Round cutting insert with anti-rotation feature

A cutting insert, anti-rotation technology, applied in the direction of milling cutting inserts, special-shaped round tools, turning equipment, etc., can solve problems such as cracking or breaking, insert damage, endangering the cutting quality of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

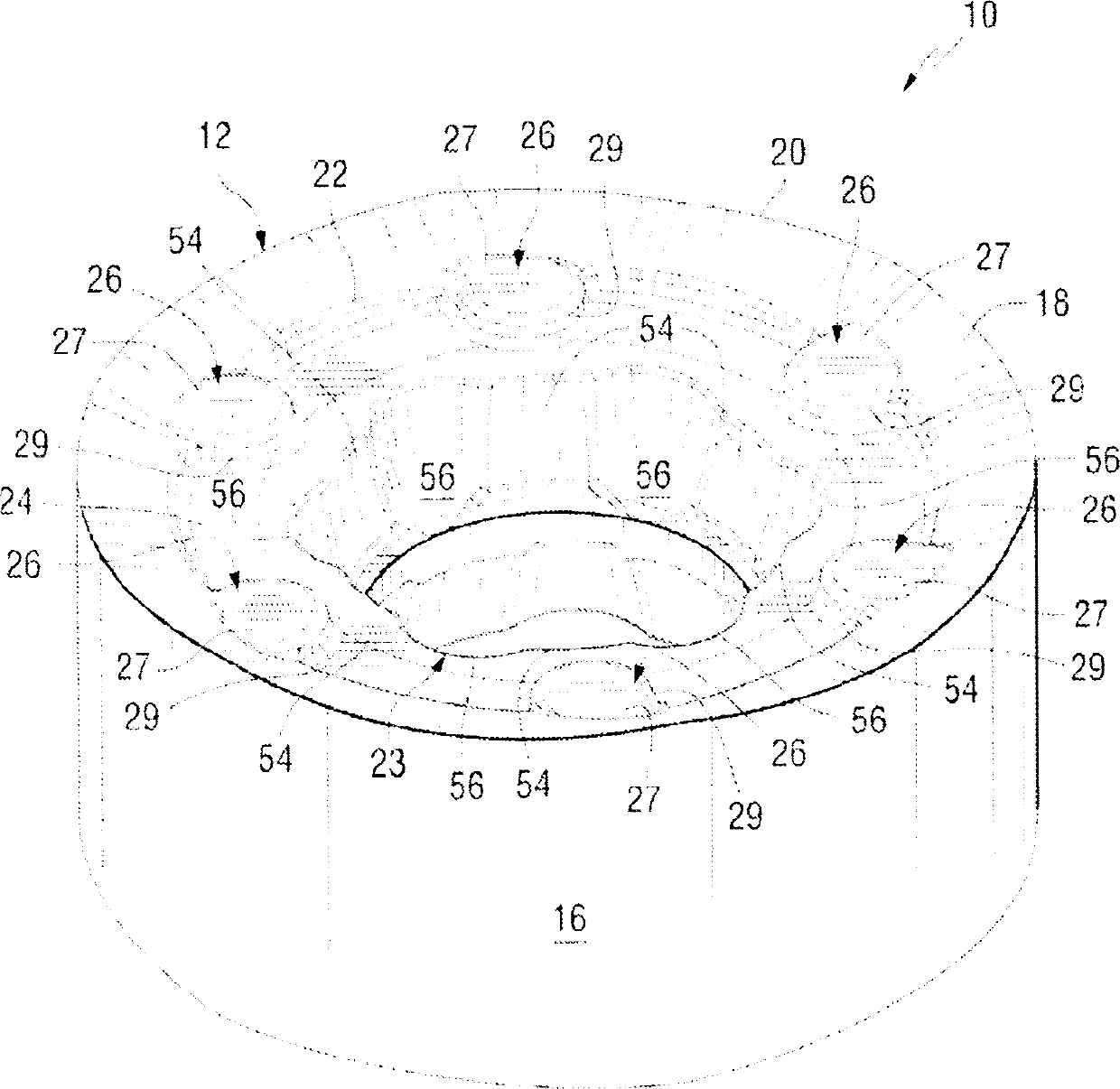

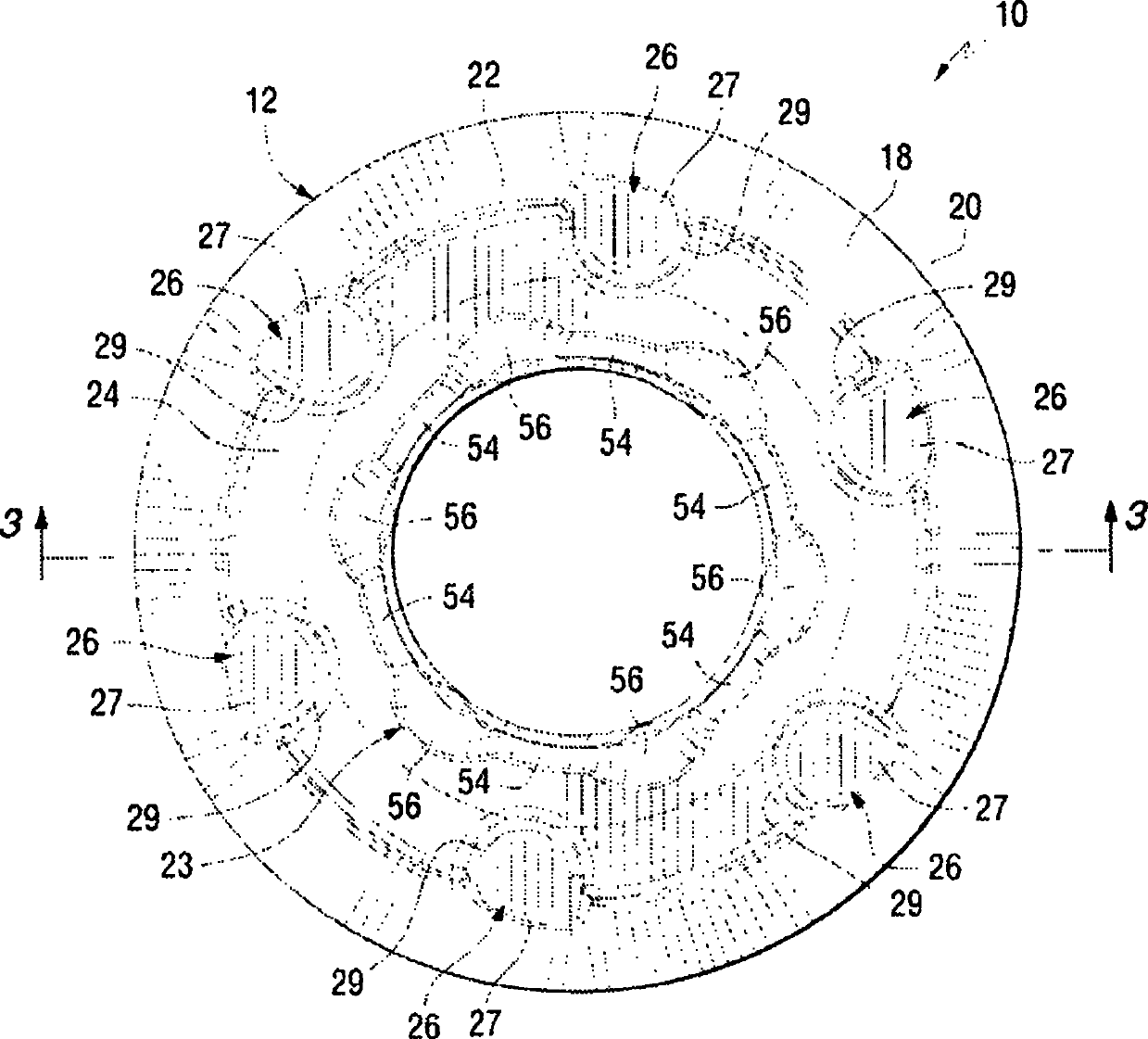

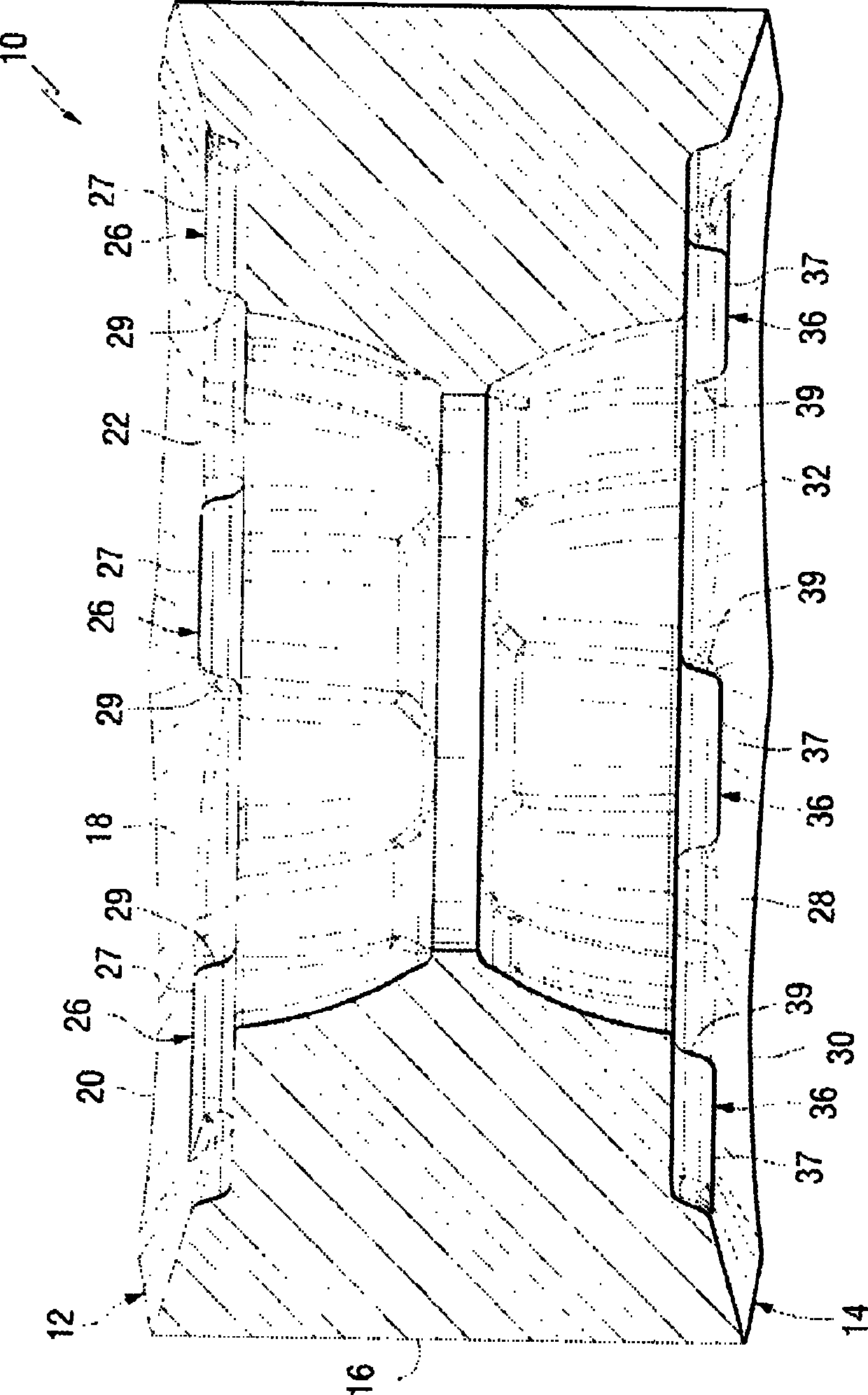

[0018] Referring to the figures, a cutting insert 10 is shown in accordance with one aspect of the present invention. The cutting insert 10 includes a first or top portion 12 (see generally figure 1 , figure 2 , image 3 and Figure 5 ) and a second or bottom portion 14 (see generally image 3 , Figure 4 and Figure 5 ) and a generally annular side portion 16 extending between the first portion 12 and the second portion 14. Thus, it should be appreciated that the cutting insert 10 is a generally circular cutting insert for positioning in a tool body for performing cutting operations on a workpiece (not shown).

[0019] like figure 1 and figure 2 As shown, the cutting insert 10 includes a first outer surface 18 that terminates in a first cutting edge 20 in a generally outward direction and terminates in a first cutting edge 20 in a generally inward direction. an inner edge 22 . In one aspect, the first outer surface 18 slopes from the first cutting edge 20 towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com