Method for preparing high interfacial strength nickel-zinc plating steel belt

A steel strip and nickel-plating technology is applied in the field of preparation of high-performance corrosion-resistant nickel-zinc-plated steel strips, which can solve the problems of reduced anti-corrosion performance, peeling off of thick coatings, and high rate of exposed iron, and improve the interface bonding force. , the surface is smooth and bright, the effect of high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

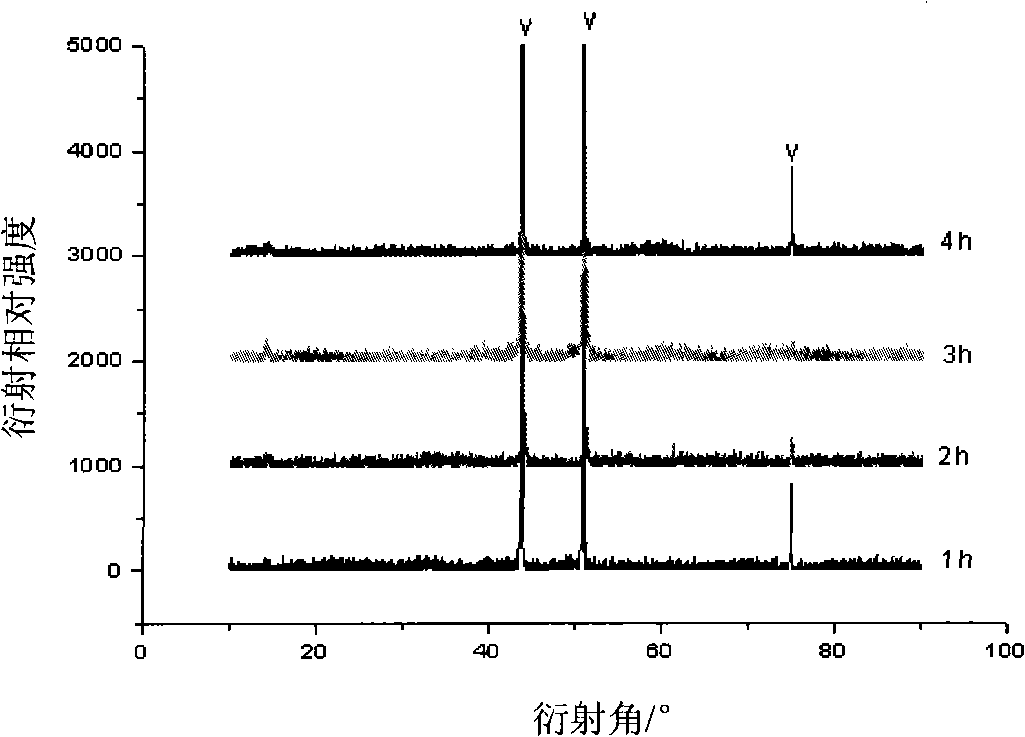

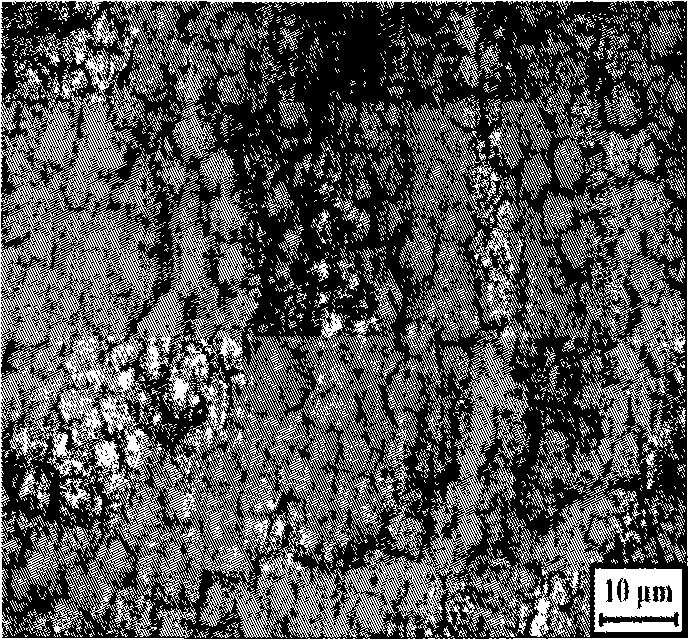

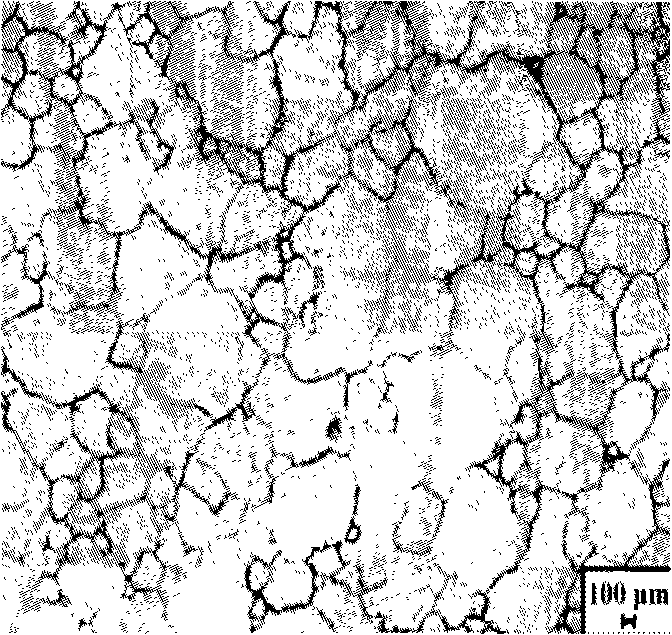

Image

Examples

Embodiment 1

[0034] The base belt is common common Q235 low carbon steel in the market, the thickness is 0.3mm, the chemical composition: C is 0.14%~0.22%, Mn is 0.30%~0.65%, Si is 0.3%, S is 0.050%, P is 0.045 %.

[0035]1) Degreasing the cold-rolled low-carbon steel strip, the degreasing is alkali cleaning and electrolytic degreasing, and the alkaline cleaning is to put the cold-rolled low-carbon steel strip in a solution tank for chemical degreasing to remove the cold-rolled low-carbon steel Grease with surface, chemical degreasing solution composition is sodium hydroxide 50g / L, sodium carbonate 35g / L, sodium phosphate 25g / L, solution temperature 70°C, current density 4A / dm 2 , Degreasing time 5min. Electrolytic degreasing is to place the cold-rolled low-carbon steel strip in a solution tank for electrochemical degreasing to further remove the residual grease on the surface. The components of the electrolytic degreasing solution are sodium hydroxide 50g / L, sodium carbonate 35g / L, and s...

Embodiment 2

[0047] 1) Degreasing the cold-rolled low-carbon steel strip, the degreasing is alkali cleaning and electrolytic degreasing, and the alkaline cleaning is to put the cold-rolled low-carbon steel strip in a solution tank for chemical degreasing to remove the cold-rolled low-carbon steel For grease with surface, the chemical degreasing solution consists of sodium hydroxide 52g / L, sodium carbonate 36g / L, sodium phosphate 26g / L, solution temperature 72°C, current density 5A / dm 2 , Degreasing time 6min. Electrolytic degreasing is to place the cold-rolled low-carbon steel strip in a solution tank for electrochemical degreasing to further remove the residual grease on the surface. The components of the electrolytic degreasing solution are sodium hydroxide 52g / L, sodium carbonate 36g / L, and sodium phosphate 42g / L, sodium silicate 3g / L, solution temperature 58°C, current density 5A / dm 2 , Degreasing time 4min.

[0048] 2) The cold-rolled low-carbon steel strip after degreasing is plac...

Embodiment 3

[0059] 1) Degreasing the cold-rolled low-carbon steel strip, the degreasing is alkali cleaning and electrolytic degreasing, and the alkaline cleaning is to put the cold-rolled low-carbon steel strip in a solution tank for chemical degreasing to remove the cold-rolled low-carbon steel For grease on the surface, the chemical degreasing solution consists of sodium hydroxide 58g / L, sodium carbonate 39g / L, sodium phosphate 29g / L, solution temperature 78°C, current density 6A / dm 2 , Degreasing time 8min. Electrolytic degreasing is to place the cold-rolled low-carbon steel strip in a solution tank for electrochemical degreasing to further remove the residual grease on the surface. The components of the electrolytic degreasing solution are sodium hydroxide 58g / L, sodium carbonate 39g / L, and sodium phosphate 44g / L, sodium silicate 3.8g / L, solution temperature 63°C, current density 5.5A / dm 2 , Degreasing time 5.5min.

[0060] 2) The cold-rolled low-carbon steel strip after degreasing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com