Port sealing process of heating container of electric water heater

A technology for heating containers and electric water heaters, applied in the field of mechanical manufacturing technology, can solve the problems of inconvenient assembly process, low compressive strength, and affecting the overall appearance, so as to avoid oxidation process, improve compressive strength and service life, and improve processing technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

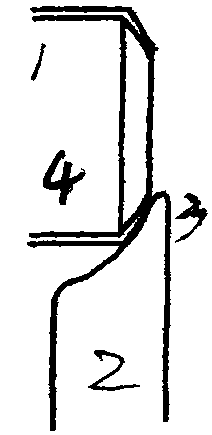

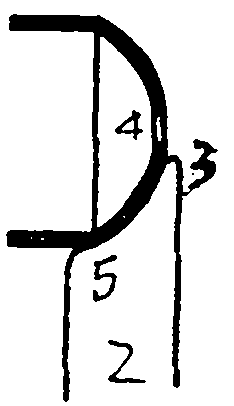

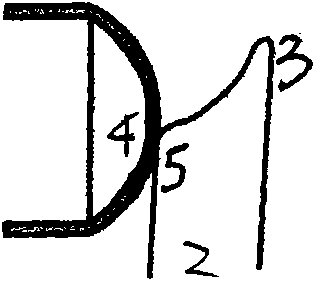

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments: the port sealing process of the electric water heater heating vessel according to the present invention. It is to prepare an ordinary machine tool with three chucks whose rotating speed is greater than 500 rpm, and prepare an arc-shaped tool with no edge. figure 1 As shown, the copper tube 1 is clamped on the machine tool with a fixture, and an edgeless tool 2 with an arc-shaped edge is used at one end, and the front end 3 of the edgeless tool 2 is used to slowly squeeze the high-speed rotating copper tube port 4 edges, the port of the copper tube 1 undergoes point-surface extrusion and friction with the front end of the bladeless tool during high-speed rotation to generate high temperature, and the port is closed inward by utilizing the characteristics of the copper extension; the purple After the port of the copper pipe is closed inward, a ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com