Smoothening machine for sheet material surface

A technology for smoothing and leveling boards, which is applied in the field of puttying and leveling devices for woodworking machinery, which can solve problems such as poor quality, low work efficiency, affecting production output and benefits, etc., achieve smooth board surfaces, solve the shortage of puttying personnel, and increase production and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

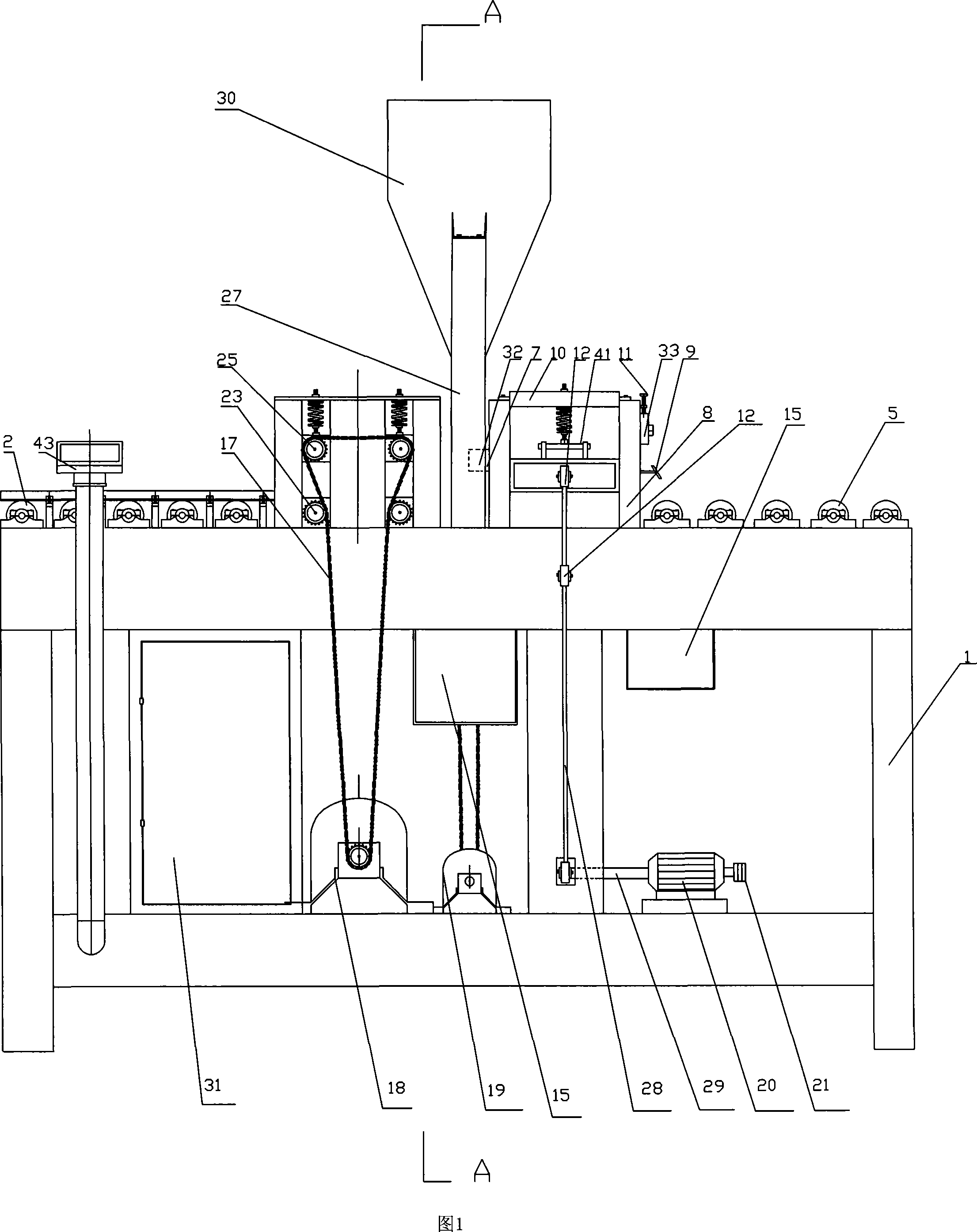

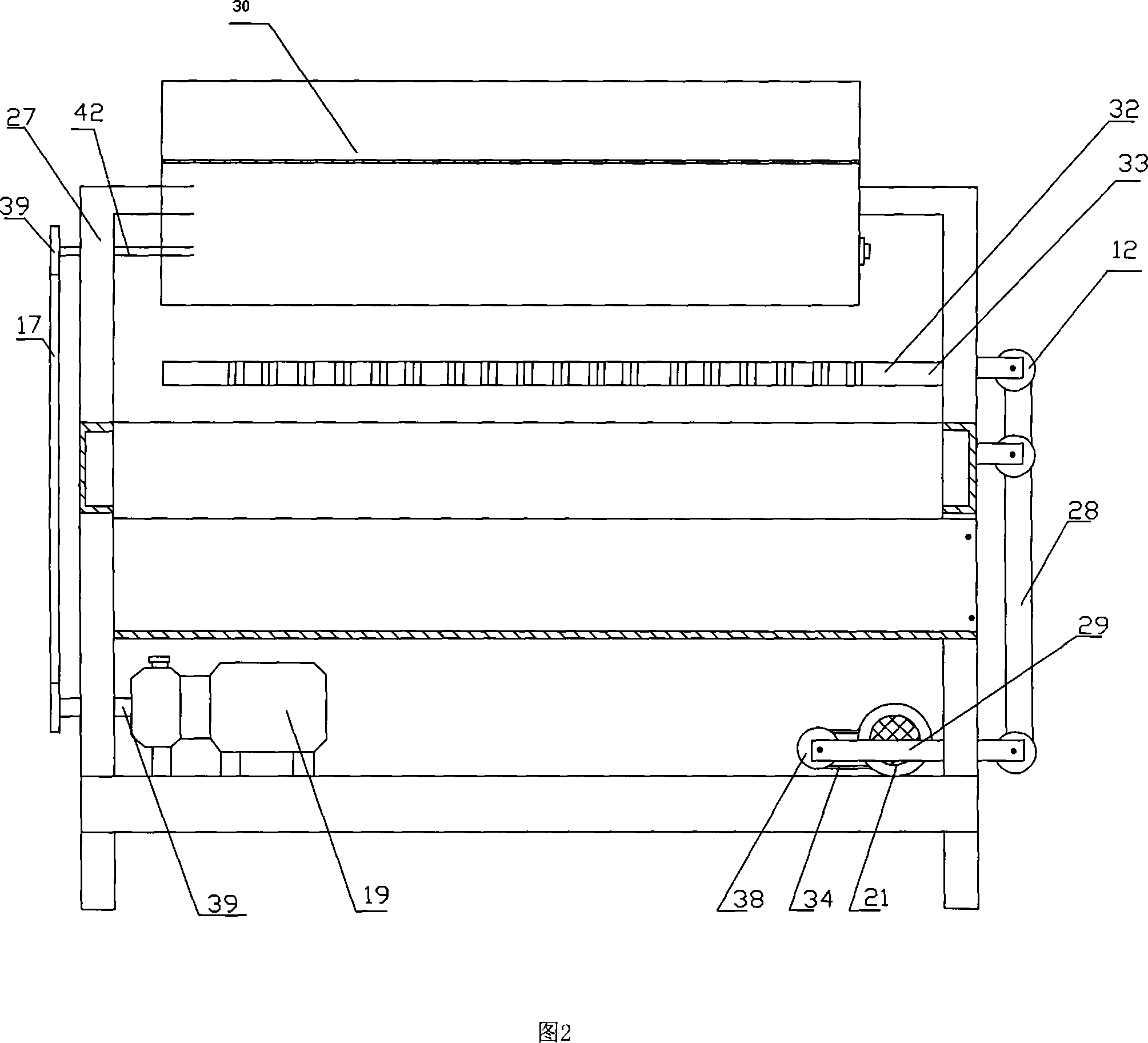

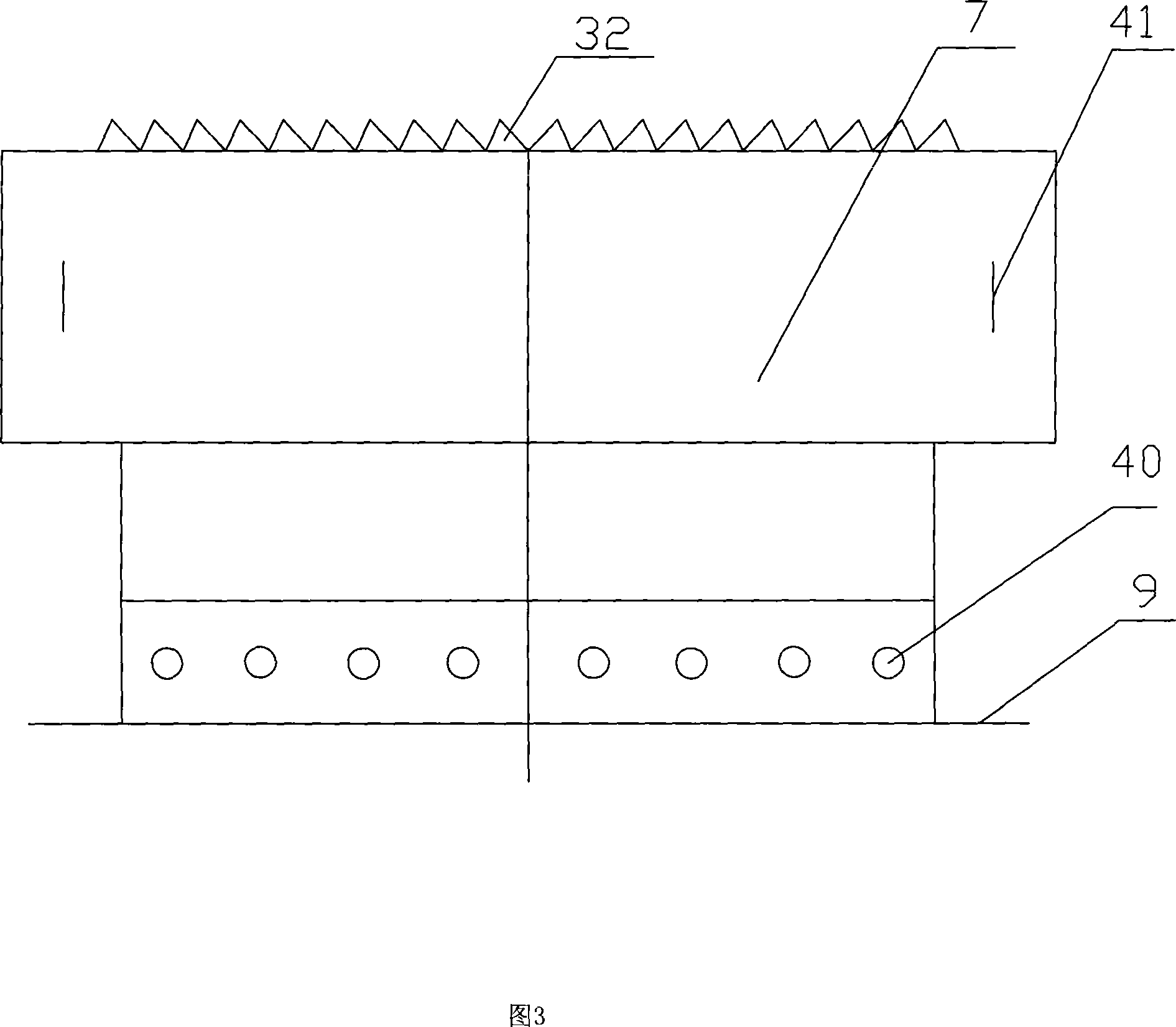

[0021] In Fig. 1, the smoothing machine for the surface of the plate is made up of a frame 1, a feeding device, a putty scraper device, a putty hopper 30 and an electric control box 31, and the putty hopper 30 is installed on the frame 1 by a hopper support 27, and the machine Frame 1 is an integral steel structure welded by channel steel. The feeding device is installed in front of the putty material box 30. The putty scraper device is installed behind the putty material box 30. The electric control box 31 is installed on the frame to control the work of the feeding device. , The electrical cabinet 31 is arranged on the inner side of the rack frame, and the control box 43 is installed on the electrical cabinet.

[0022] The feeding device is composed of a feeding roller 23 and a driven roller 25. The feeding roller 23 is driven by a speed controller 18. The feeding roller 23 is connected with the speed controller 18 through a chain 17. The feeding roller is made of a steel rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com