Power supply method based on honeycomb structure for new energy automobile

A new energy vehicle, honeycomb structure technology, applied in structural parts, batteries, circuits, etc., can solve problems such as increasing support costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

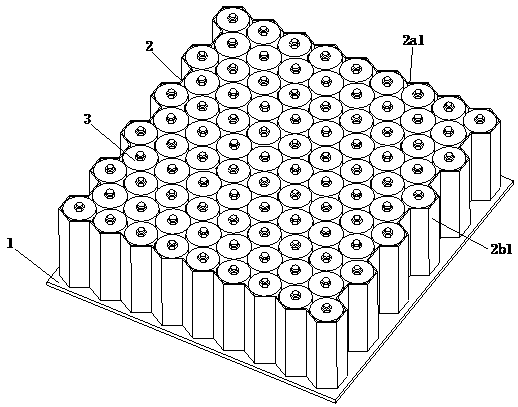

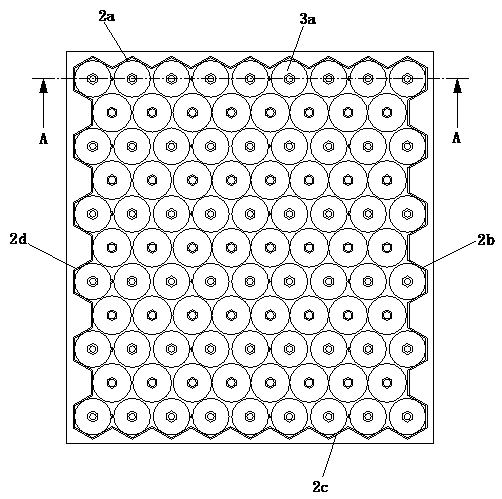

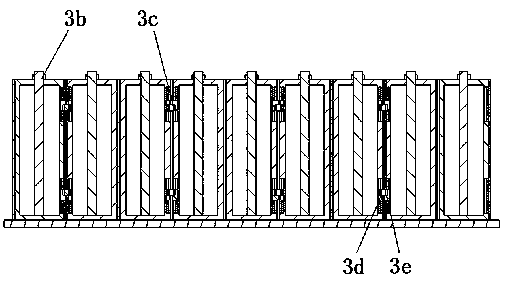

[0033]The second embodiment; a new energy vehicle honeycomb chassis structure, including a base plate 1, a detachable limit frame 2 mounted on the base plate 1, and several fixed components 3 distributed in the limit frame 2 in a matrix structure, the limit The frame 2 has a hollow structure and the outer edge is honeycomb-shaped. Several fixing components 3 include multiple bearing groups 3a distributed at equal intervals along the horizontal direction. Each bearing group 3a includes several bearing parts 3b arranged on the same horizontal straight line. The bearing parts 3b located at the inner edge of the limiting frame 2 are all in conflict with the limiting frame 2, and a connecting part 3c is arranged between two adjacent bearing parts 3b. The clamping component 3d and the locking component 3e provided on the other bearing part 3b, in the installed state, the clamping component 3d is lockingly engaged with the locking component 3e;

[0034] Each bearing part 3b includes ...

no. 3 approach

[0039] The third embodiment: a power supply method based on a honeycomb structure for a new energy vehicle, in which a plurality of battery packs are arranged in the chassis structure of the vehicle, wherein the chassis adopts a sandwich structure of multi-layer bottom plates 1, and between every two adjacent bottom plates 1 A single battery pack is fixedly installed in the interlayer, and a single battery pack formed by splicing multiple battery bearing parts 3b has a honeycomb structure. Each battery bearing part 3b is a hollow cylindrical tube 3b1 structure that facilitates the installation of a single battery. A detachable plug-in locking fit is adopted between the parts 3b, and the plug-in locking fit realizes the parallel electrical connection between the batteries in the battery-carrying parts 3b of adjacent rows while realizing the mechanical splicing between the battery-carrying parts 3b And the series electrical connection of the batteries in the battery bearing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com