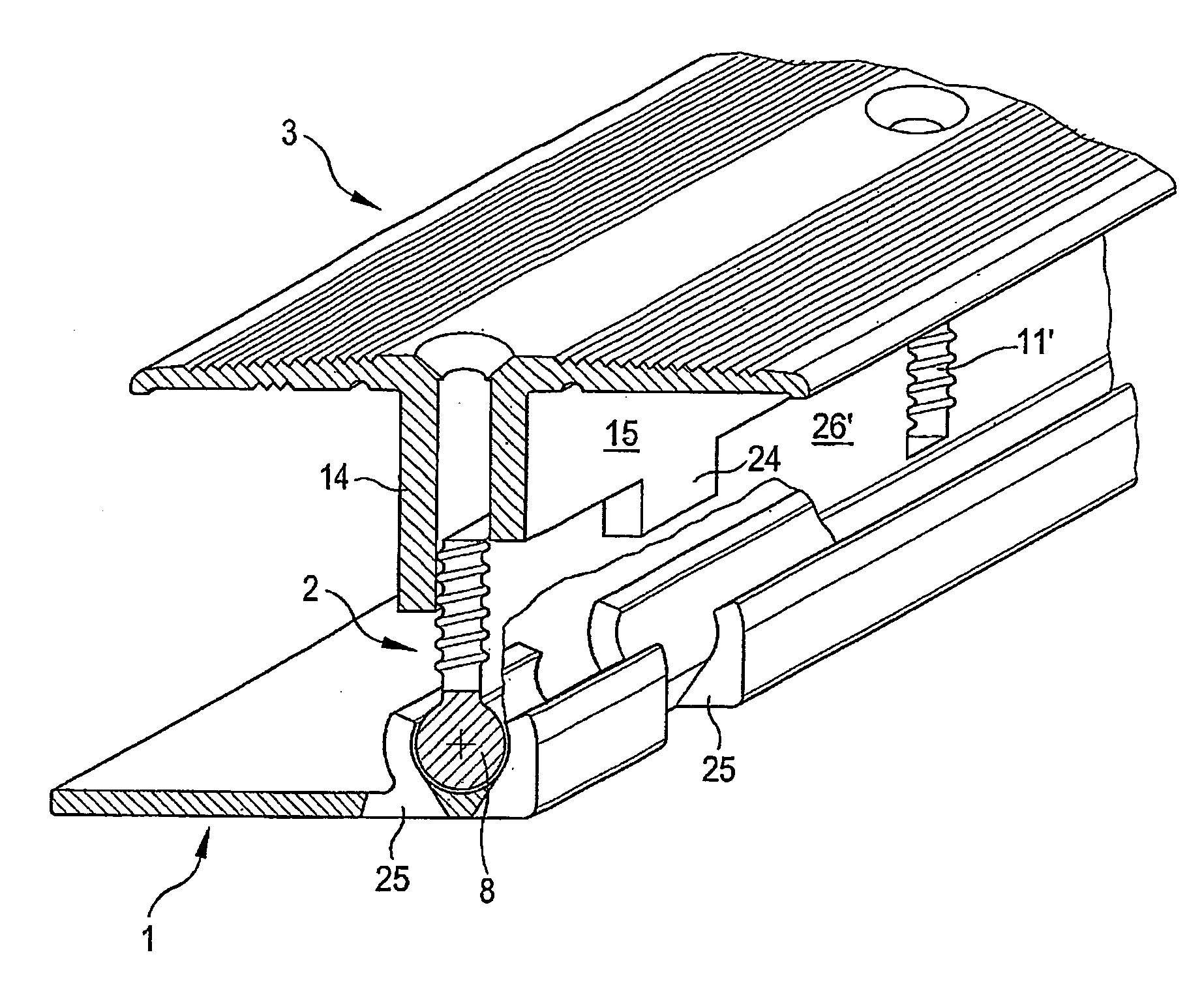

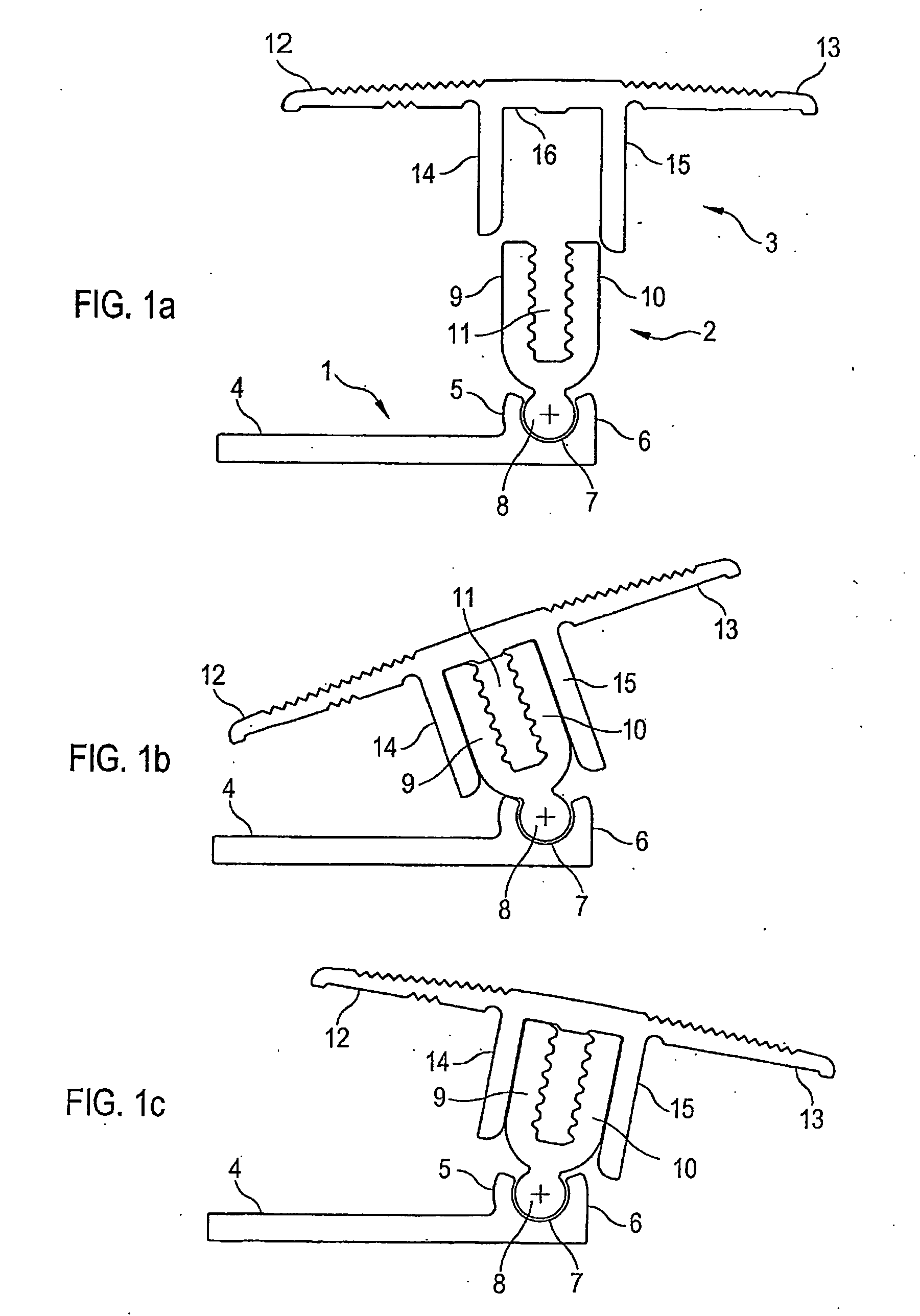

Floor Profile Arrangement Comprising a Joint

InactiveUS20080115441A1Great difference in heightConvenient ArrangementRoof covering using tiles/slatesWallsSection planeEngineering

A floor profile arrangement is provided, in particular for bridging a joint between adjacent floor coverings, with a base profile, a covering profile with at least one sideways projecting covering wing, and a web arrangement as a connection between the base profile and the covering profile, and with an articulation arrangement, the articulation arrangement consisting of an articular cavity disposed on the base profile or the covering profile and an articulation element formed on the lower or on the upper edge of the pivoting web arrangement.

Owner:HERM FRIEDR KUENNE GMBH & CO

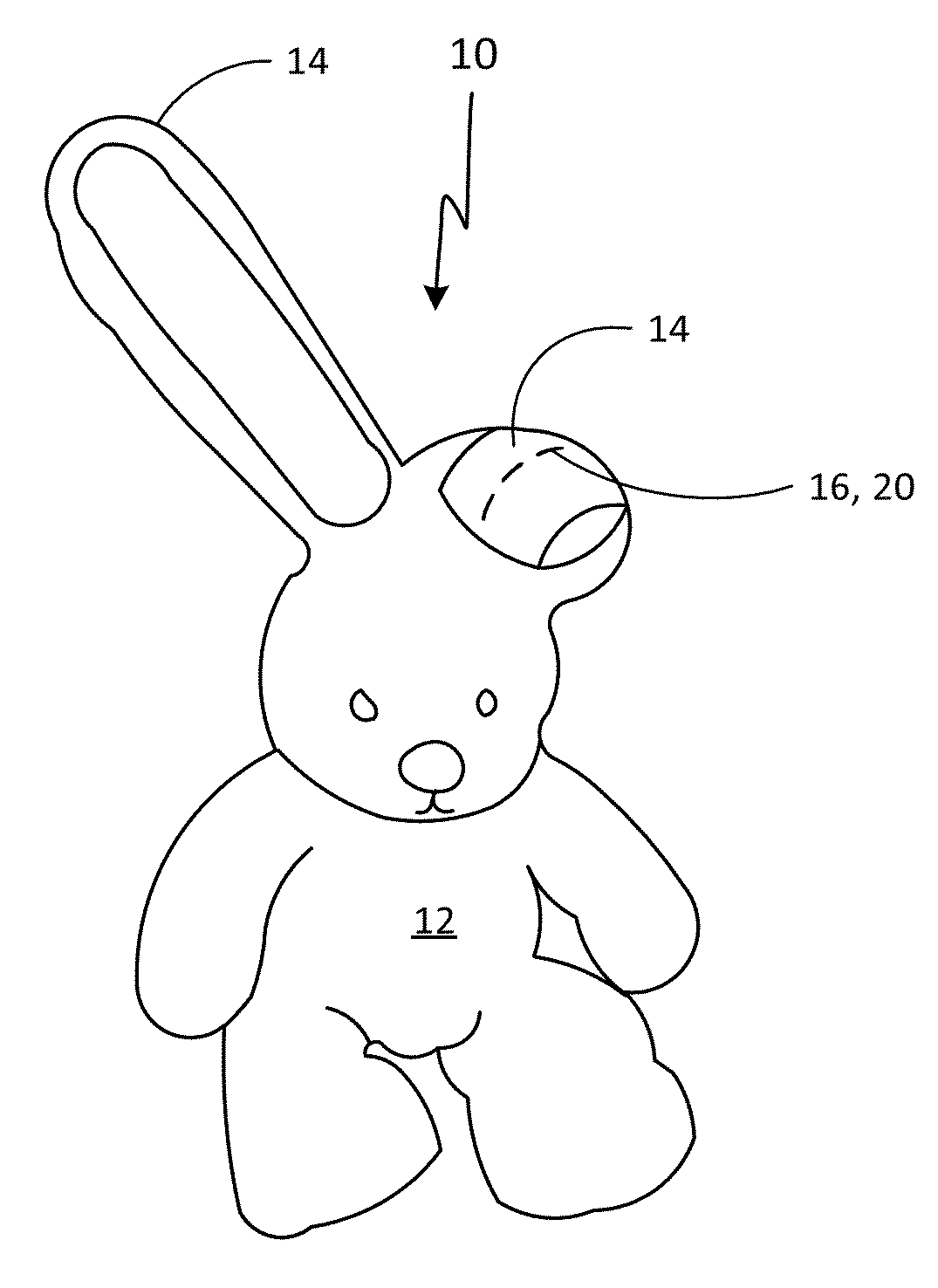

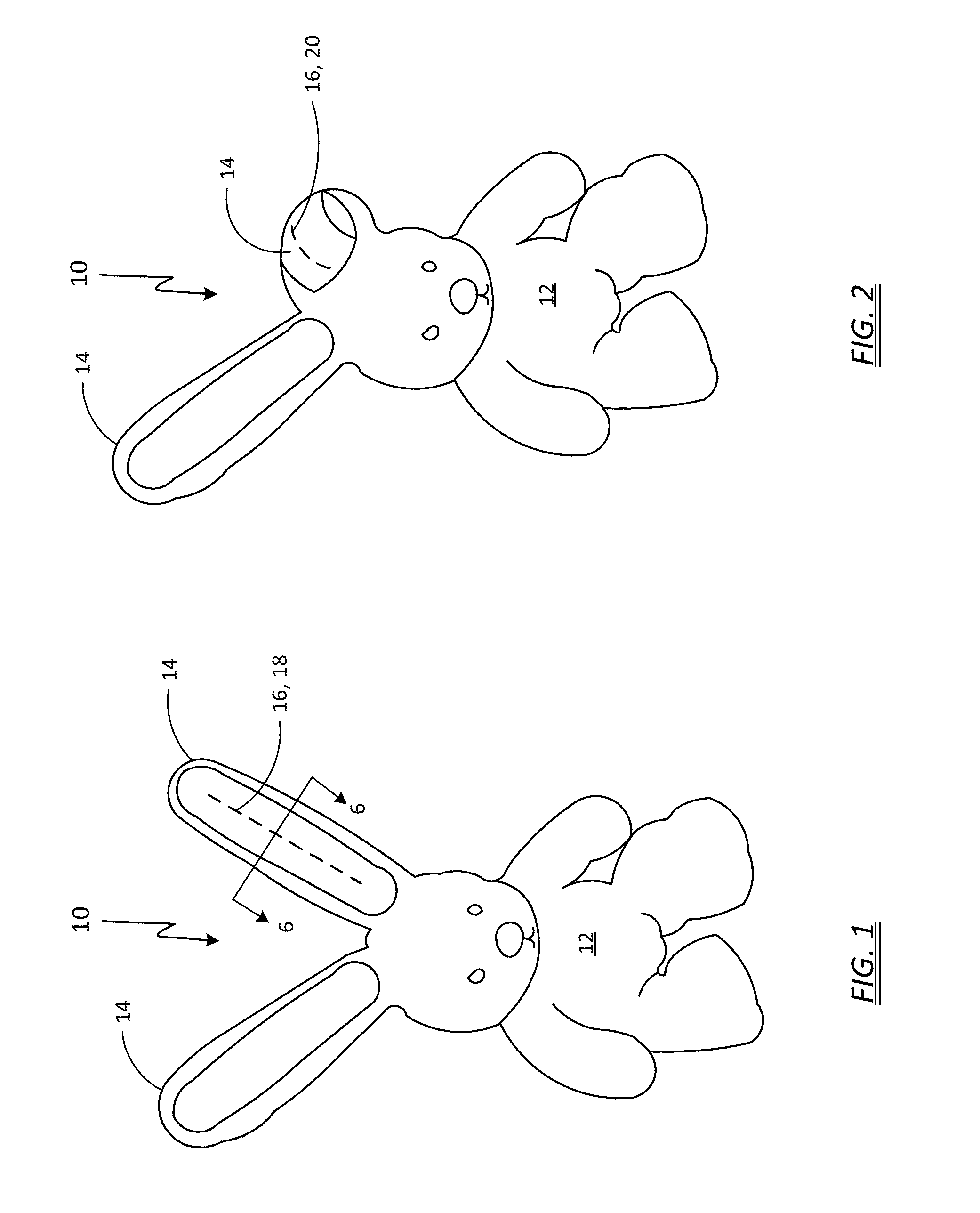

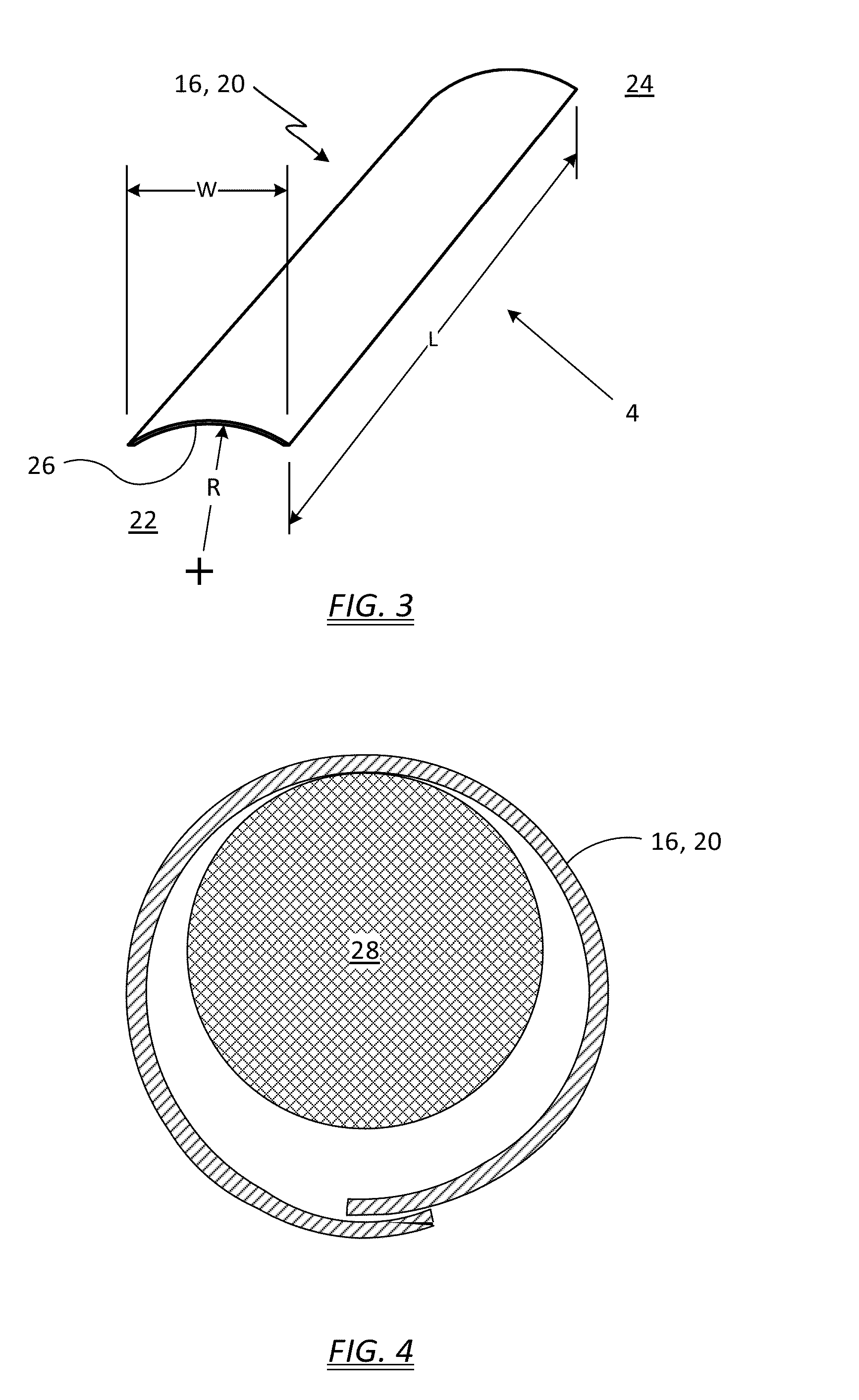

Spring-actuated appendage for stuffed animal and method for use

A stuffed animal includes a body and an appendage attached to the body. The appendage includes an elongate bi-stable spring element movable between a first extended position that is straight and a second articulated position that forms a loop. The stuffed animal further includes a material covering the body appendage. Deflecting the surface of the bi-stable spring element, such as by lightly rapping it, causes the spring element to move to the second articulated position and wrap the appendage around an object, such as a wrist, a child's bed rail, or stroller bar. The stuffed animal hangs from the object by the appendage, and will stay attached until pulled off, thereby preventing the accidental loss of the animal.

Owner:COILY Q TOYS

Windscreen wiper device

ActiveUS20110005019A1Less materialImprove propertiesWindow cleanersVehicle cleaningReciprocating motionEngineering

A windscreen wiper device, particularly for automobiles, includes comprising an elastic, elongated carrier element, as well as an elongated wiper blade of a flexible material, which can be placed in abutment with a windscreen to be wiped, which wiper blade is of the flat blade type and includes at least one groove, in which groove a longitudinal strip of the carrier element is disposed. The windscreen wiper device further includes a mounting head for transferring a reciprocal movement to the wiper blade, with the special feature of a connecting device for detachably connecting the wiper blade directly to the mounting head, wherein the connecting device is positioned near one end of the wiper blade.

Owner:TRICO BELGIUM SA

Surgical plate system and method

ActiveUS9084636B2Reduce the overall diameterAvoid articulationInternal osteosythesisProsthesisTransverse axisAnterior surface

A surgical plate system, components and methods of using are described. A surgical plate system includes a plate having an anterior surface, a posterior surface, a longitudinal axis, a transverse axis and a through hole passing through the anterior and posterior surfaces. A variable fastener is configured and dimensioned to connect to the plate, the variable fastener having a head and a shaft extending distally from the head. The head is configured to assume different proximal end diameters. The head, in a first configuration allows inward flexing to reduce a diameter of the head to allow the head to pass through an entrance opening of the through hole. In a second configuration, the head is prevented from flexing inwardly thereby preventing the head from backing out of the entrance opening, while allowing articulation of the head, within the through hole, relative to the plate.

Owner:SPINECRAFT

Windscreen wiper device

ActiveUS8881337B2Less materialImprove propertiesWindow cleanersVehicle cleaningReciprocating motionEngineering

A windscreen wiper device, particularly for automobiles, includes comprising an elastic, elongated carrier element, as well as an elongated wiper blade of a flexible material, which can be placed in abutment with a windscreen to be wiped, which wiper blade is of the flat blade type and includes at least one groove, in which groove a longitudinal strip of the carrier element is disposed. The windscreen wiper device further includes a mounting head for transferring a reciprocal movement to the wiper blade, with the special feature of a connecting device for detachably connecting the wiper blade directly to the mounting head, wherein the connecting device is positioned near one end of the wiper blade.

Owner:TRICO BELGIUM SA

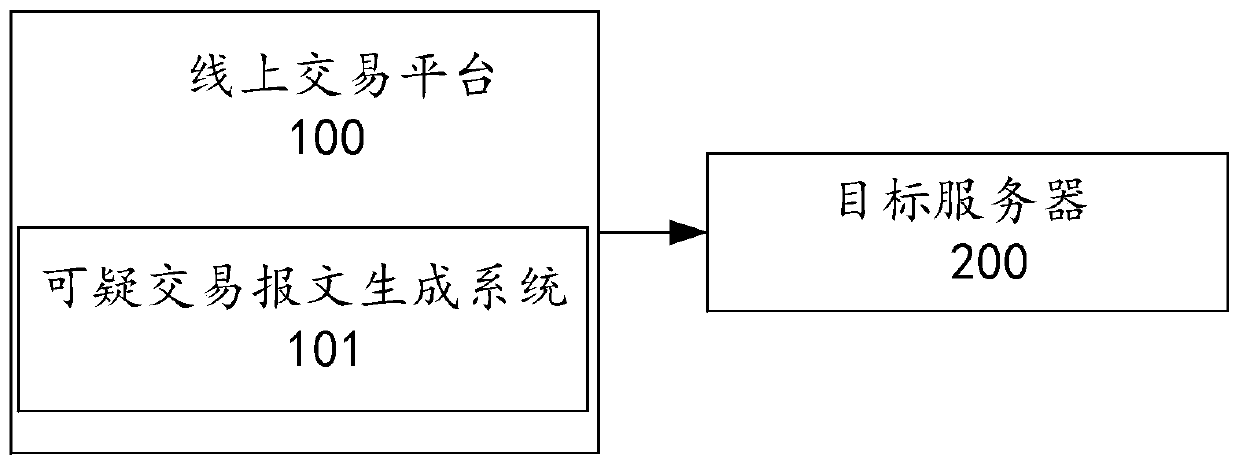

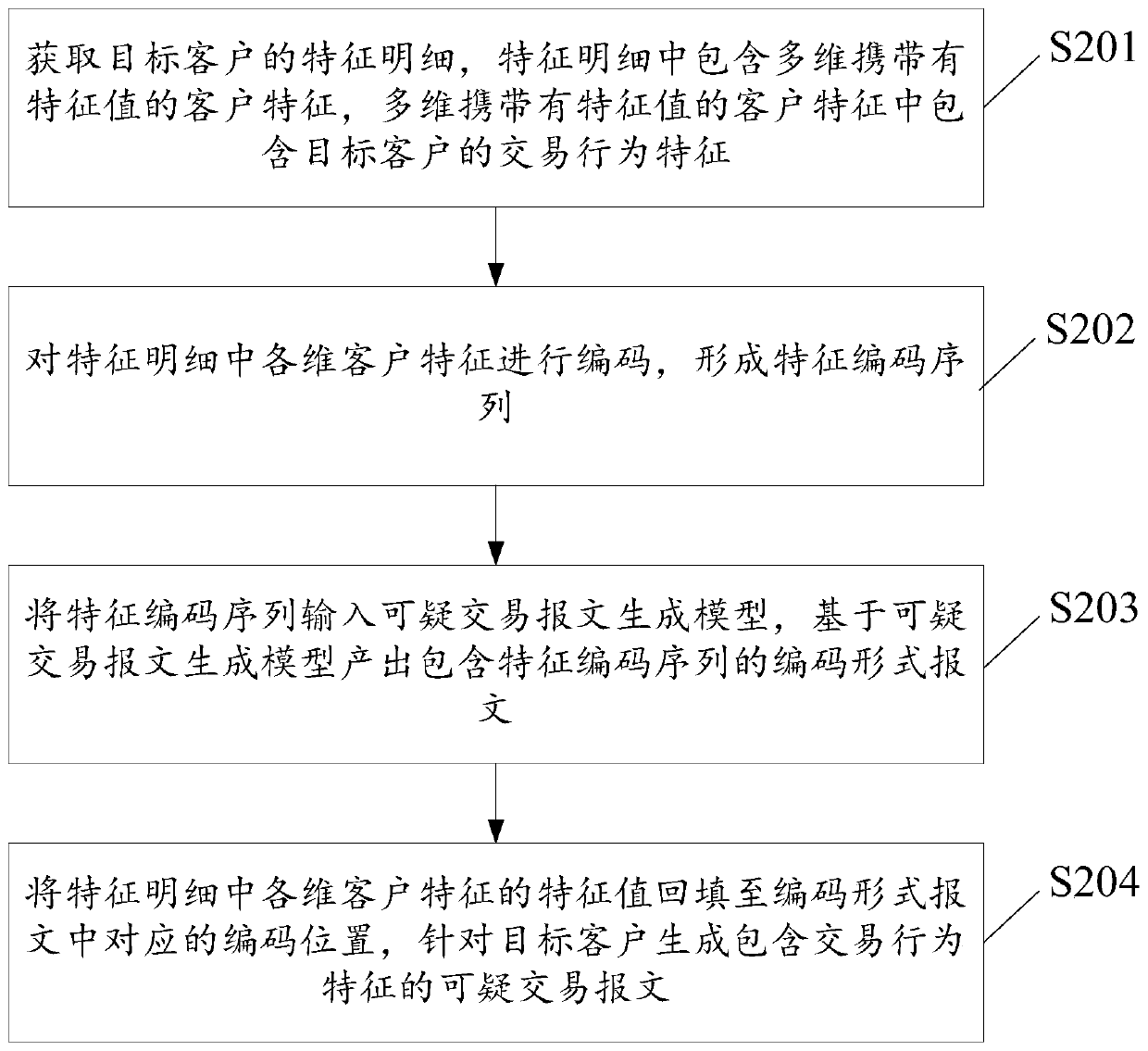

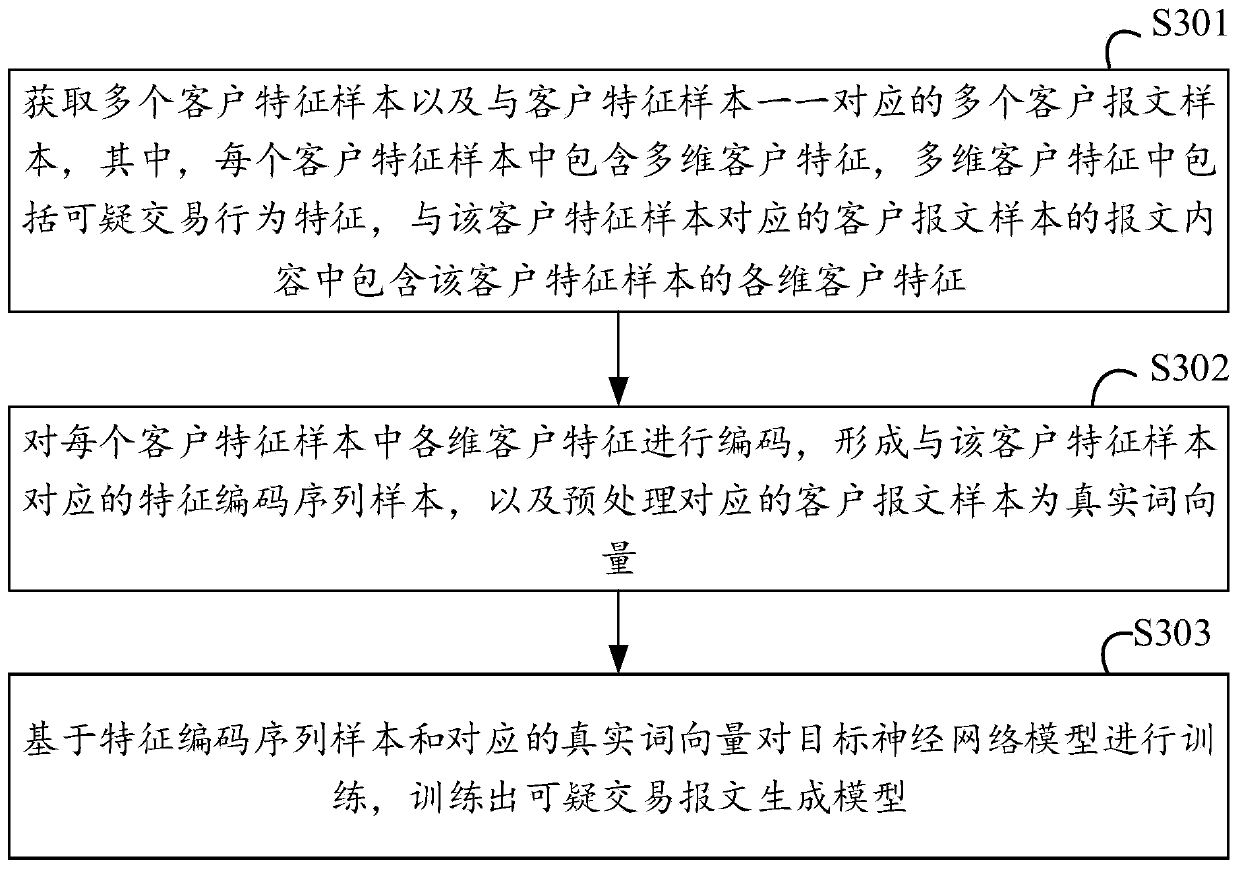

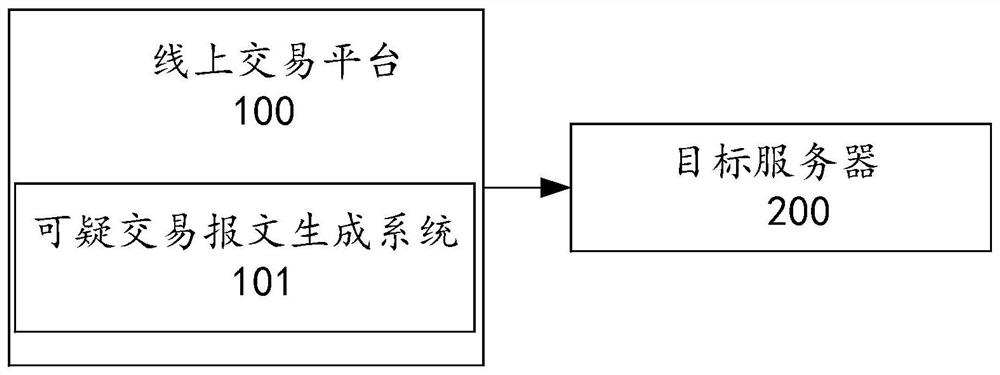

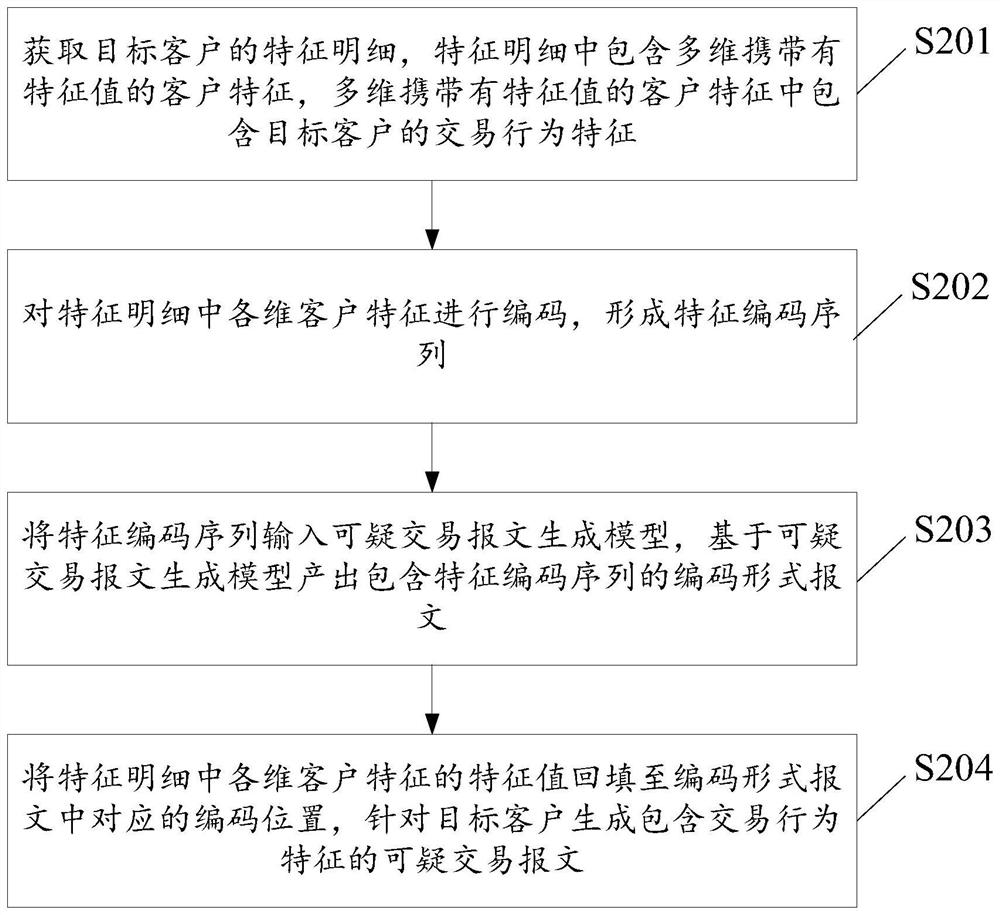

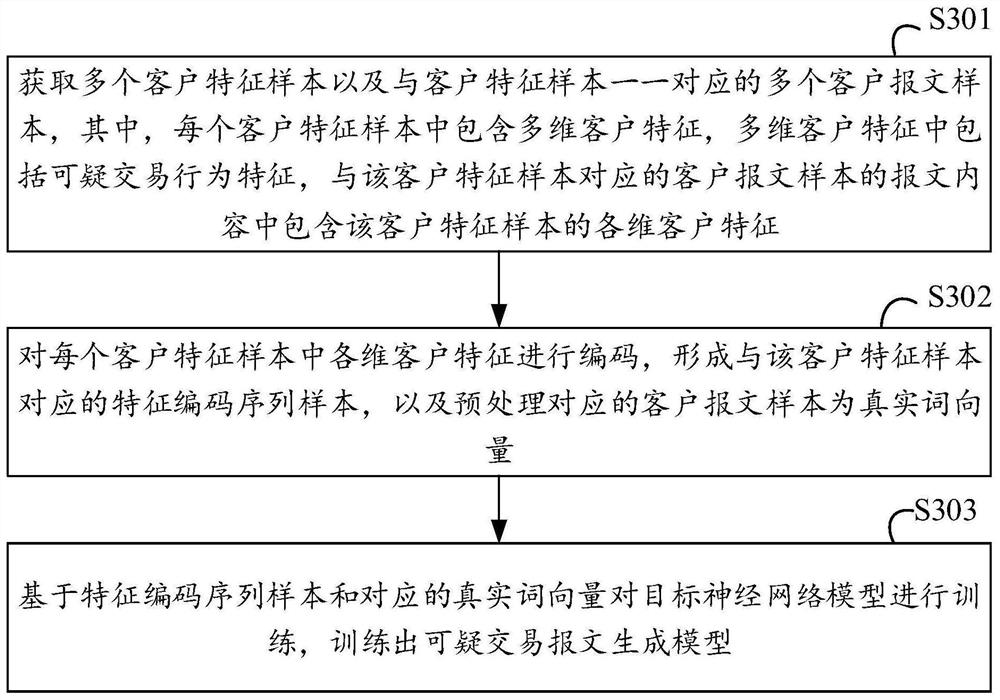

Suspicious transaction message generation method and device and server

ActiveCN110213239AReduce complexityAvoid articulationFinanceTransmissionProgramming languageGenerative model

The embodiment of the invention provides a suspicious transaction message generation method and device and a server, and the method comprises the steps: carrying out the coding of the features of clients in a feature detail, and forming a feature code sequence corresponding to the feature detail; inputting the feature code sequence into a suspicious transaction message generation model, and generating a code form message containing the feature code sequence based on the suspicious transaction message generation model; backfilling the characteristic values of the characteristic details to the corresponding coding positions in the coding form message to generate the suspicious transaction message for the target client, so that message connection, message sequence and maintenance of a large number of rules in message screening caused by message splicing are avoided, the complexity of generating the suspicious transaction message is reduced, and more time is saved, and the efficiency is improved.

Owner:ADVANCED NEW TECH CO LTD

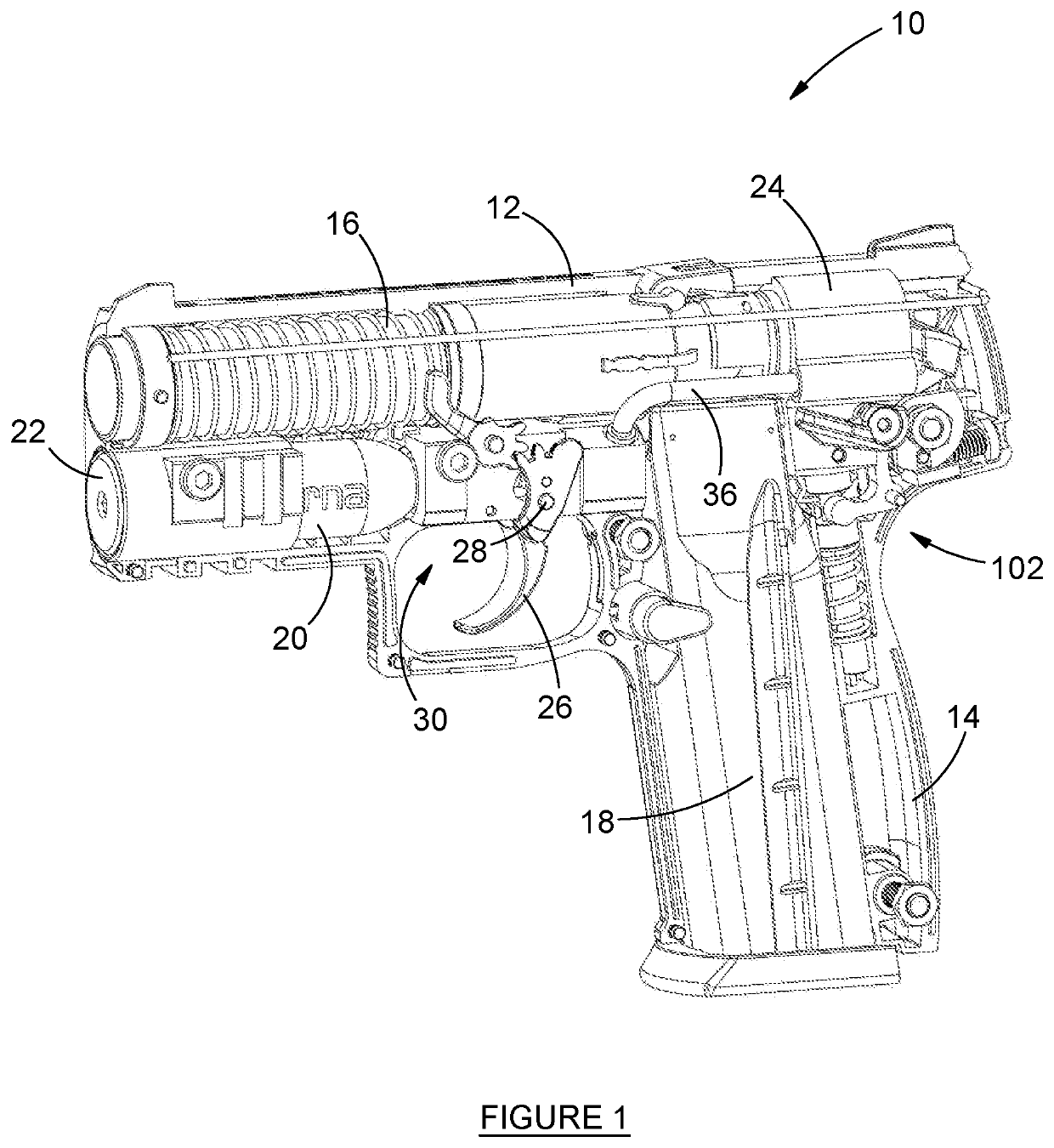

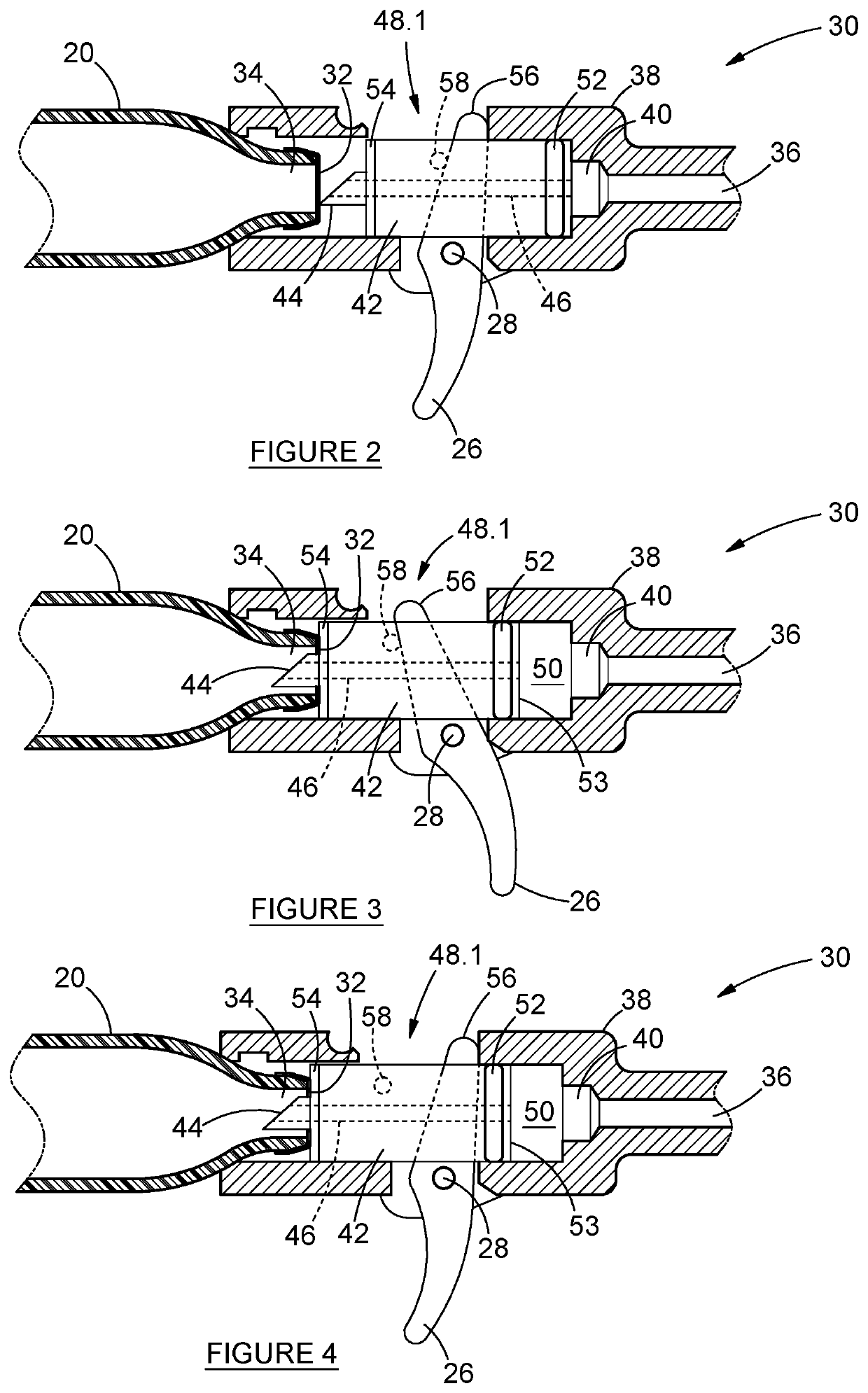

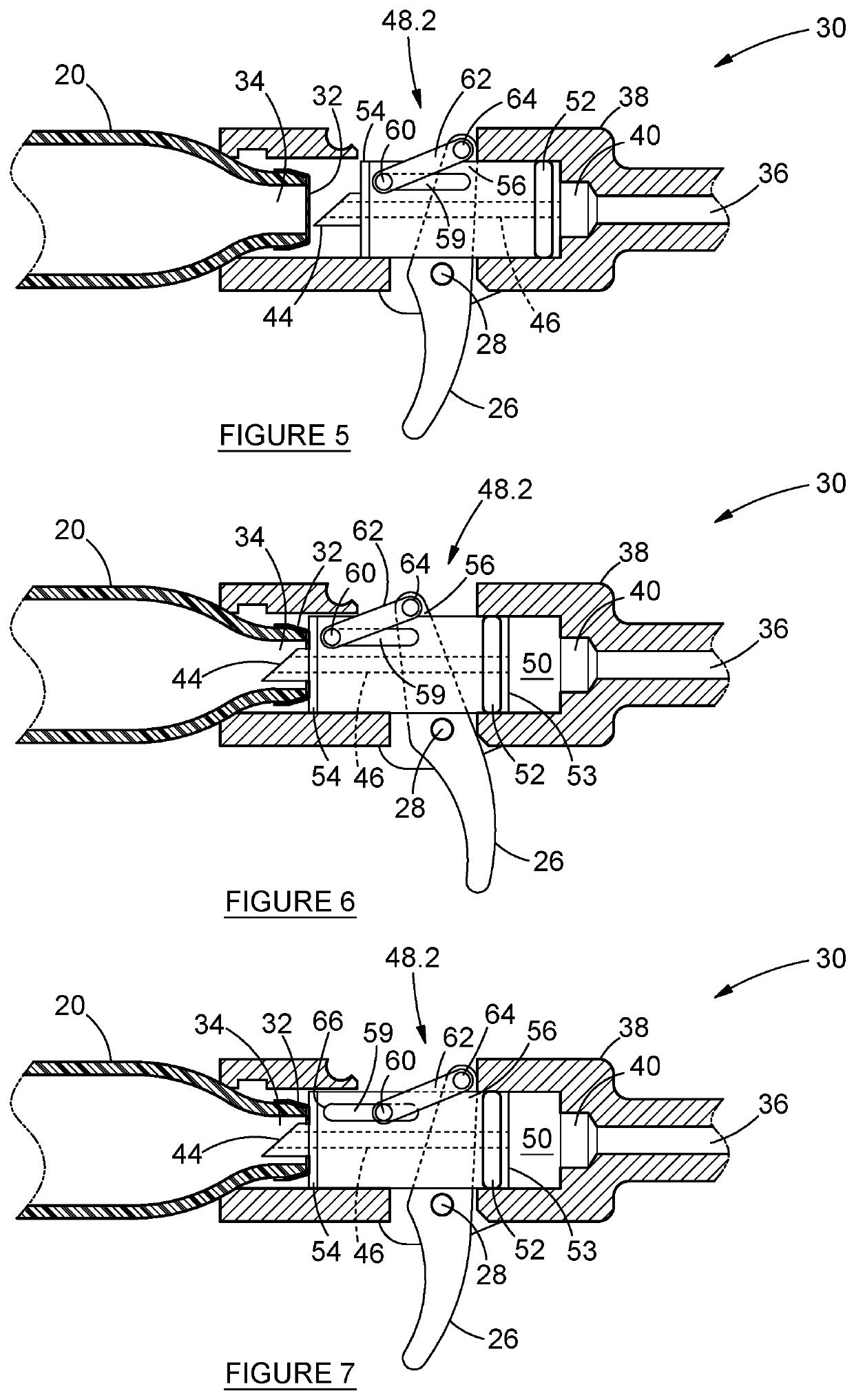

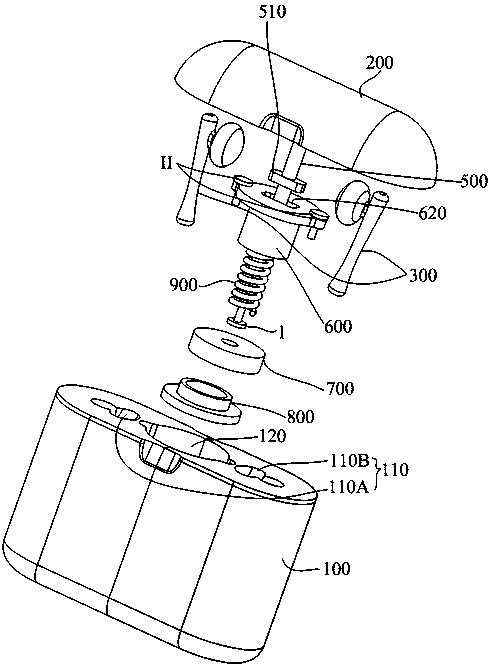

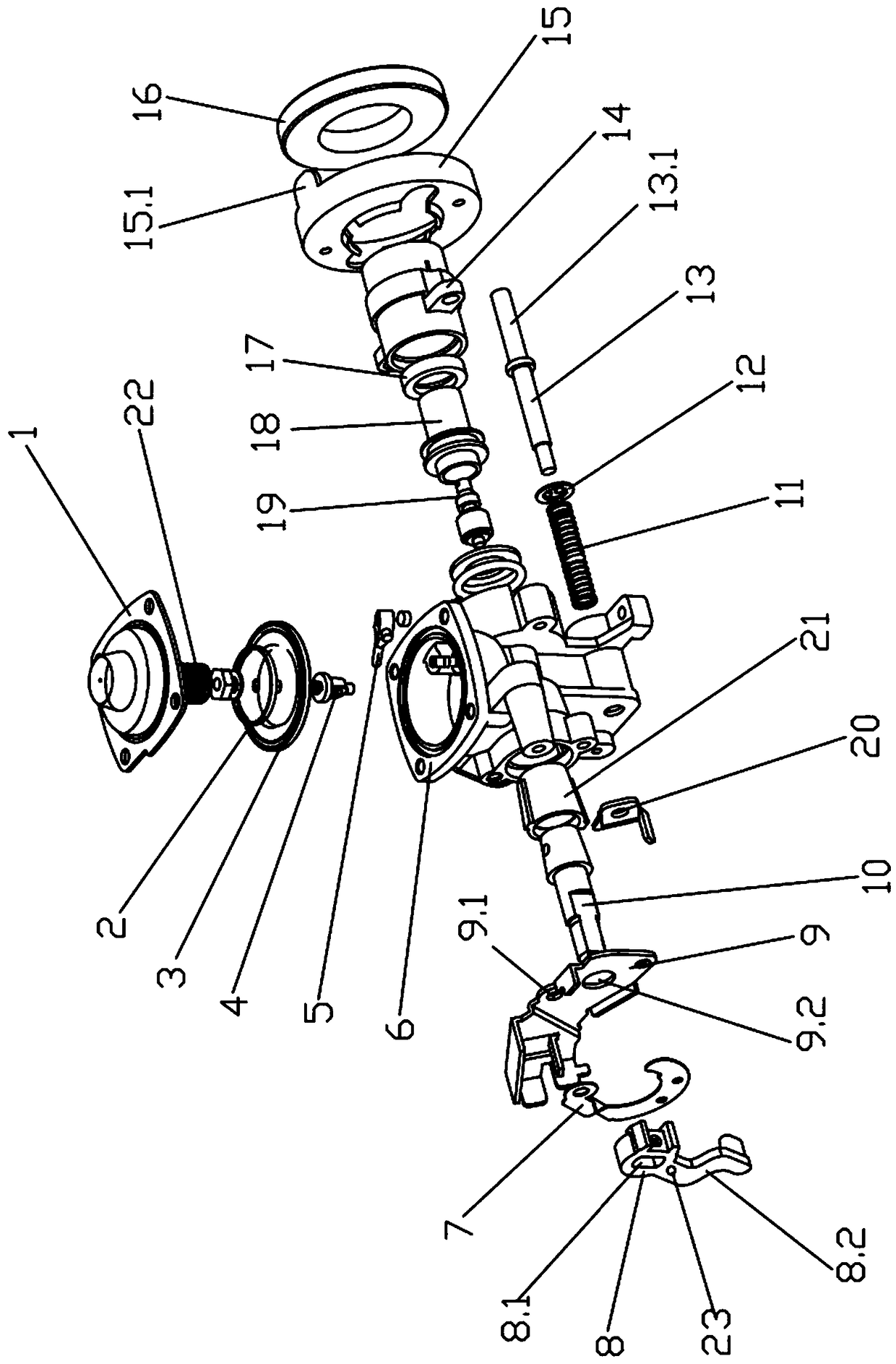

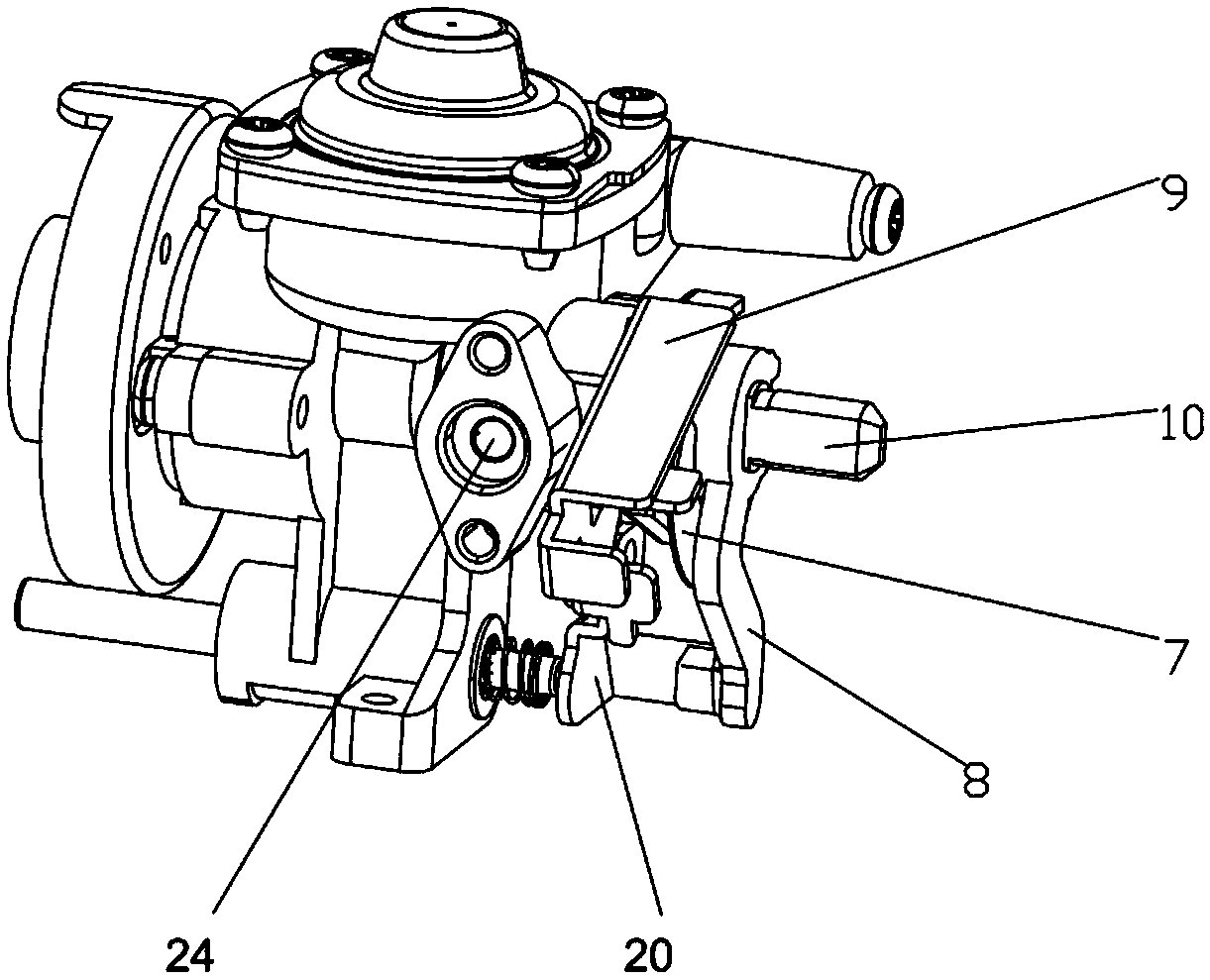

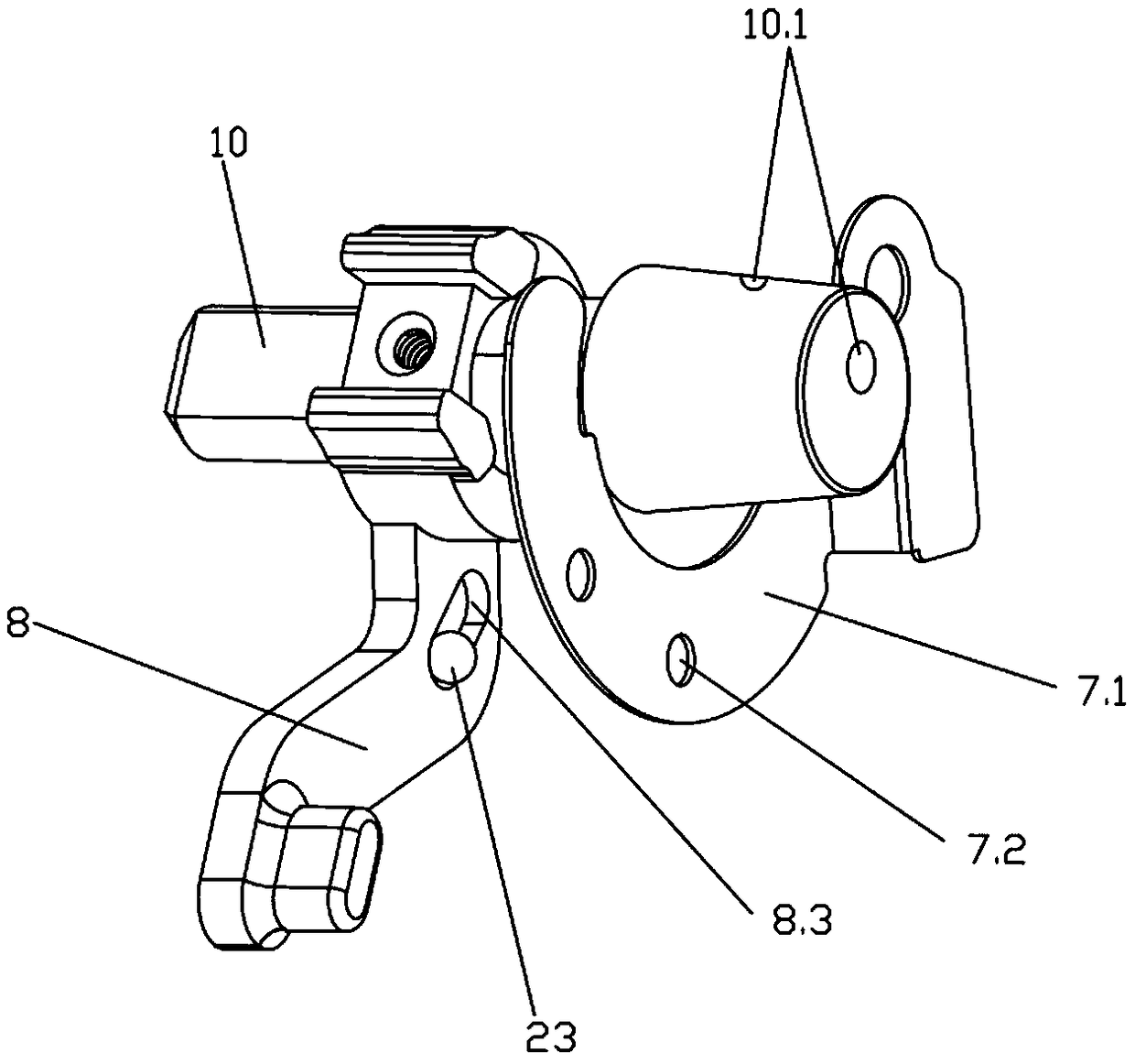

A pneumatic arrangement of a less-lethal device

ActiveUS20210381797A1Prevent escapeAvoid articulationSafety arrangementCompressed gas gunsClassical mechanicsEngineering

This invention relates to a pneumatic arrangement of a less-lethal device, which pneumatic arrangement comprises a puncture mechanism used for puncturing a sealed mouth of a canister of compressed gas, in use received within a body of the less-lethal device; a pressure sensitive activation assembly used to inhibit the device from propelling a projectile therefrom before a predetermined pressure is reached within a release valve of the device; a release valve assembly for venting compressed gas to a barrel to propel the projectile from the device; and a propelling assembly for adjusting the kinetic force with which a hammer impacts a release valve of the device. The invention also relates to a method of propelling a projectile from a less-lethal device.

Owner:BYRNA TECH INC

Earphone charging box

ActiveCN110769342AImprove reliabilityExtended service lifeCharging attachments/accumulatorsHeadphonesMechanical engineering

Owner:GEER TECH CO LTD

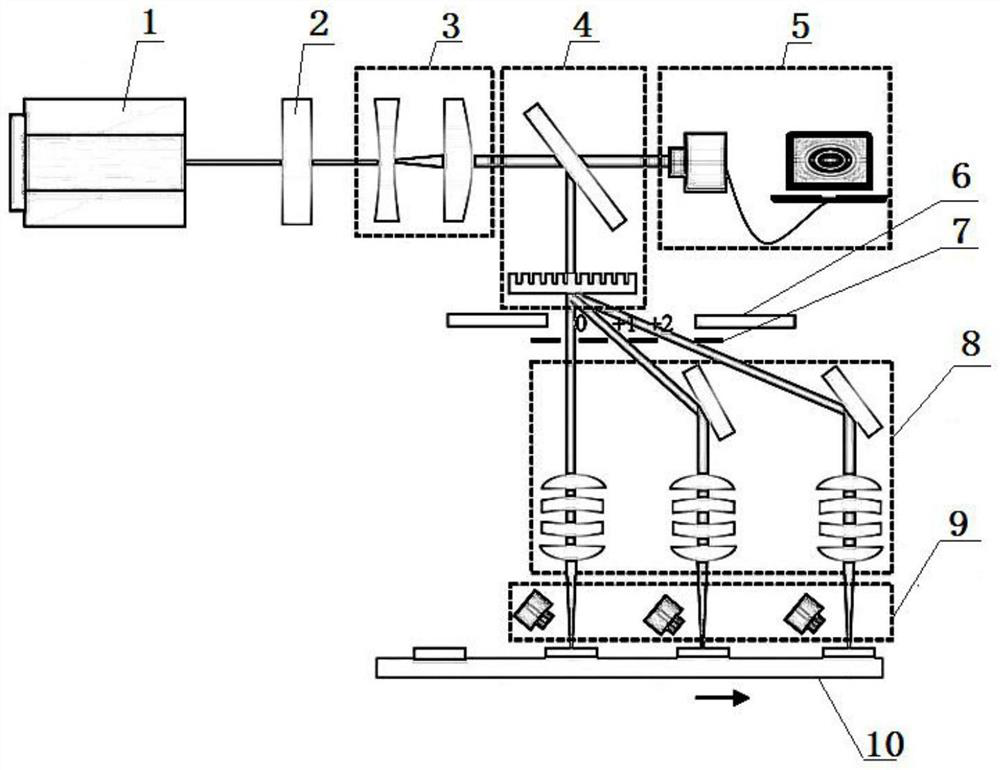

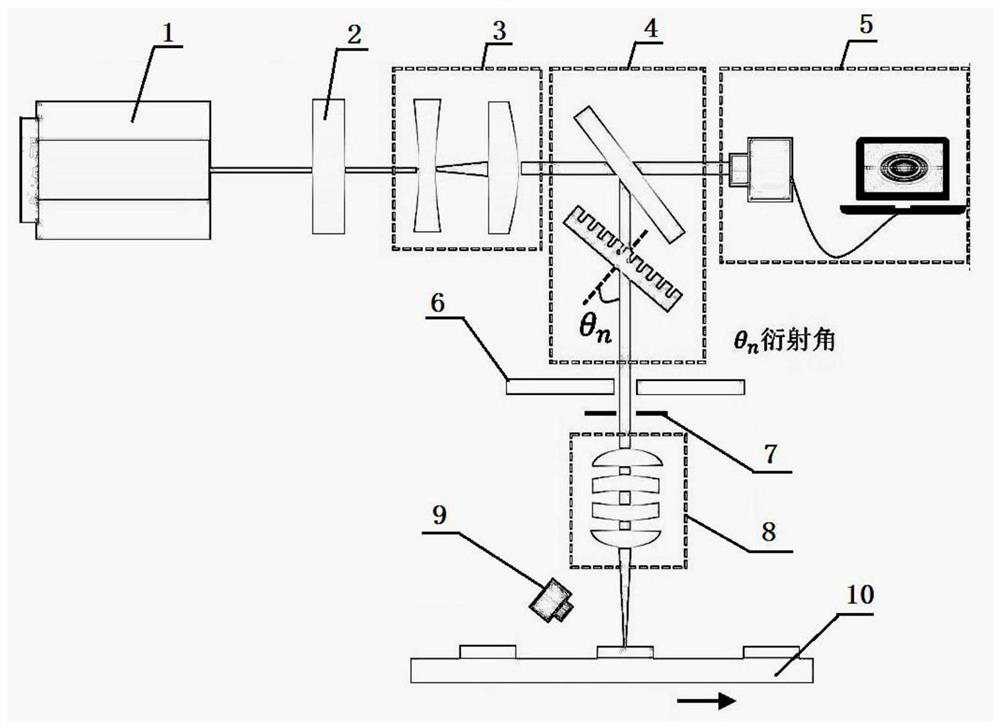

Gradient machining system and method for atomic-scale surface and structure

The invention relates to an atomic-scale surface and structure gradient machining system and method, and the system is sequentially provided with an energy regulator, a light beam shaping module and a grating beam splitting module along a light path, and the grating beam splitting module is used for splitting a machining light beam into a light beam which is suitable for the machining of each precision grade and has required irradiation energy density; the diaphragm is used for limiting the diffracted light beams entering a subsequent processing system; the optical switch is used for controlling whether the processing light beam is emitted or not; and the light beam focusing module is used for focusing light beams. The machining method comprises the steps of fixing the grating and moving a workpiece for different-precision machining; or the workpiece is fixed, and the grating is adjusted to realize in-situ machining with different precisions. According to the invention, cross-scale micron-scale, nano-scale and atomic-scale material removal is realized, the integration degree of the processing system is high, and the problem of connection and difficulty in repeated positioning caused by various processing methods and equipment are avoided; and by means of the ionization effect of high photon energy and fine regulation and control of ultrashort pulses on the material, lattice damage to the final surface is effectively reduced, and the machining precision is improved.

Owner:TIANJIN UNIV

Magnet valve and gas furnace thereof

InactiveCN109282325AImprove securityAvoid articulationDomestic stoves or rangesLighting and heating apparatusMagnetEngineering

The invention discloses a magnet valve and a g as furnace thereof. A cavity of the magnet valve is provided with an air inlet channel and an air outlet channel, a sleeve ring is assembled in the air outlet channel, an insertion end of an adjusting rod is sleeved with the sleeve ring, the rotary knob end of the adjusting rod is sleeved with a sounding part, a groove is formed in the inner side of the sounding part, and the groove can contain a rolling impact part; a swing prompt part is arranged between the sounding part and a port of the air outlet channel, when the rotary knob adjusting rod drives the sounding part to rotate, the impact part in the groove of the sounding part makes contact with the prompt part, prompt sounds are generated, the fire function of the gas furnace is promoted,the adjusting position of the adjusting rod is distinguished by means of sounds, and operation accuracy positioning can be achieved; meanwhile, due to the fact that the adjusting rod can be recognized, when the adjusting rod is reset, the phenomenon that a gas bottle is forced to connect with the magnet valve by accident is avoided, the phenomenon that the magnet valve gas bottle ejector rod partis damaged, and a gas bottle is exploded is avoided, and the safety of the gas furnace is improved.

Owner:中山亨泰燃气具有限公司

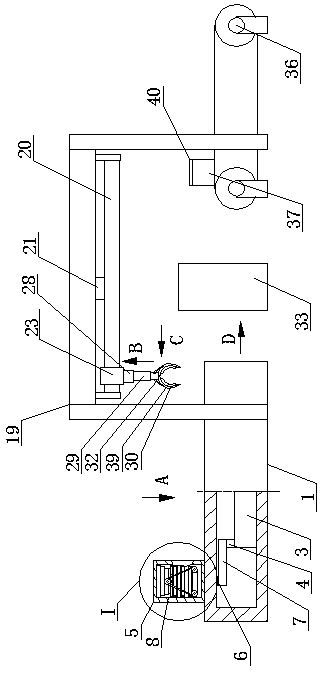

Medical pipe machining device and machining method thereof

The invention relates to the field of pipe machining, in particular to a medical pipe machining device and a machining method thereof. The machining method comprises the following steps that adding pipes needing to be subjected to continuous arc bending are heated through a limiting frame to be added; a combined driver intermittently drives an intermittent driving adder to intermittently add the adding pipes through the adding rubber rollers and then stops; the combined driver drives a pressurizing intermittent driving gear, a sliding gear ring plate and a lower sliding base, so that an arc-shaped extruder extrudes the heated and softened adding pipes onto an arc-shaped top base; meanwhile, the arc-shaped extruder stably drives the adding pipes in an extruding process through meshing of a fixing gear and a fixing rack, and damage caused by excessive extruding is avoided; after being extruded into an arc shape, the combined driver intermittently drives a reciprocating driving direction changing device to drive an intermittent driving steering gear to rotate so as to convey out the adding pipes at the arc-shaped part, and interference is avoided; and the process is repeated.

Owner:张香连

Clothing production and processing transmission equipment

ActiveCN107600480BAvoid damageAvoid articulationIndividual articlesEngineeringMechanical engineering

Owner:CHANGCHUN INST OF TECH

A seat tube for a new energy vehicle

ActiveCN109017491BAvoid replacementTake advantage ofVehicle seatsElectric propulsion mountingInterior spaceNew energy

The invention relates to the field of new energy sources, in particular to a seat barrel for a new energy vehicle, which includes a seat, a tank body and a tank cover; a lid of that box is overlappedon the top of the box body, the box body is vertically arranged and the opening of the box body is arranged upward, the box body is provided with a partition plate vertically arranged, the partition plate divides the space in the box into a first accommodation cavity and a second accommodation cavity, the first accommodating cavity is provided with a first supporting assembly for supporting the box cover, the second accommodating cavity is provided with a second supporting assembly for supporting the box cover, the bottom of the box cover is embedded in the box body, and the top of the box cover is provided with a positioning seat for fixing the seat. The invention has the beneficial effect that the interior space of the new energy vehicle is fully utilized, the structural strength of theseat barrel is ensured, and the battery is protected.

Owner:东营市大学科技园发展有限责任公司

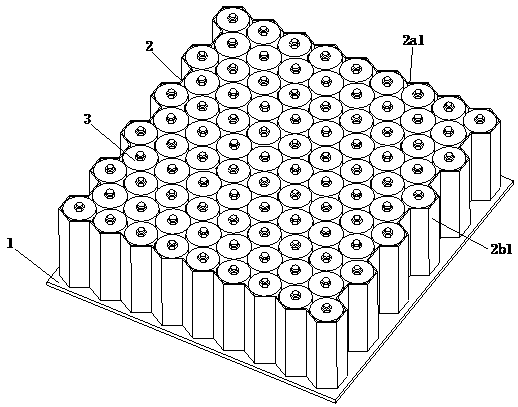

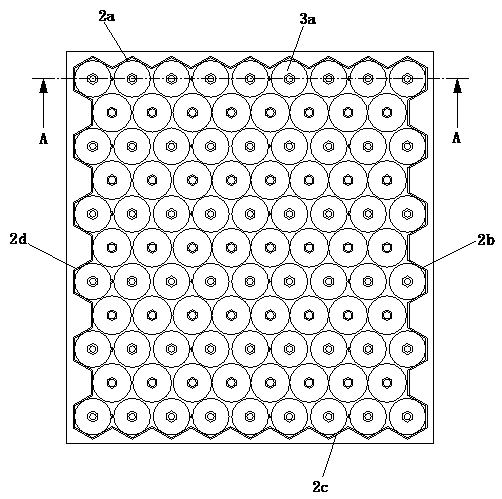

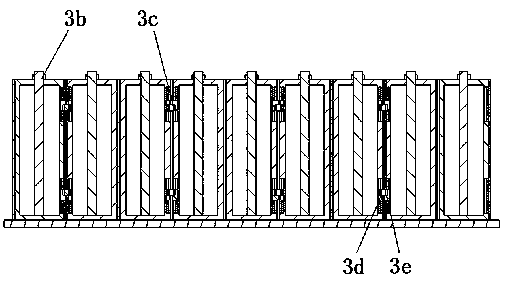

Power supply method based on honeycomb structure for new energy automobile

InactiveCN108832044AAvoid jammingAvoid replacementElectric propulsion mountingCell component detailsElectricityElectrical battery

The invention relates to a power supply method based on a honeycomb structure for a new energy automobile. According to the power supply method, a plurality of battery packs are arranged in an automobile chassis structure, a chassis adopts an interlayer structure with a plurality of layers of base plates, one single battery pack is fixedly arranged in an interlayer between every two adjacent baseplates, one single battery pack formed by splicing a plurality of battery bearing parts is of the honeycomb structure, each battery bearing part is of a hollow cylindrical tubular structure which facilitates the installation of one single battery, every two adjacent battery bearing parts adopt a detachable plug-in locking fit way, and by means of the plug-in locking fit way, mechanical splicing among the battery bearing parts is realized, and meanwhile, the parallel electrical connection among batteries in every two adjacent rows of battery bearing parts and the series electrical connection among the batteries in each single row of battery bearing parts are realized.

Owner:陈志军

Headphone charging box

ActiveCN110769342BImprove reliabilityExtended service lifeCharging attachments/accumulatorsEngineeringStructural engineering

Owner:GEER TECH CO LTD

Suspicious transaction message generation method, device and server

The embodiment of this specification provides a method, device and server for generating a suspicious transaction message, including: encoding the customer features of each dimension in the feature details to form a feature encoding sequence corresponding to the feature details; inputting the feature encoding sequence into a suspicious transaction message to generate Model, based on the suspicious transaction message generation model, an encoded form message containing a feature encoding sequence is produced; by backfilling the characteristic value of the feature details into the corresponding encoding position in the encoded form message, a suspicious transaction message for the target customer is generated, In this way, the maintenance of a large number of rules in message concatenation, message sequence, and message screening caused by message splicing is avoided, and the complexity of generating suspicious transaction messages is reduced, which is more time-saving and efficient.

Owner:ADVANCED NEW TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com