Patents

Literature

33results about "Profiled circular tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

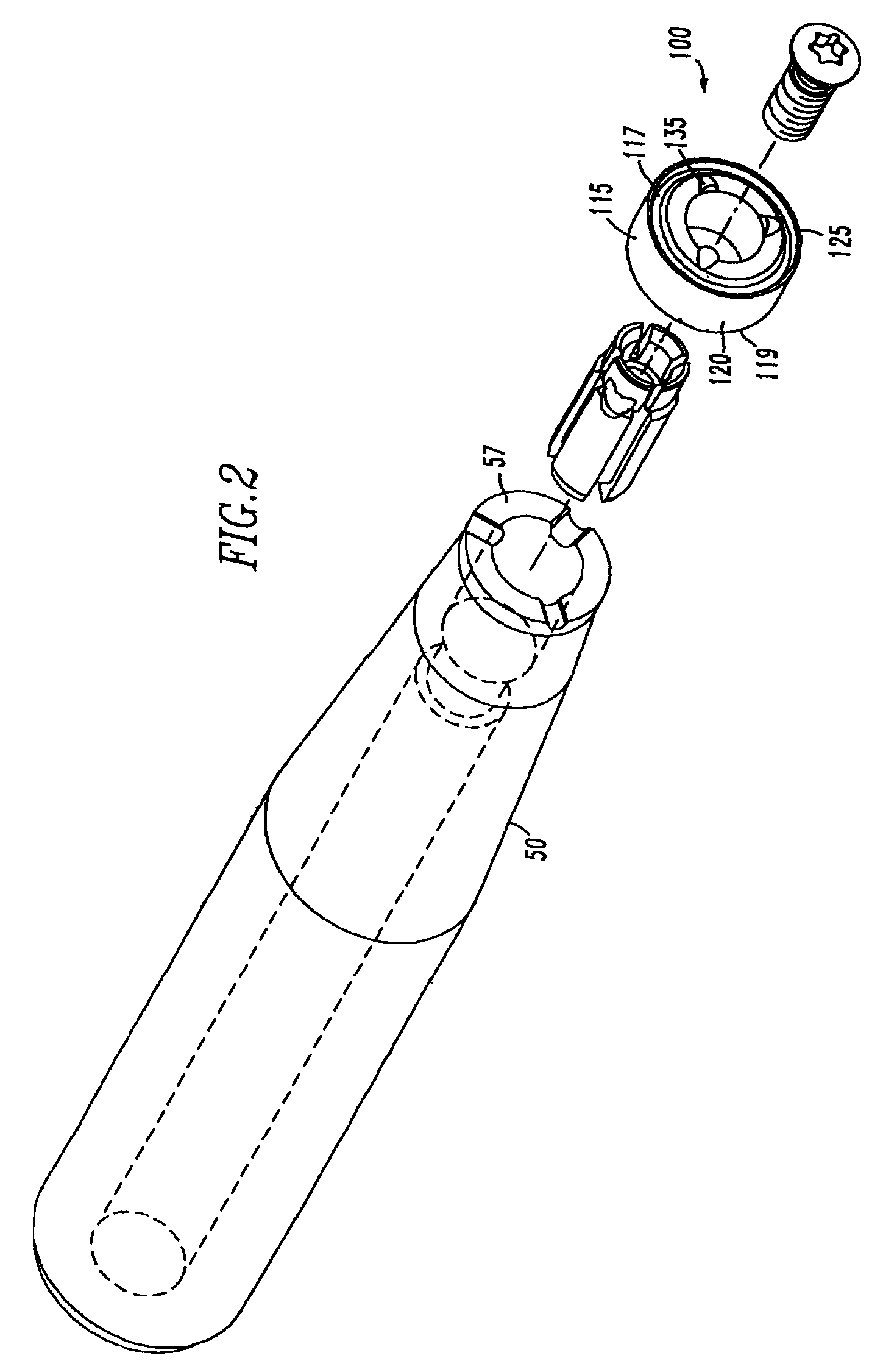

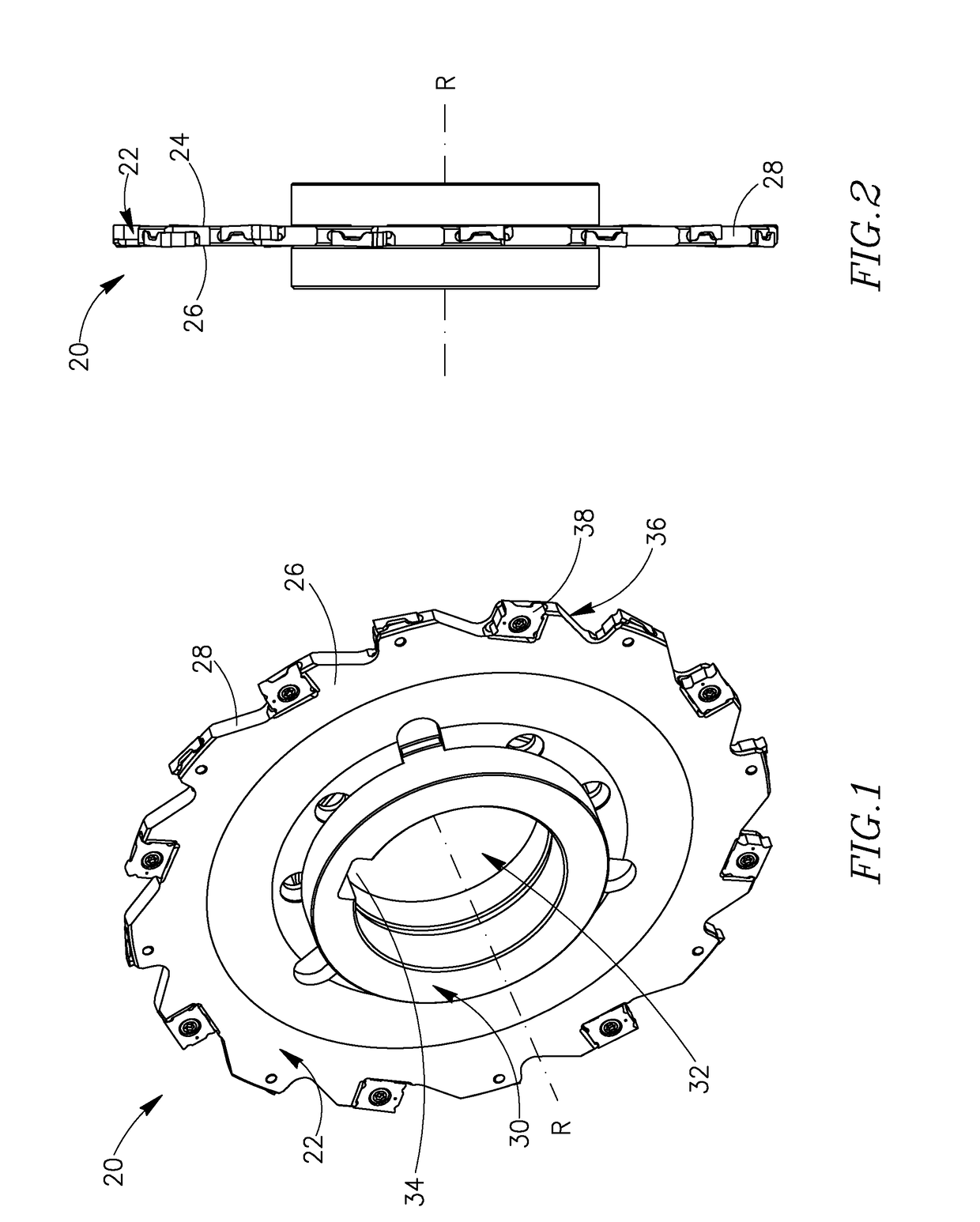

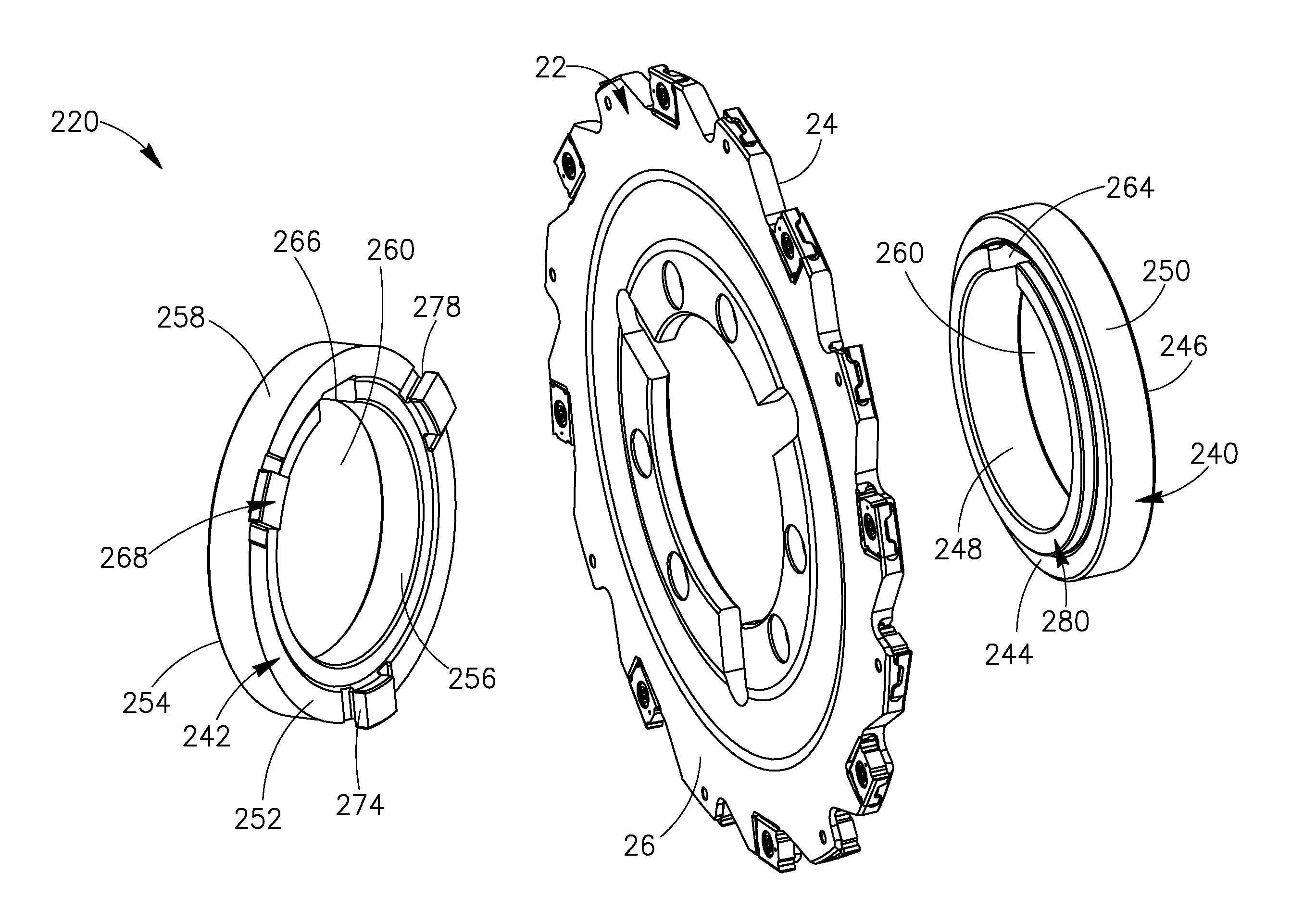

Round Cutting Insert With Anti-Rotation Feature

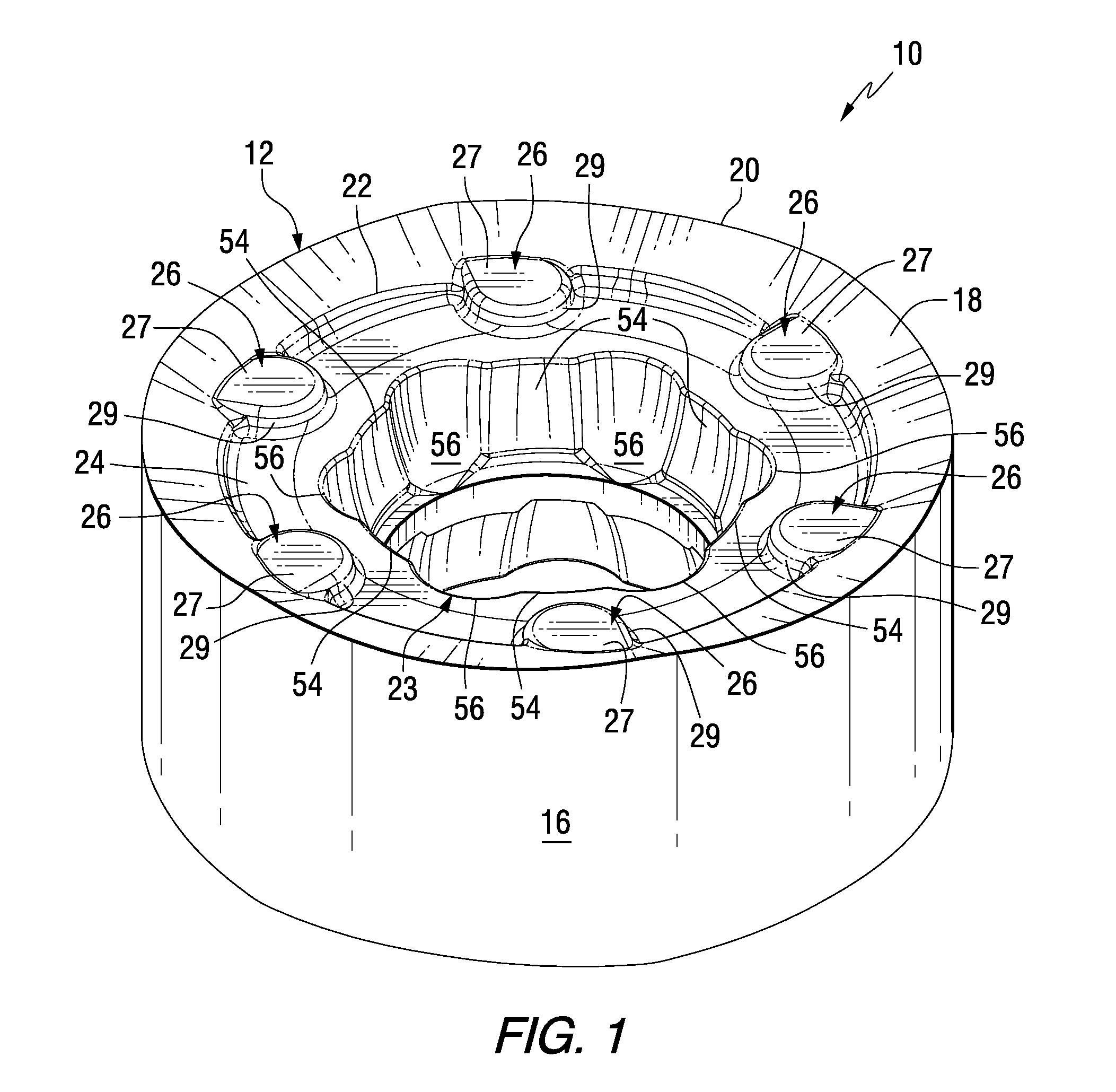

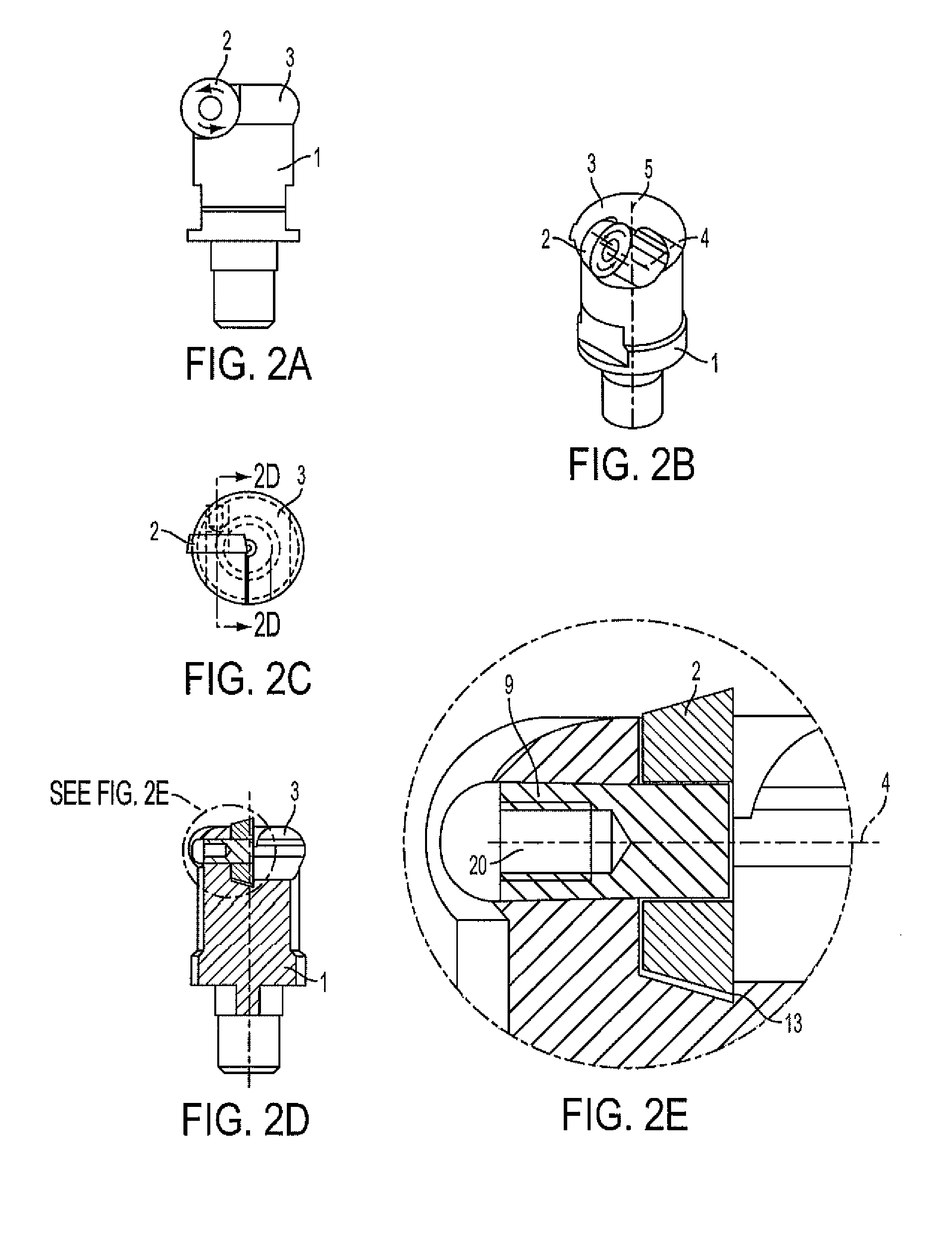

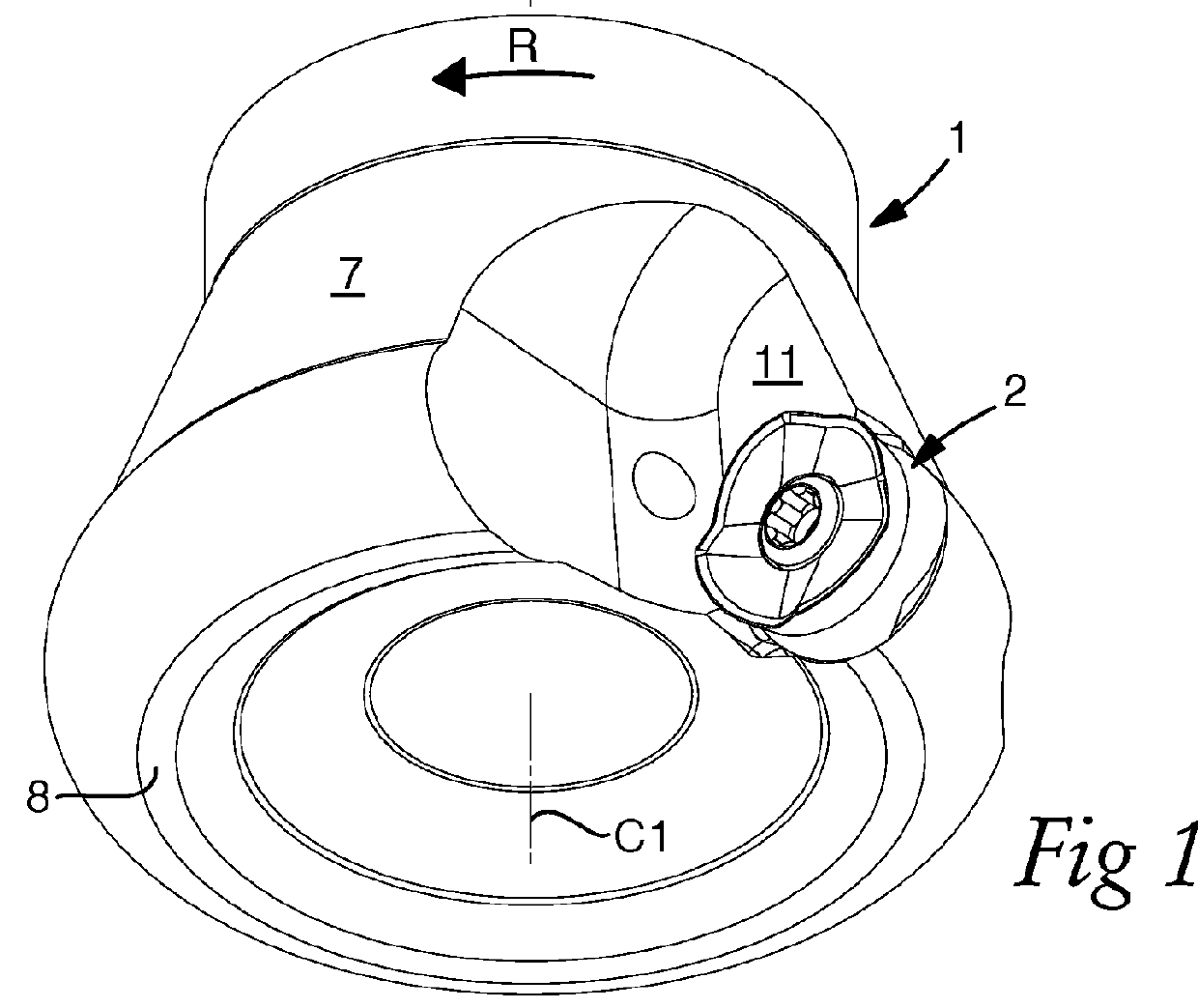

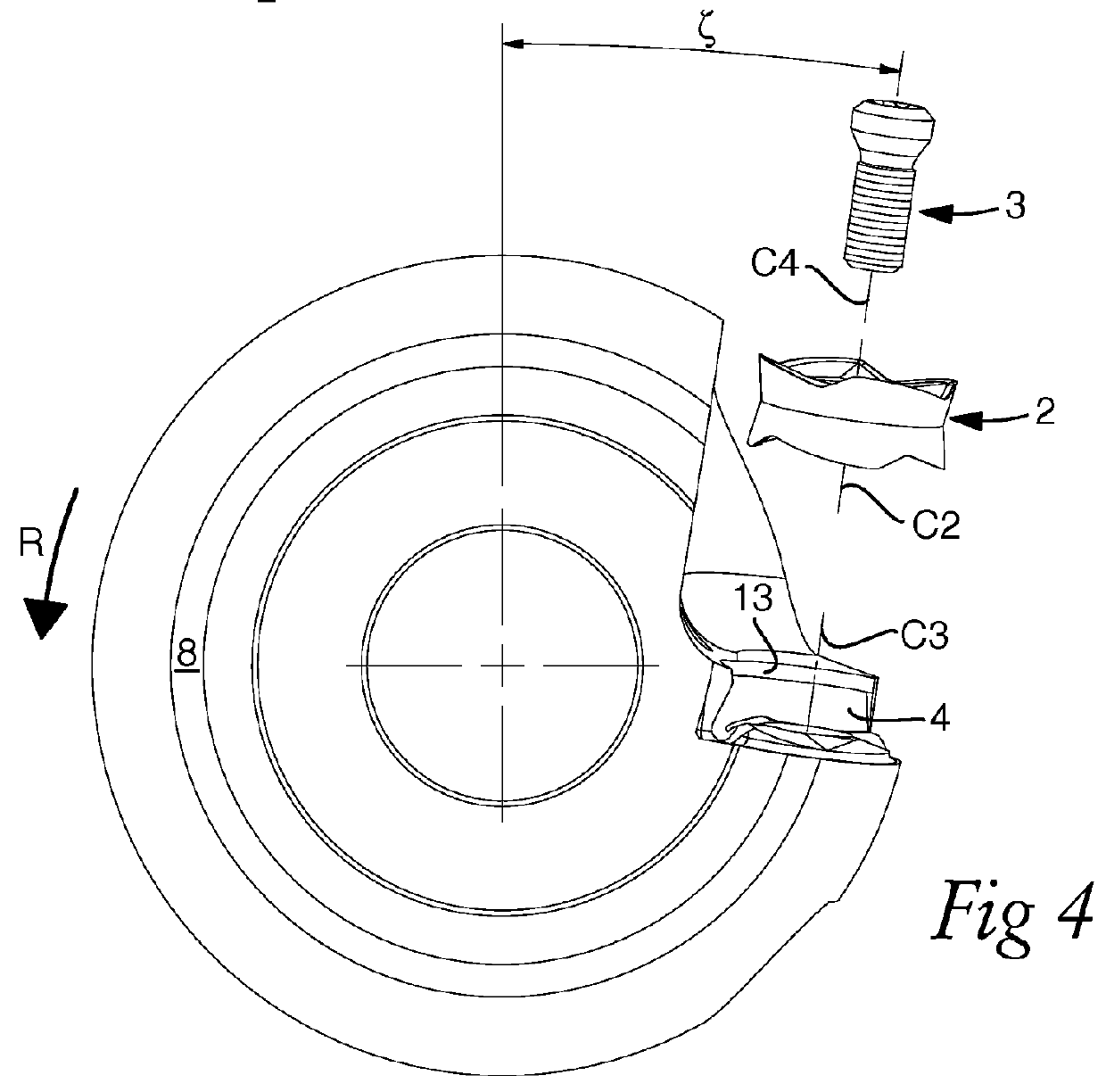

A round cutting insert with an anti-rotation feature. The round cutting insert includes a plurality of projections formed on a first surface and another plurality of projections formed on an opposing surface. The round cutting insert is reversible and indexable. The round cutting insert is removably received in an insert receiving pocket in a tool body wherein the insert receiving pocket includes a plurality of dimples for receiving one of the plurality of first projections or the plurality of second projections. This arrangement prevents rotation of the round cutting insert while mounted in the insert receiving pocket.

Owner:KENNAMETAL INC

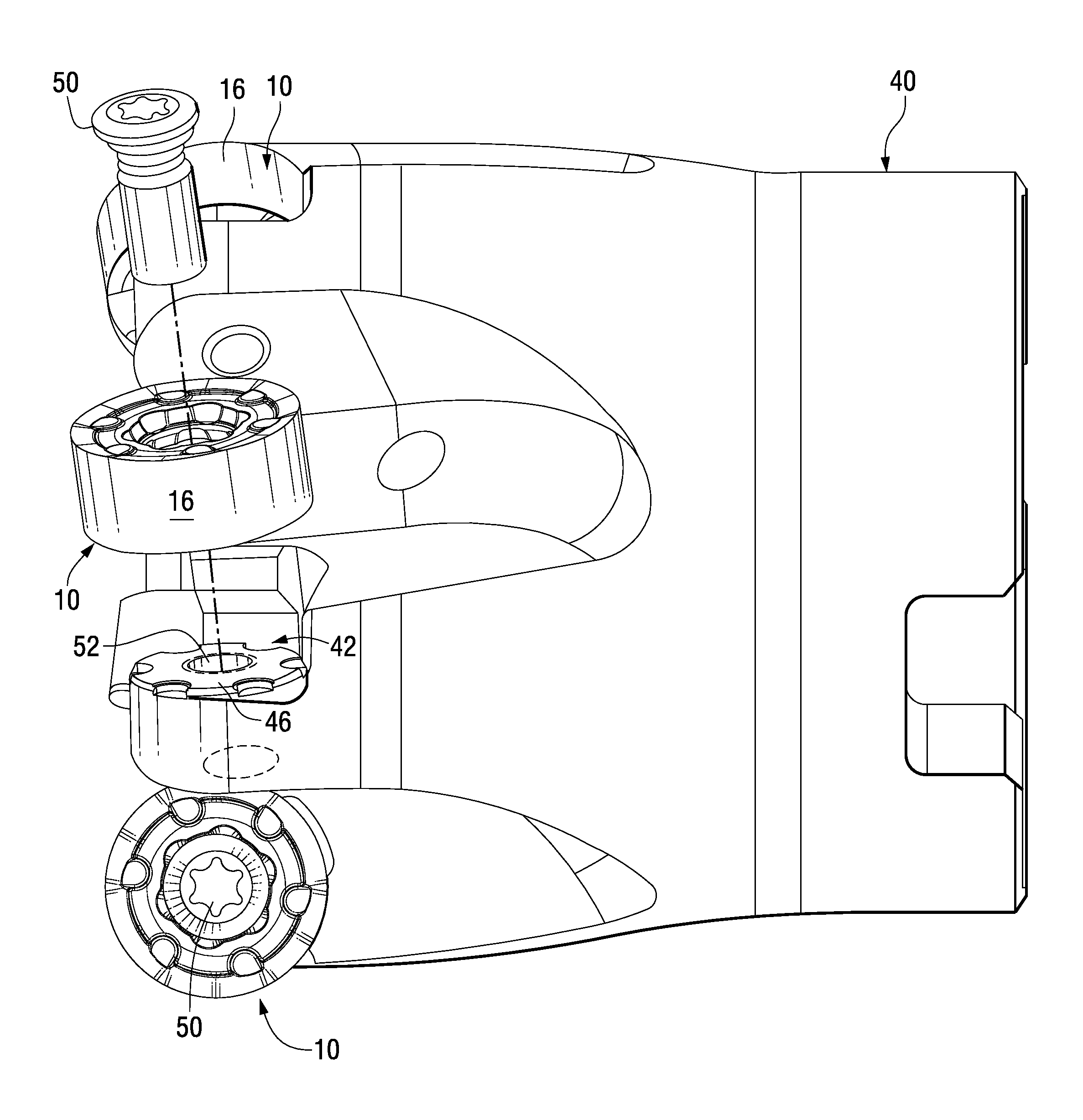

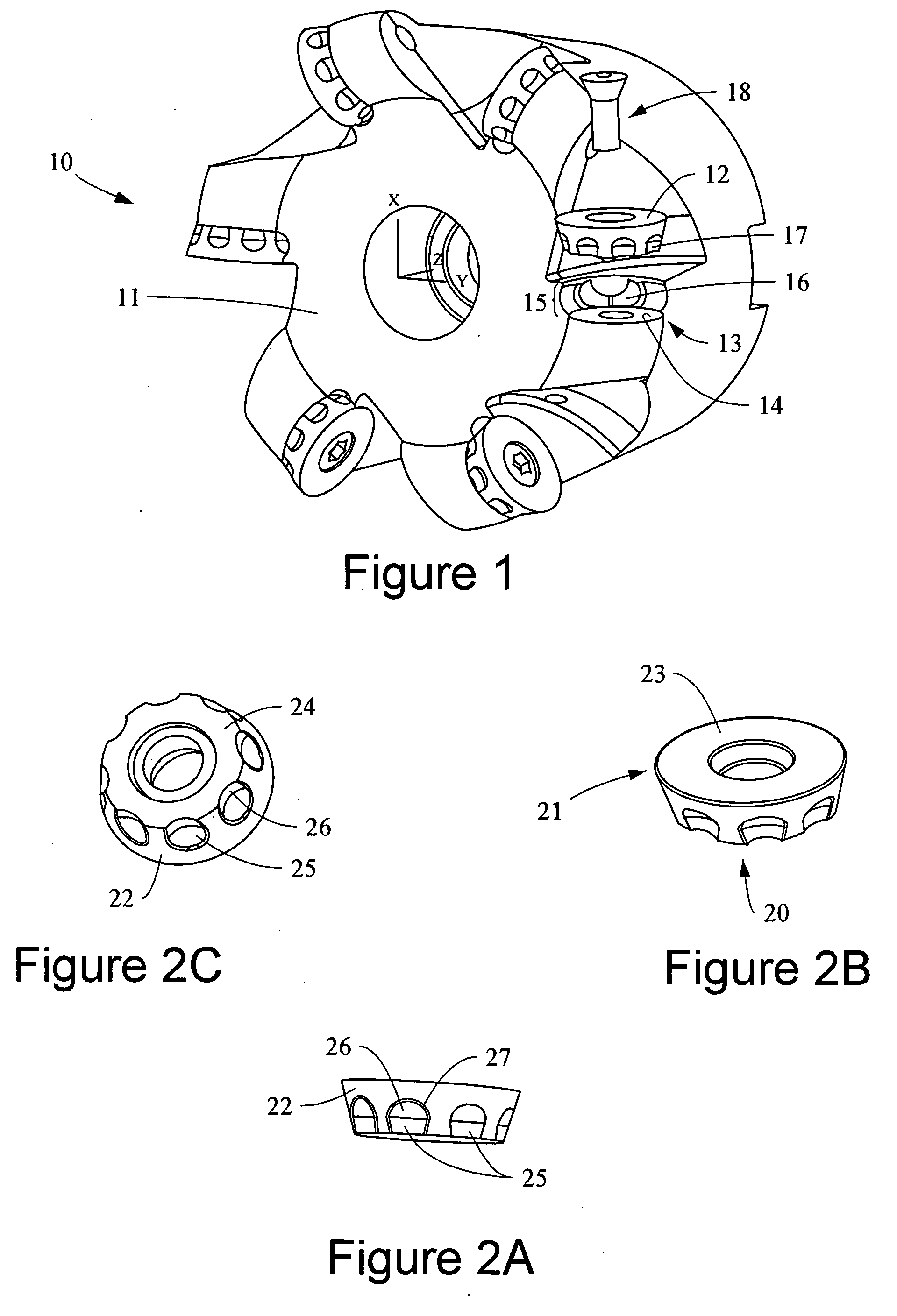

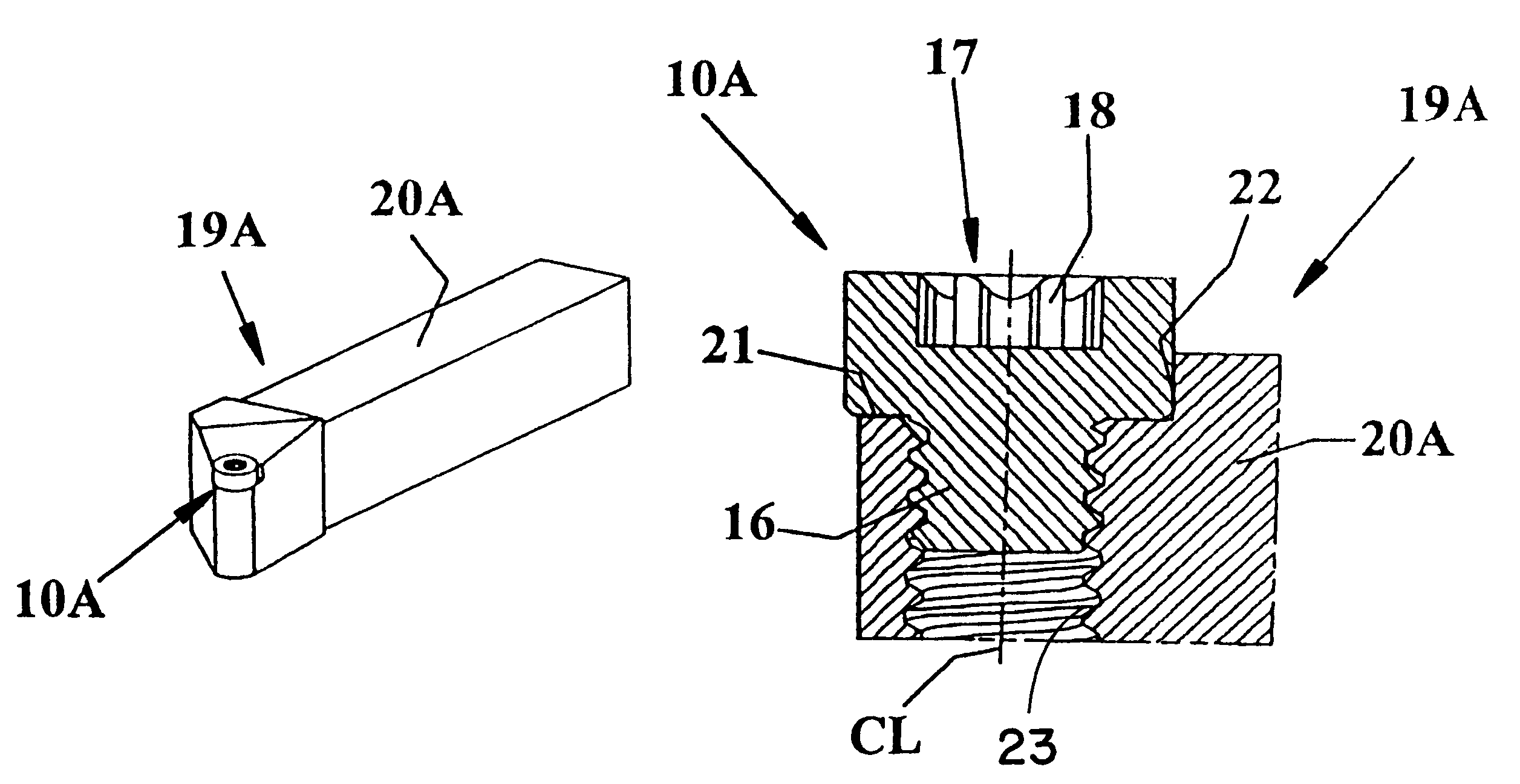

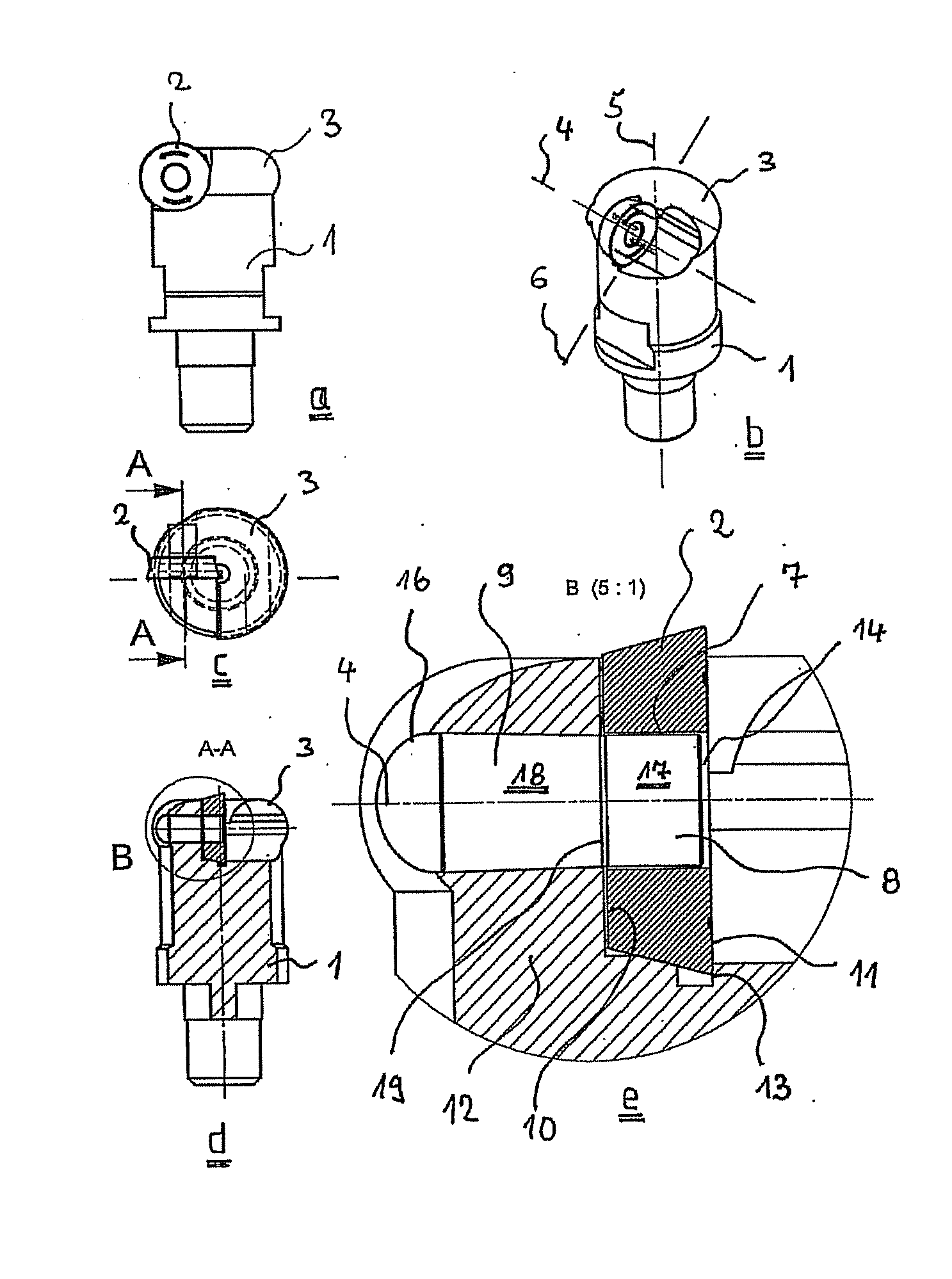

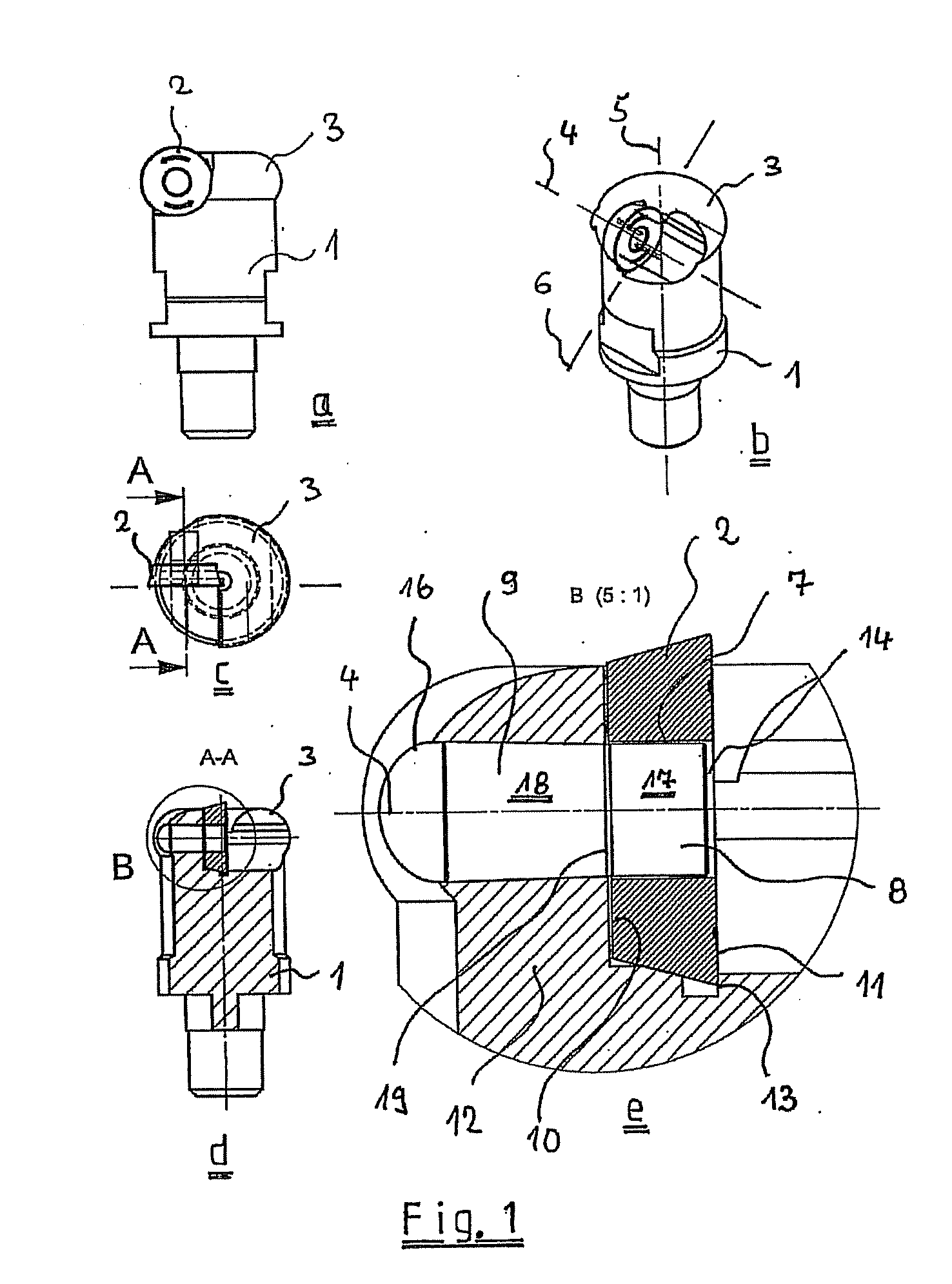

Antirotation tool holder and cutting insert

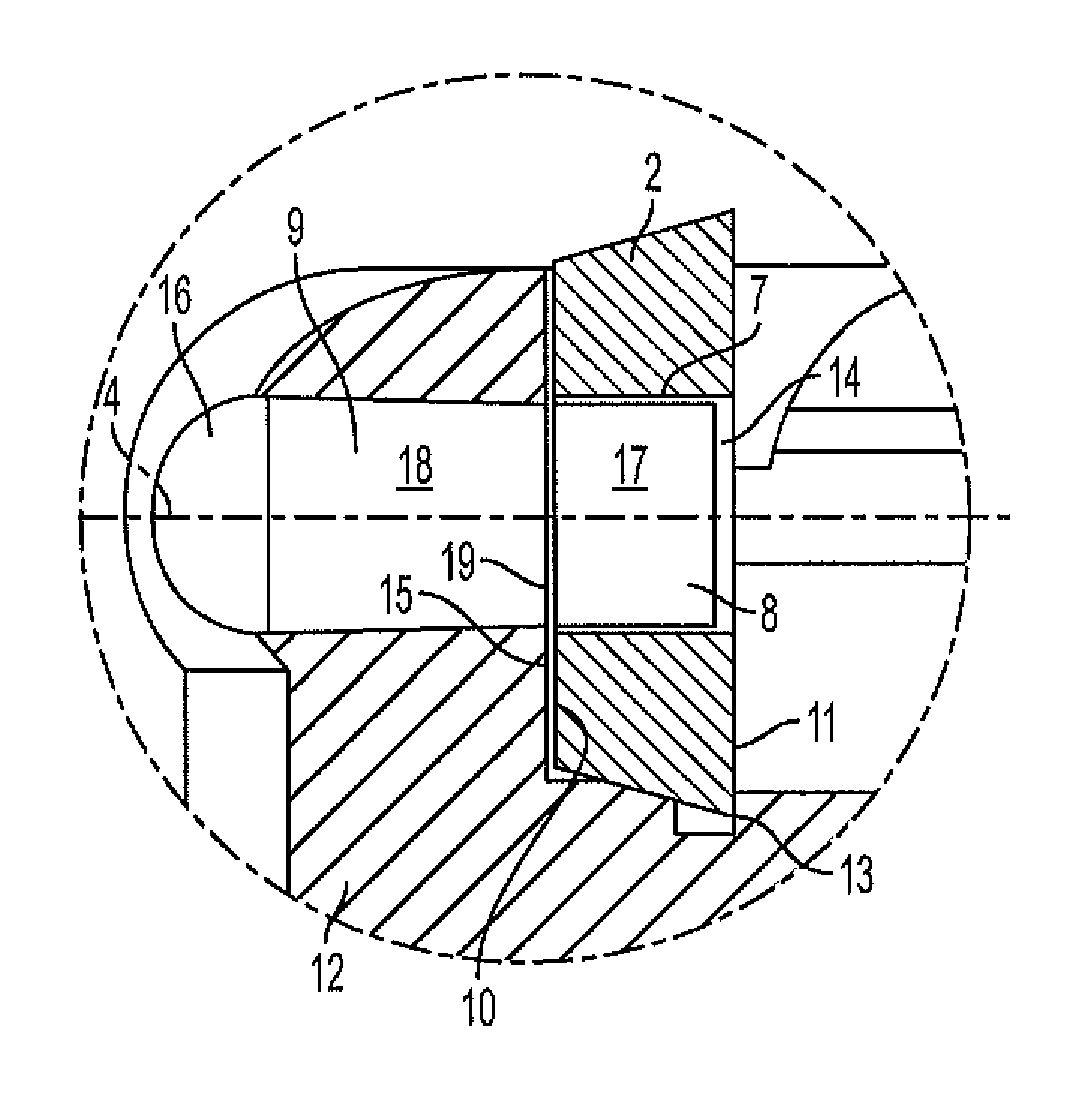

The present invention relates to embodiments of a cutting tool holder having at least one insert pocket, wherein at least one insert pocket comprises a side surface and at least one antirotation stop protruding from the side surface. The antirotation stop may comprise at least two substantially planar surfaces. In certain embodiments, the cutting tool holder may have a pocket which comprises a bottom surface and an antirotation stop having three substantially planar surfaces that are substantially perpendicular to the bottom surface. The antirotation stop may be integral to the tool holder or may be produced separately and attached, either permanently or temporarily, to the tool holder. Embodiments may further comprise additional antirotation stops if desired by the machining application. In one embodiment, the cutting tool holder includes an insert pocket in the tool holder and at least one antirotation stop protruding from at least one of a side wall and the bottom surface of the insert pocket, wherein the antirotation stop comprises at least two substantially planar surfaces. A cutting insert may be secured in the tool holder, wherein the cutting insert has a recess having a shape that is non-complementary to the shape of the antirotation stop and may be made from tungsten based carbide or cermet.

Owner:KENNAMETAL INC

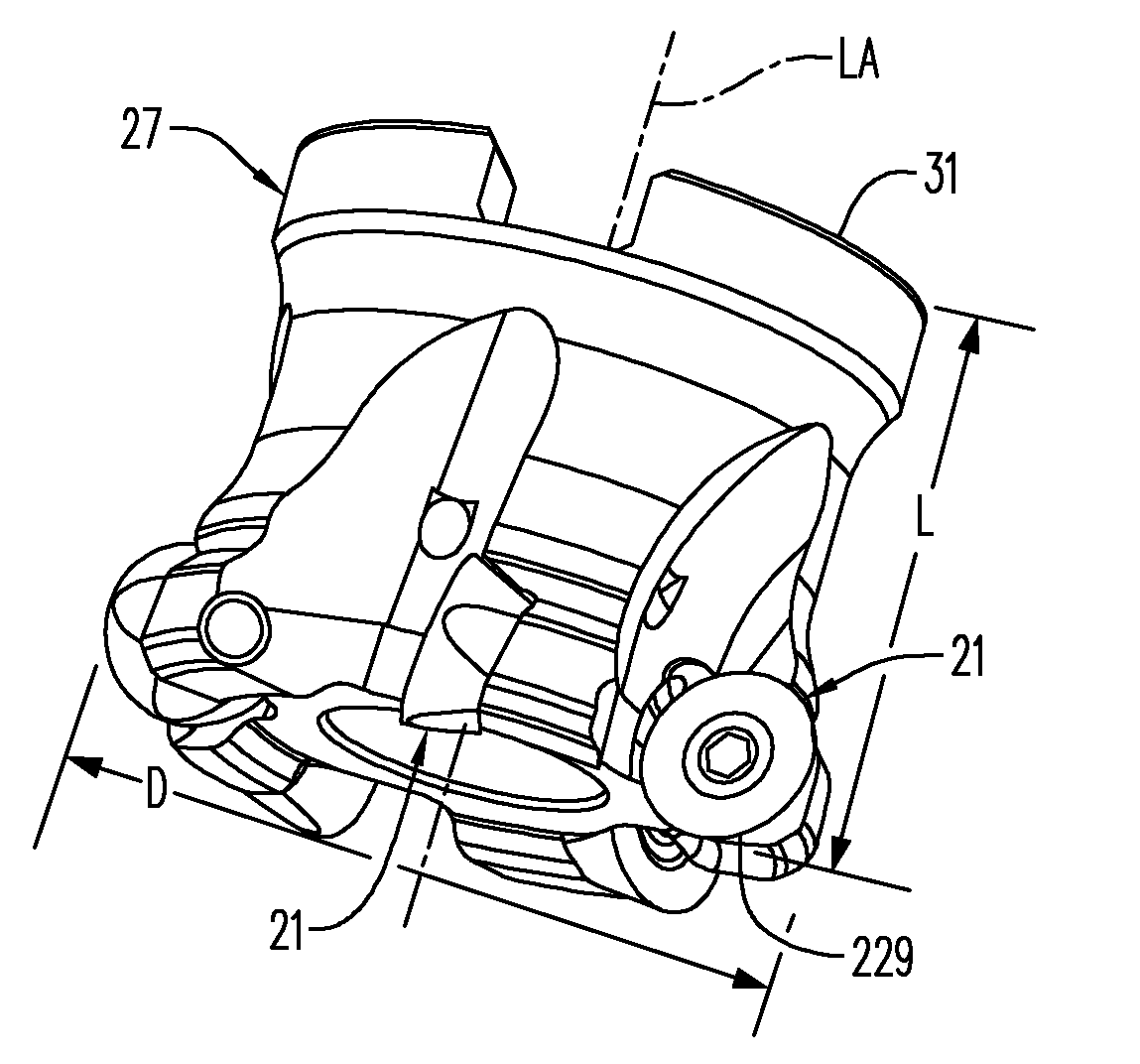

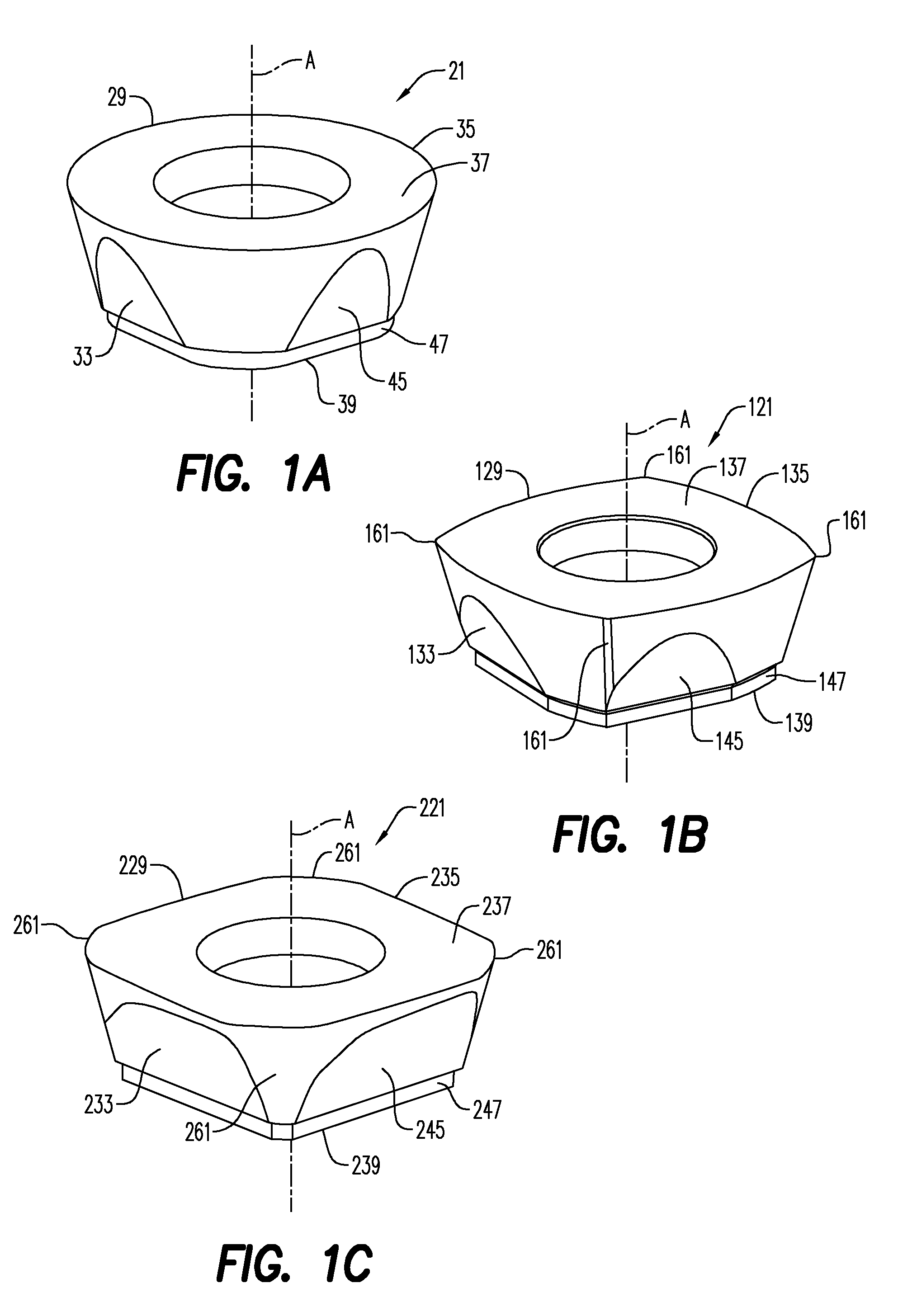

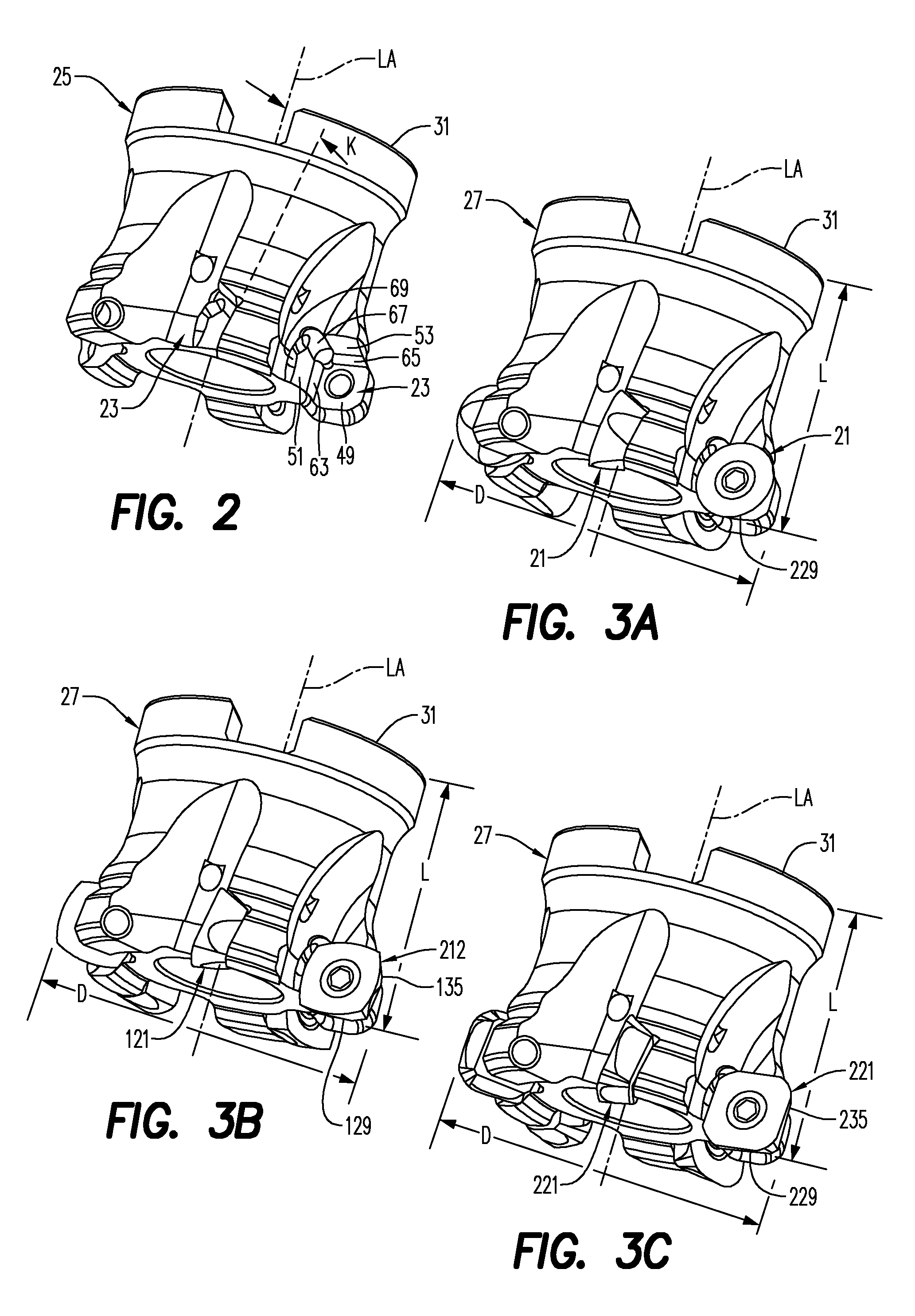

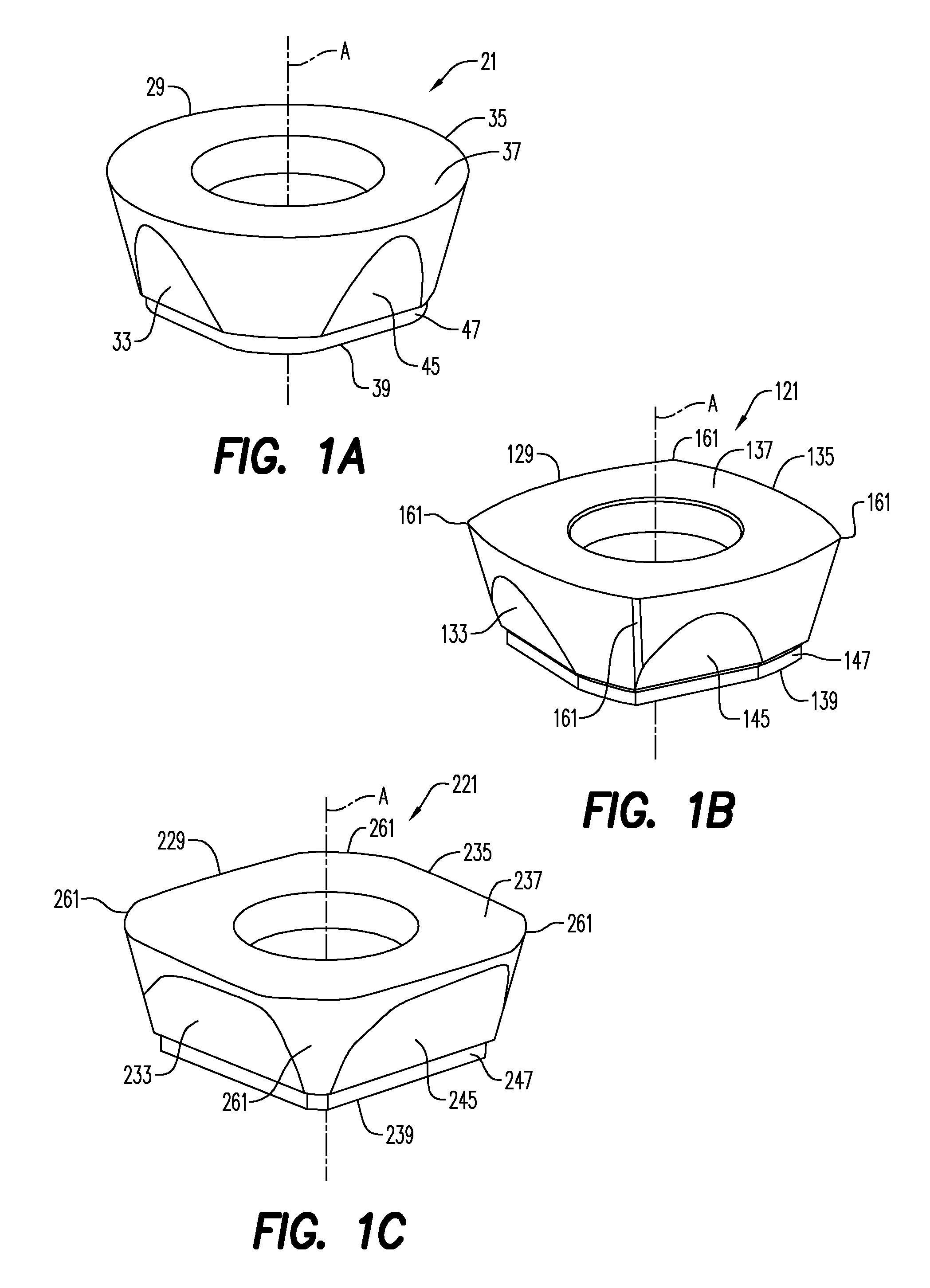

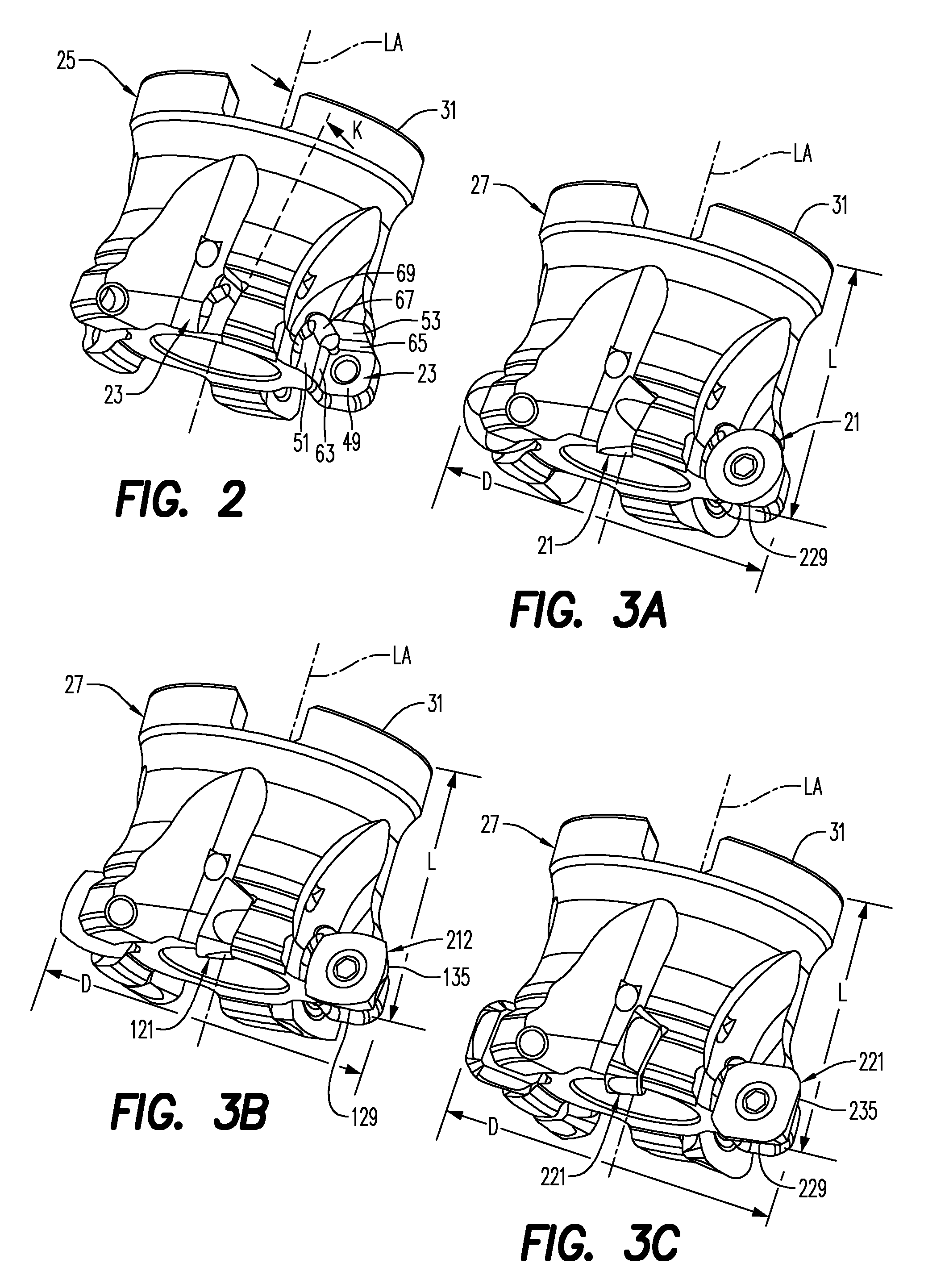

Round cutting insert with reverse Anti-rotation feature

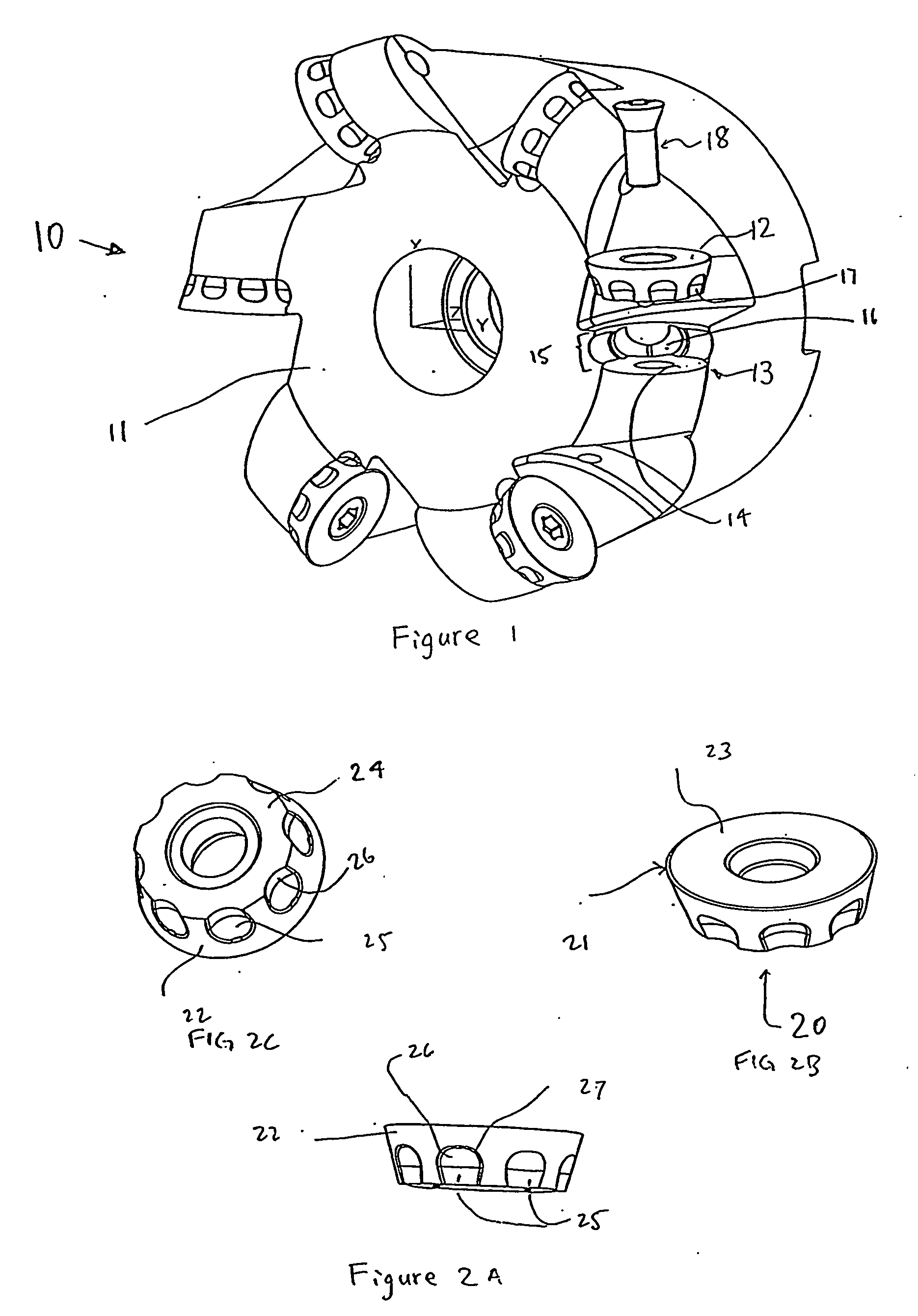

A round cutting insert with a reverse anti-rotation feature that can be manufactured easily and inexpensively is disclosed. The round cutting insert includes a plurality of dimples formed on a first surface and another plurality of dimples formed on a second, opposing surface. The round insert is reversible and indexable. The round cutting insert is removable received in an insert receiving pocket in a tool body. The insert receiving pocket includes a single projection that is capable of being received in one of the plurality of dimples. The cooperation between the projection and one of the plurality of dimples prevents rotation of the round cutting insert when mounted in the insert receiving pocket. The plurality of dimples and the projection can be any desirable complimentary shape, such as a slot, a V-shape, a wagon wheel, a sports wheel, a pyramid, and the like.

Owner:KENNAMETAL INC

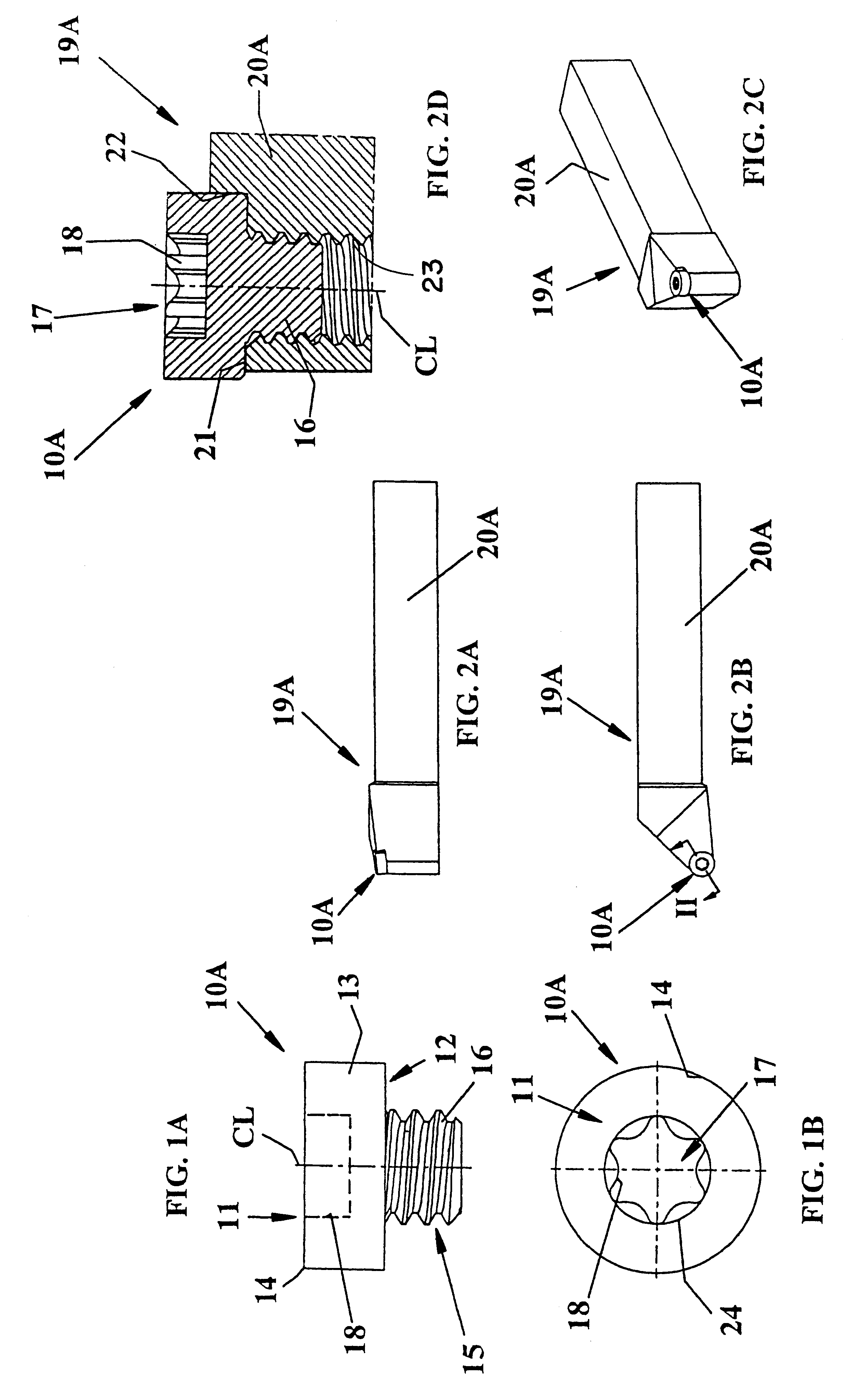

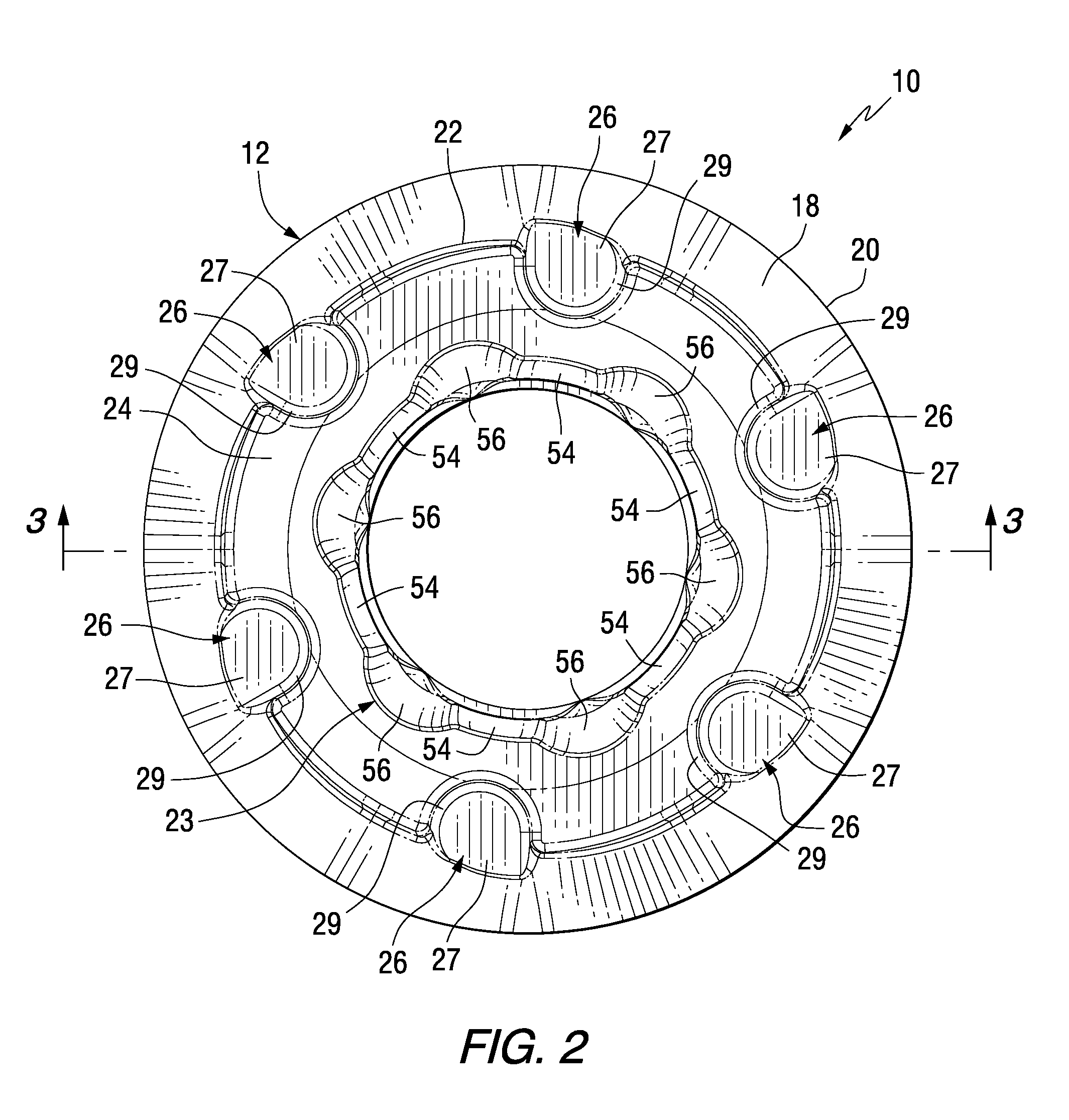

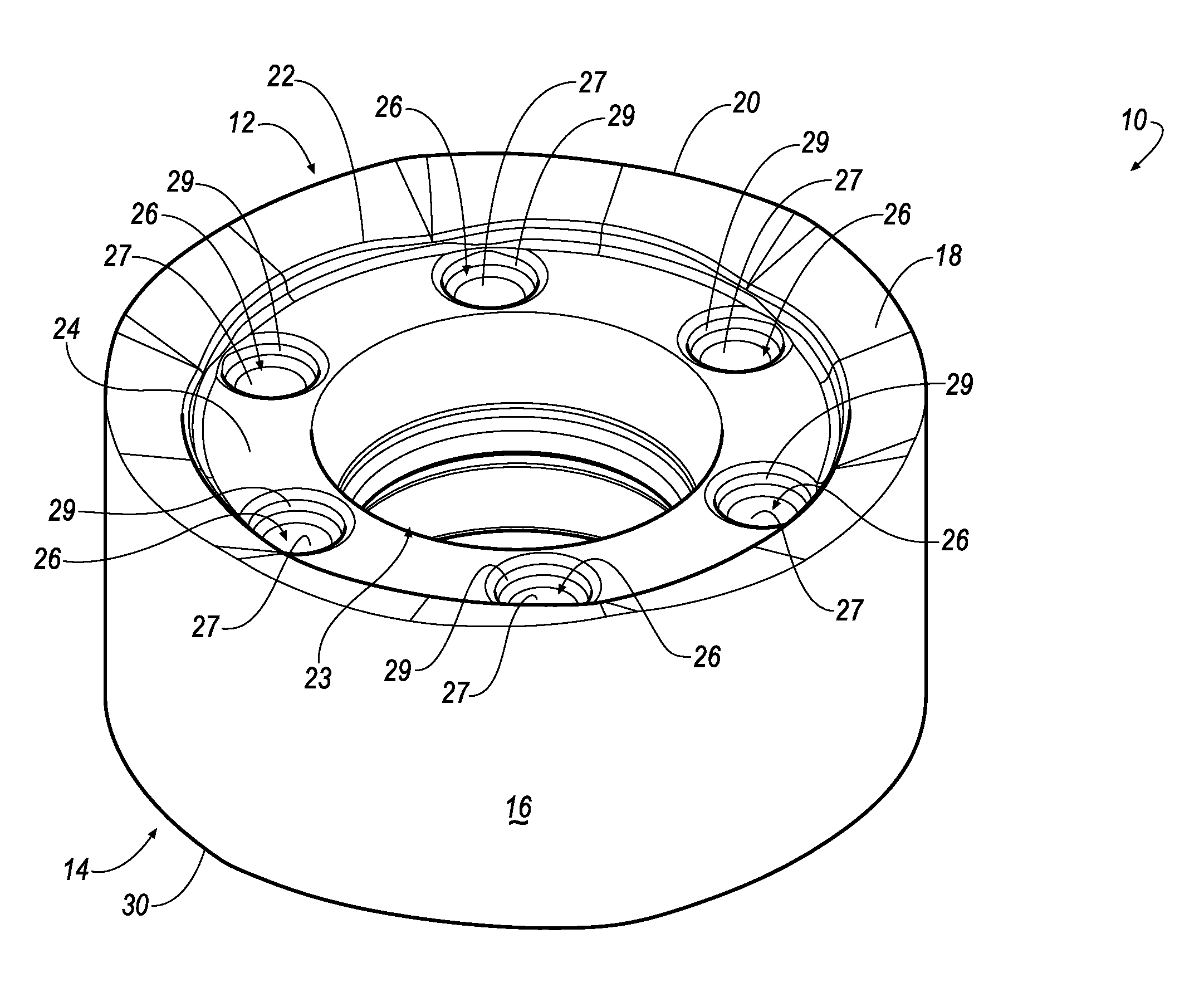

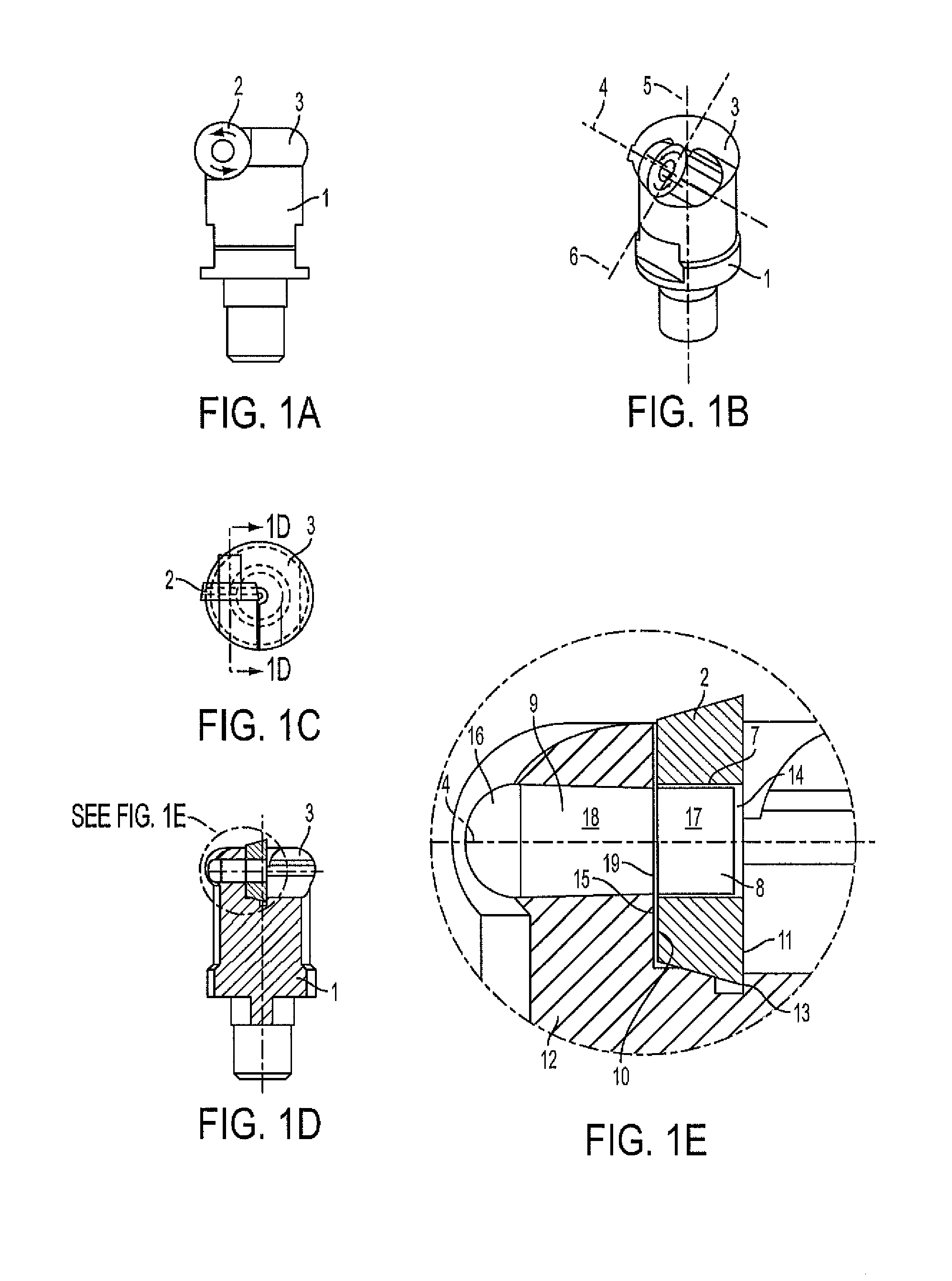

Cemented carbide cutting insert having integral structure for securing the insert in a holder

InactiveUS6273650B1High strengthEasy to operateTool workpiece connectionTransportation and packagingAlloyEngineering

A cutting insert intended for chip removing machining includes a body forming at least one cutting edge, a securing structure such as a helical thread disposed at one side of the body, and a key grip such as a profiled recess disposed at an opposite side. The insert is formed of injection molded cemented carbide such that the body, the securing structure, and the key grip are all integral with one another. The insert is secured in a holder by rotating the insert using a key which engages the key grip, whereupon the securing structure engages a complementary securing structure on the holder to pull the insert body against the holder.

Owner:SECO TOOLS AB

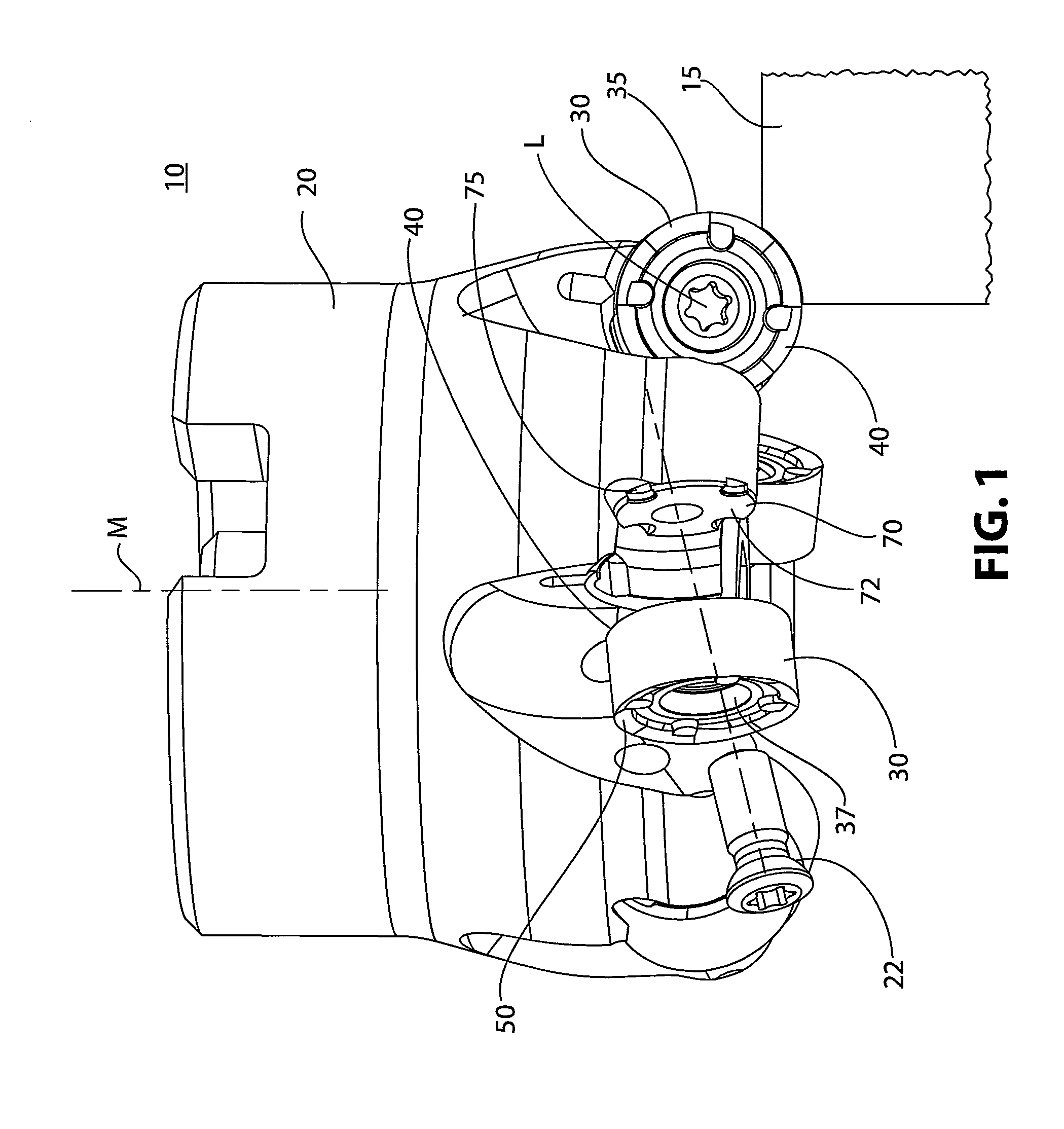

Antirotation tool holder and cutting insert

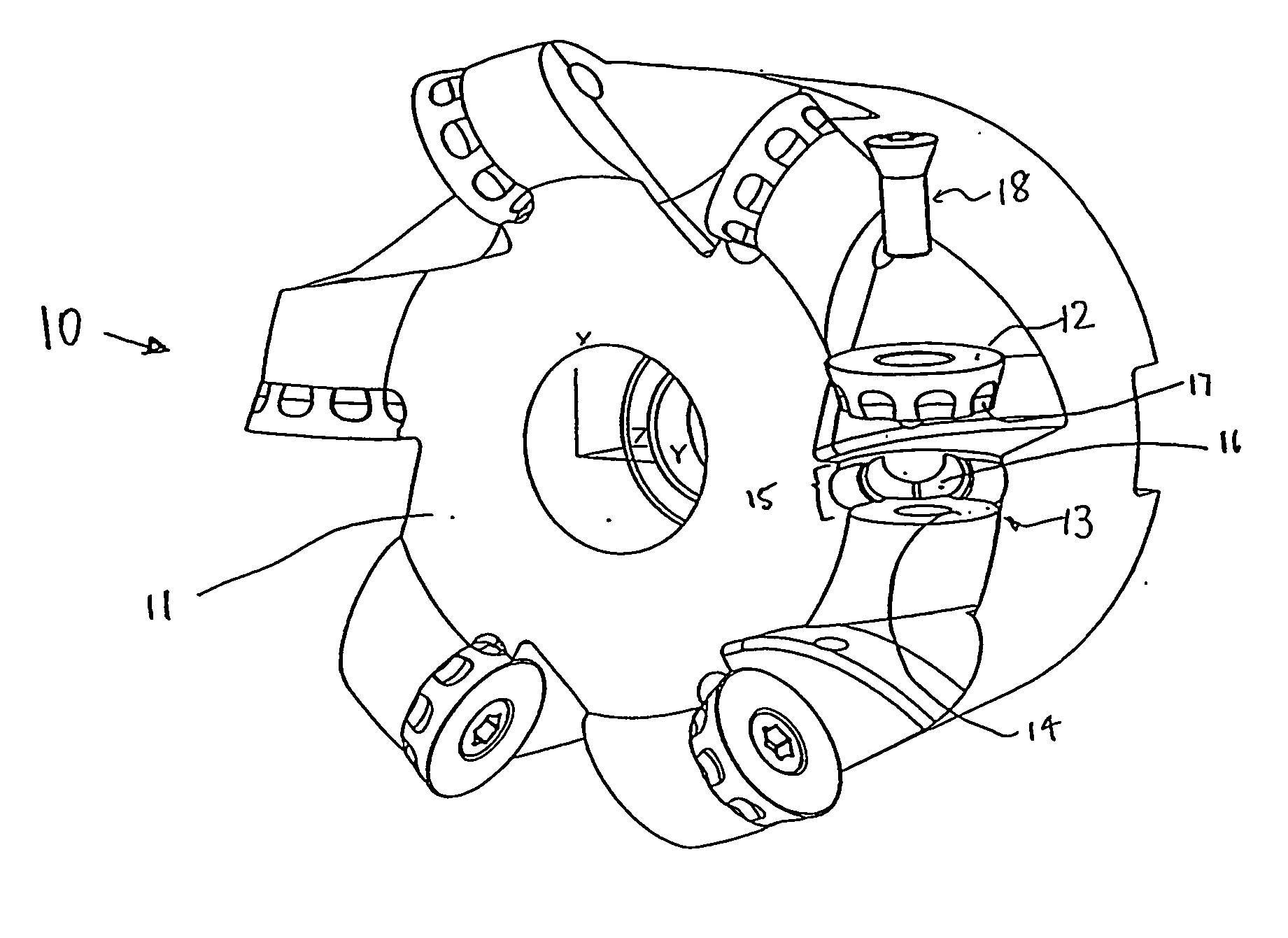

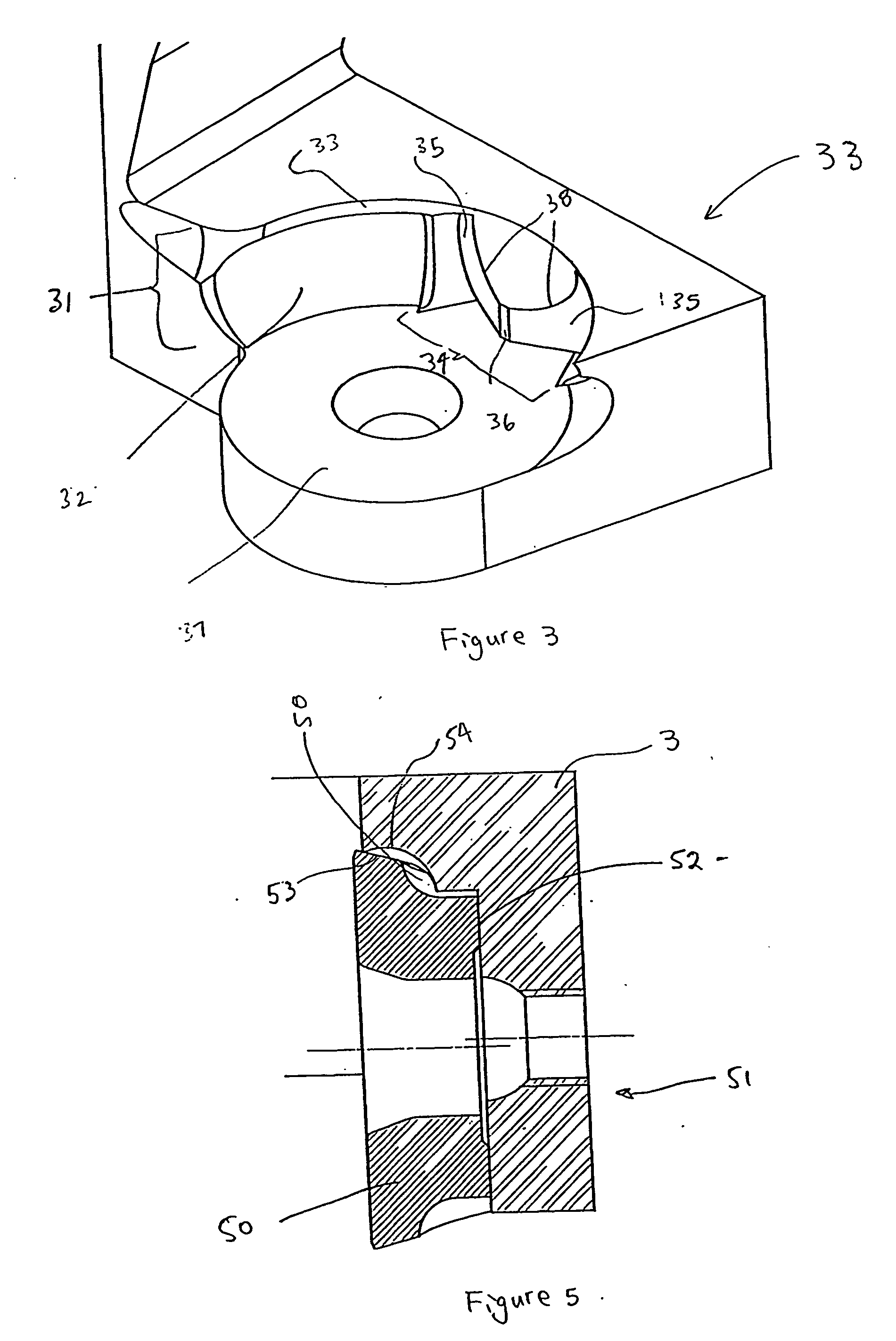

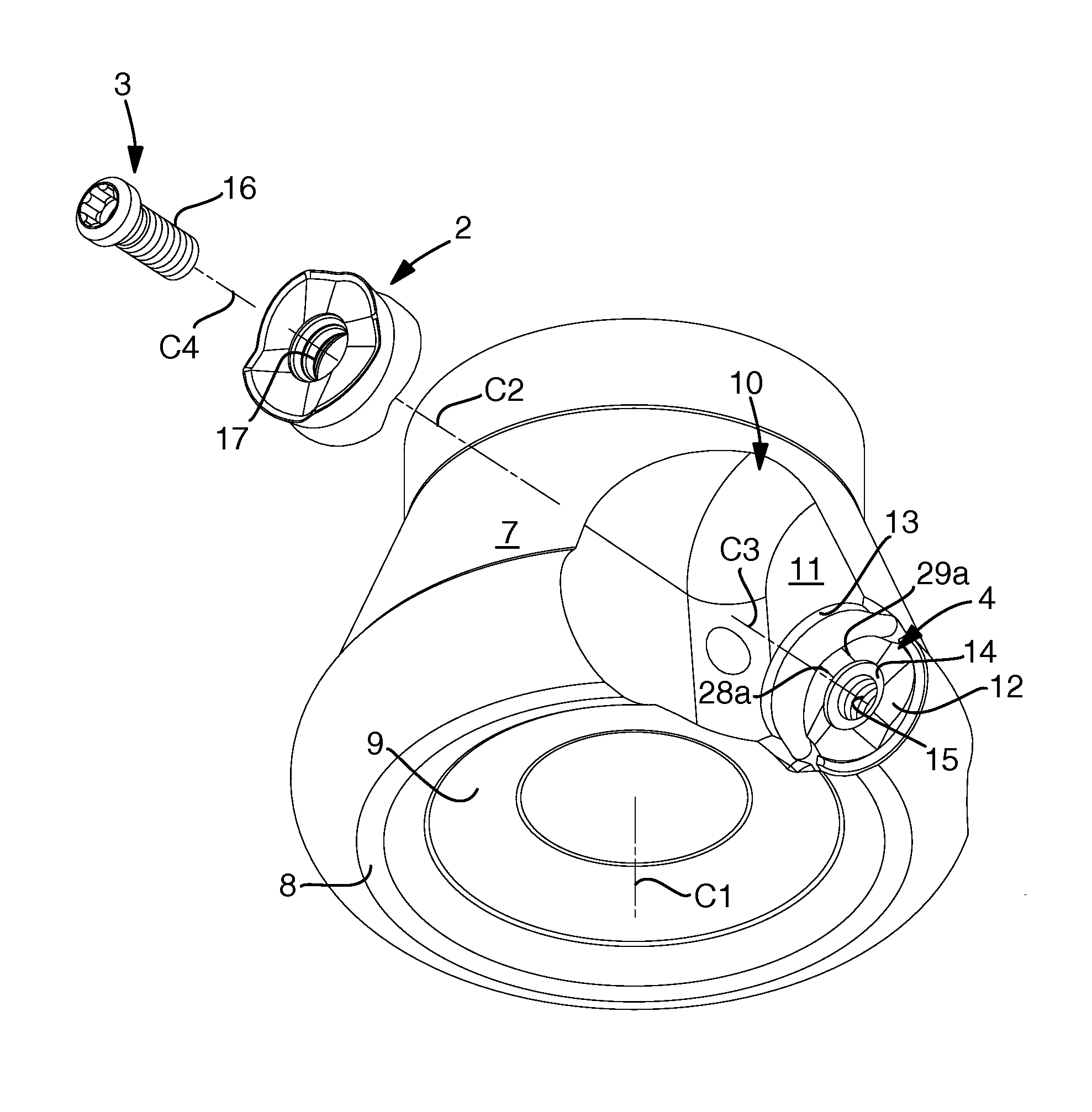

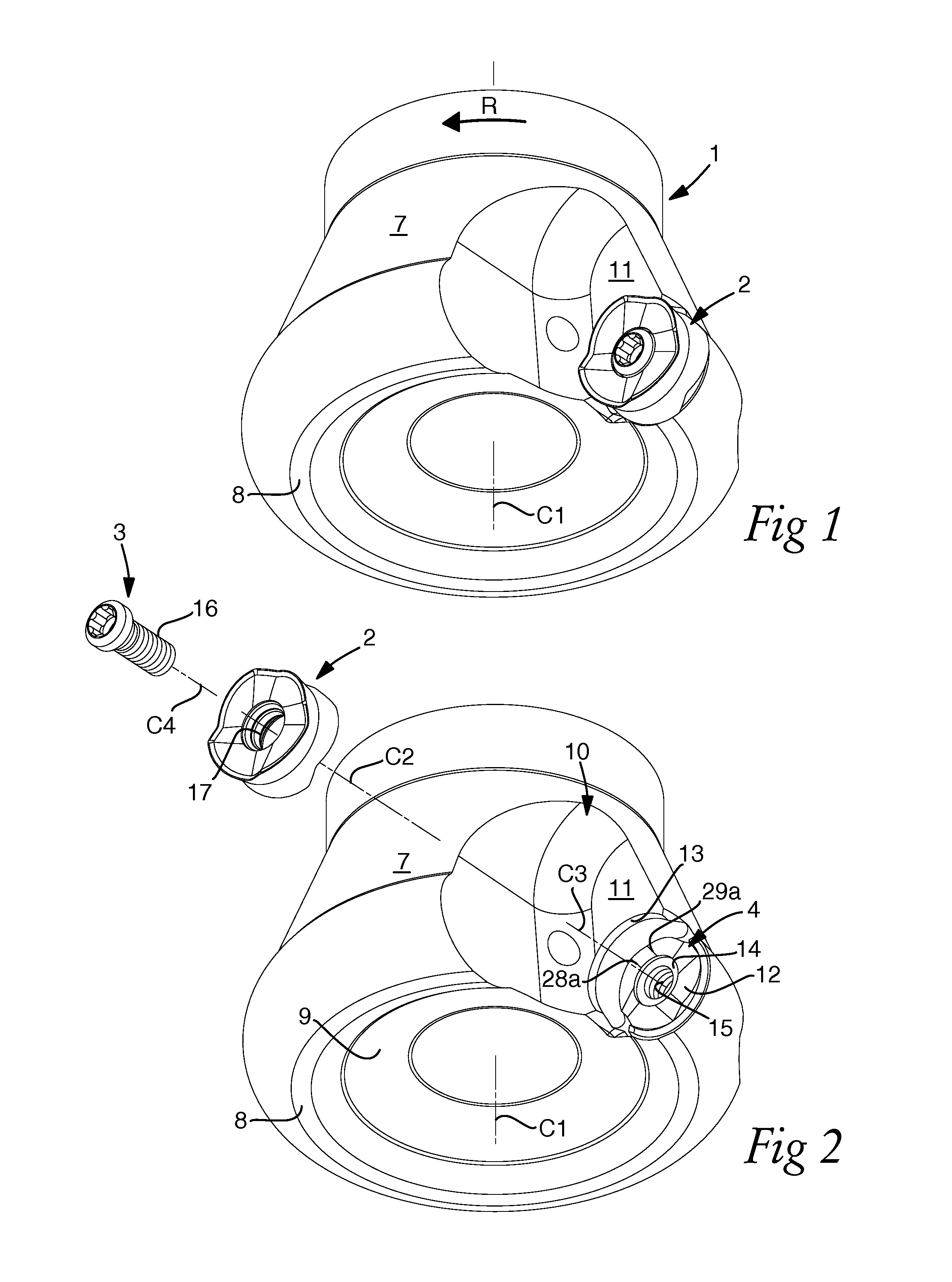

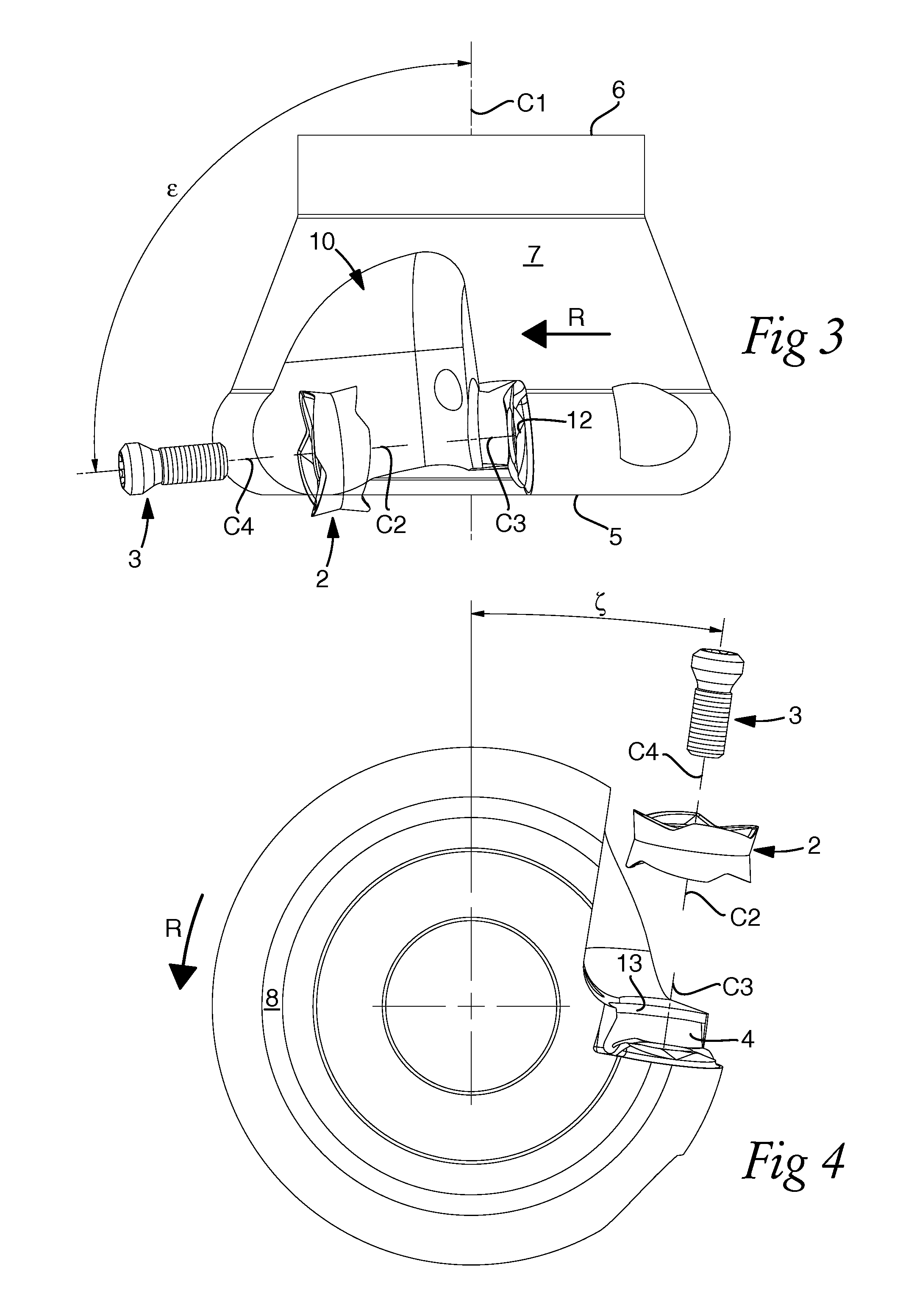

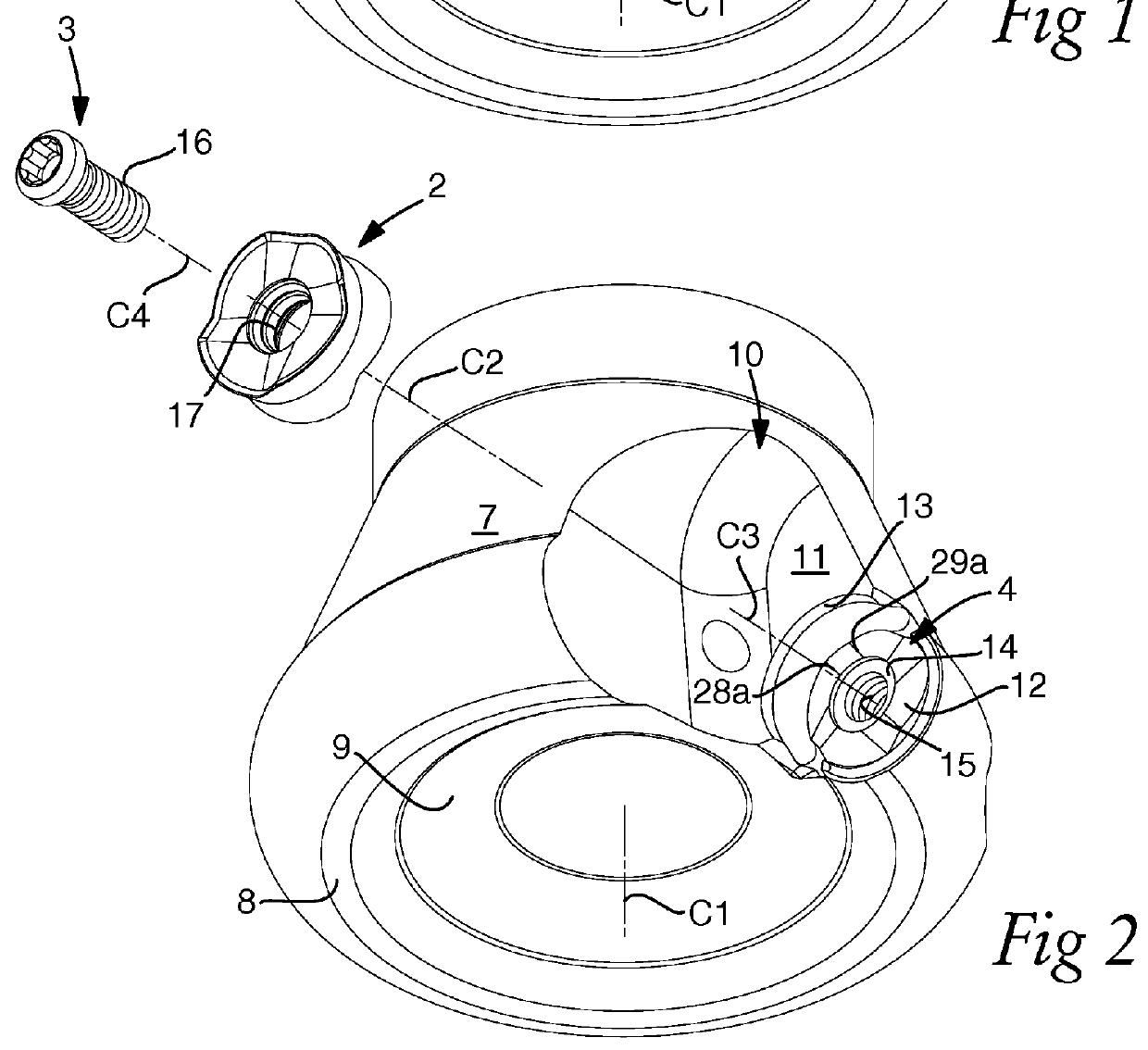

The present invention relates to embodiments of a cutting tool holder (10) having at least one insert pocket (13), wherein at least one insert pocket comprises a side surface (15) and at least one antirotation stop (16) protruding from the side surface. The antirotation stop may comprise at least two substantially planar surfaces. In certain embodiments, the cutting tool holder may have a pocket which comprises a bottom surface and an antirotation stop having three substantially planar surfaces that are substantially perpendicular to the bottom surface. The antirotation stop may be integral to the tool holder or may be produced separately and attached, either permanently or temporarily, to the tool holder. Embodiments may further comprise additional antirotation stops is desired by the machining application. In one embodiment, the cutting tool holder includes an insert pocket in the tool holder and at least one antirotation stop protruding from at least one of a side wall and the bottom surface of the insert pocket, wherein the antirotation stop comprises at least two substantially planar surfaces. A cutting insert (12) may be secured in the tool holder, wherein the cutting insert has a recess (17) having a shape that is non-complementary to the shape of the antirotation stop and may be made from tungsten based carbide or cermet.

Owner:KENNAMETAL INC

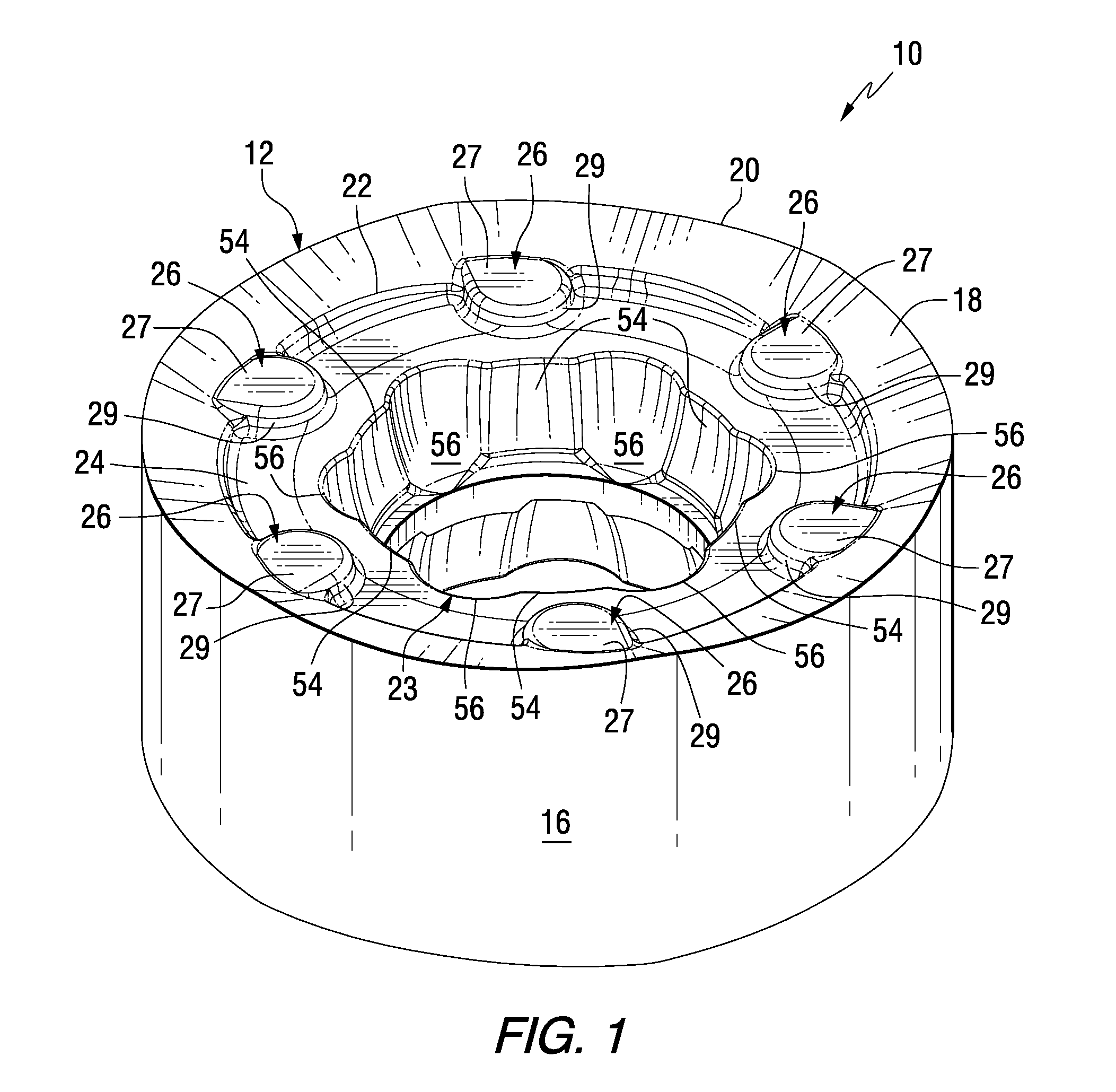

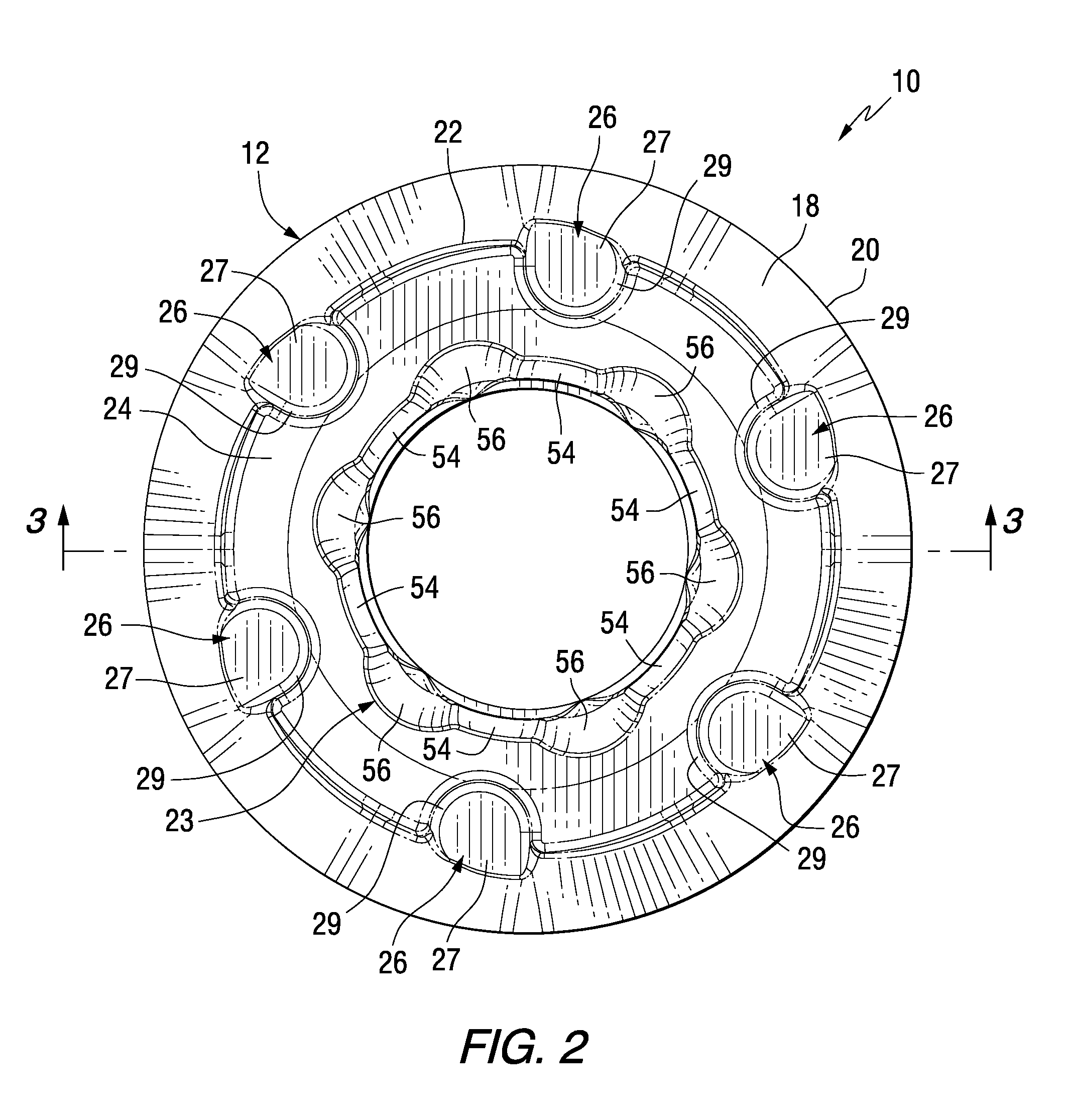

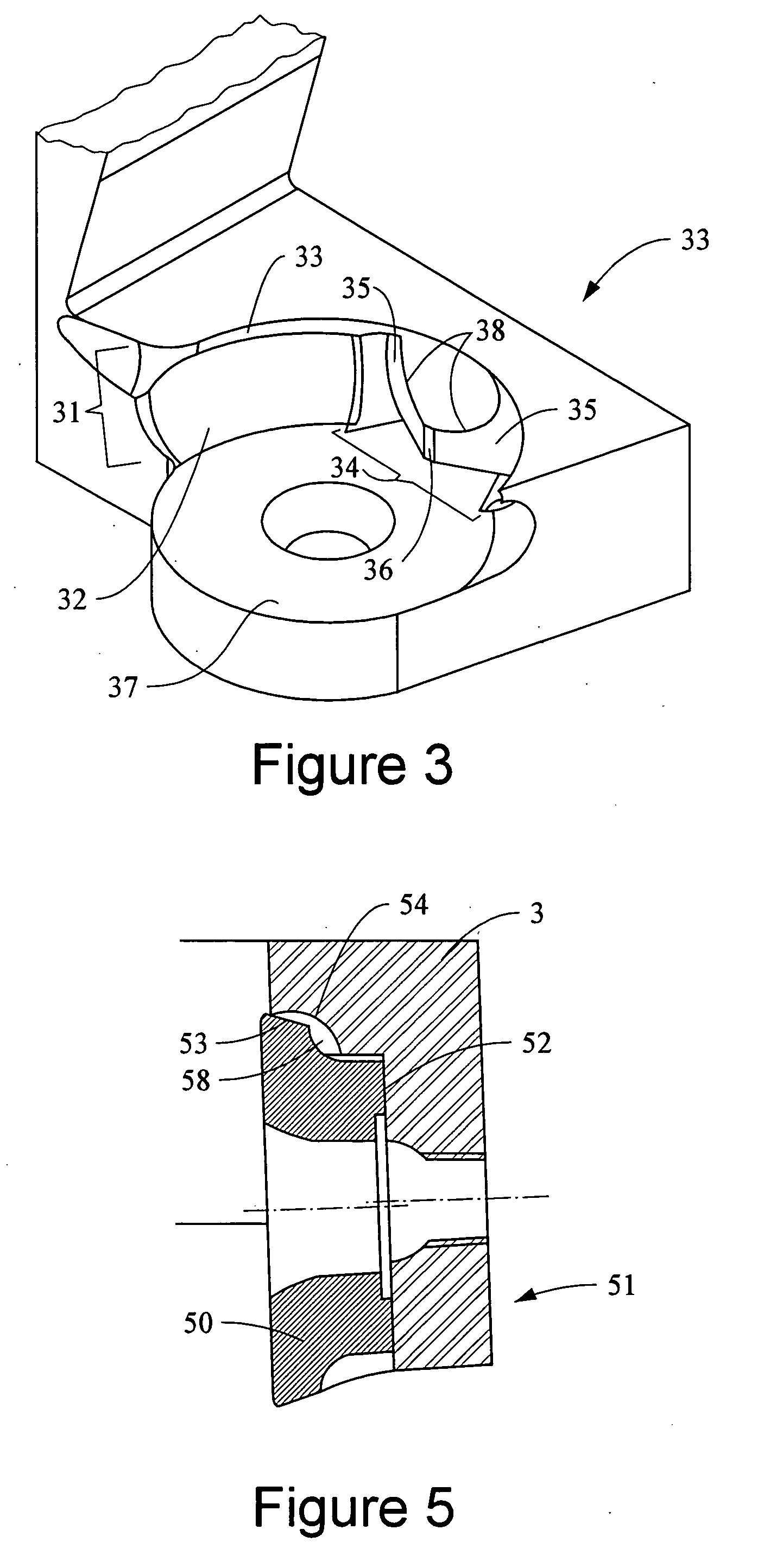

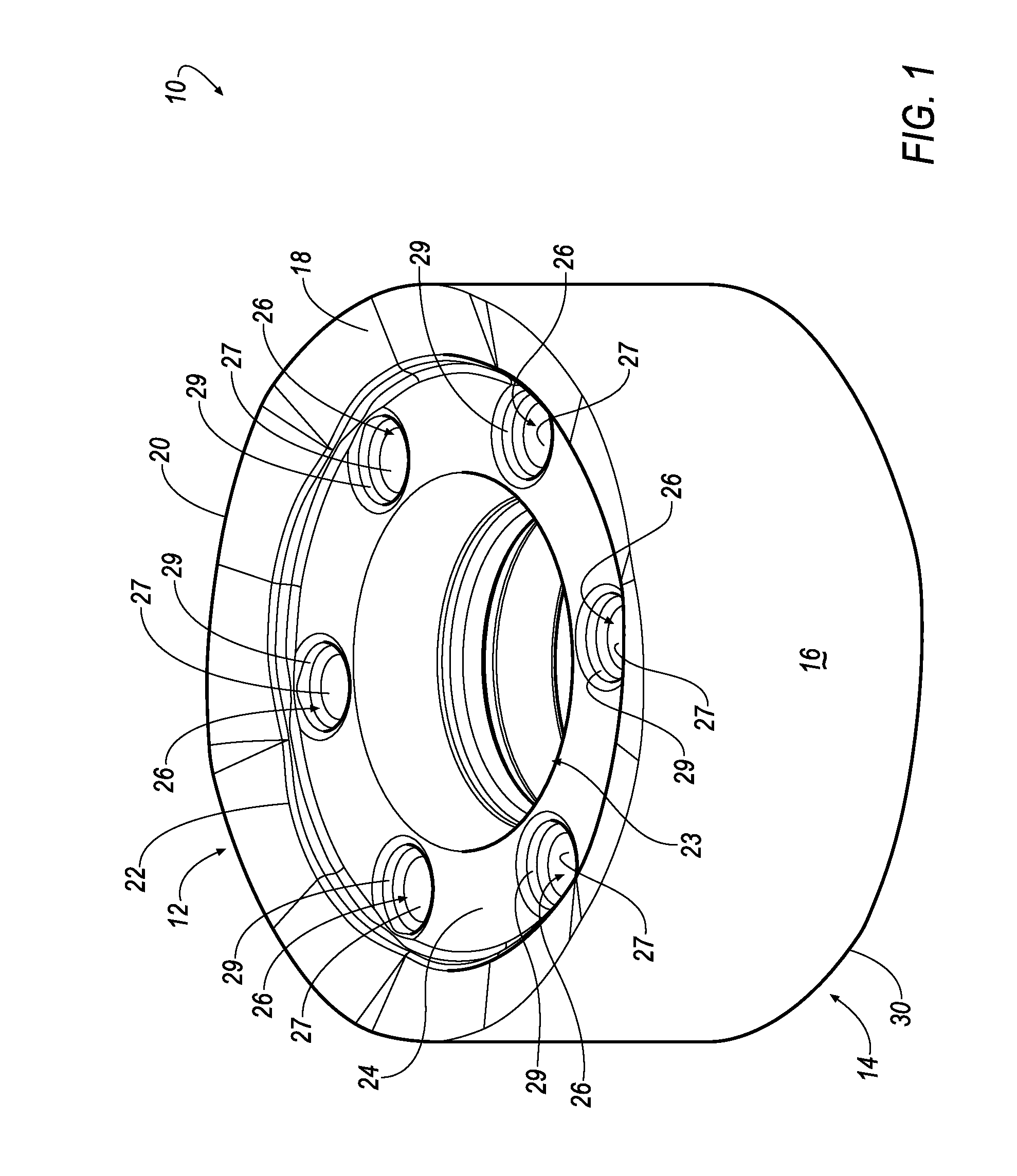

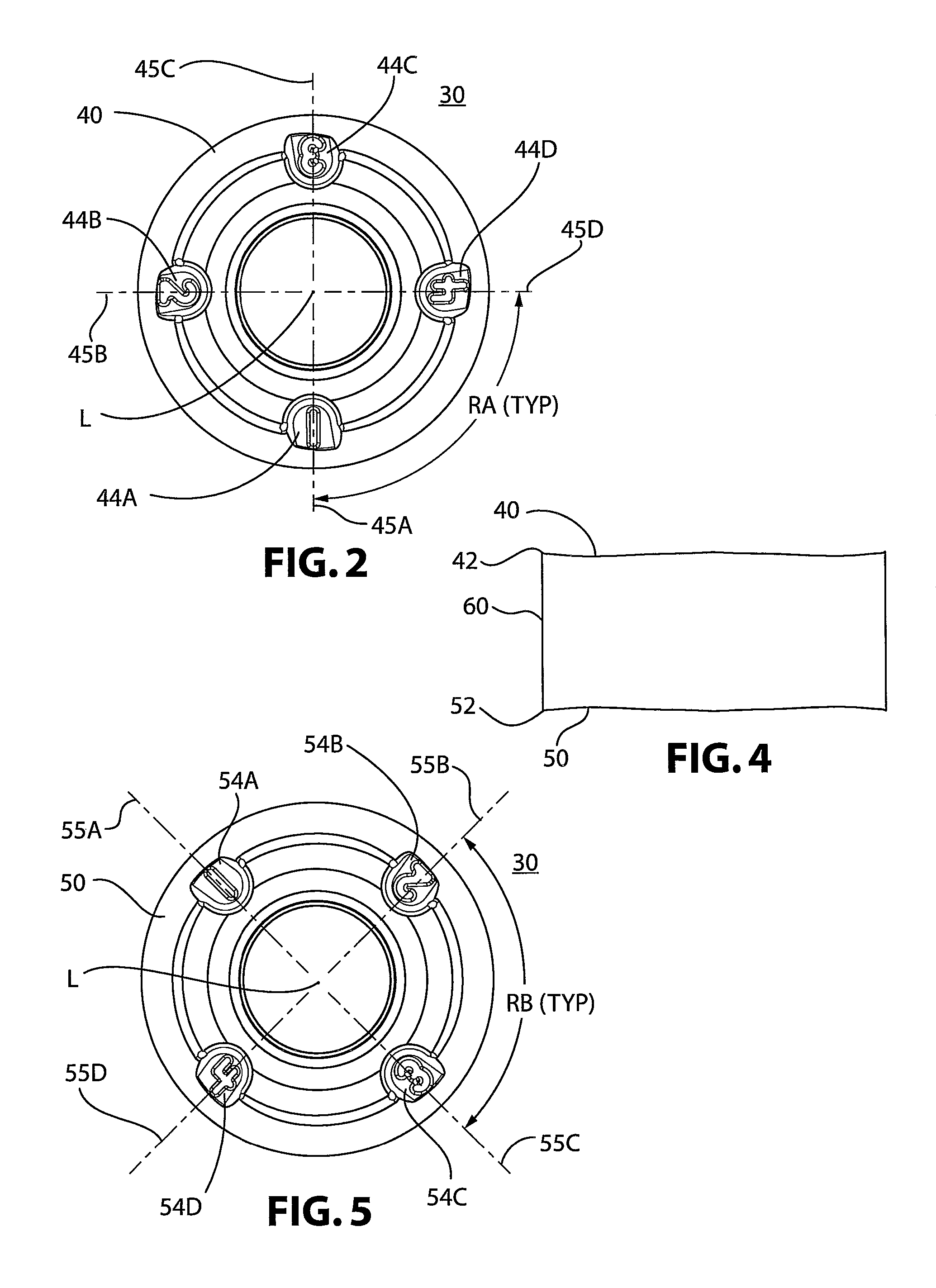

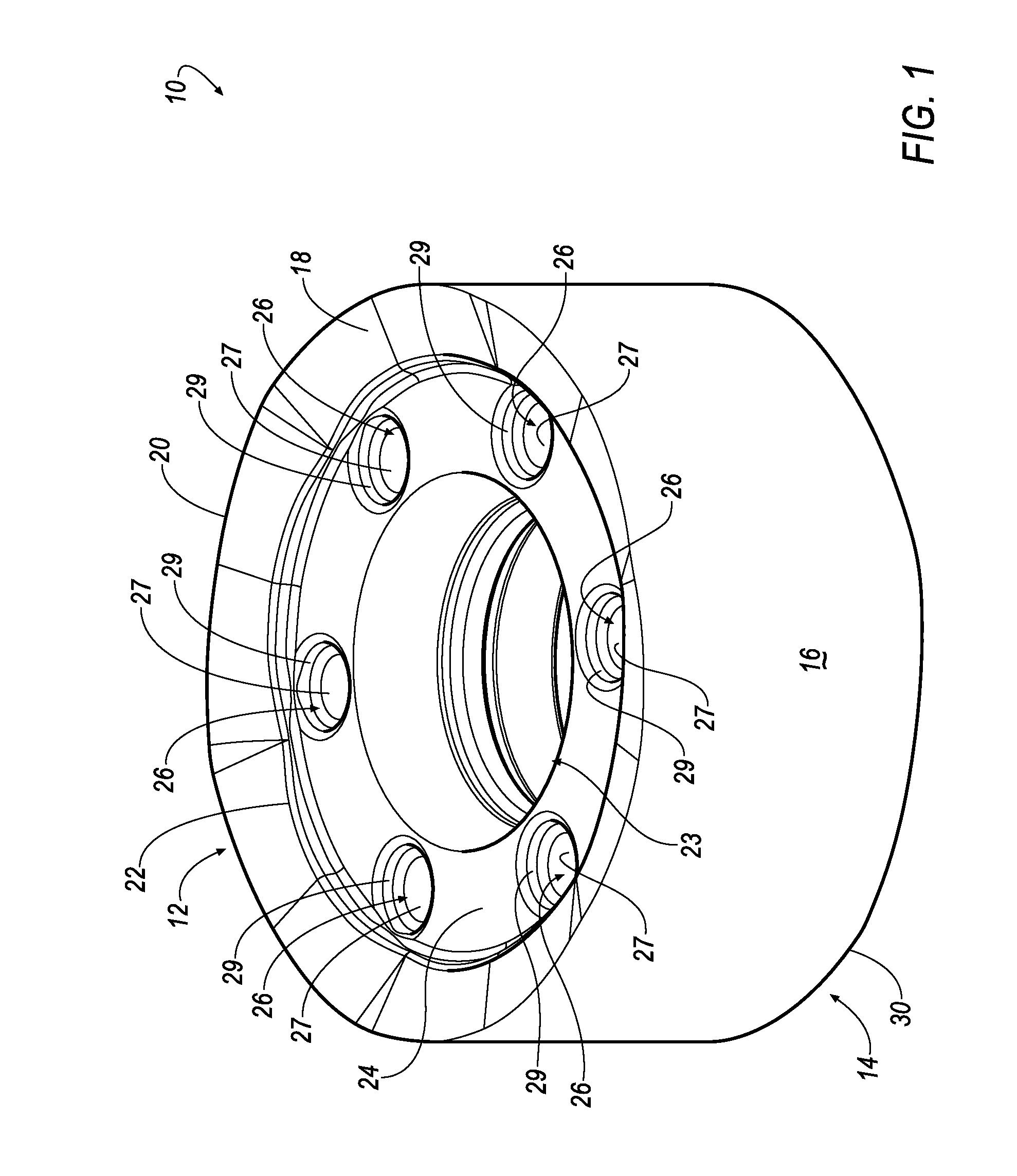

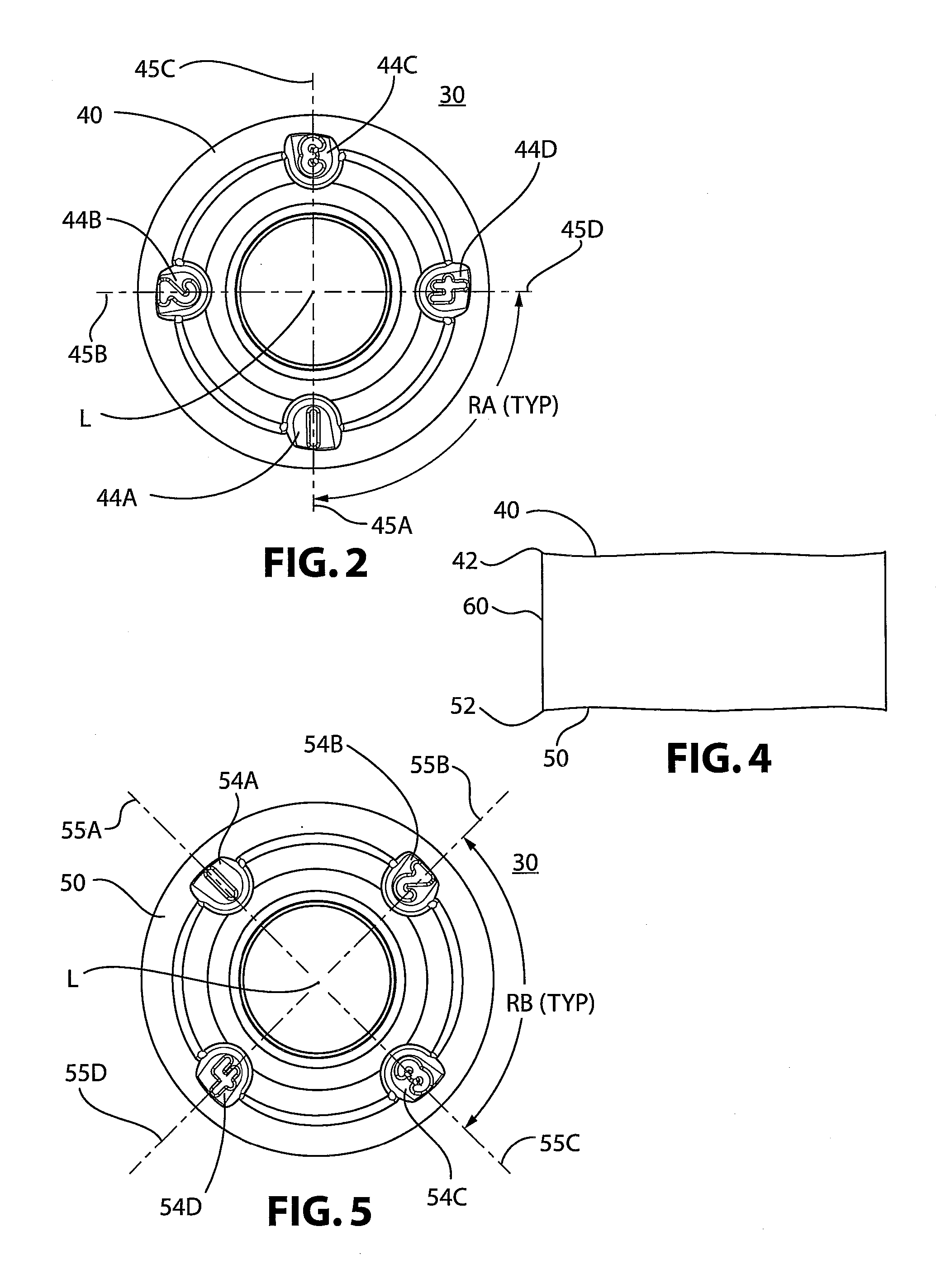

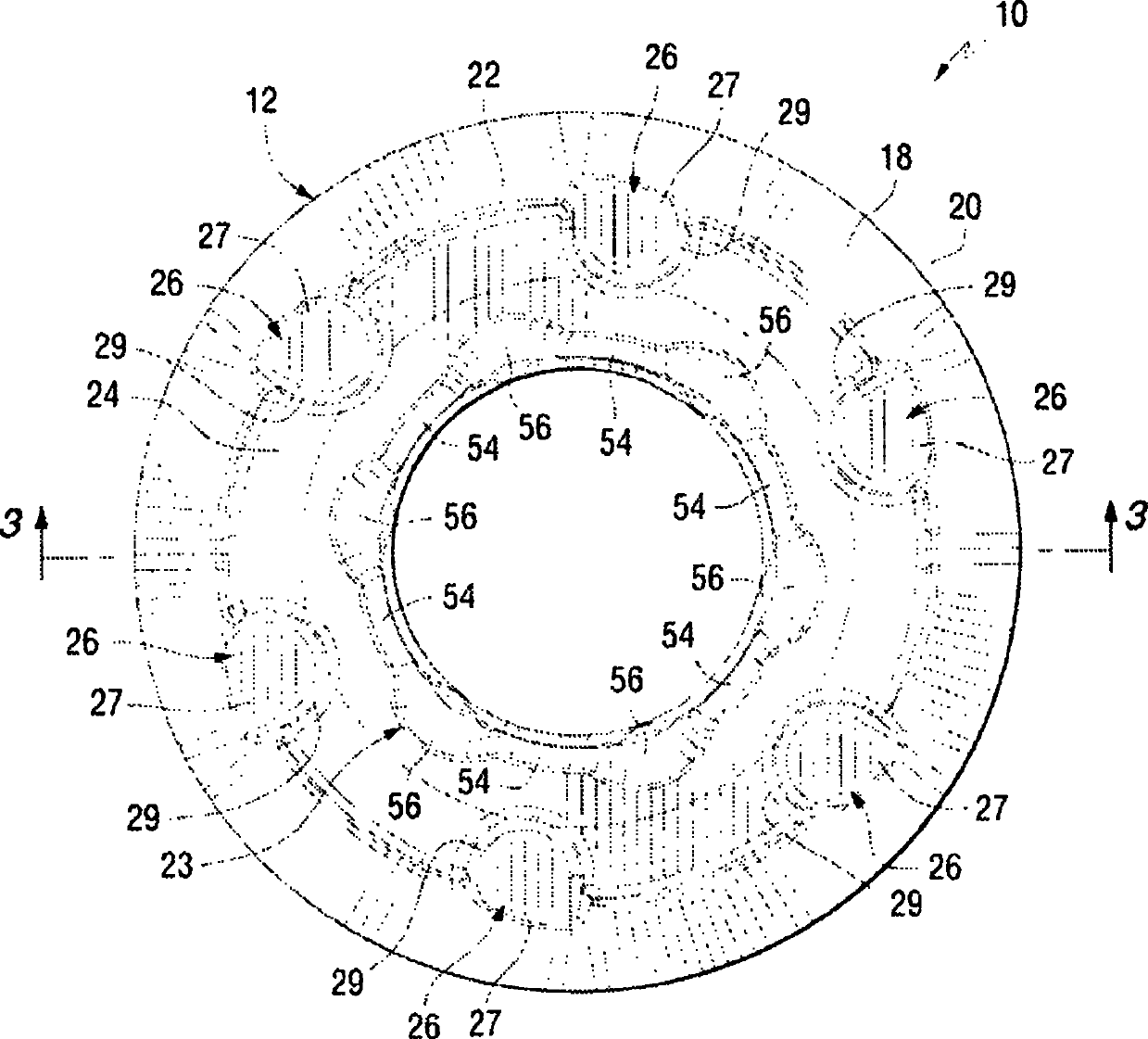

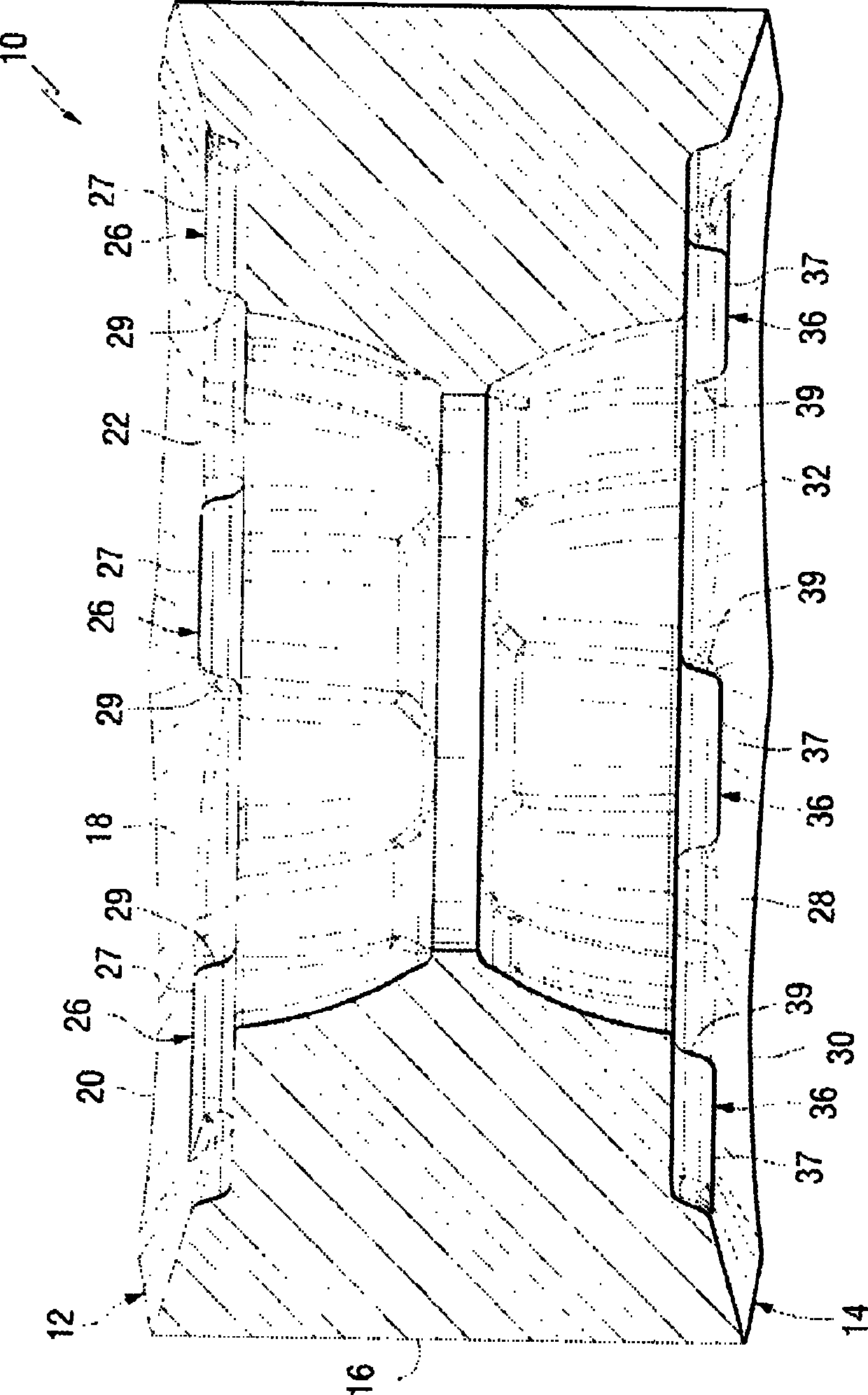

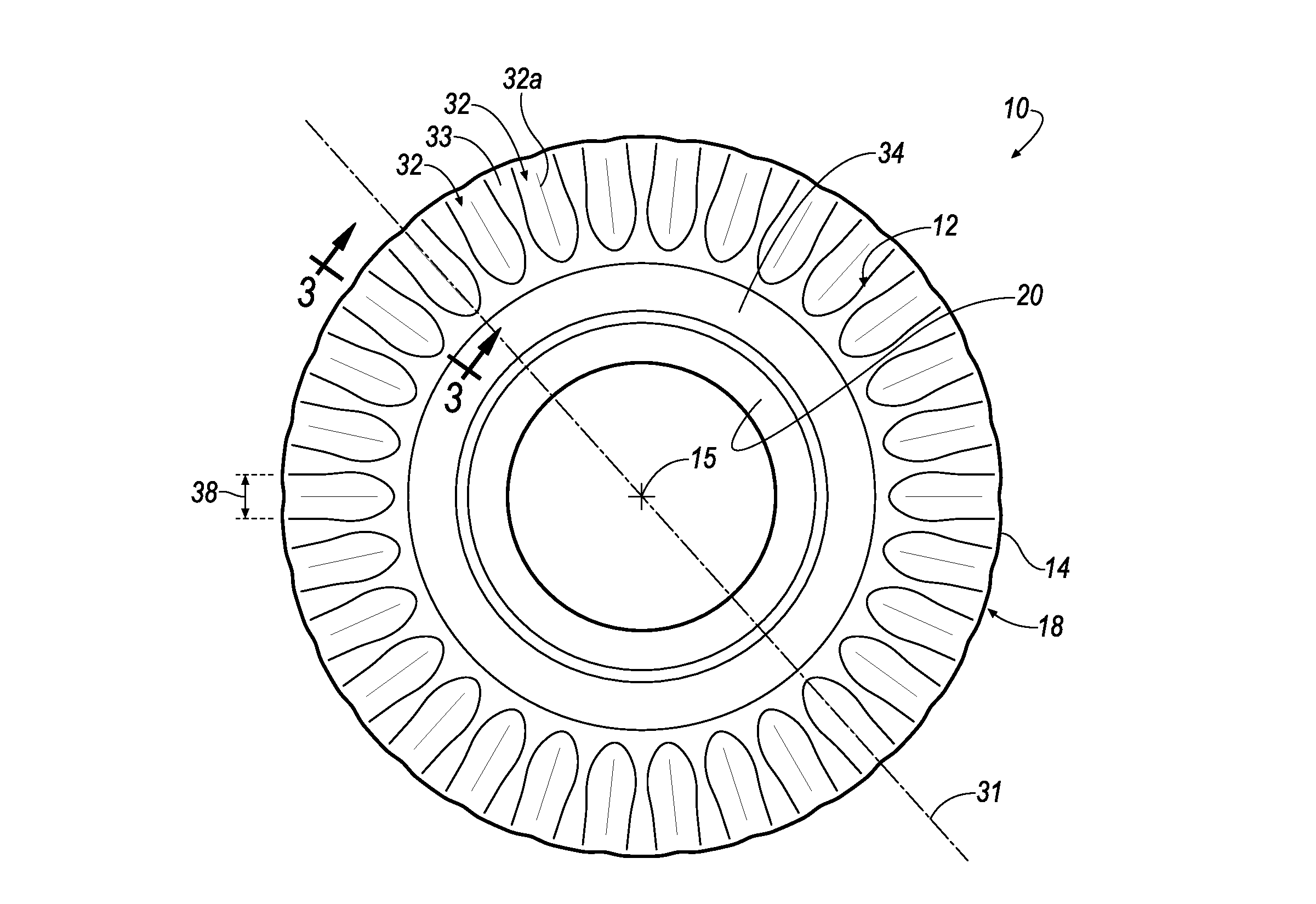

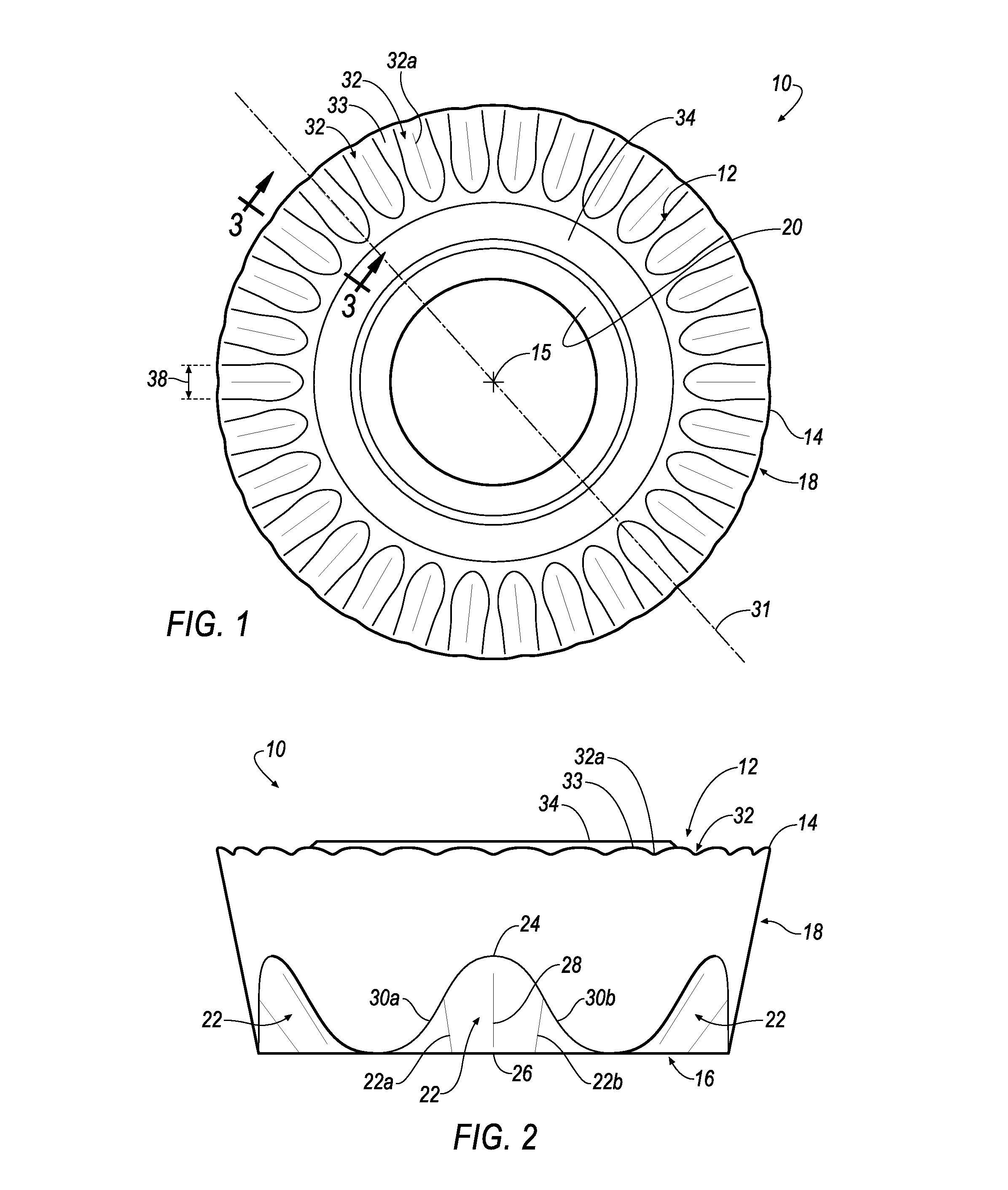

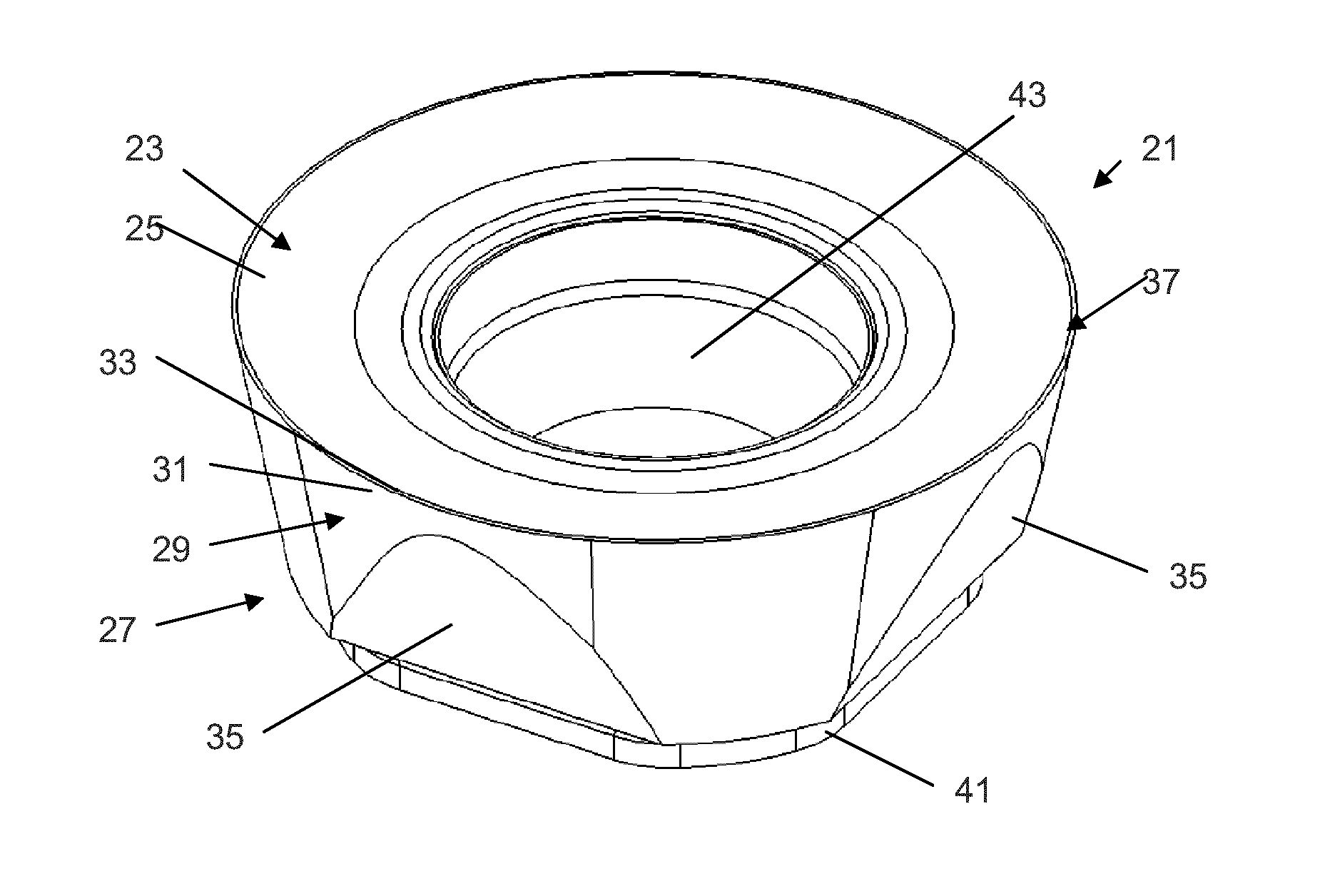

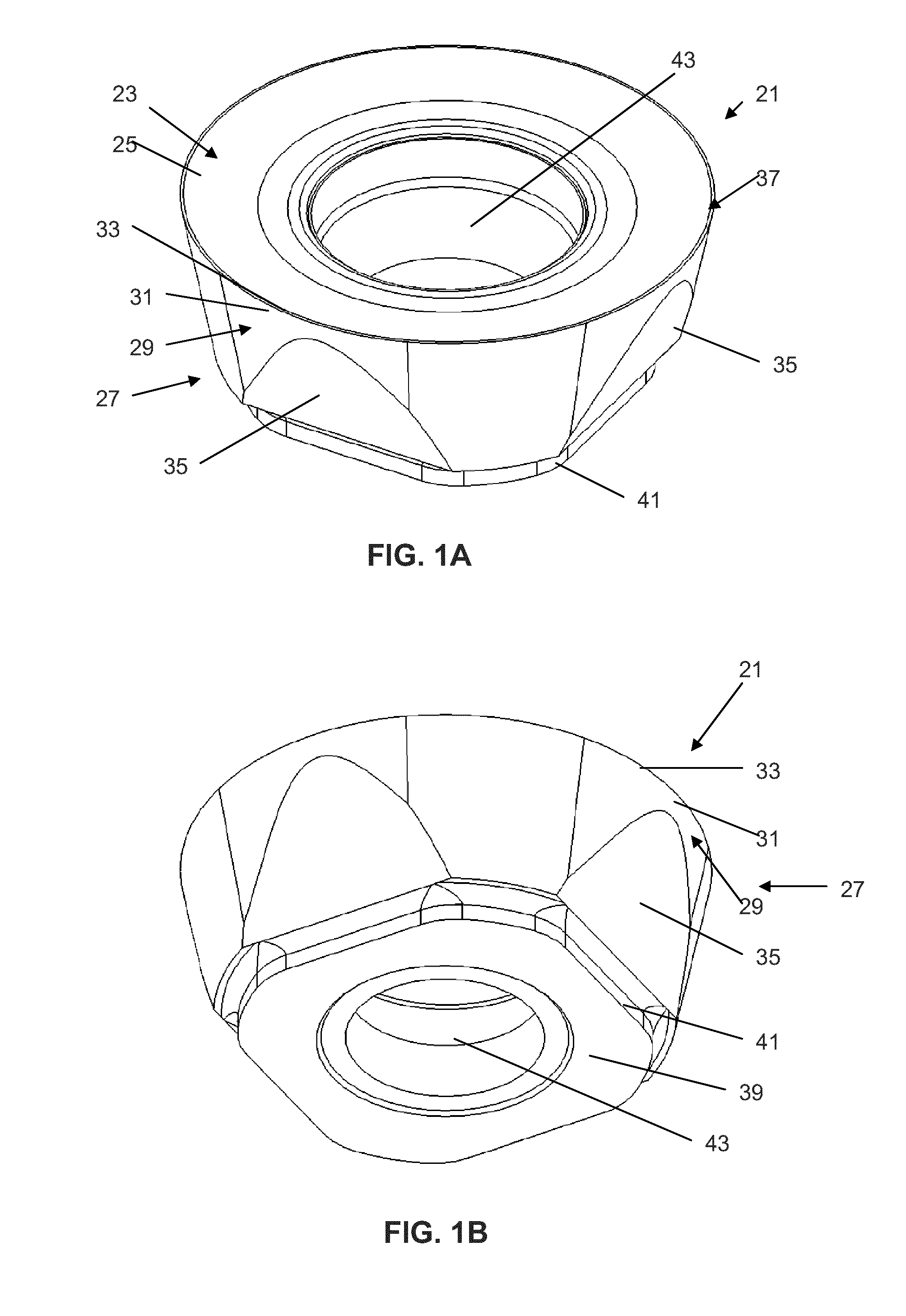

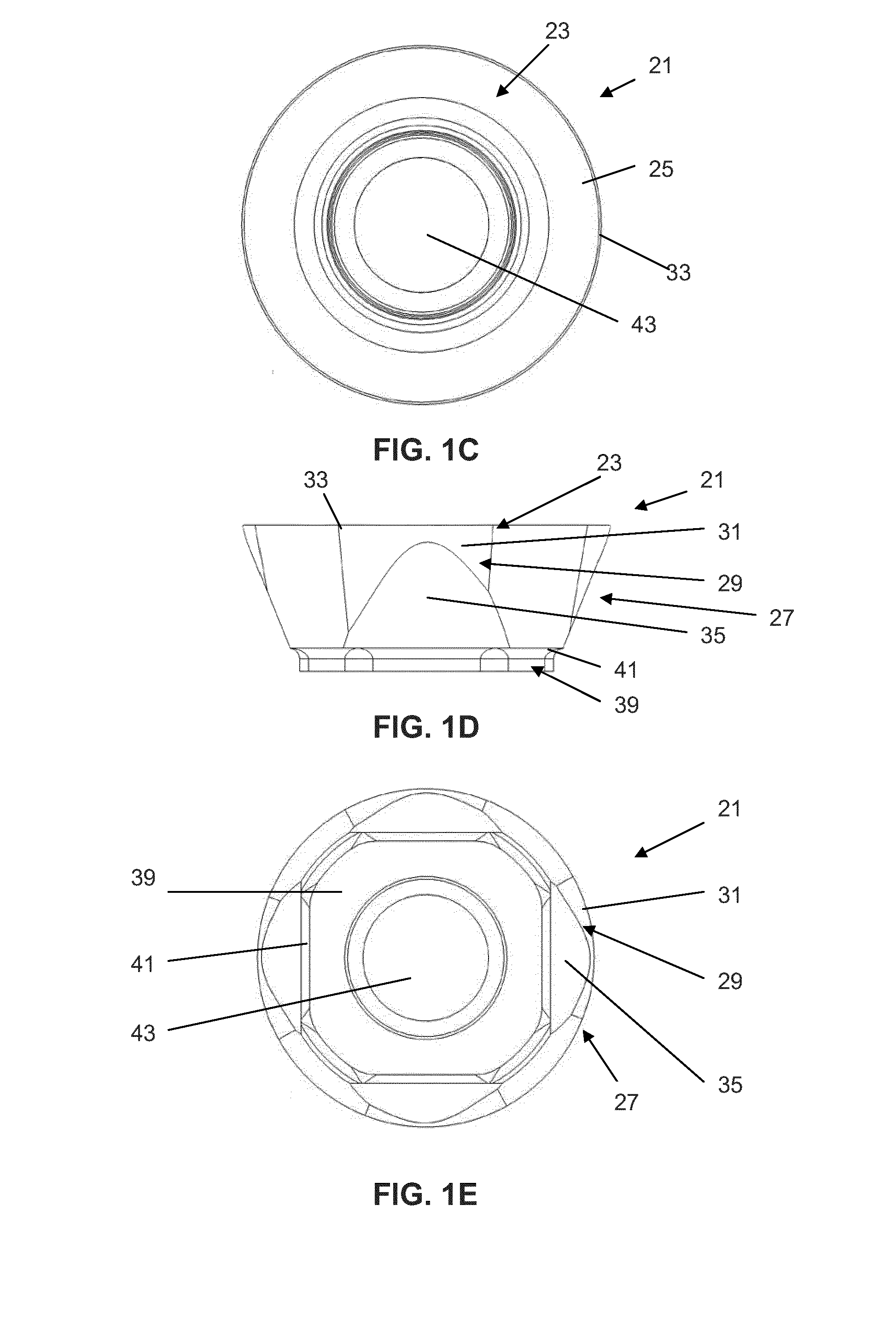

Round cutting insert with anti-rotation feature

A round cutting insert with an anti-rotation feature. The round cutting insert includes a plurality of projections formed on a first surface and another plurality of projections formed on an opposing surface. The round cutting insert is reversible and indexable. The round cutting insert is removably received in an insert receiving pocket in a tool body wherein the insert receiving pocket includes a plurality of dimples for receiving one of the plurality of first projections or the plurality of second projections. This arrangement prevents rotation of the round cutting insert while mounted in the insert receiving pocket.

Owner:KENNAMETAL INC

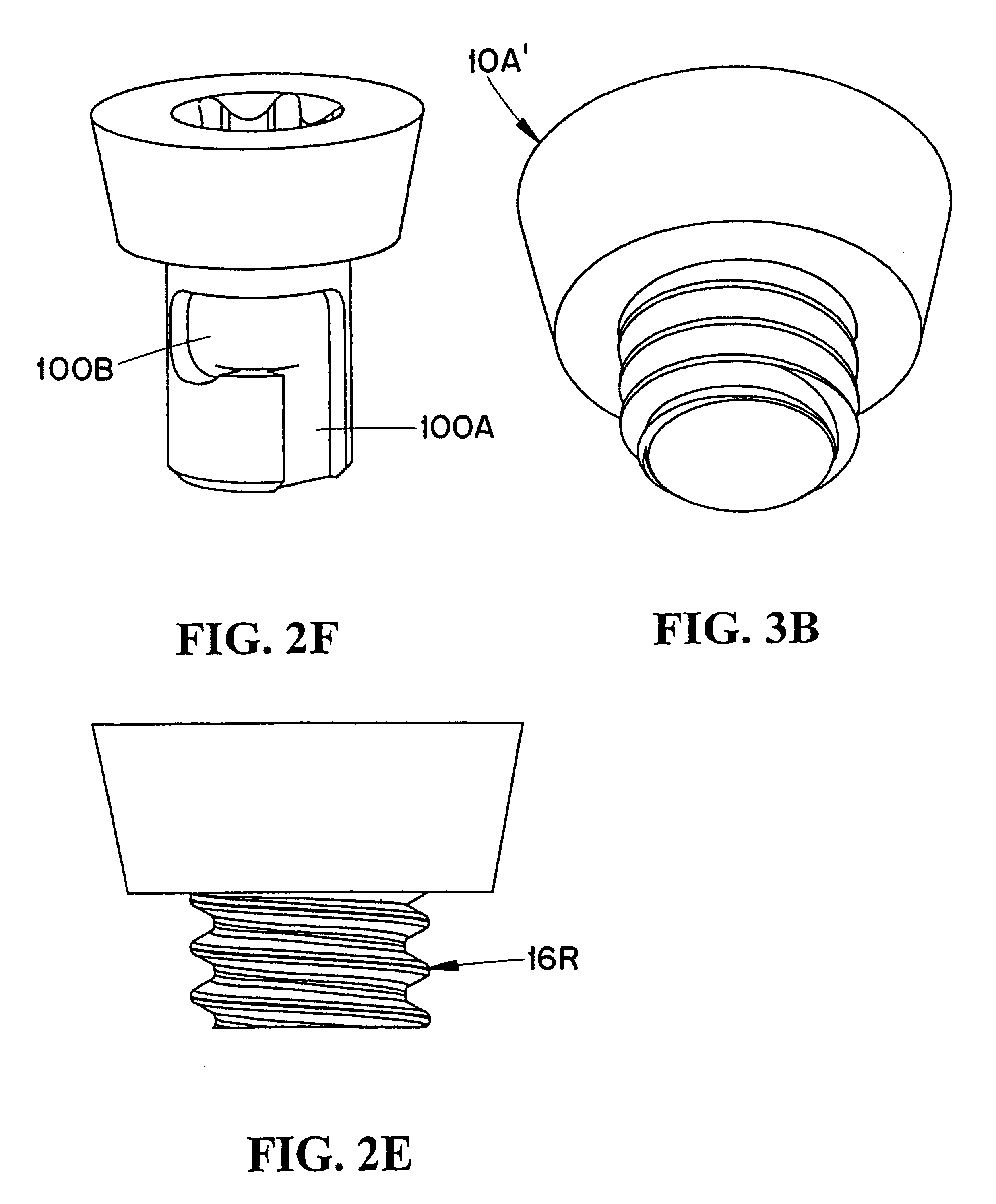

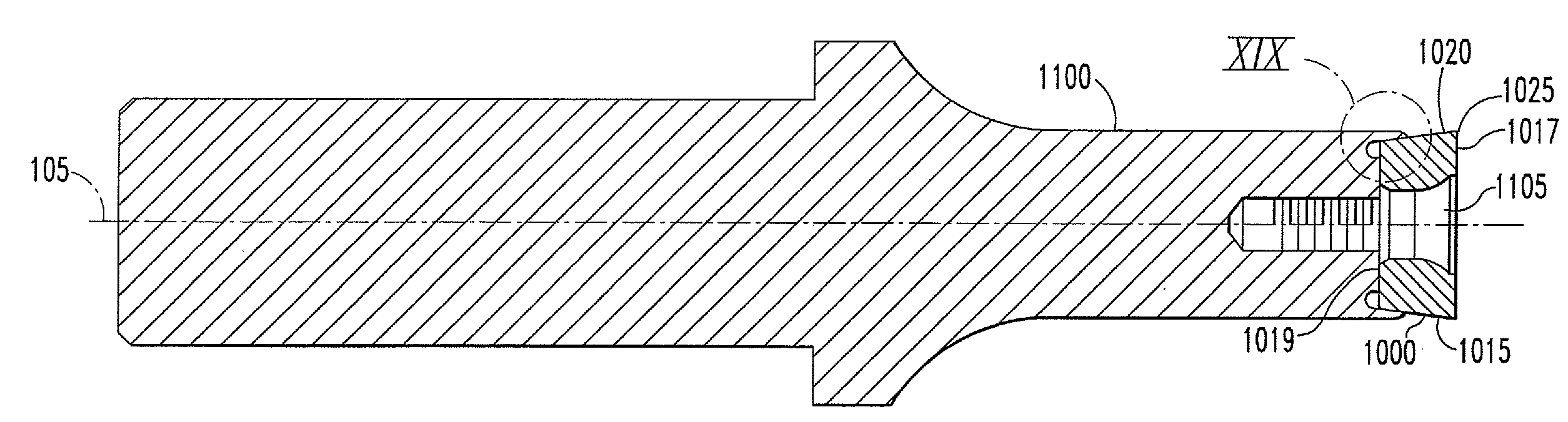

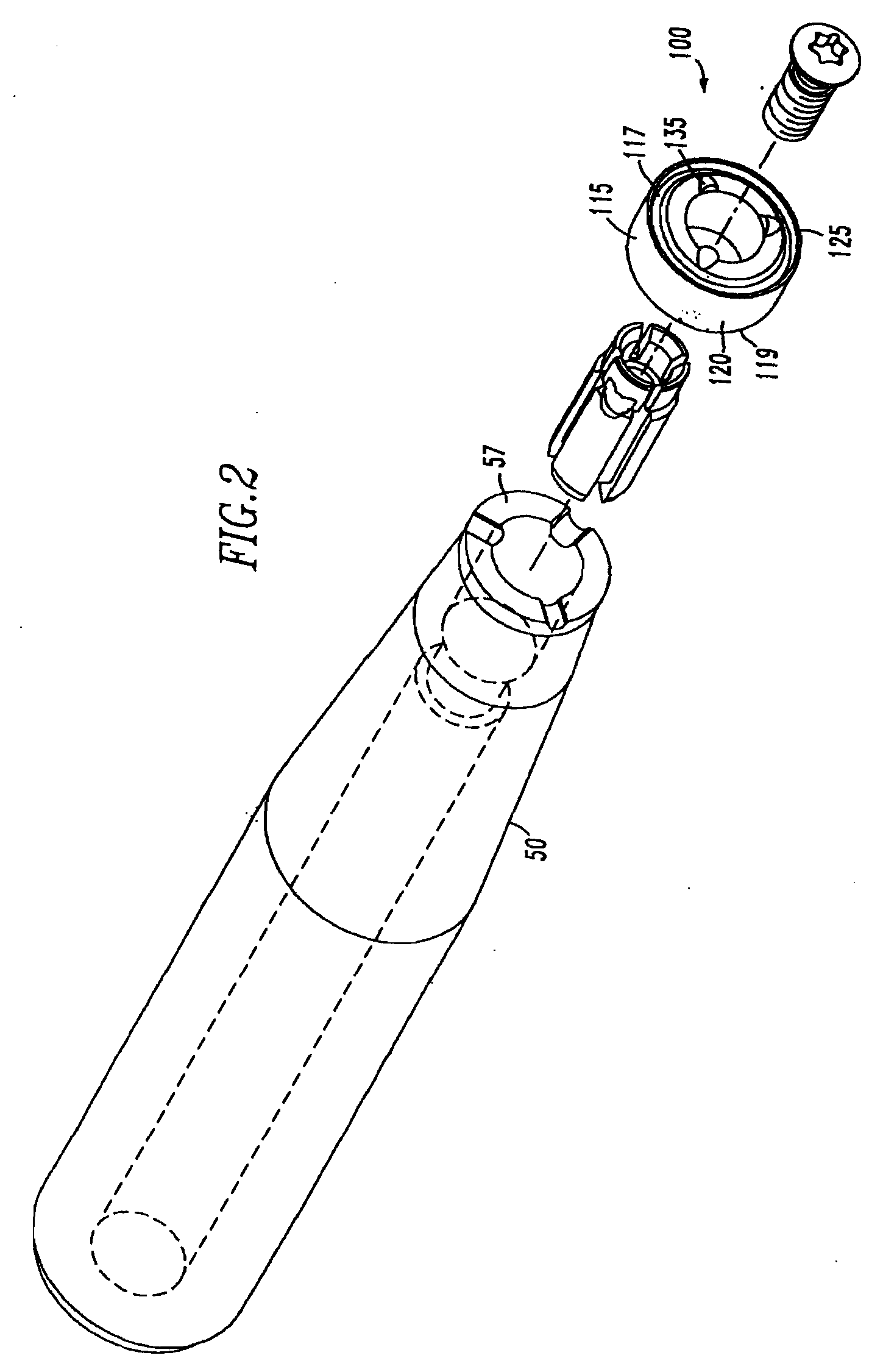

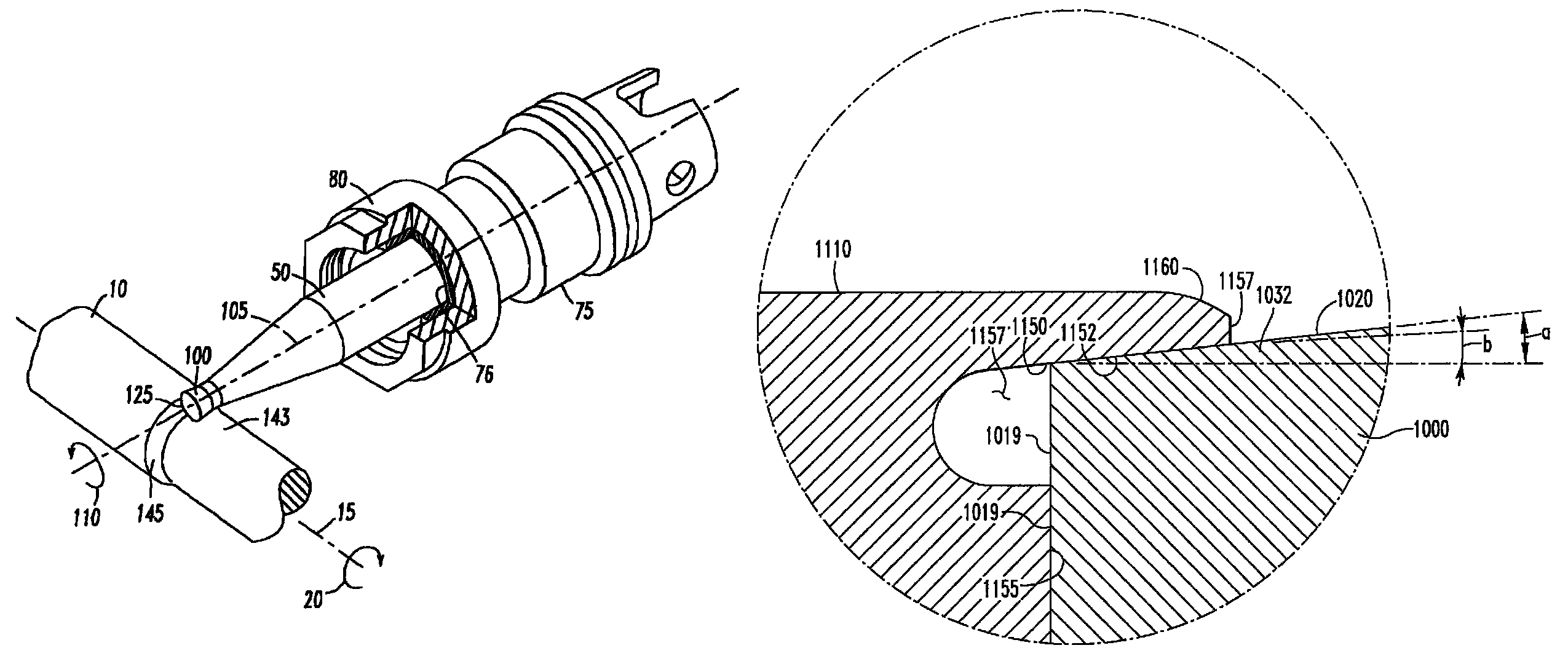

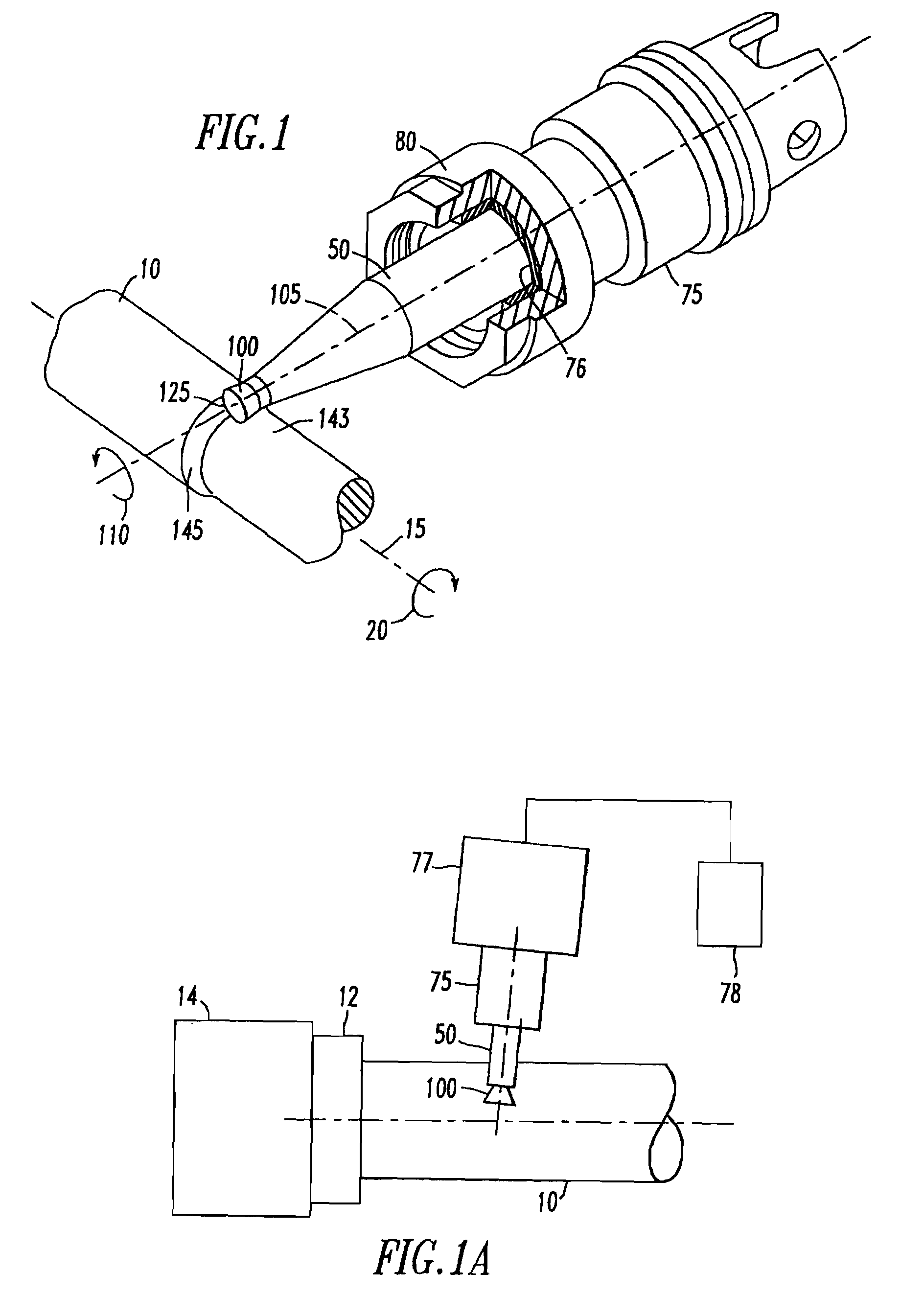

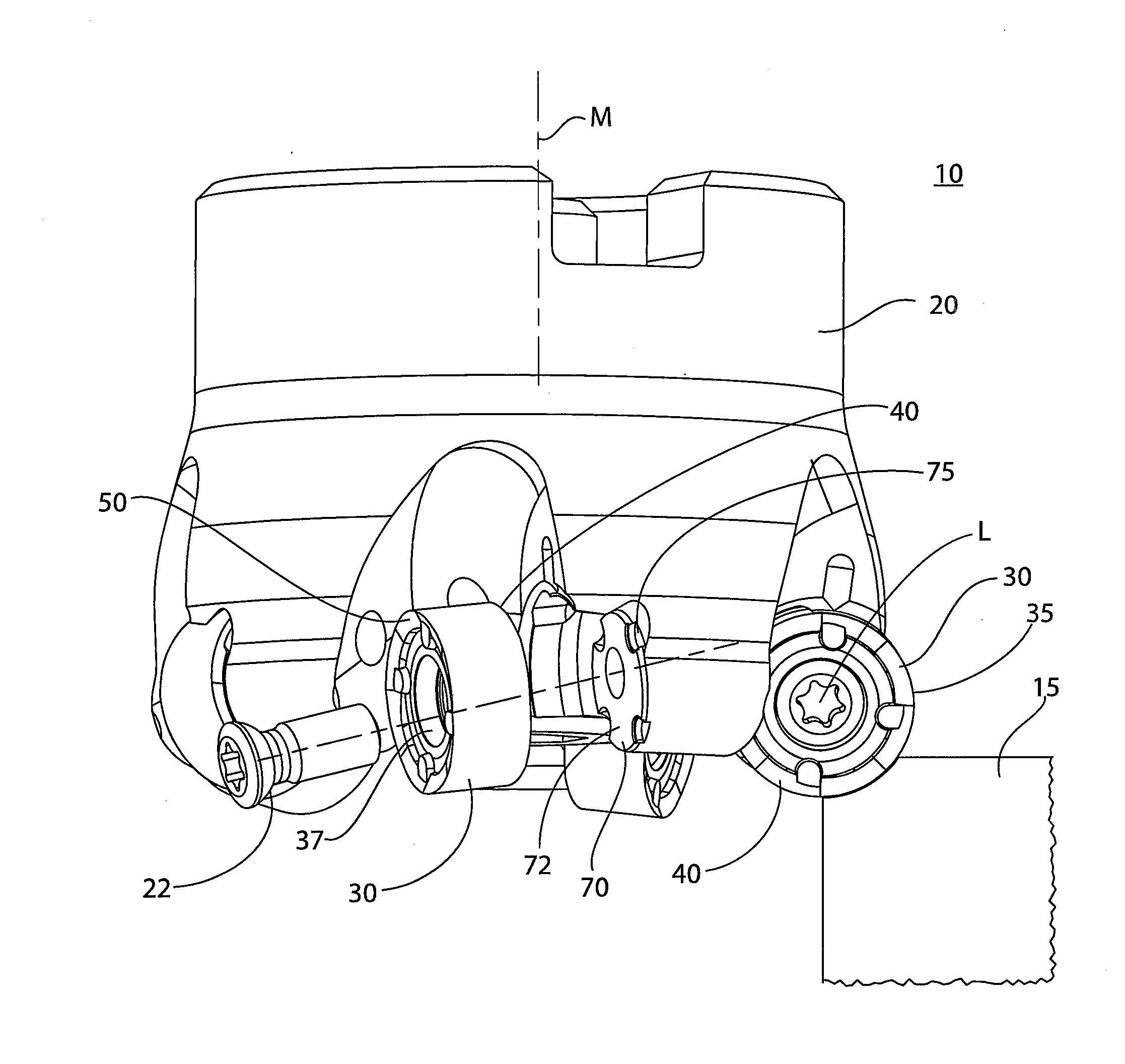

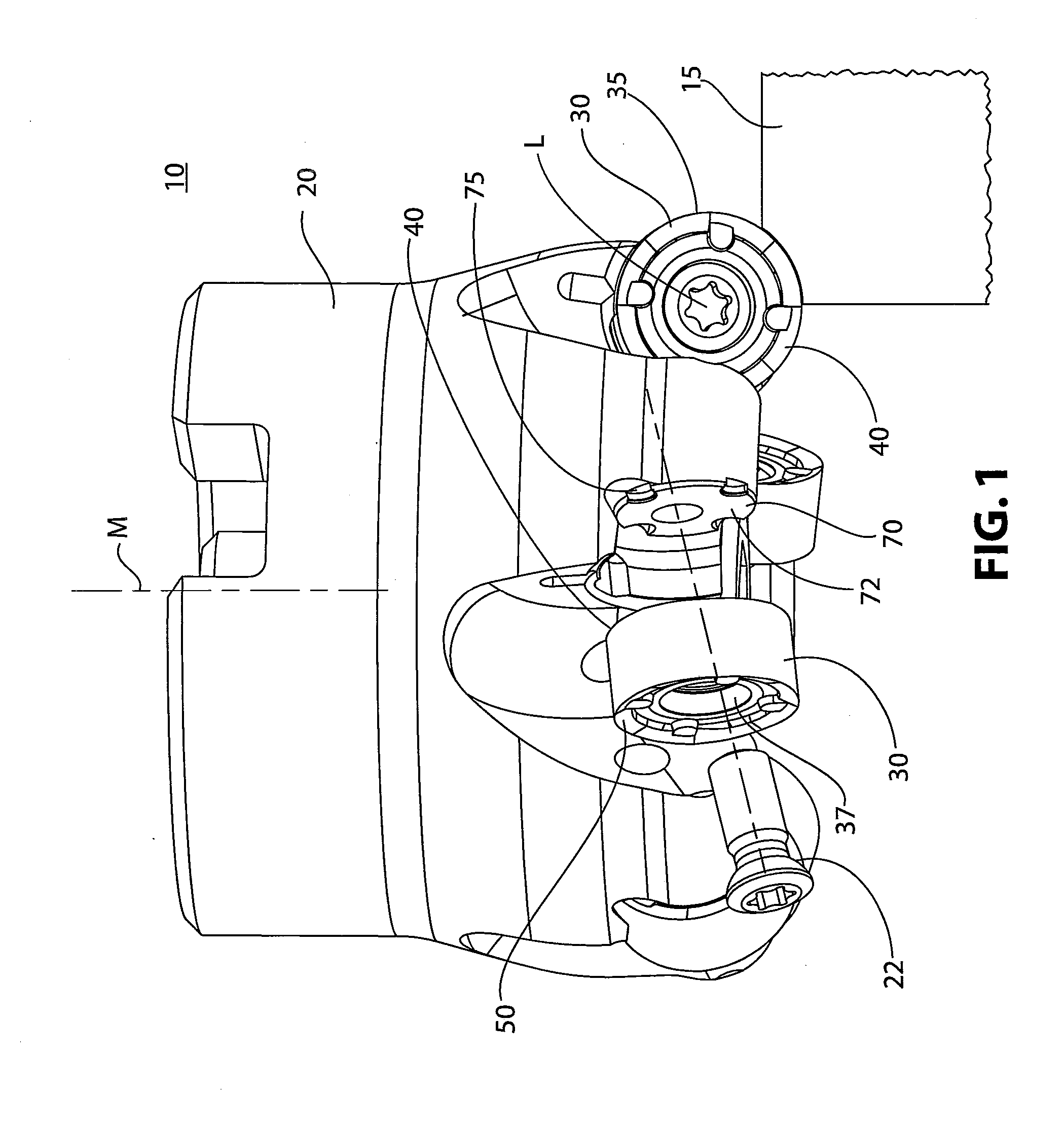

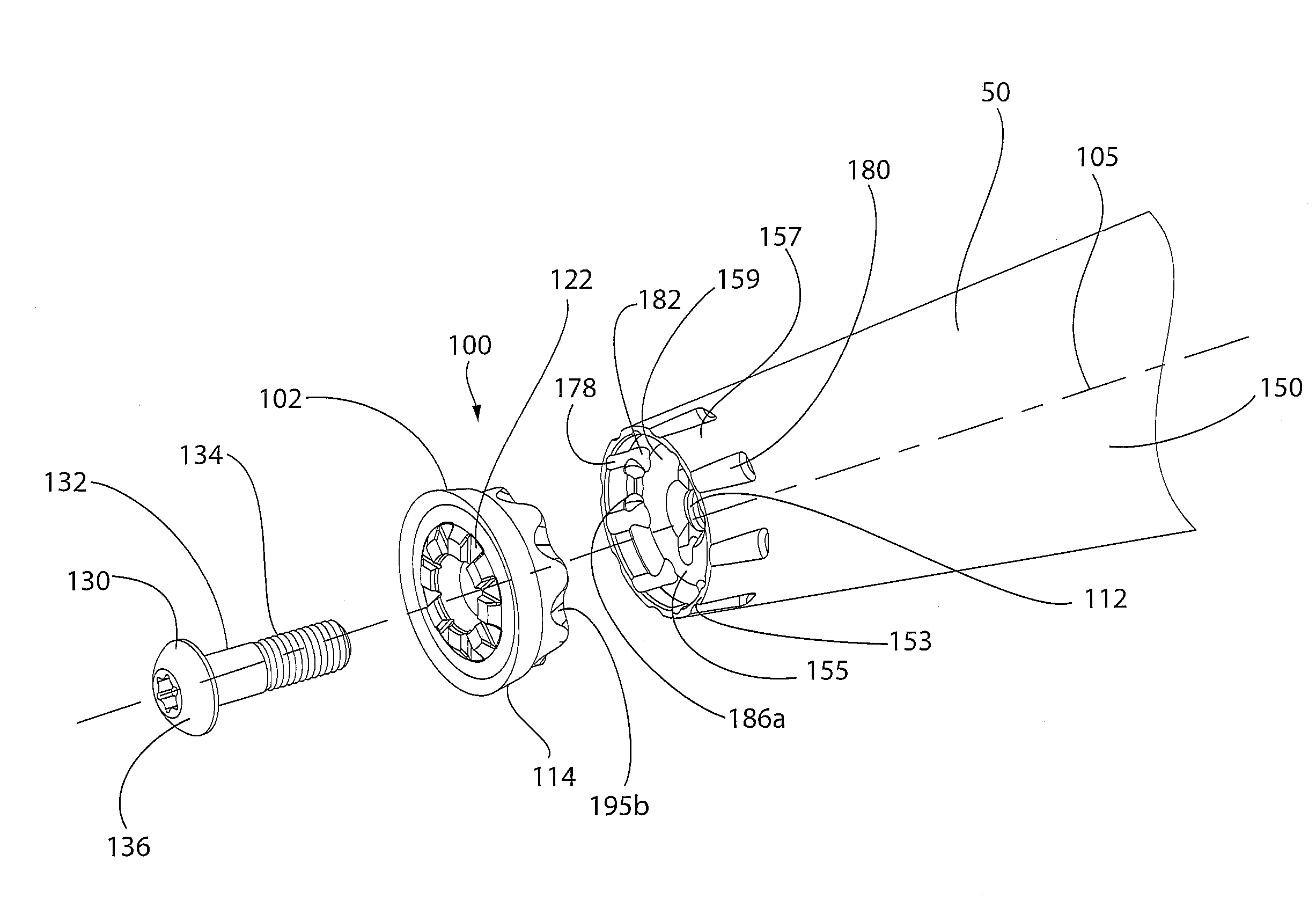

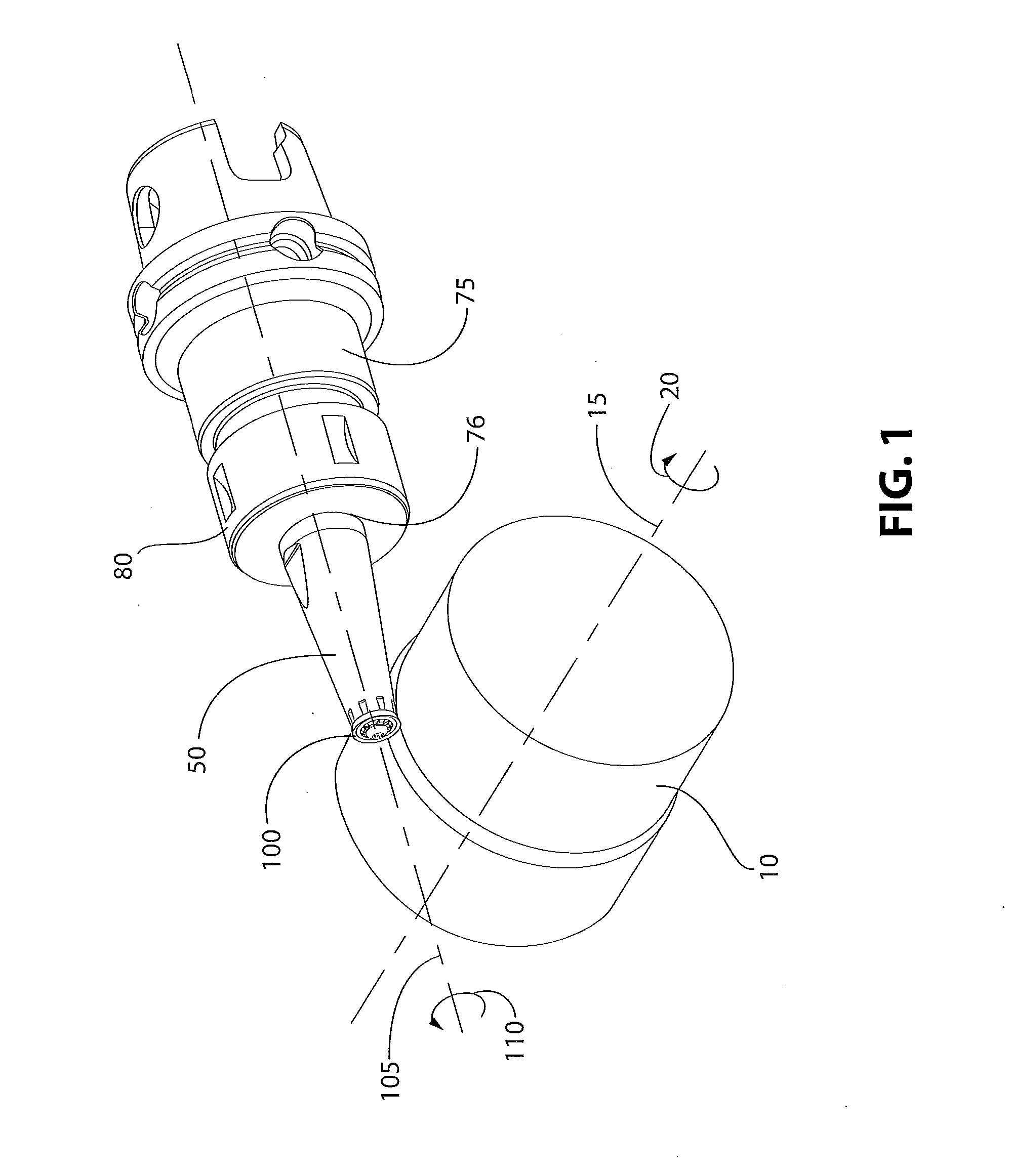

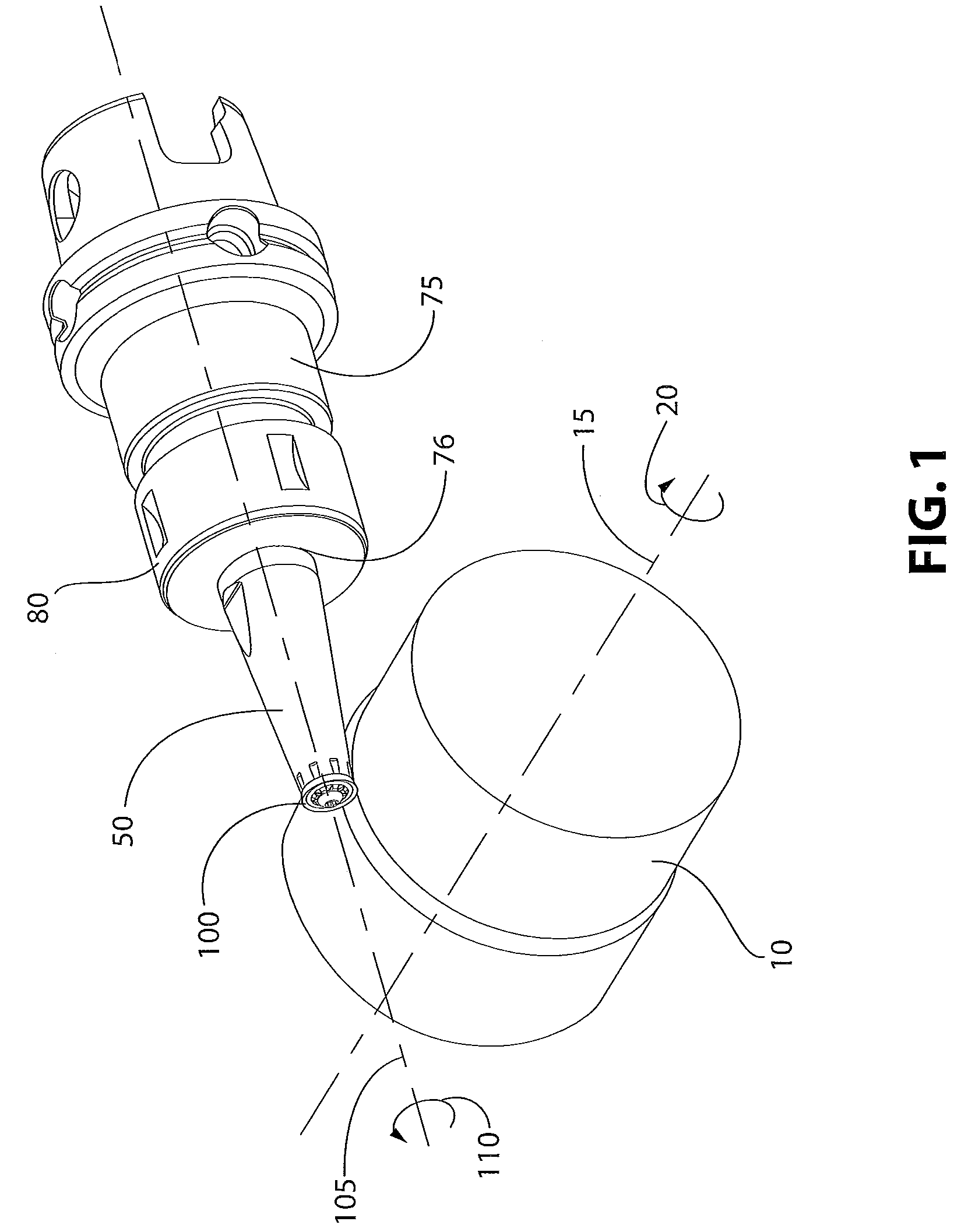

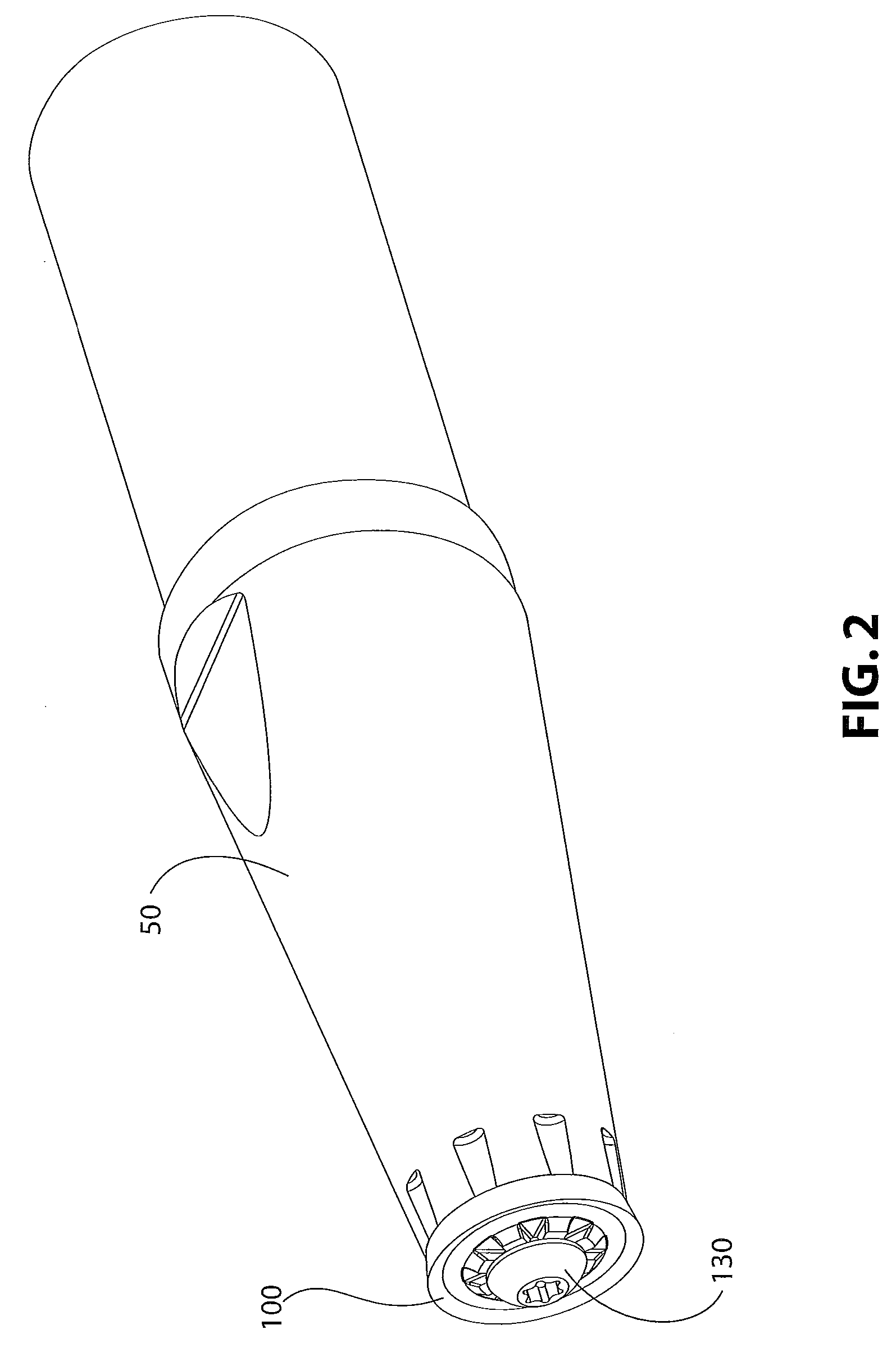

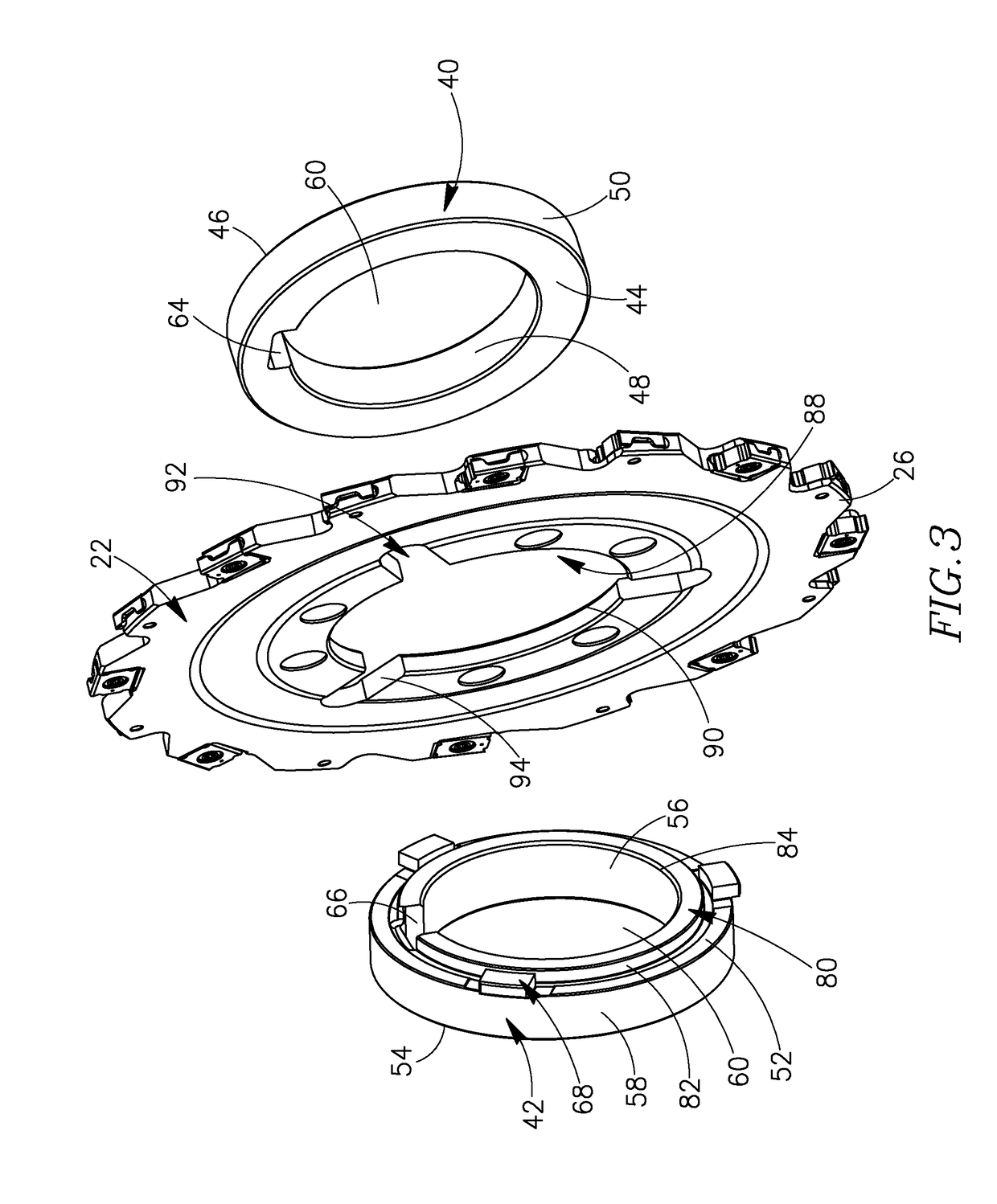

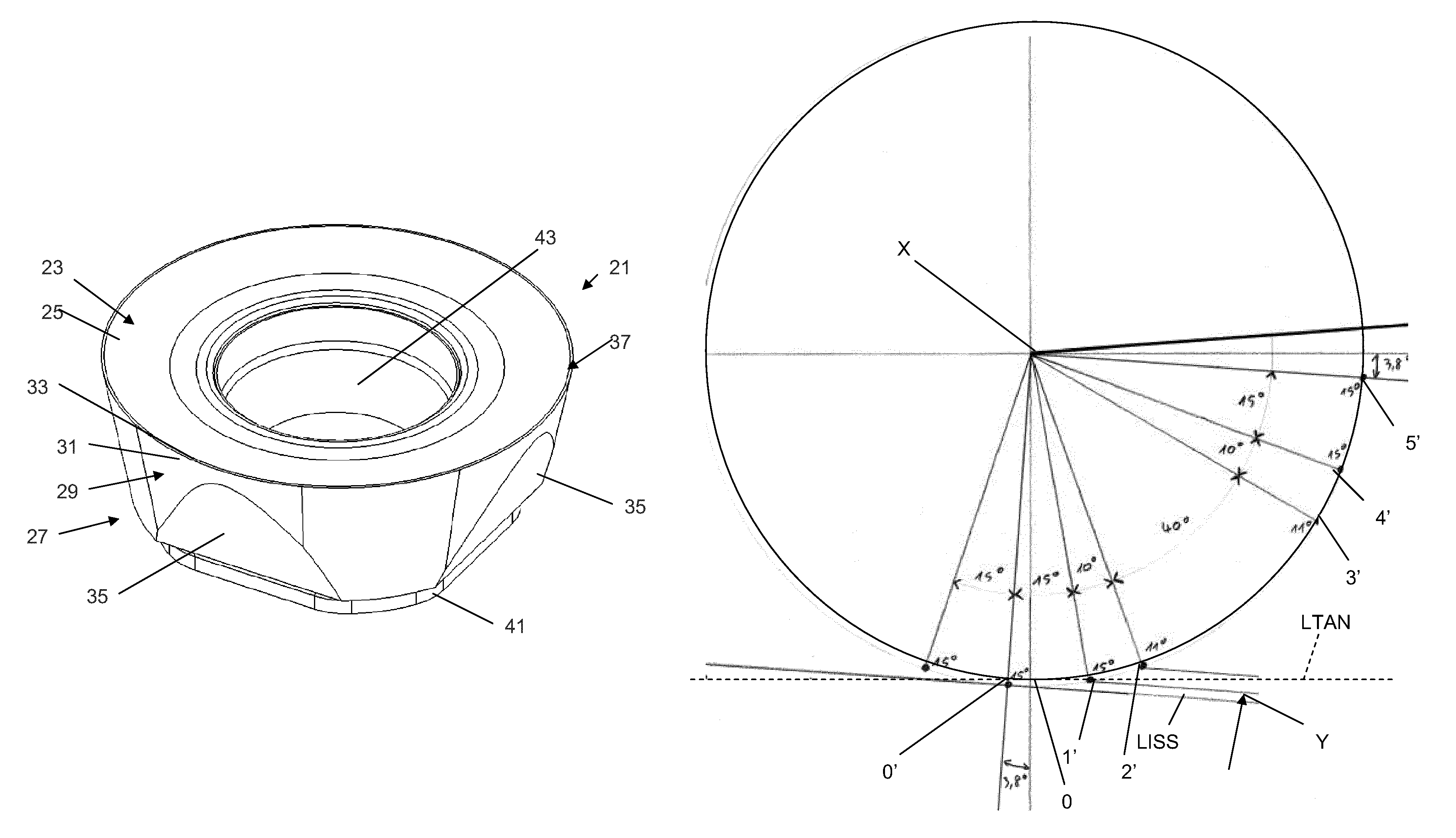

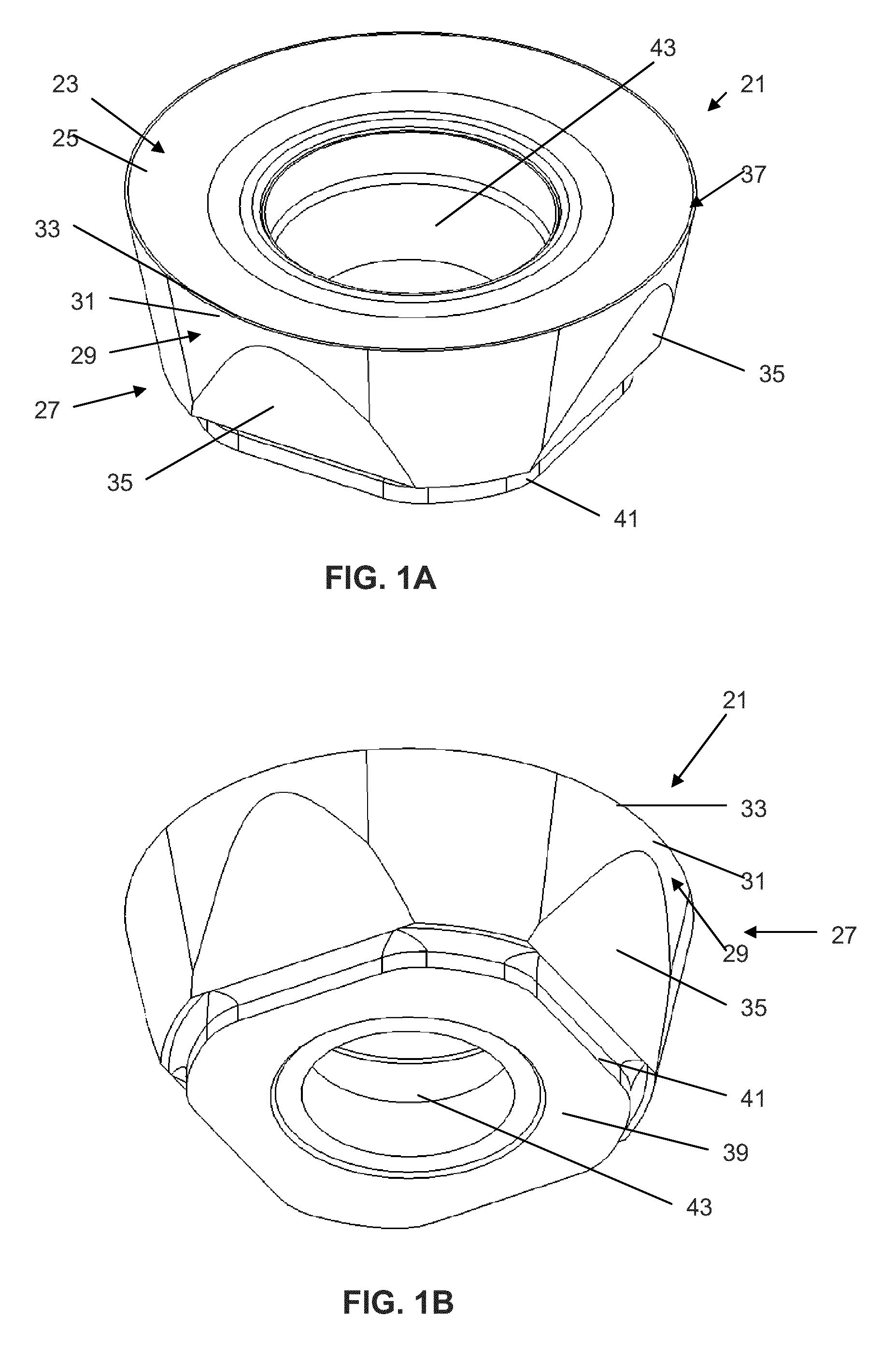

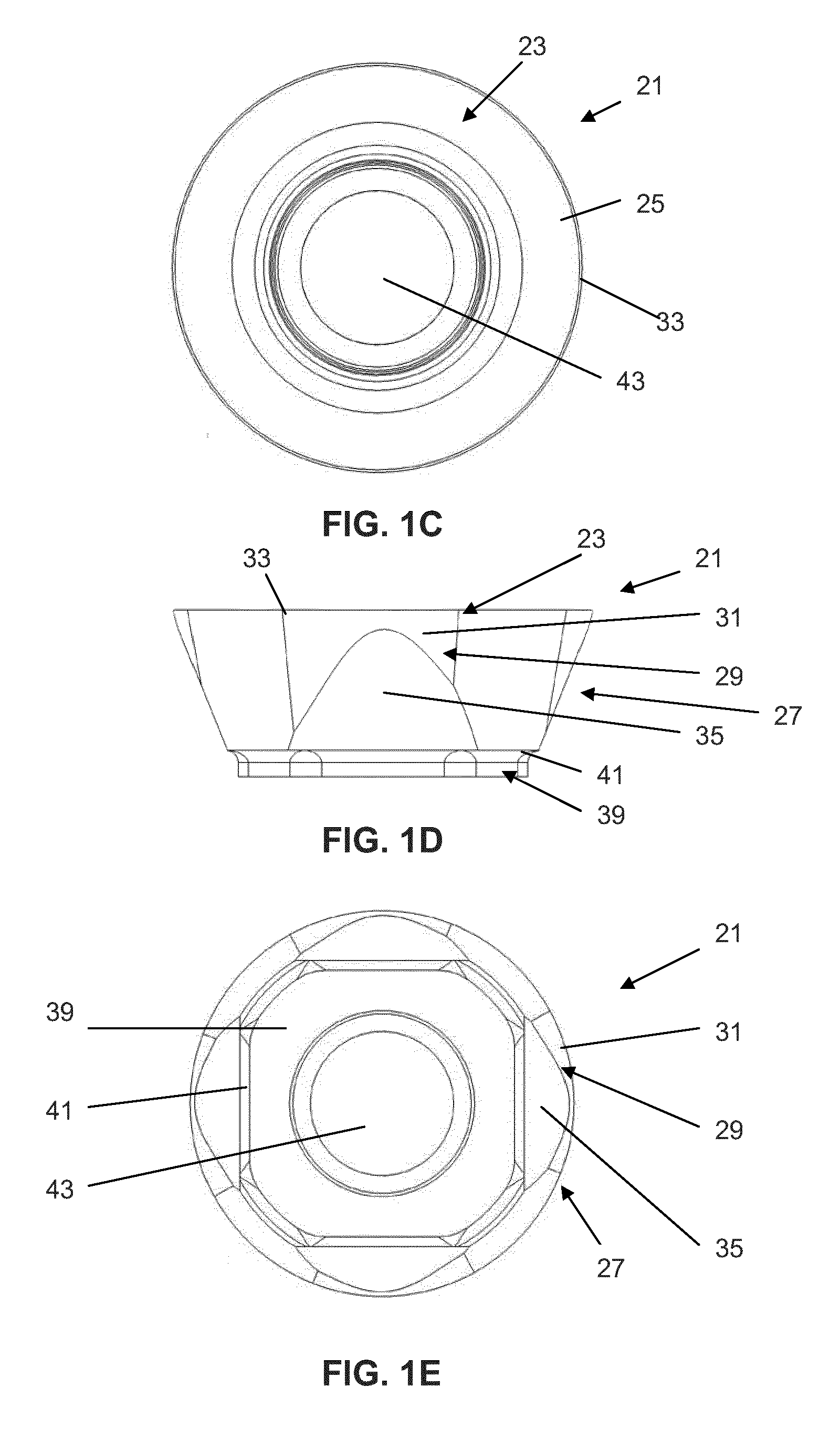

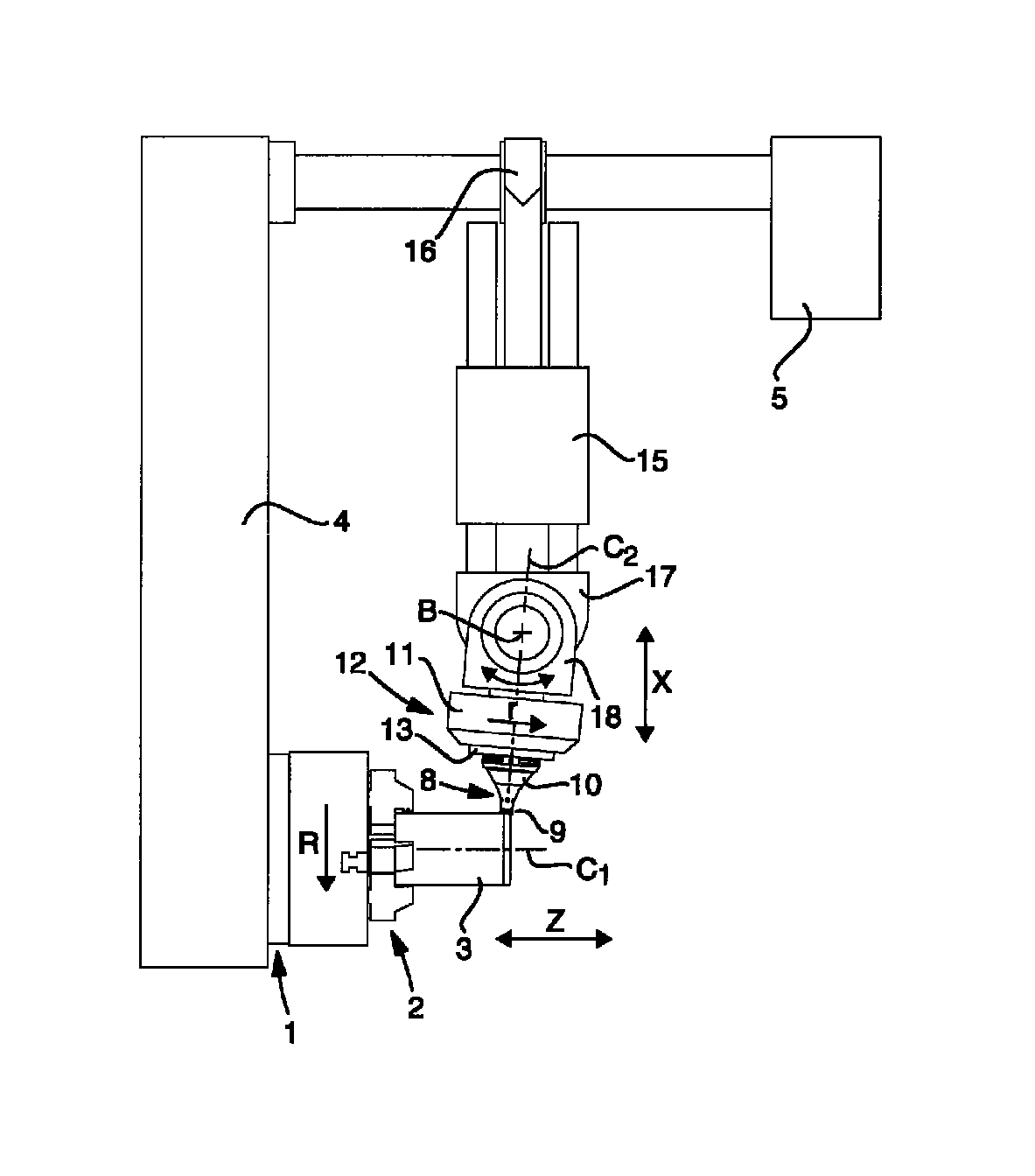

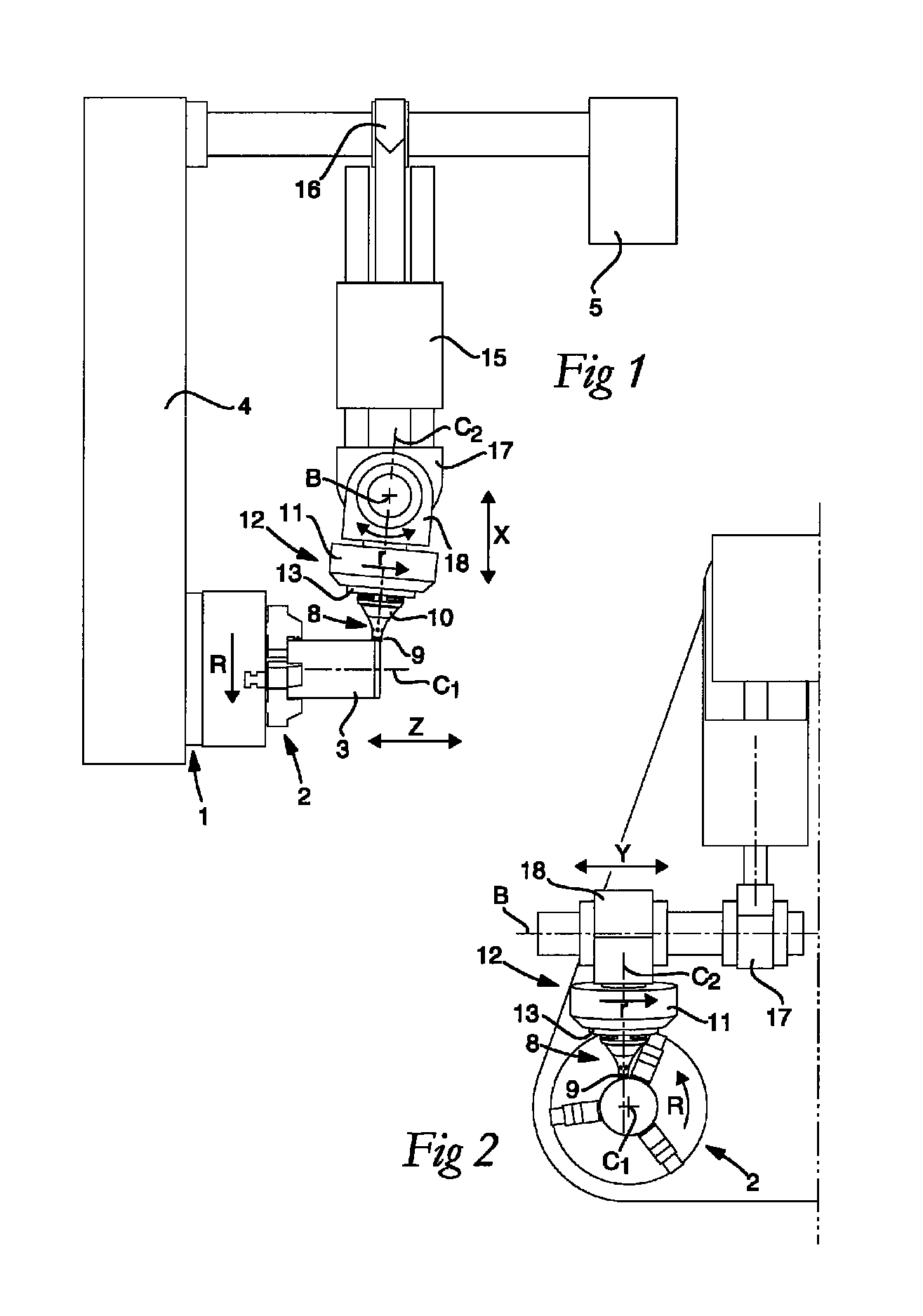

Assembly For Rotating A Cutting Insert During A Turning Operation And Inserts Used Therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. The cutting insert is secured within a toolholder having features to secure the insert but at the same time make for efficient removal of the insert from the toolholder.

Owner:KENNAMETAL INC

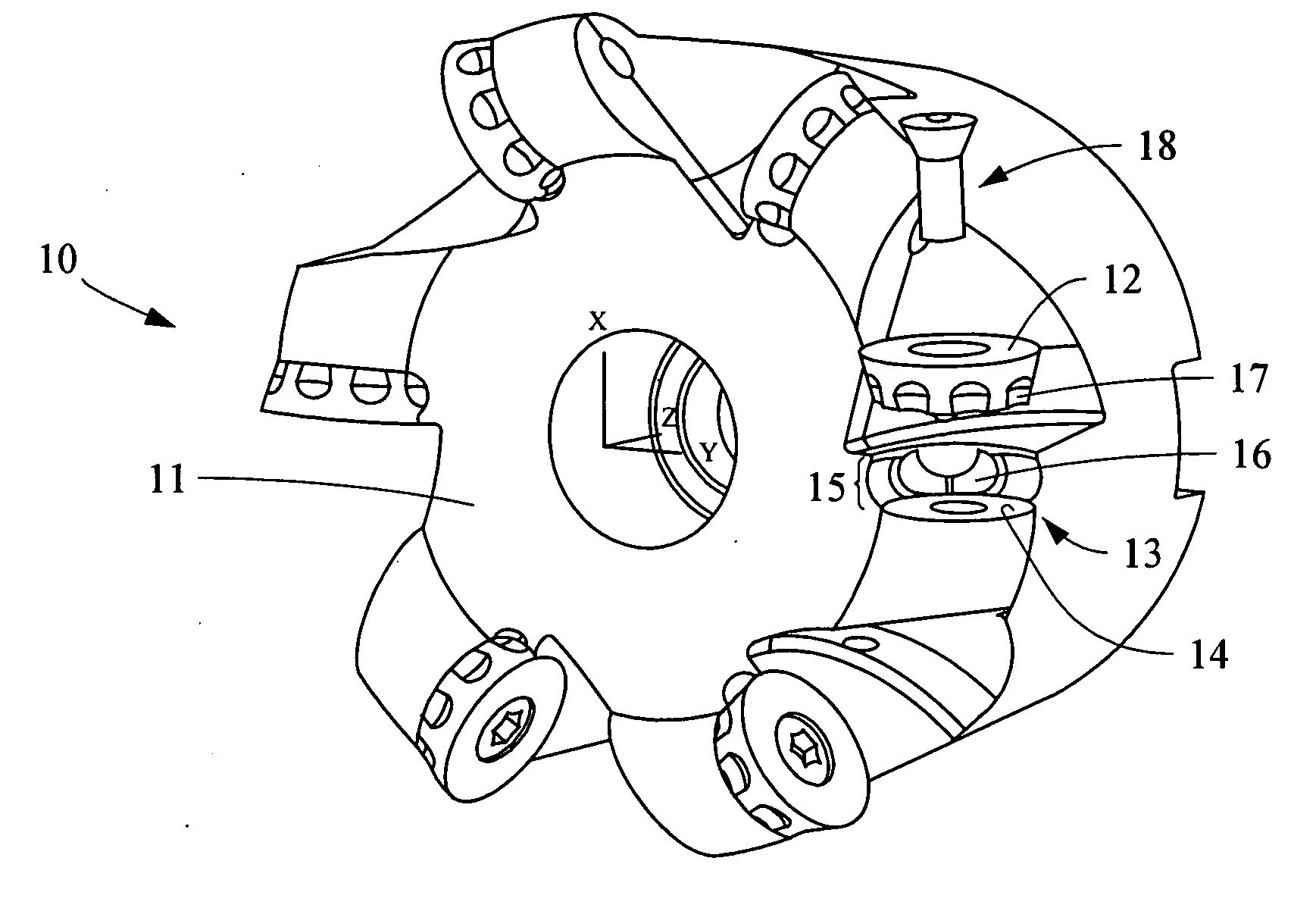

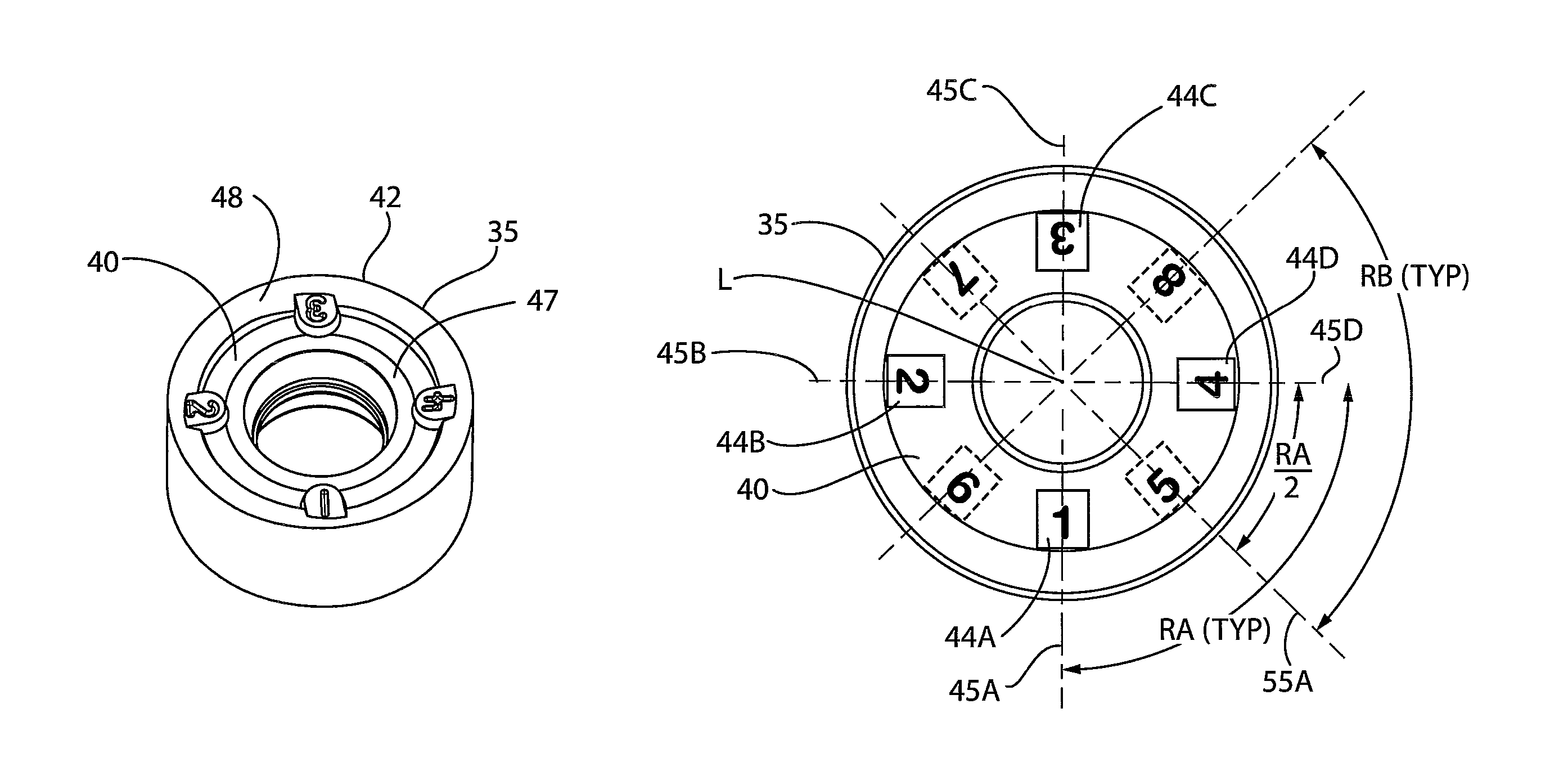

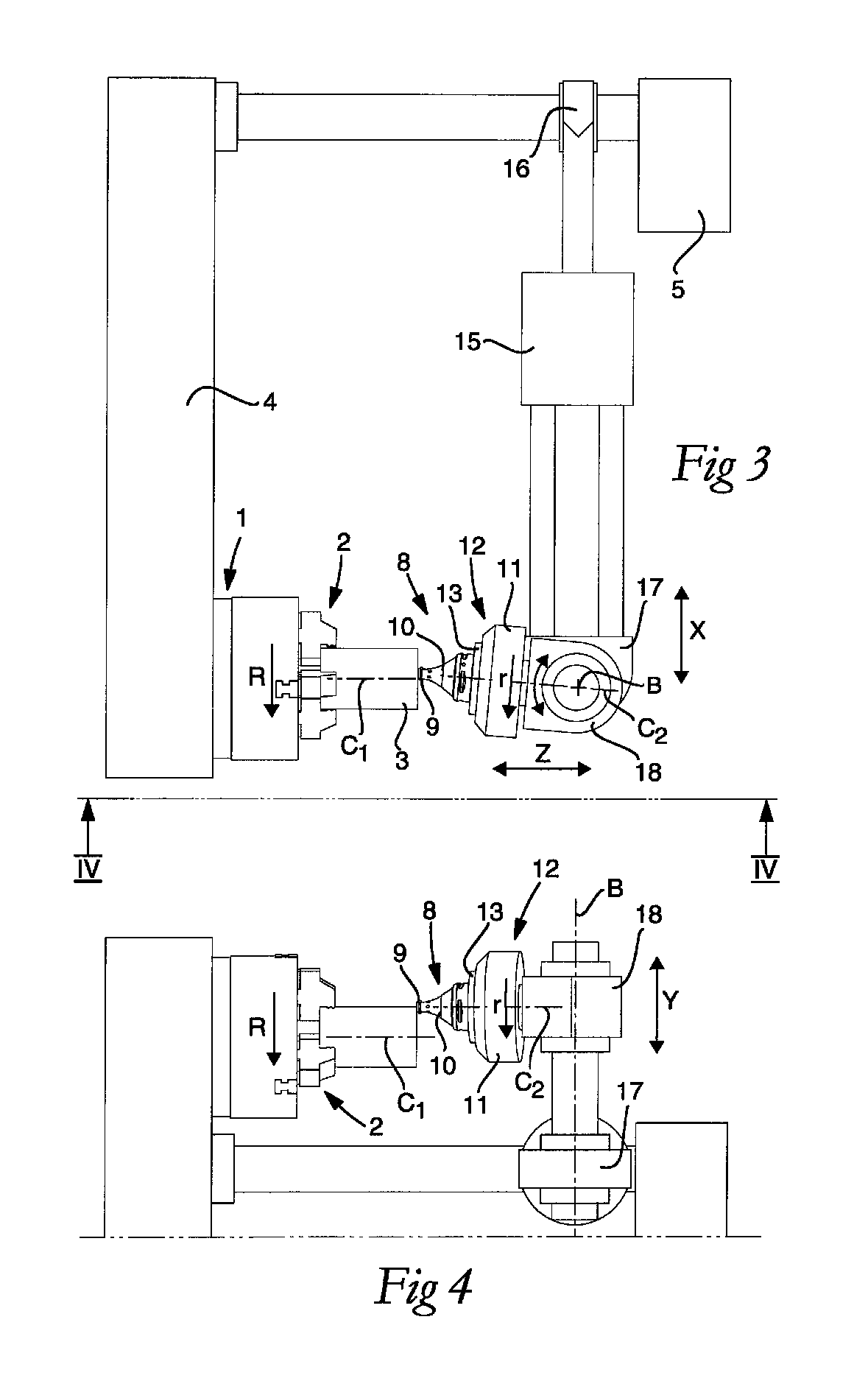

Indexable circular cutting insert

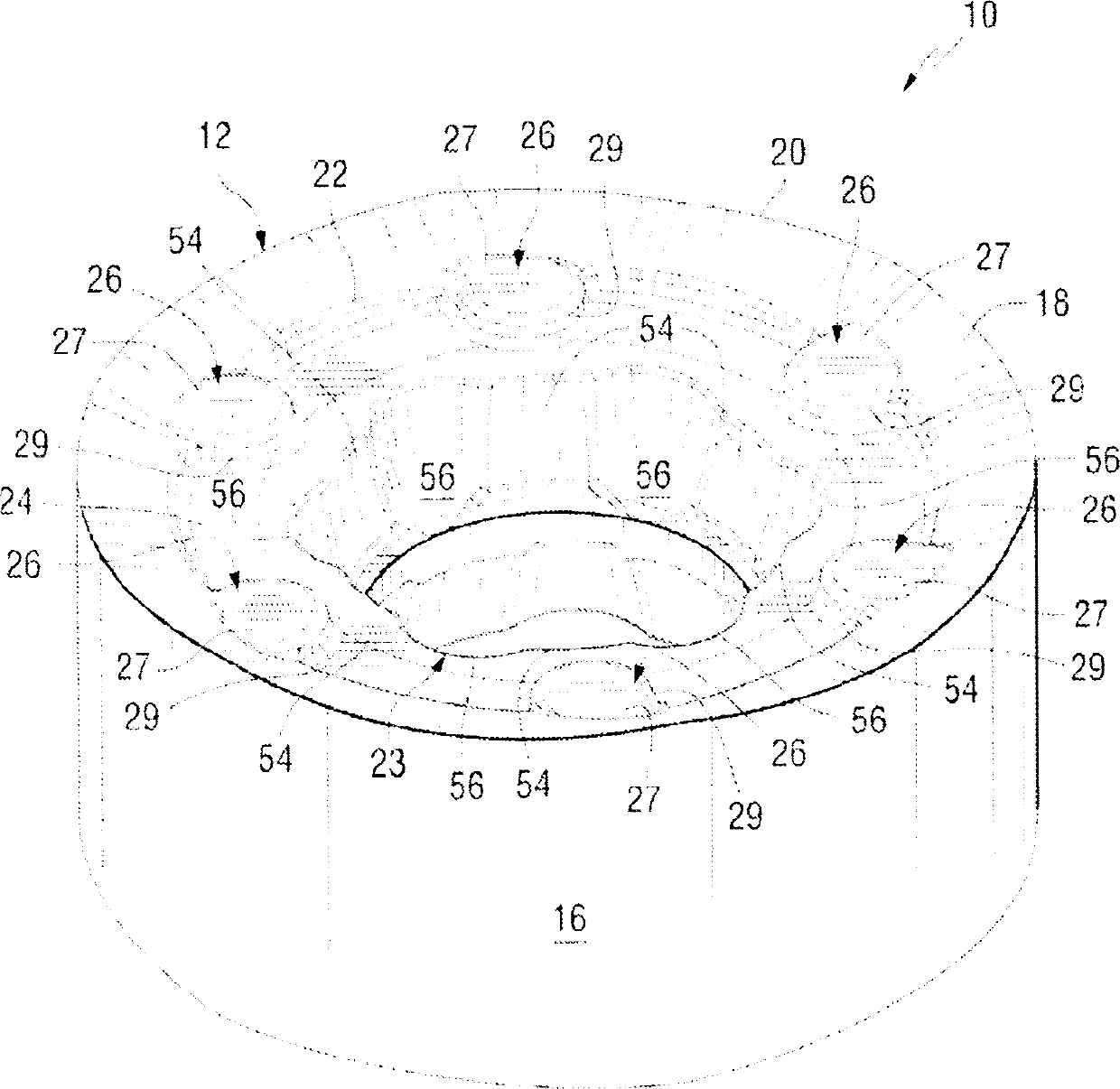

An indexable, invertable cutting insert has radially-oriented positioning segments on a front face of the insert and radially-oriented positioning segments on the back face of the insert. The radially-oriented positioning segments are shifted on the front face relative to those on the back face such that, when the cutting insert is engaged within the toolholder, the cutting segment utilized on the front face will never be directly opposite the cutting segment utilized on the back face. A toolholder system is made up of the cutting insert and a toolholder capable of securing and indexing the cutting insert.

Owner:KENNAMETAL INC

Assembly for rotating a cutting insert during a turning operation and inserts used therein

Owner:KENNAMETAL INC

Round cutting insert with reverse anti-rotation feature

A round cutting insert with a reverse anti-rotation feature that can be manufactured easily and inexpensively is disclosed. The round cutting insert includes a plurality of dimples formed on a first surface and another plurality of dimples formed on a second, opposing surface. The round insert is reversible and indexable. The round cutting insert is removable received in an insert receiving pocket in a tool body. The insert receiving pocket includes a single projection that is capable of being received in one of the plurality of dimples. The cooperation between the projection and one of the plurality of dimples prevents rotation of the round cutting insert when mounted in the insert receiving pocket. The plurality of dimples and the projection can be any desirable complimentary shape, such as a slot, a V-shape, a wagon wheel, a sports wheel, a pyramid, and the like.

Owner:KENNAMETAL INC

Family of cutting inserts, milling cutting tool, and cutting insert

ActiveUS20110091294A1High leading angleHigh radial cutting forceMilling cuttersArc segment toolEngineeringKnife blades

Owner:SECO TOOLS AB

Indexable circular cutting insert

An indexable, invertable cutting insert has radially-oriented positioning segments on a front face of the insert and radially-oriented positioning segments on the back face of the insert. The radially-oriented positioning segments are shifted on the front face relative to those on the back face such that, when the cutting insert is engaged within the toolholder, the cutting segment utilized on the front face will never be directly opposite the cutting segment utilized on the back face. A toolholder system is made up of the cutting insert and a toolholder capable of securing and indexing the cutting insert.

Owner:KENNAMETAL INC

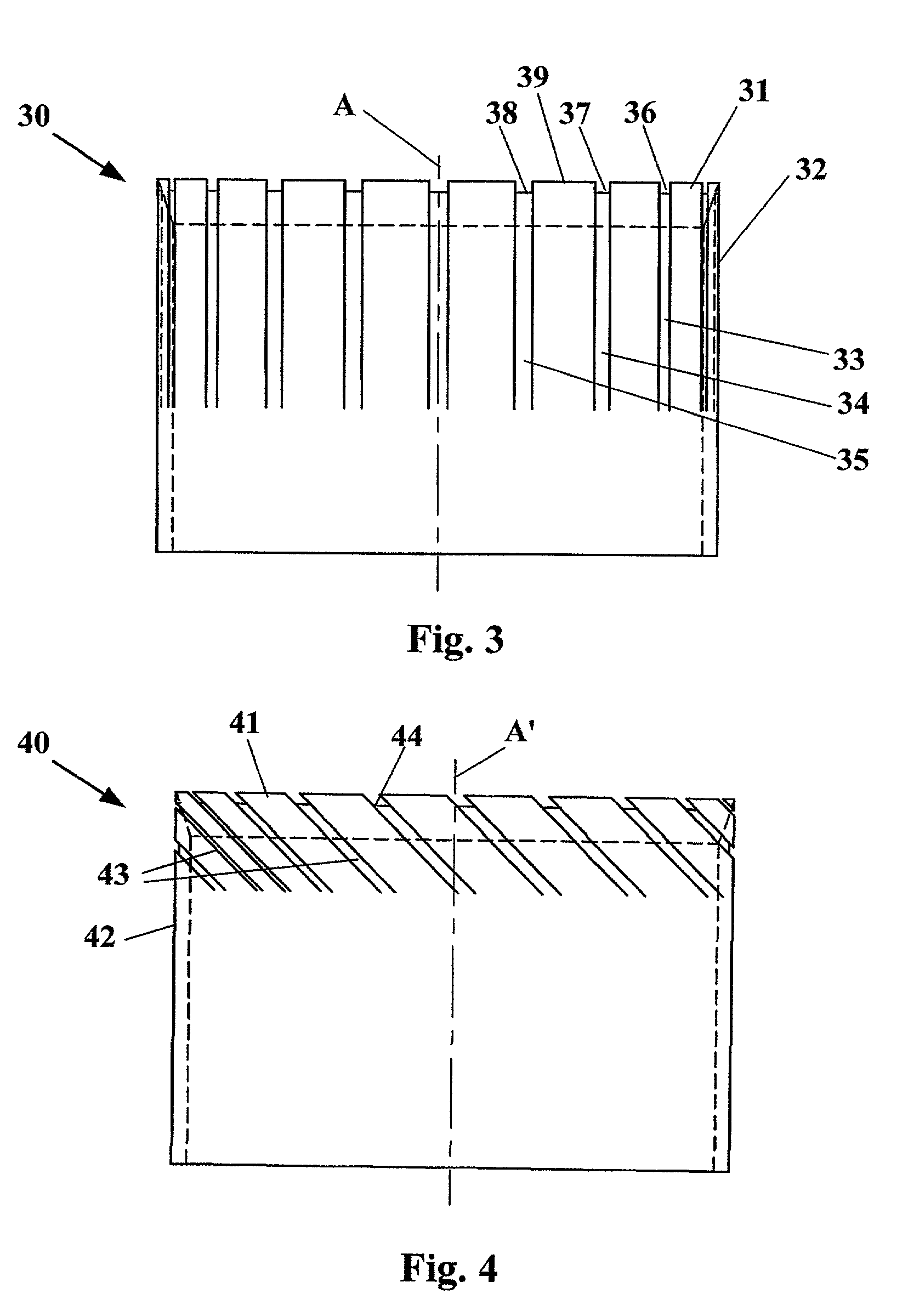

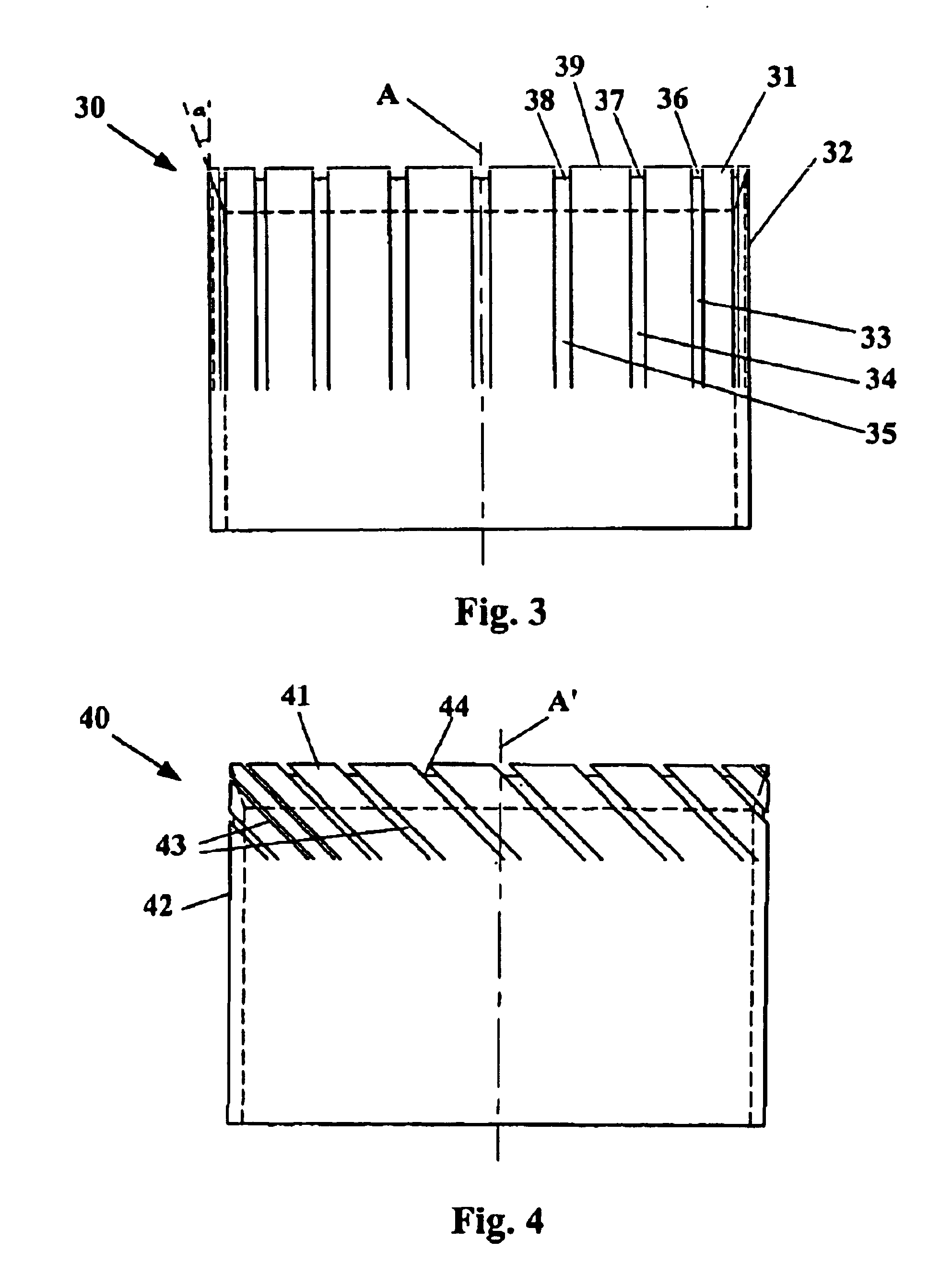

Milling tool as well as a milling insert

ActiveUS20140030034A1Ample ramping angleSimple and cost-effective wayTransportation and packagingMilling cuttersEdge segmentNeutral plane

A double-sided, indexable milling insert has a round basic shape defined by an imaginary cylinder, which is concentric with a center axis and extends between two reference planes that extend perpendicular to the center axis and are equidistantly separated from a neutral plane. The milling insert includes a pair of opposite chip faces located in the reference planes between which an envelope surface concentric with the center axis extends, a plurality of identical and alternately usable cutting edges along the peripheries of the chip faces, and lock means for rotationally securing the milling insert in one of several predetermined index positions. The individual cutting edge has the shape of a wave trough and includes two edge segments that meet at a bottom point.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

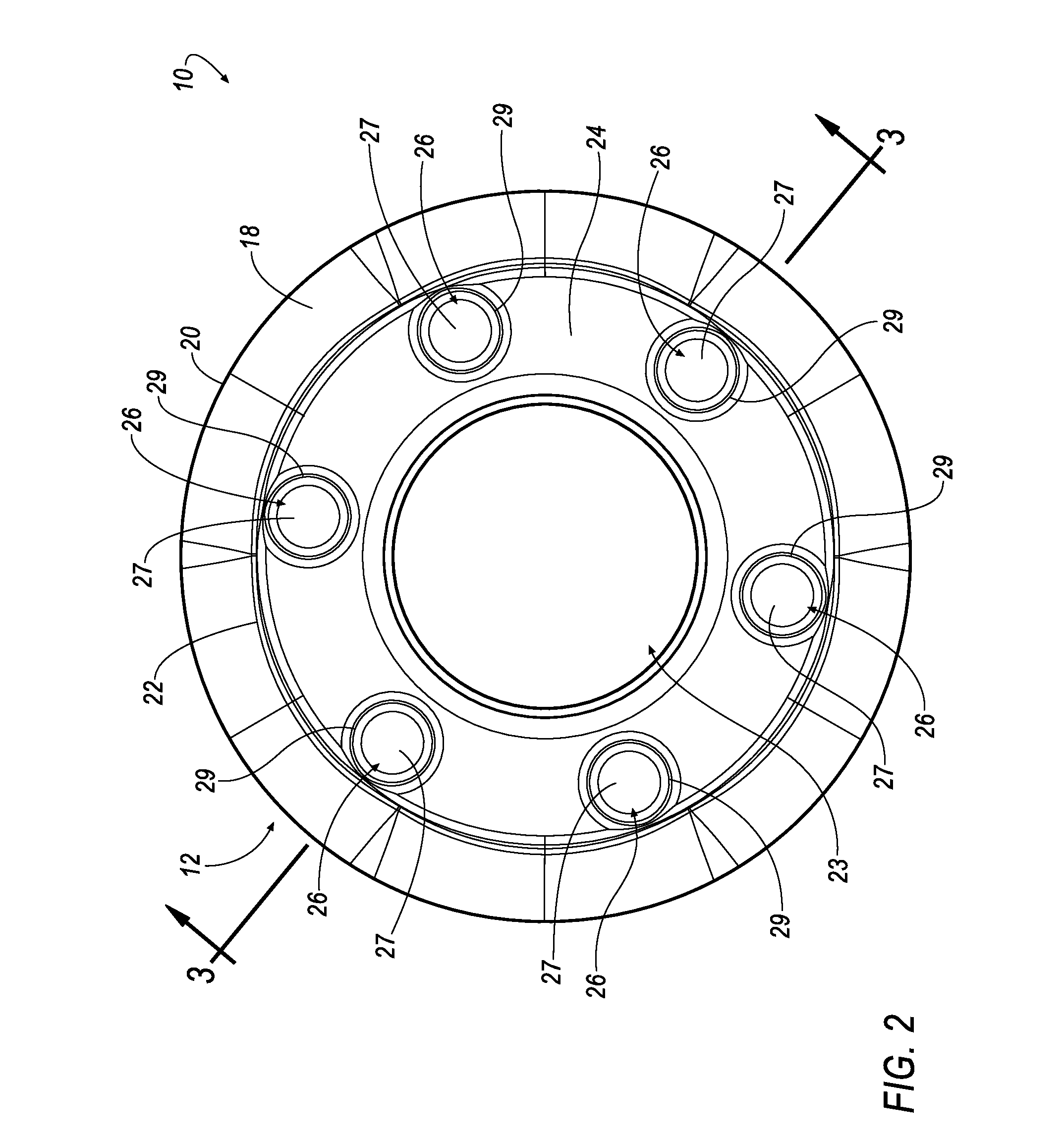

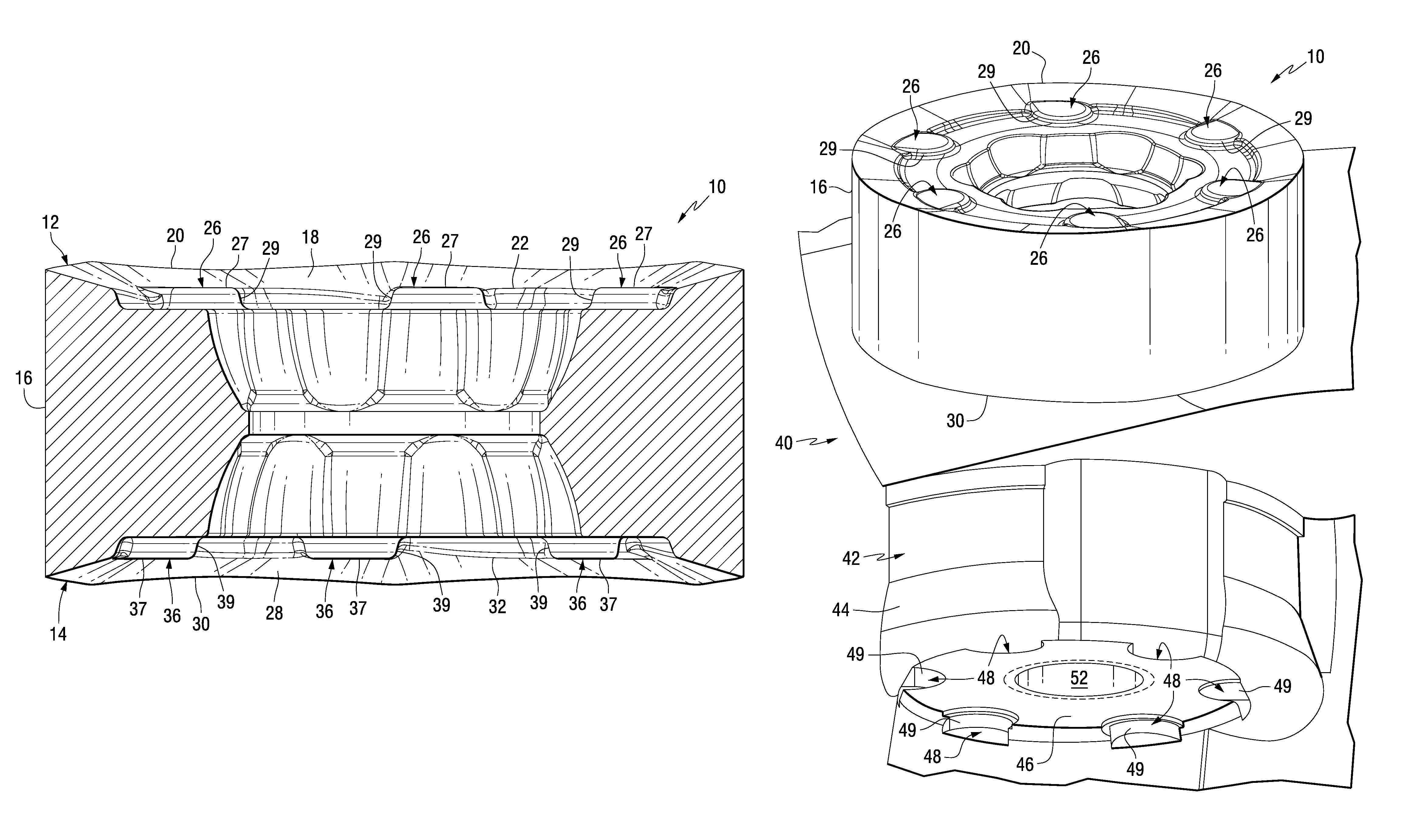

Round cutting insert with anti-rotation feature

A round cutting insert (10) with an anti-rotation feature. The round cutting insert (10) includes a plurality of projections (26) formed on a first surface (12) and another plurality of projections (36) formed on an opposing surface (14). The round cutting (10) insert is reversible and indexable. The round cutting insert (10) is removably received in an insert receiving pocket (42) in a tool body (40) wherein the insert receiving pocket (42) includes a plurality of dimples (48) for receiving one of the plurality of first projections (26) or the plurality of second projections (36). This arrangement prevents rotation of the round cutting insert (10) while mounted in the insert receiving pocket (42).

Owner:KENNAMETAL INC

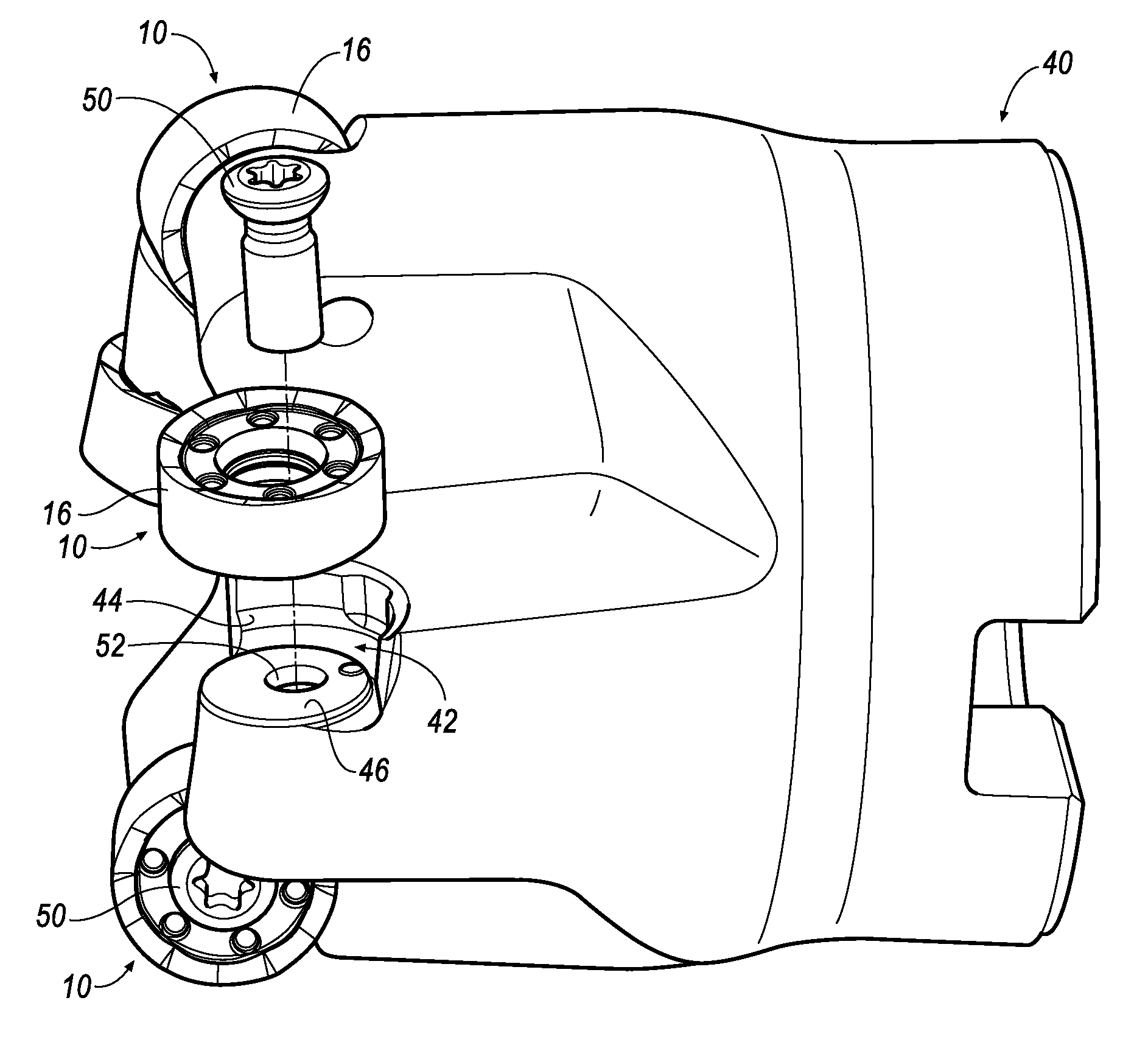

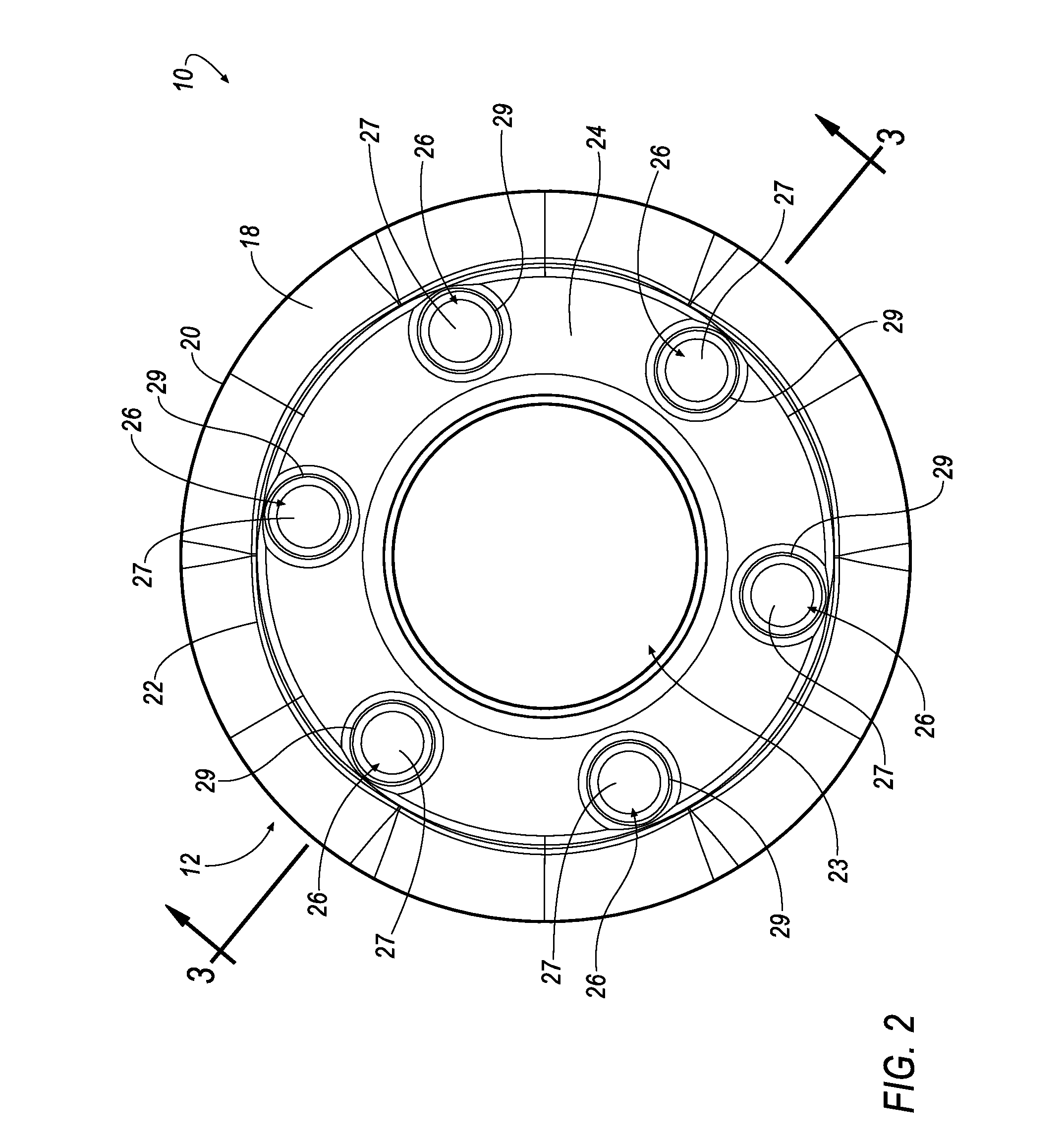

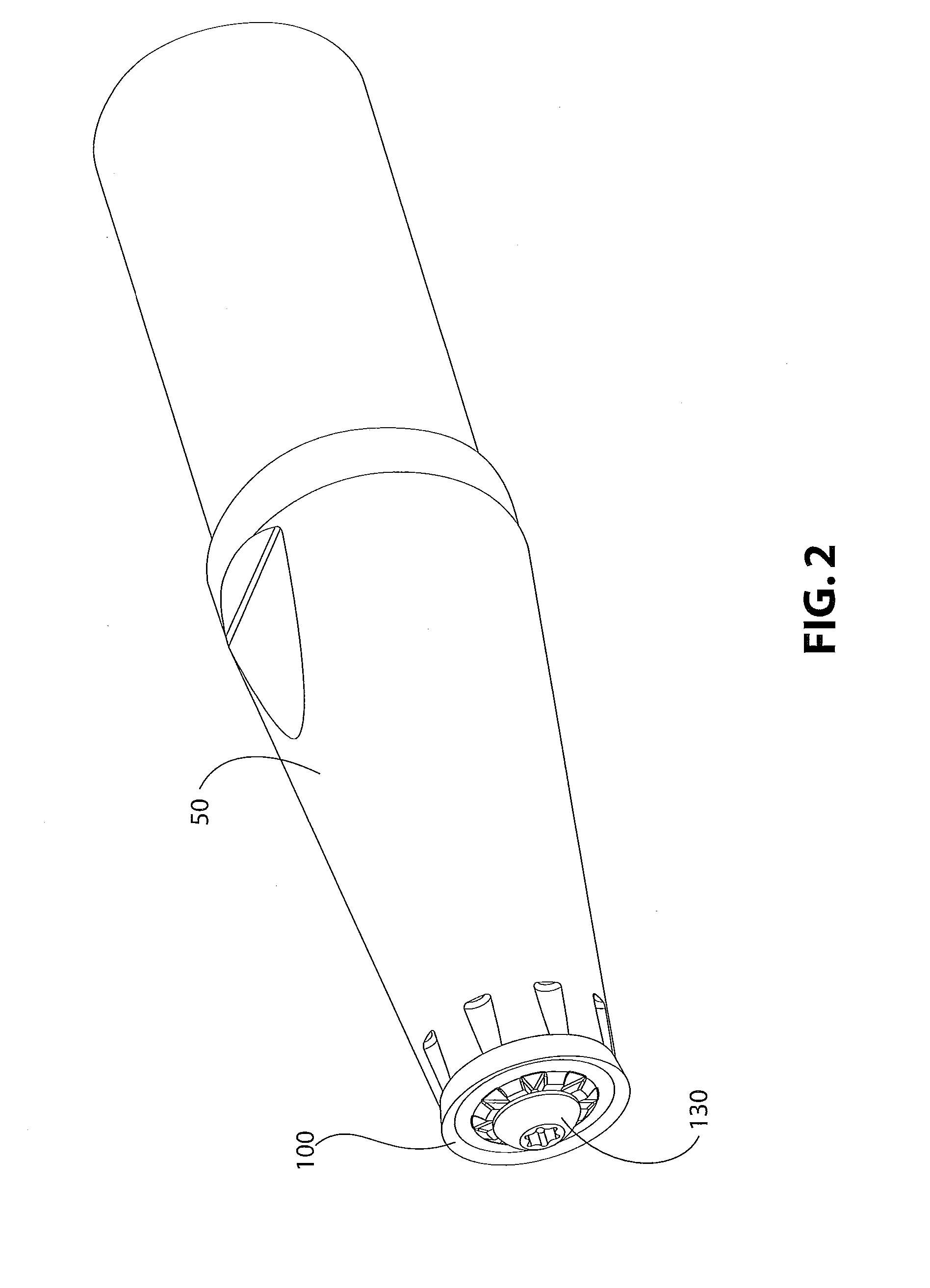

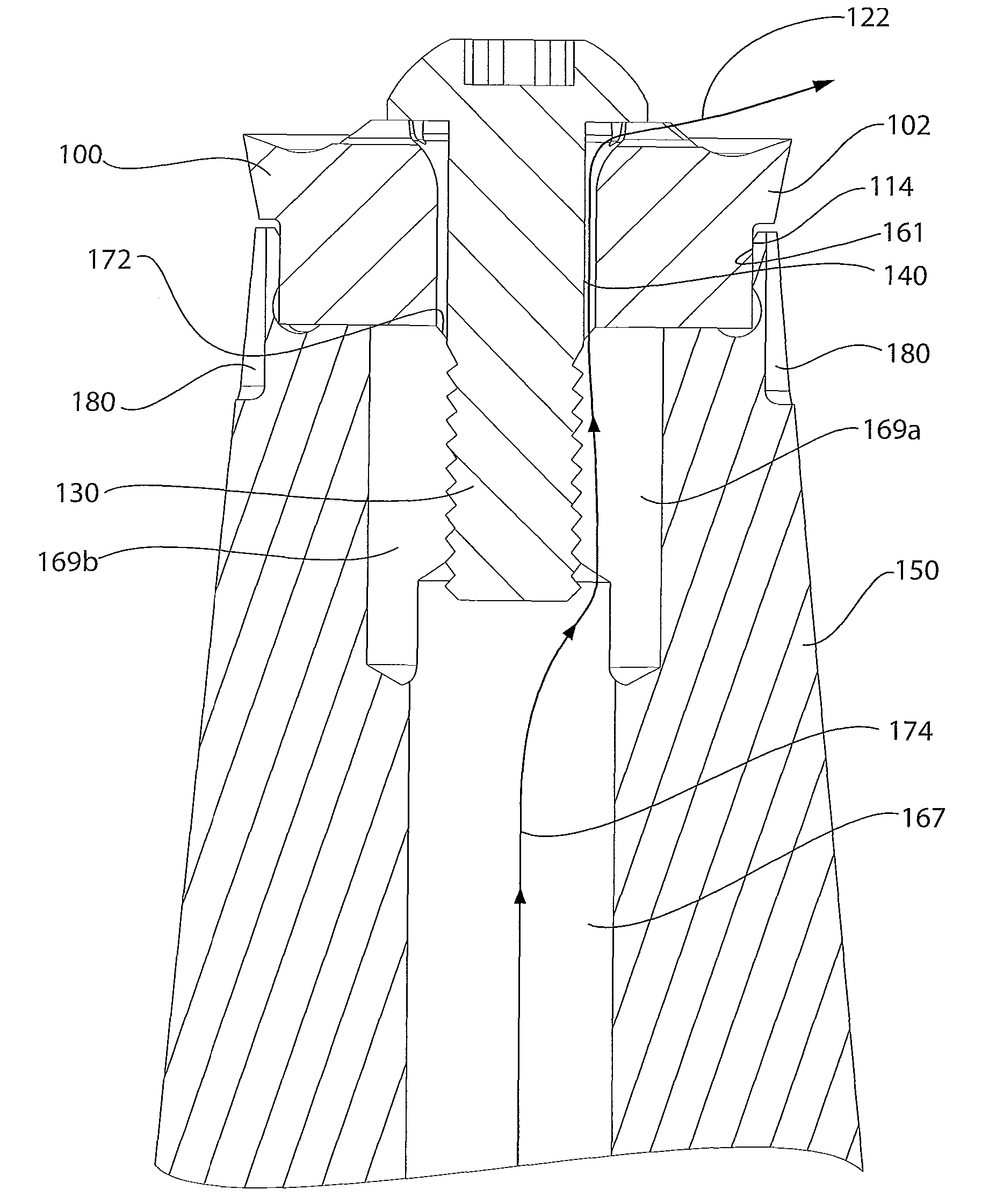

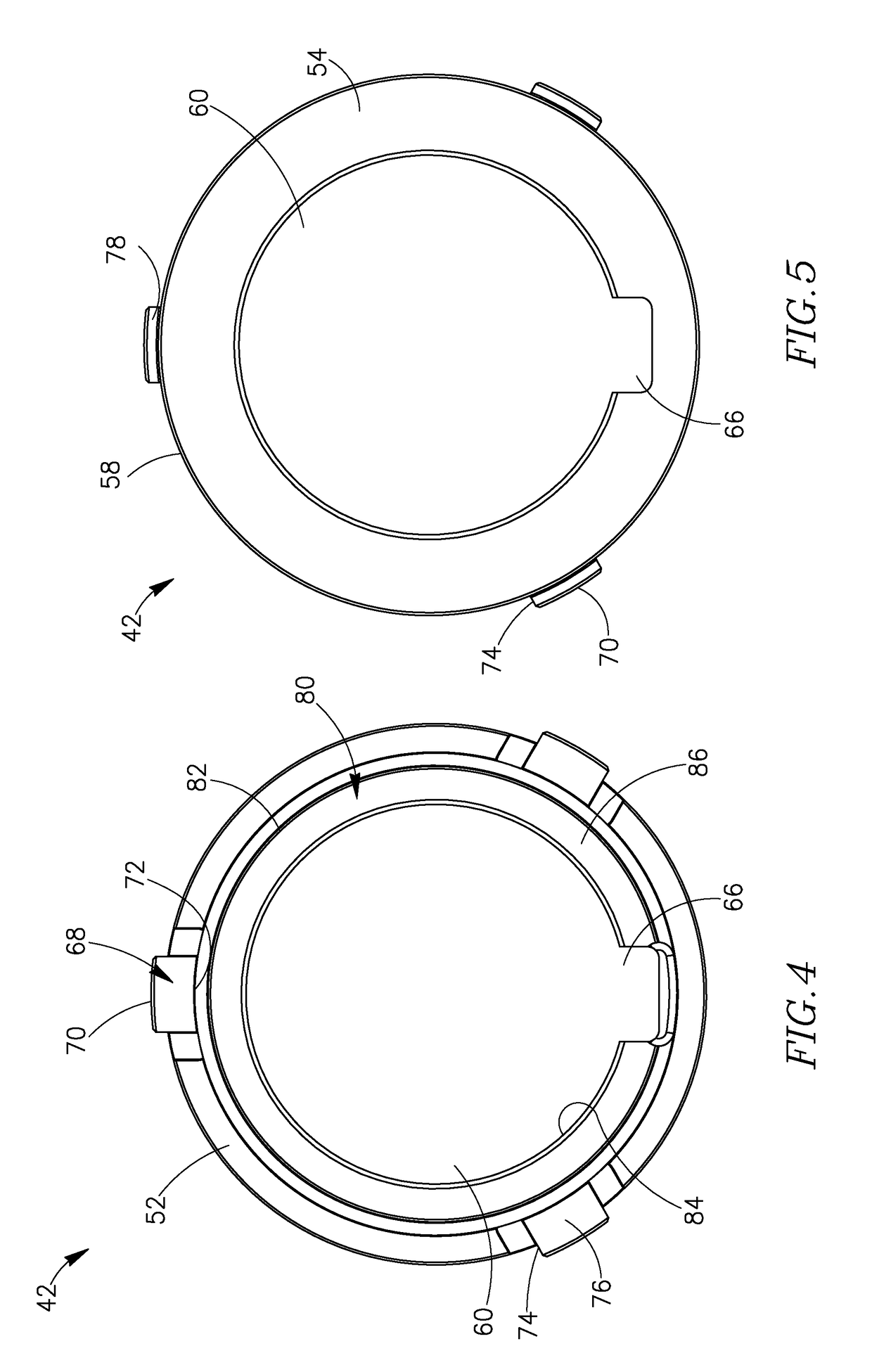

Cutting Insert And Holder For Rotating Applications

ActiveUS20110318117A1Provide flexibilityFlexibility for radial expansion of the hoopCutting insertsTurning toolsMetal workingCoolant

A cutting insert rotated about an axis may be utilized during a metal working operation and applied against the rotating workpiece to enhance tool performance. Coolant may be provided through the central bore of the cutting insert utilizing bypass ports around the threaded hold-down bolts. Additionally, the cutting insert may be held within the toolholder pocket utilizing hoop walls which follow a serpentine path to provide flexibility. Finally, relative rotation of the cutting insert with respect to the toolholder body may be prevented utilizing a pair of protrusions within the toolholder pocket which engage a pair of recesses within a side of the cutting insert.

Owner:KENNAMETAL INC

Cutting insert and holder for rotating applications

ActiveUS8459904B2Flexibility for radial expansion of the hoopProvide flexibilityCutting insertsTurning toolsEngineeringMetal working

Owner:KENNAMETAL INC

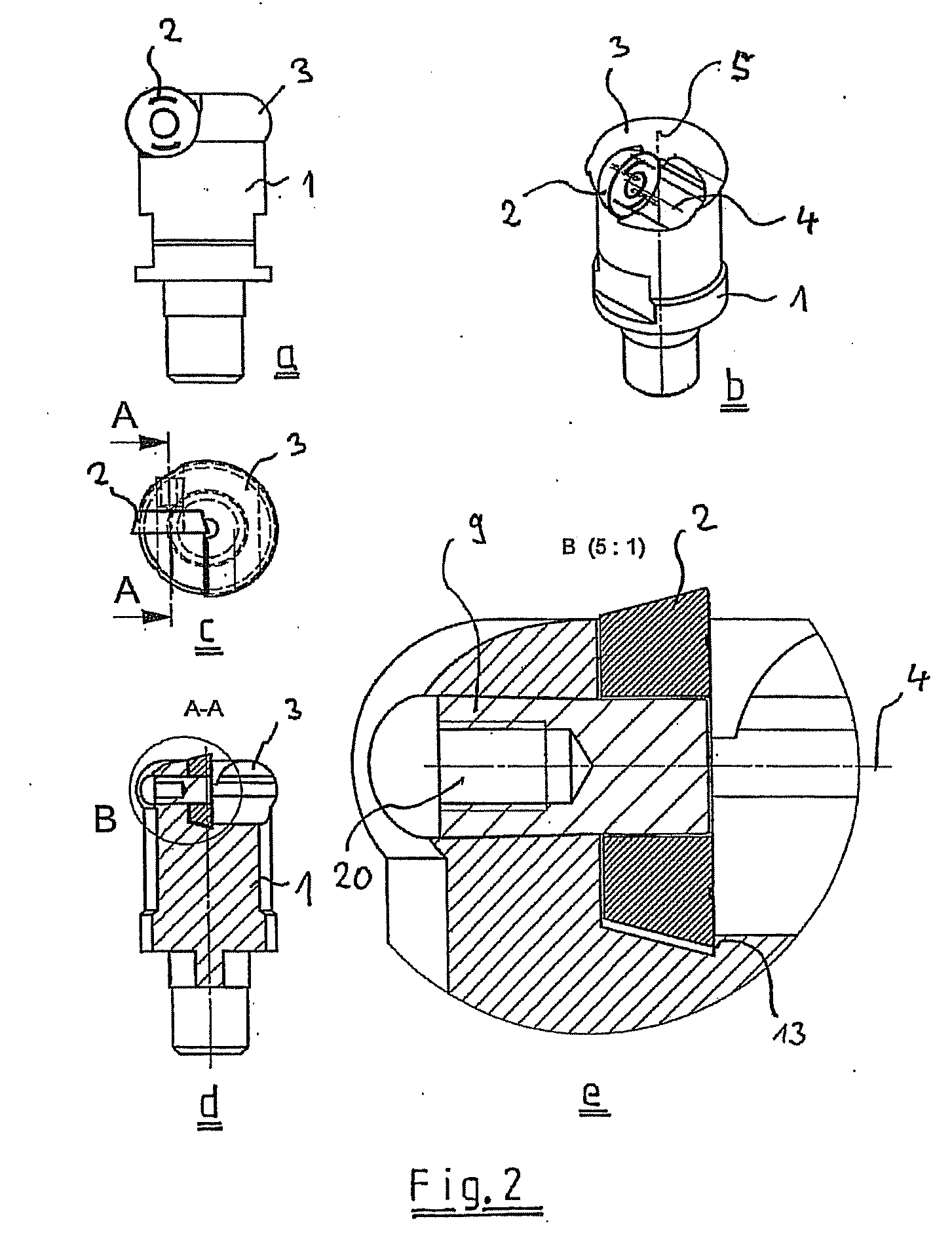

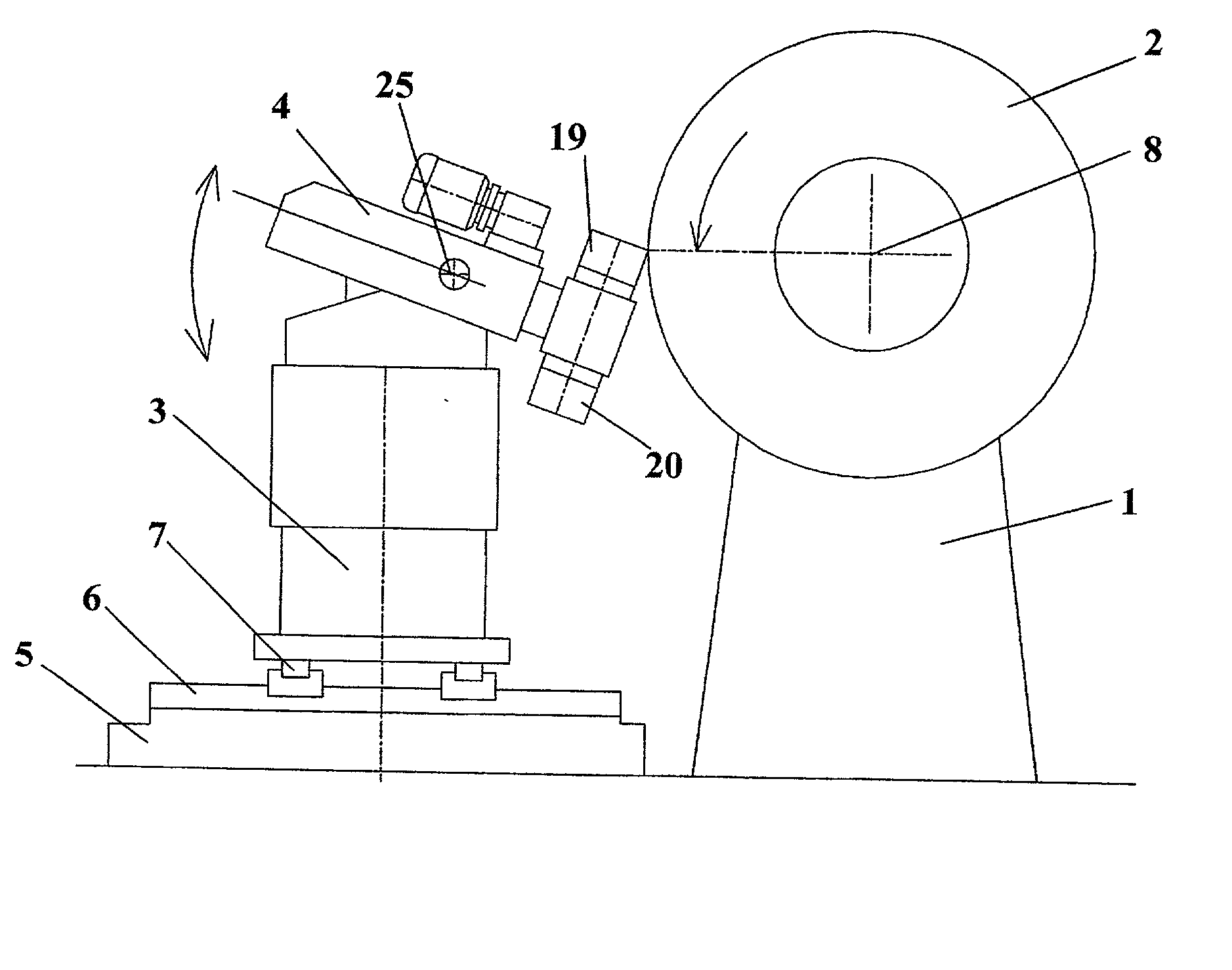

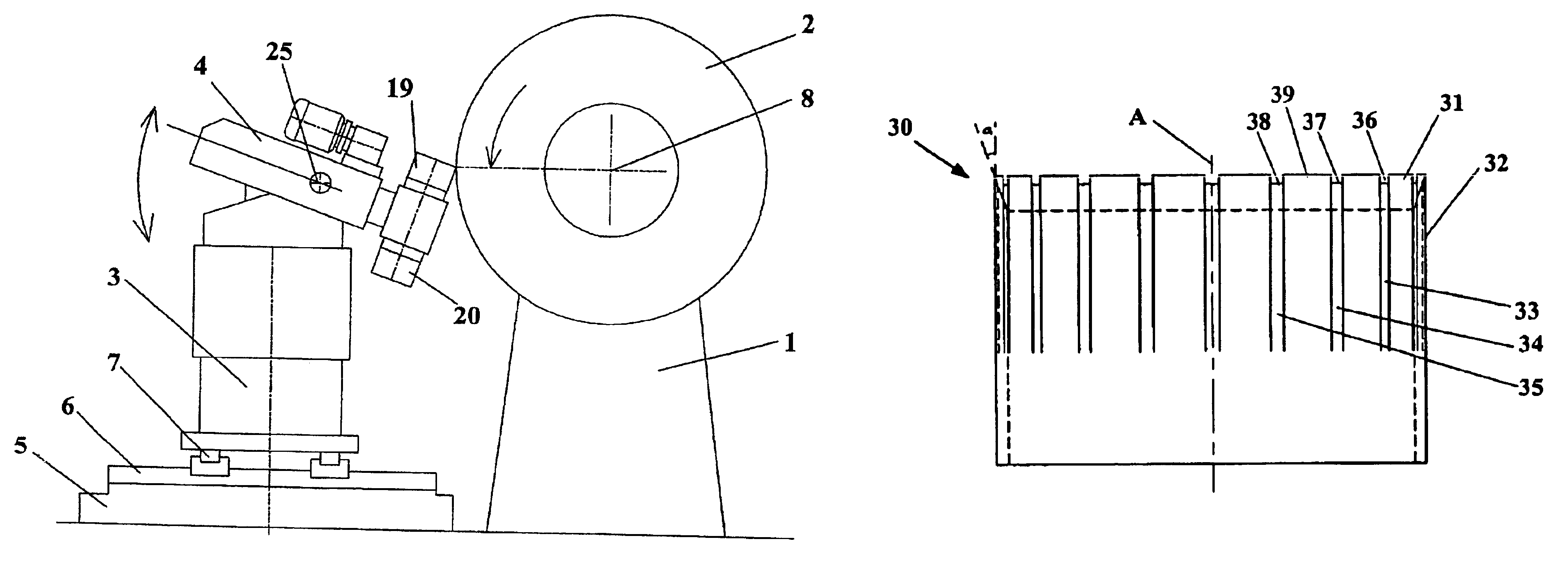

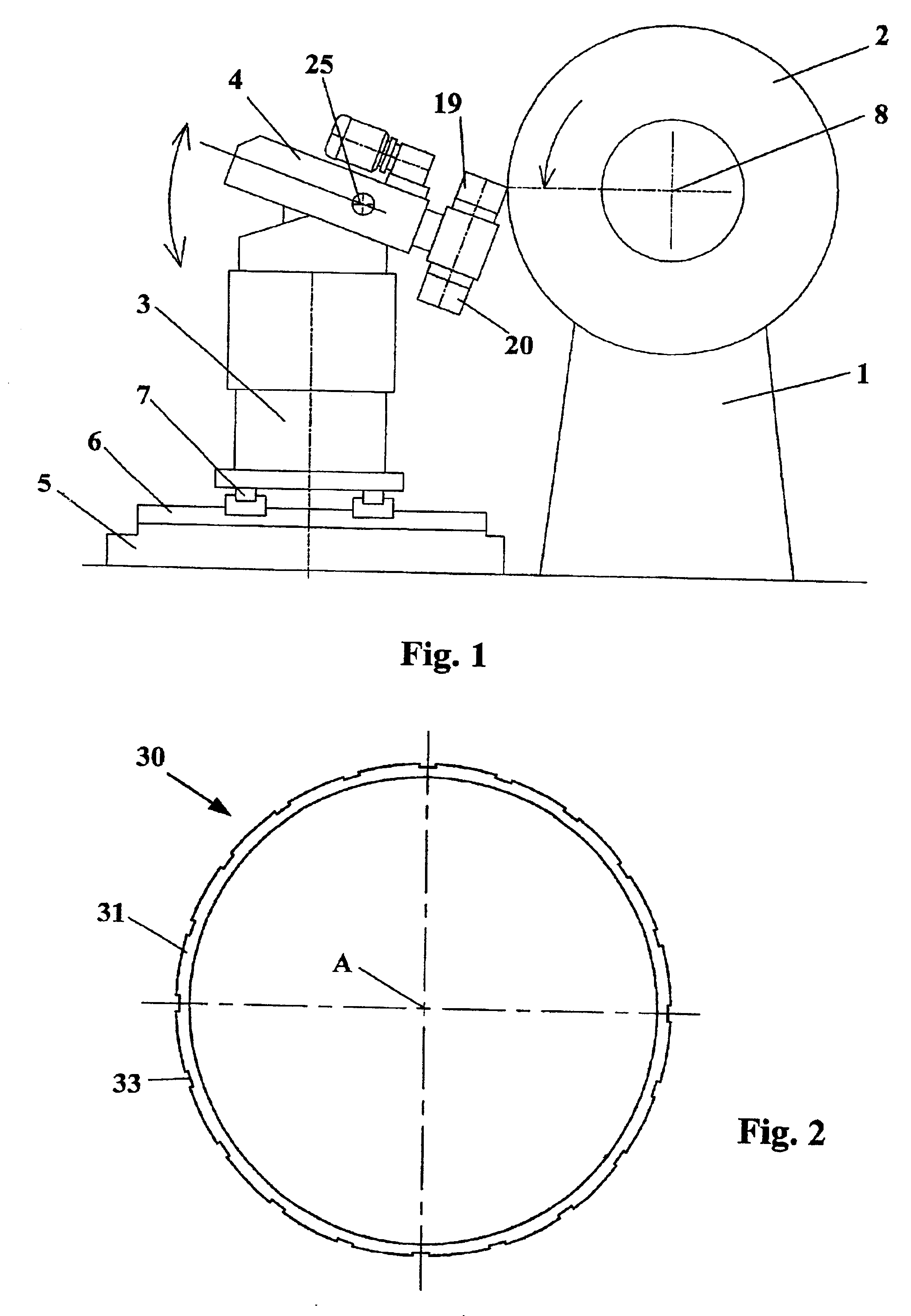

Milling tool for machining work pieces

ActiveUS20110013997A1Simple processMilling cuttersMetal working apparatusEngineeringMechanical engineering

The invention related to a milling tool (1) for machining work pieces, comprising at least one blade that is arranged in a radial manner on the milling head (2) that is rotationally mounted on a rotationally symmetrical designed Y-axis (4) on the milling head. According to the invention, said indexable cutting insert (2) is arranged below a tolerance play (7) in a freely rotating manner on the free end (8) of a mounting pin (9) secured in a detachable manner to the milling head (3) below the clamping seat. The freely rotationally mounted indexable cutting insert (2) is mounted or surrounded on the entire surface of the rear side (10) and on certain pats on the front side (11) such that the mounting pin (9) does not detach itself from the material (12) of the milling head (3).

Owner:POKOLM FRANZ JOSEF

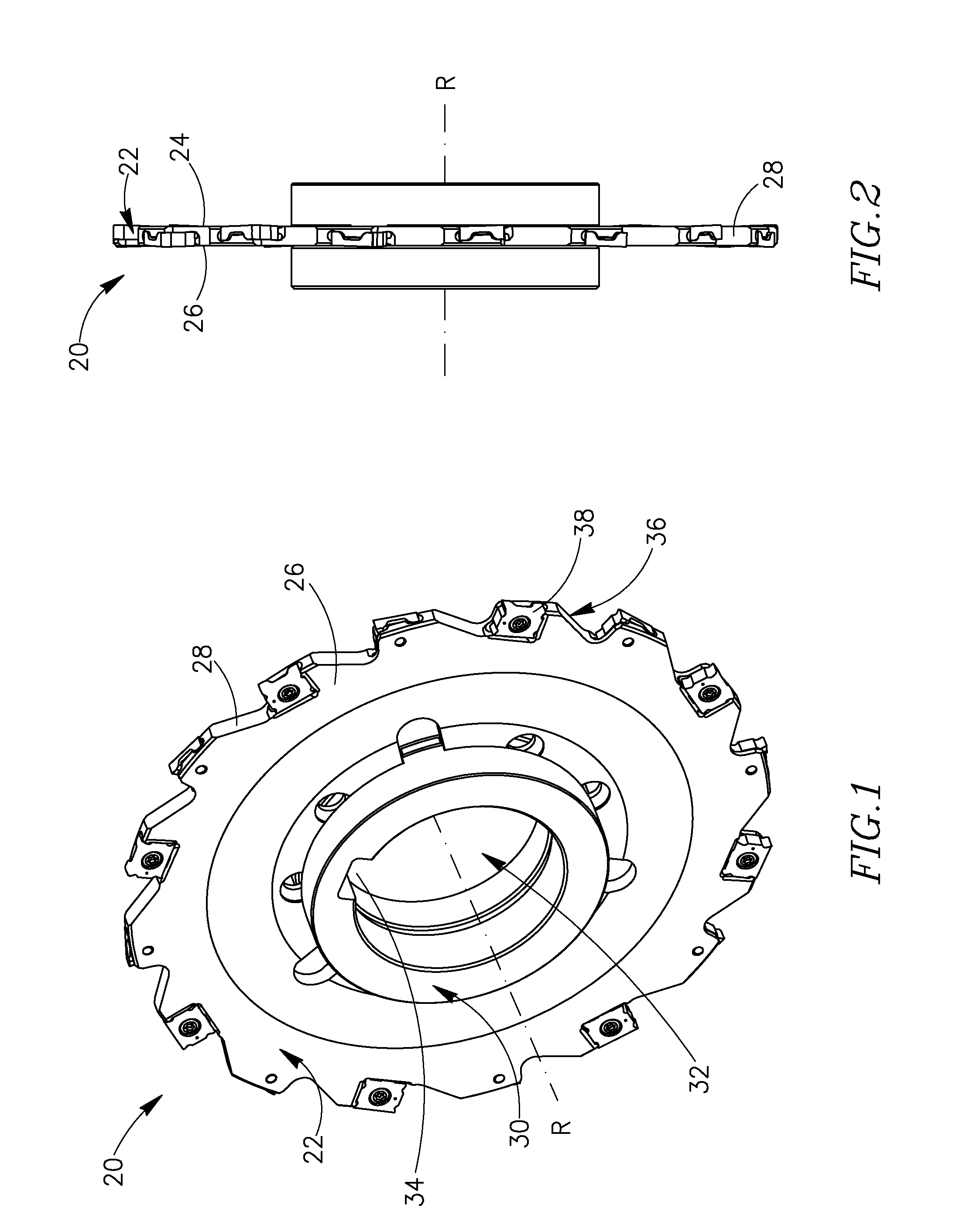

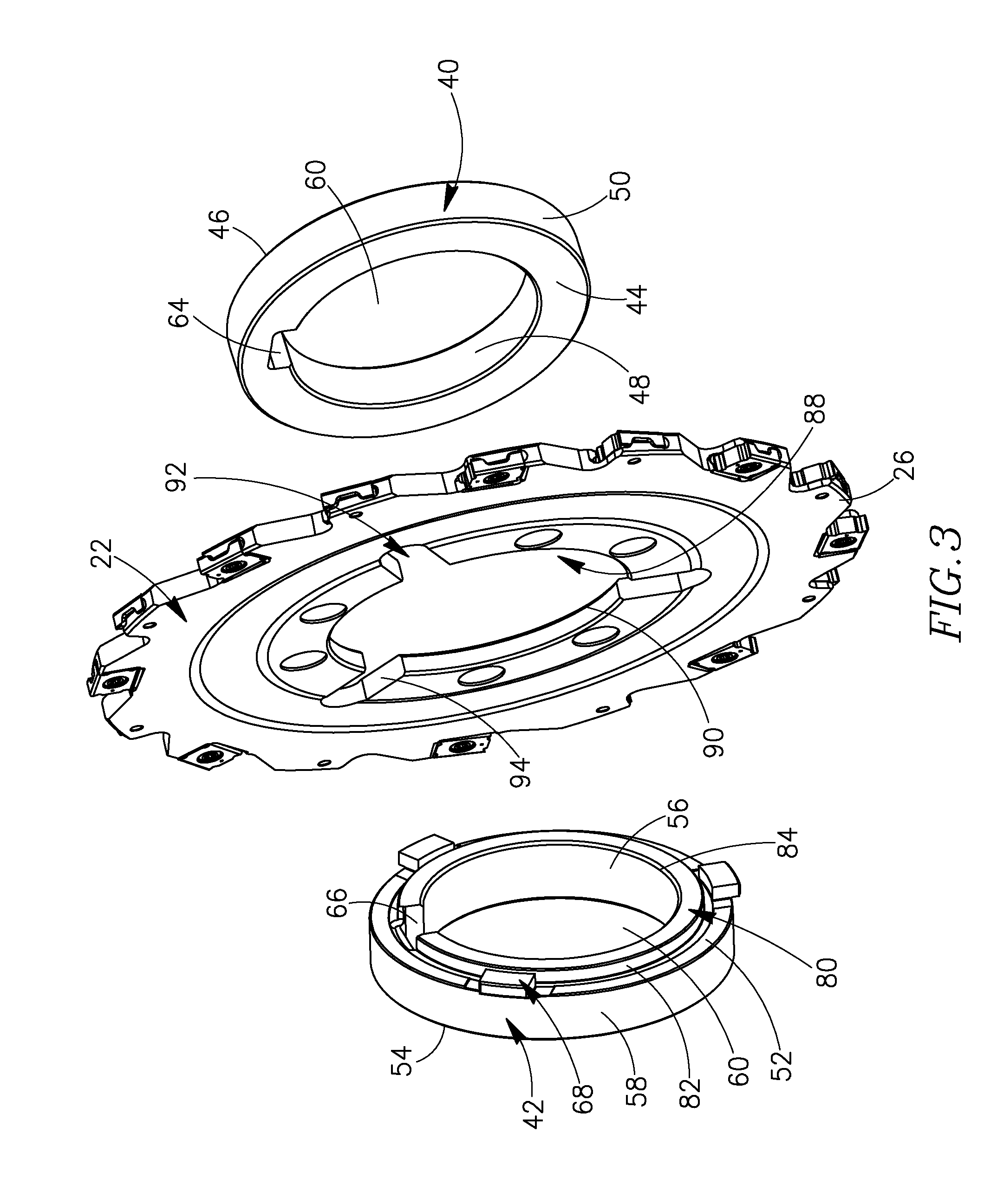

Milling cutter

A milling cutter includes a disk like cutter body having radially directed slots and a central aperture. An exchangeable hub of the milling cutter has two adapter members located on either side of the cutter body and has an inner side wall. One of the adapter members has at least two protrusions formed on the adapter inner side wall and one of the two adapter members has a raised portion located on the adapter inner side wall. The adapter members are secured to the cutter body by the protrusions positioned in the slots and the raised portion positioned in the central aperture.

Owner:ISCAR LTD

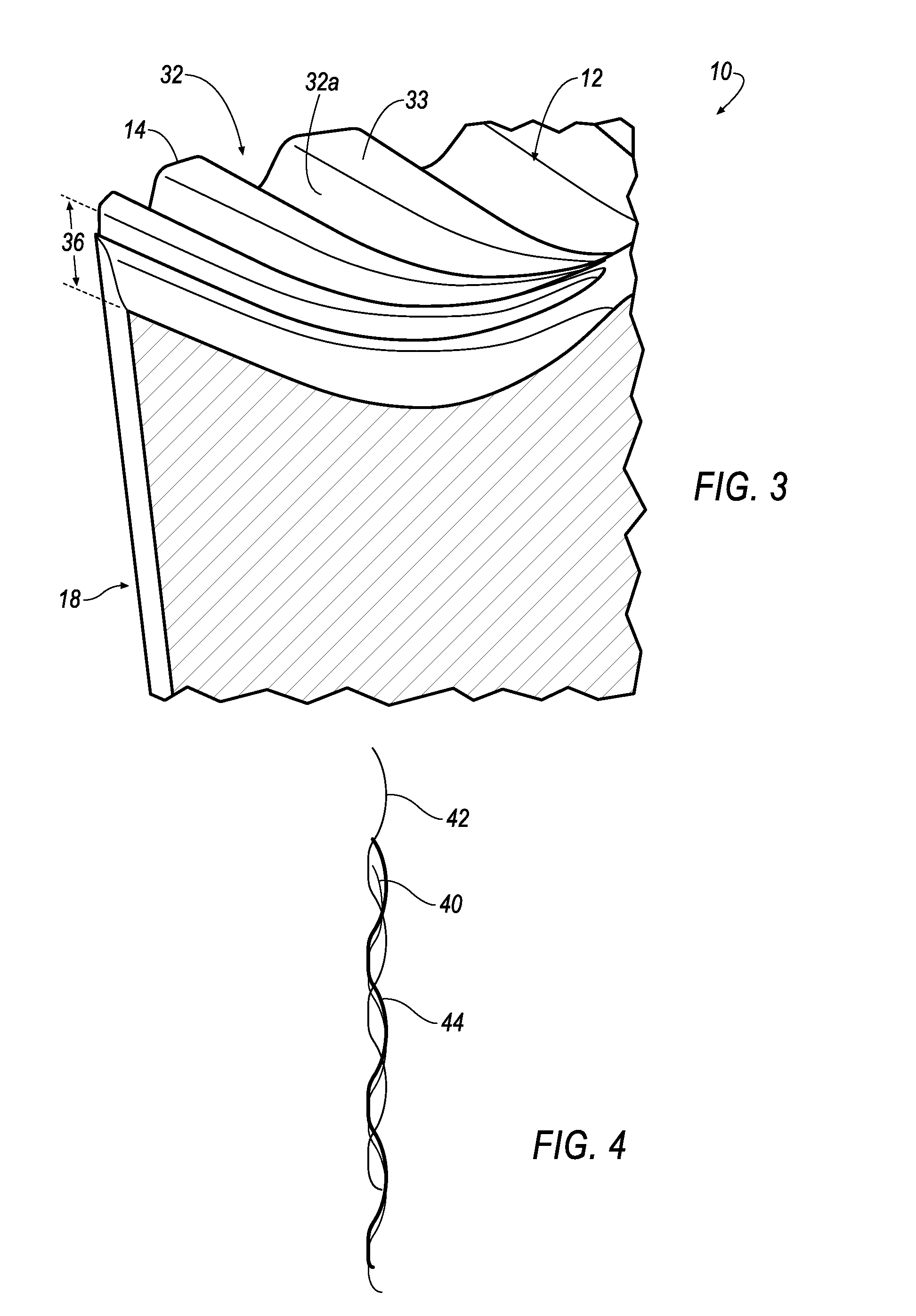

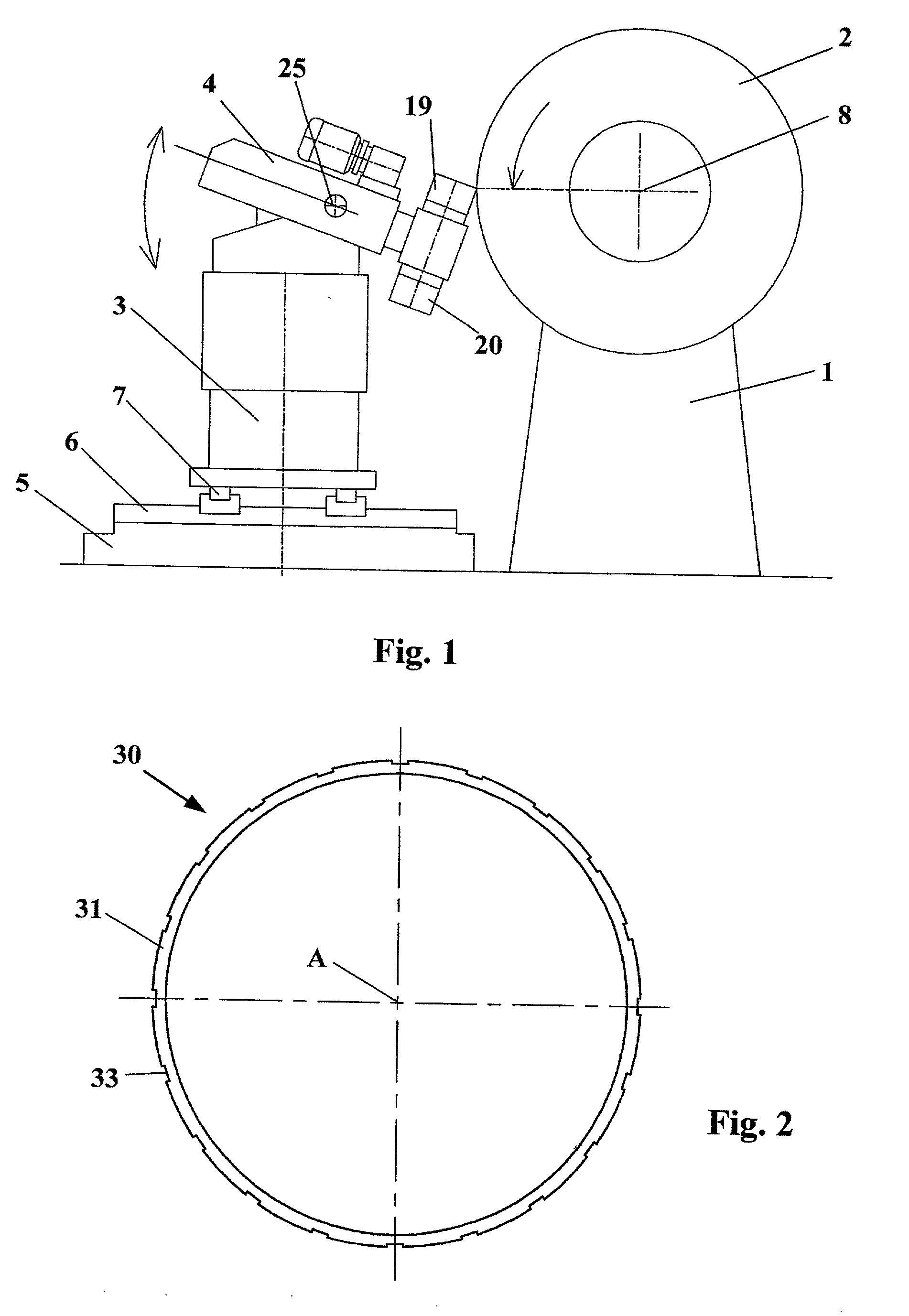

Round cutting insert with serrated topography

ActiveUS20140219734A1Reducing regenerative chatterMilling cuttersAdverse effect compensationEngineeringMechanical engineering

A cutting insert with a serrated topography includes a top surface terminating in a circular cutting edge, a bottom surface and a frusto-conical sidewall interconnecting the top surface and the bottom surface, and a plurality of serrations on the top surface uniformly disposed around the circular cutting edge and extending radially inward from the cutting edge in such a way that a bisector through each serration passes through a central axis of the cutting insert. The plurality of serrations are positioned in a cutting tool in such a way so as to reduce regenerative chatter during a cutting operation. A method of reducing generative chatter by positioning the cutting inserts in a particular fashion in a cutting tool is also disclosed.

Owner:KENNAMETAL INC

Cutting insert with evolutive wedge or clearance angle and toolholder using such a cutting insert

ActiveUS20140003874A1Easy to cutImprove edge strengthMilling cuttersMetal working apparatusWedge angleKnife holder

A circular cutting insert includes a top surface having a top edge portion, a side surface having a clearance surface and a clearance edge portion. A cutting edge is formed between the clearance edge portion and the top edge portion. The clearance edge portion and the top edge portion form a wedge angle. The wedge angle varies as a function of circumferential position about a central axis of the insert relative to a point on the cutting edge.

Owner:SECO TOOLS AB

Cutting insert with evolutive wedge or clearance angle and toolholder using such a cutting insert

A circular cutting insert includes a top surface having a top edge portion, a side surface having a clearance surface and a clearance edge portion. A cutting edge is formed between the clearance edge portion and the top edge portion. The clearance edge portion and the top edge portion form a wedge angle. The wedge angle varies as a function of circumferential position about a central axis of the insert relative to a point on the cutting edge.

Owner:SECO TOOLS AB

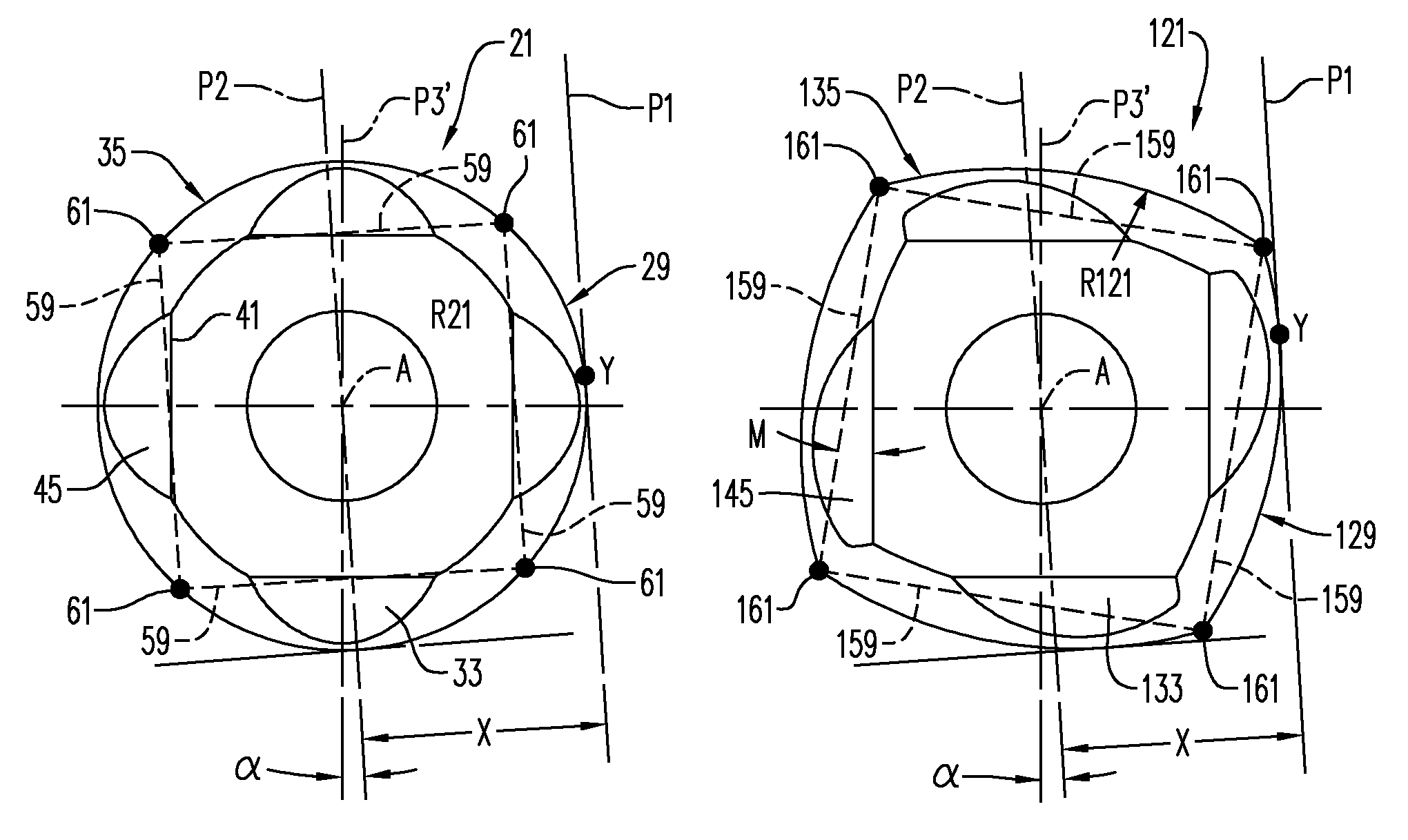

Turning insert, a tool part, a method as well as a machine tool for chip-cutting metal machining

InactiveUS8776649B2Short processing timeReduce the temperatureLathesAutomatic/semiautomatic turning machinesMetal machiningEngineering

A turning insert formed for chip-cutting metal machining of a workpiece that rotates in a direction of rotation at a first speed of rotation around a workpiece axis, the turning insert including a front surface, an envelope surface, and a circular cutting edge located where the front surface meets the envelope surface. The cutting edge extends around the front surface and lays in a plane that forms an angle α with the envelope surface. A tool axis extends through the turning insert in a normal direction in respect of the plane, and the turning insert, during the chip-cutting metal machining, is formed to rotate around the tool axis at a second speed of rotation. The envelope surface forms a chip surface and is arranged to meet chips formed in the chip-cutting metal machining, and the chip surface includes chip breaking means.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Milling Cutter

A milling cutter includes a disk like cutter body having radially directed slots and a central aperture. An exchangeable hub of the milling cutter has two adapter members located on either side of the cutter body and has an inner side wall. One of the adapter members has at least two protrusions formed on the adapter inner side wall and one of the two adapter members has a raised portion located on the adapter inner side wall. The adapter members are secured to the cutter body by the protrusions positioned in the slots and the raised portion positioned in the central aperture.

Owner:ISCAR LTD

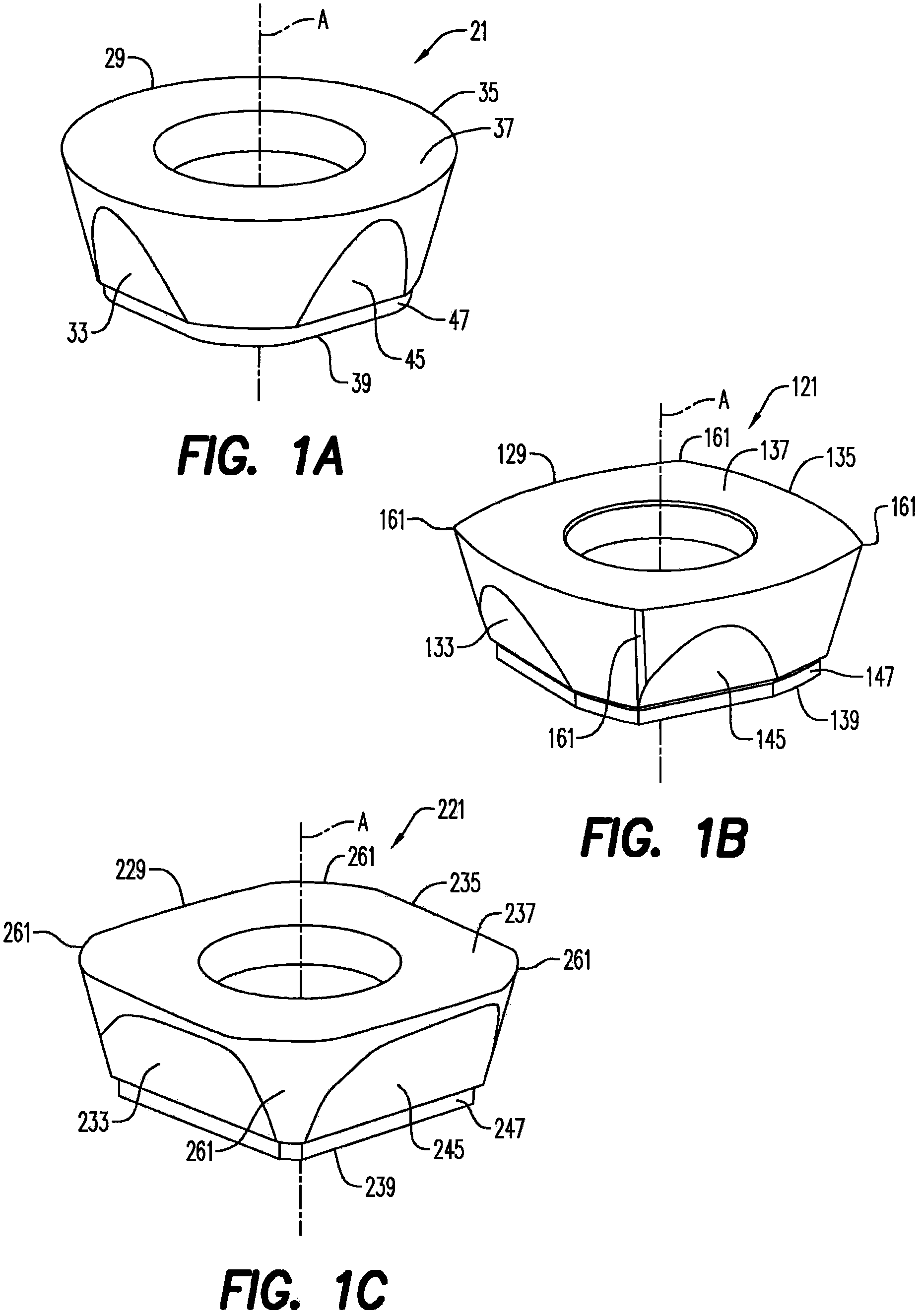

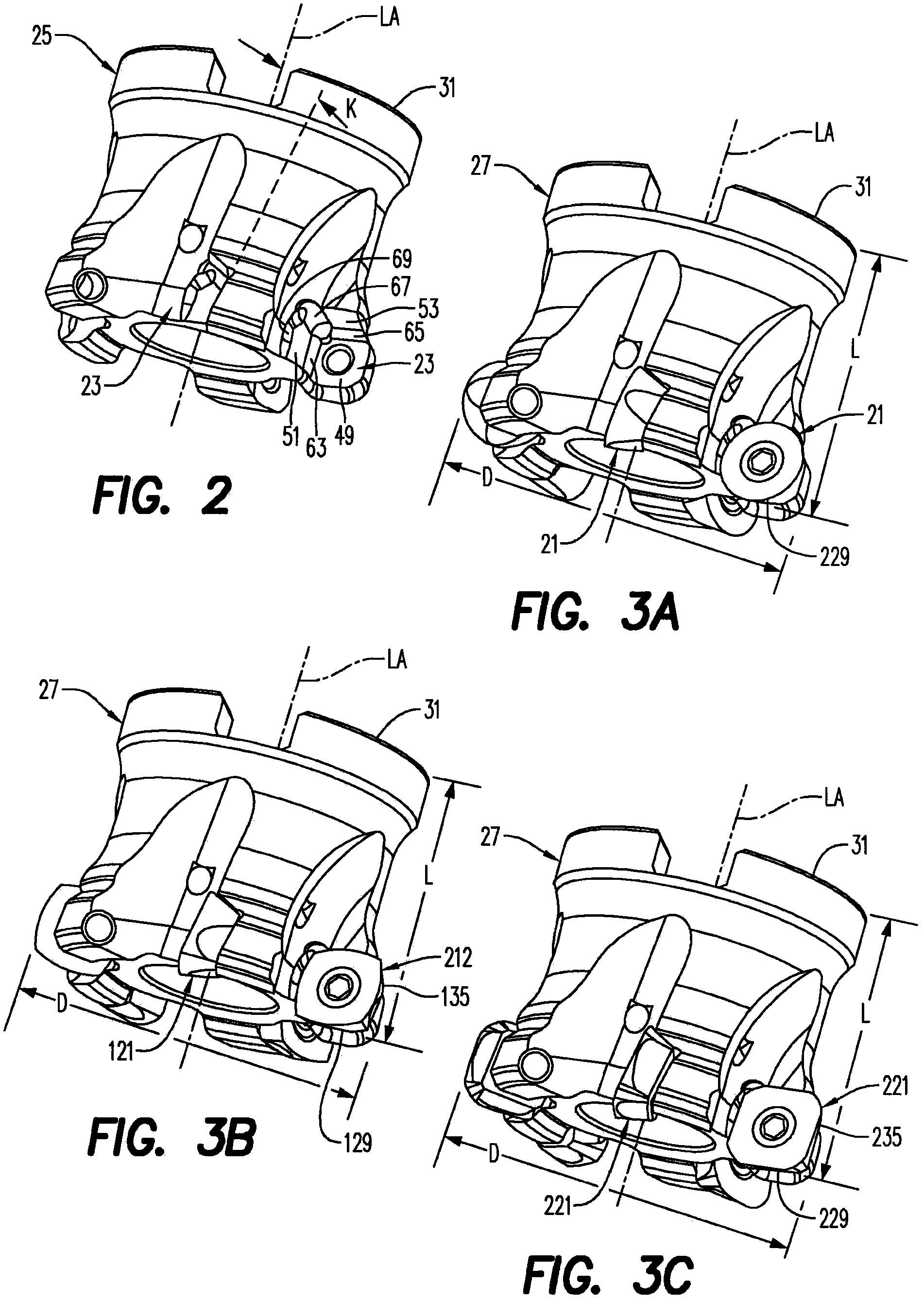

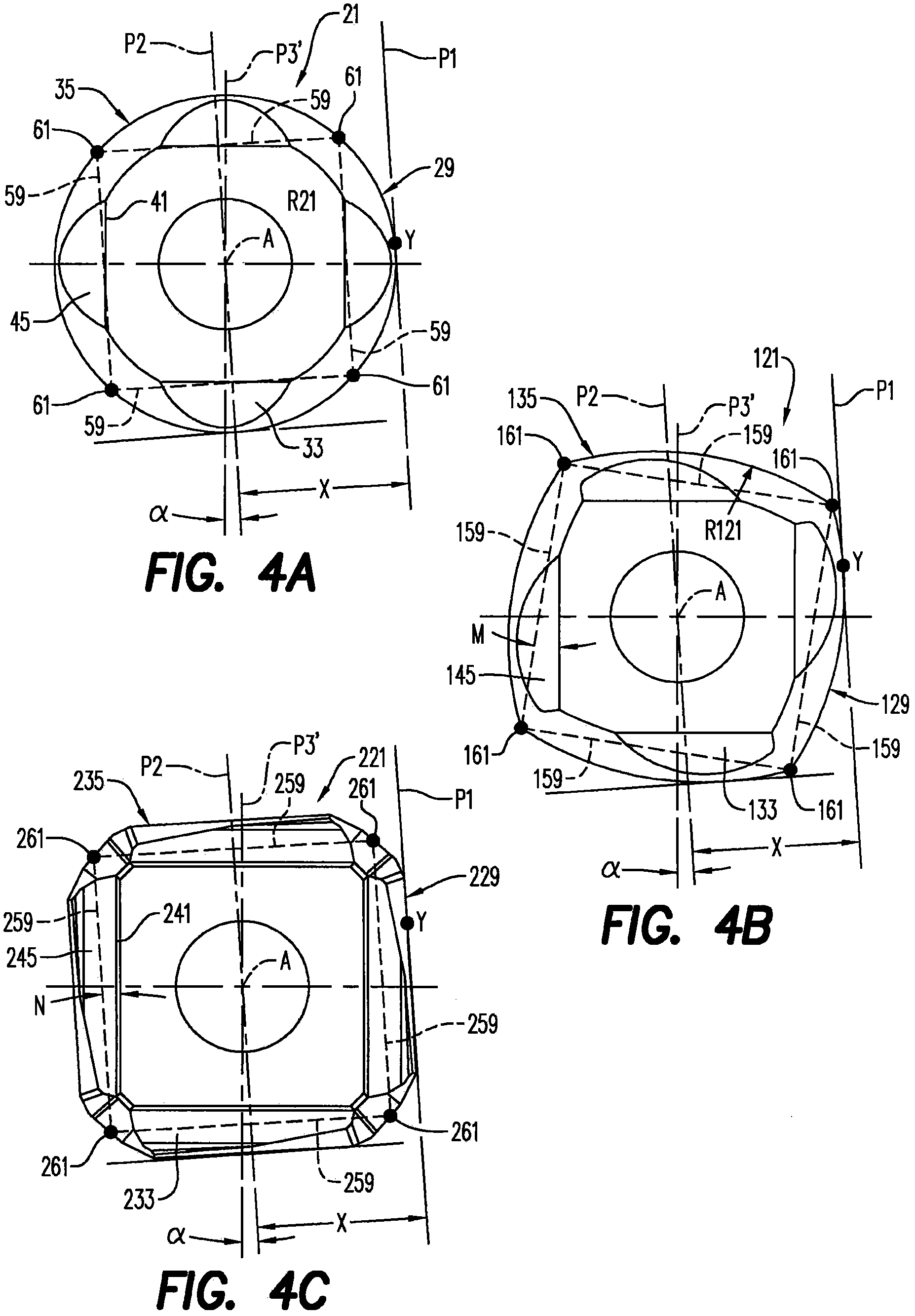

Family of cutting inserts, milling cutting tool, and cutting insert

Owner:SECO TOOLS AB

Family of cutting inserts, milling cutting tool, and cutting insert

ActiveUS9149878B2High leading angleAvoid reaching a high feed per toothMilling cuttersArc segment toolEngineeringMechanical engineering

A family of cutting inserts includes a plurality of different inserts, each having a different geometry. Each insert of the plurality of different inserts is adapted to be mounted in a common insert-receiving pocket on a toolholder of a milling cutting tool so that an outer diameter generated by the milling cutting tool is the same, regardless which insert of the plurality of inserts is mounted in the pocket.

Owner:SECO TOOLS AB

Milling tool for machining work pieces

ActiveUS8690490B2Simple processMilling cuttersMetal working apparatusEngineeringMechanical engineering

Owner:POKOLM FRANZ JOSEF

Component for holding down measuring leads

InactiveUS6637720B2Simple and cost-effectiveEasy to installThermometer detailsGas turbine plantsEngineeringMechanical engineering

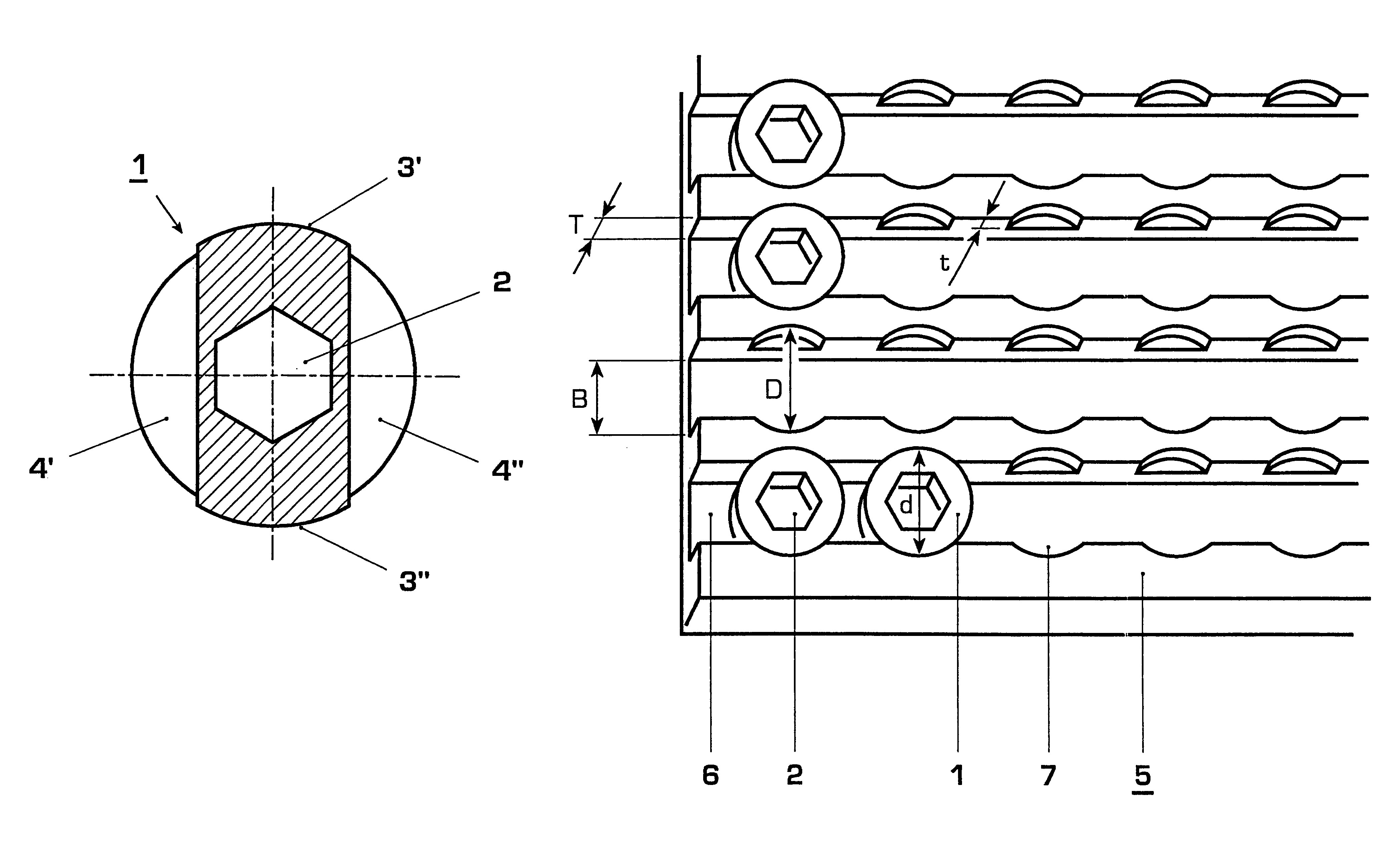

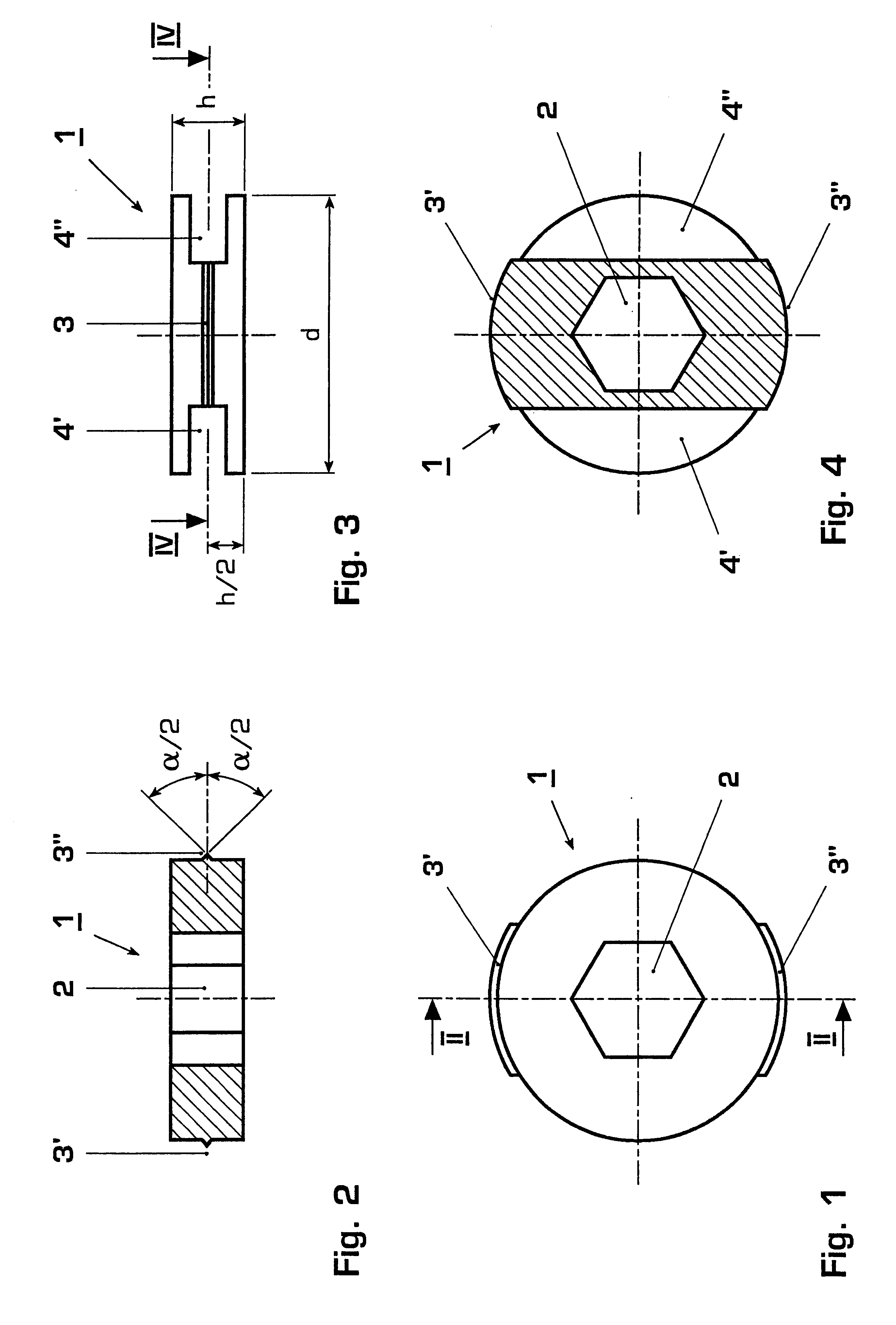

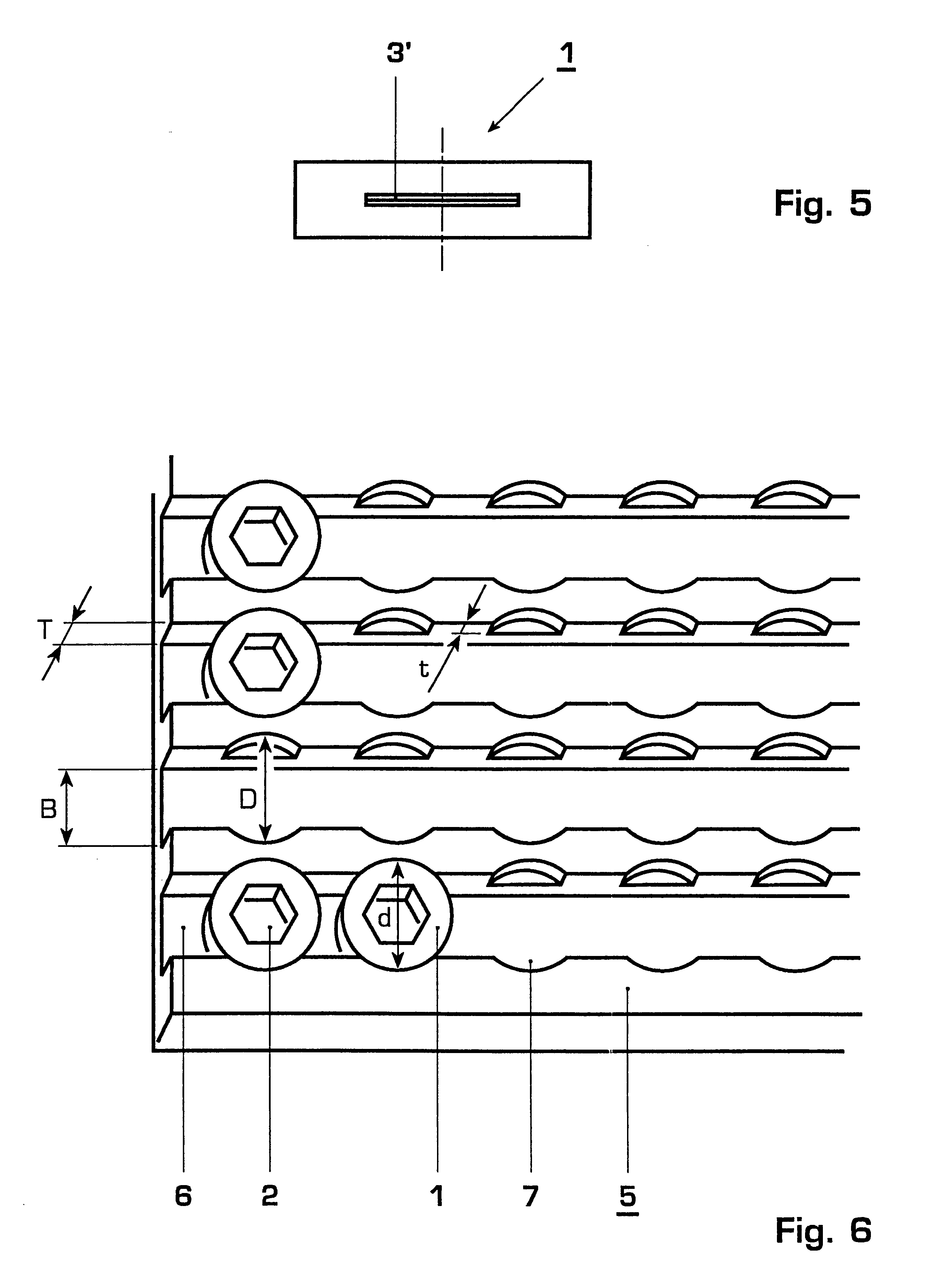

The invention relates to a component for holding down measuring leads and measuring devices in a groove (6), provided therefor and having holes (7), of a machine part (5). It is characterized in that the component is designed in the form of a disk (1) which has a cutting edge (3) on its circumference, the cutting edge (3) not being formed continuously over the entire circumference but consisting of two partial cutting edges (3', 3'') circumferentially opposite one another. In addition, the disk (1) has a central opening (2) in the form of a hexagon socket. For fitting, the disk (1) is put into the hole (7) in such a way that its two partial cutting edges (3', 3'') point in the longitudinal direction of the groove (6), then a hexagon socket key is inserted into the opening (2) of the disk (1) and the key is turned while the disk (1) is pressed down at the same time, so that the cutting edges (3', 3'') cut into the material of the machine part (5) and jam tight.

Owner:ALSTOM TECH LTD

Milling tool as well as a milling insert

ActiveUS9333568B2Ample ramping angleSimple and cost-effective wayTransportation and packagingMilling cuttersEdge segmentEngineering

A double-sided, indexable milling insert has a round basic shape defined by an imaginary cylinder, which is concentric with a center axis and extends between two reference planes that extend perpendicular to the center axis and are equidistantly separated from a neutral plane. The milling insert includes a pair of opposite chip faces located in the reference planes between which an envelope surface concentric with the center axis extends, a plurality of identical and alternately usable cutting edges along the peripheries of the chip faces, and lock means for rotationally securing the milling insert in one of several predetermined index positions. The individual cutting edge has the shape of a wave trough and includes two edge segments that meet at a bottom point.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com