Environment-friendly low-resistance graphene carbon fiber conductive carbon paste and preparation method thereof

A technology of carbon fiber and conductive carbon paste, which is applied in the field of environmentally friendly low-resistance graphene carbon fiber conductive carbon paste and its preparation, can solve the problems of uneven distribution of carbon materials, uneven heating, easy aging, etc., and achieve good electrical conductivity, The effect of stable resistance value and easy coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

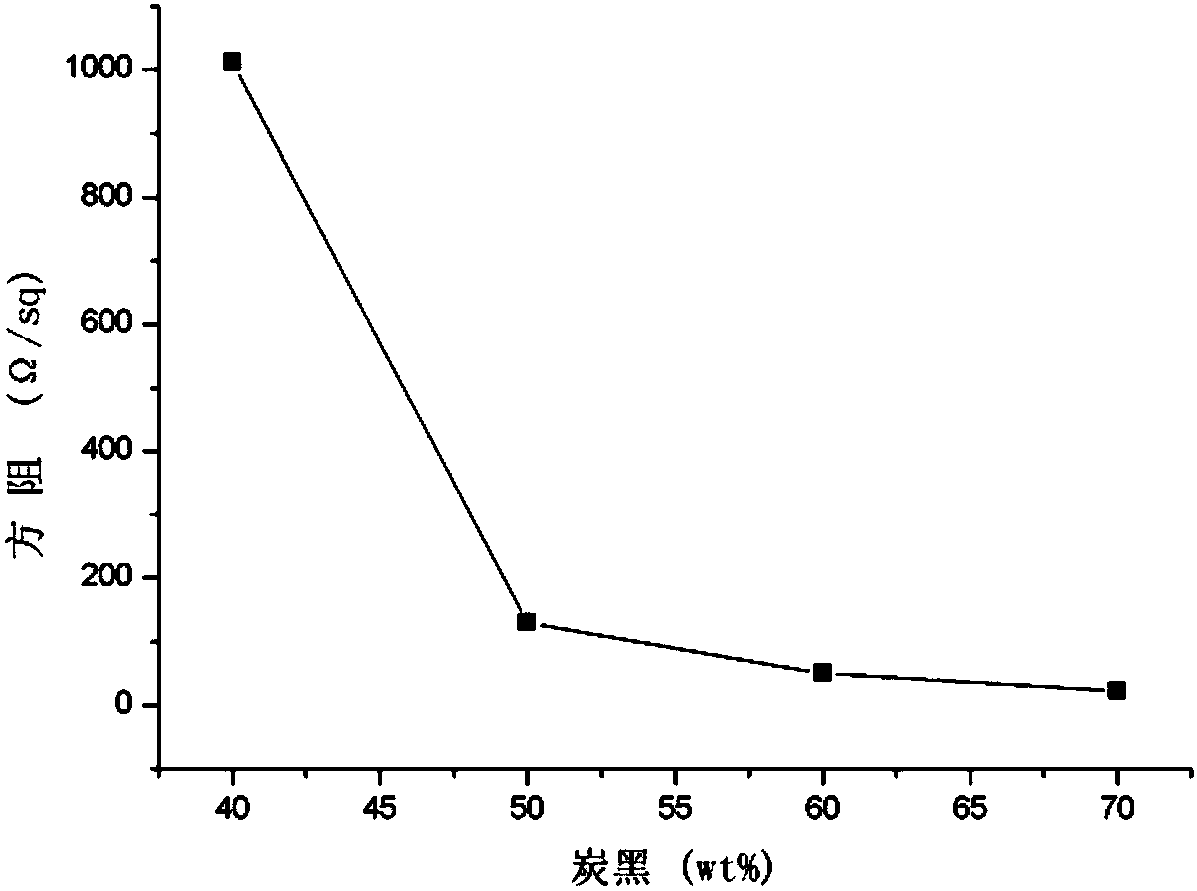

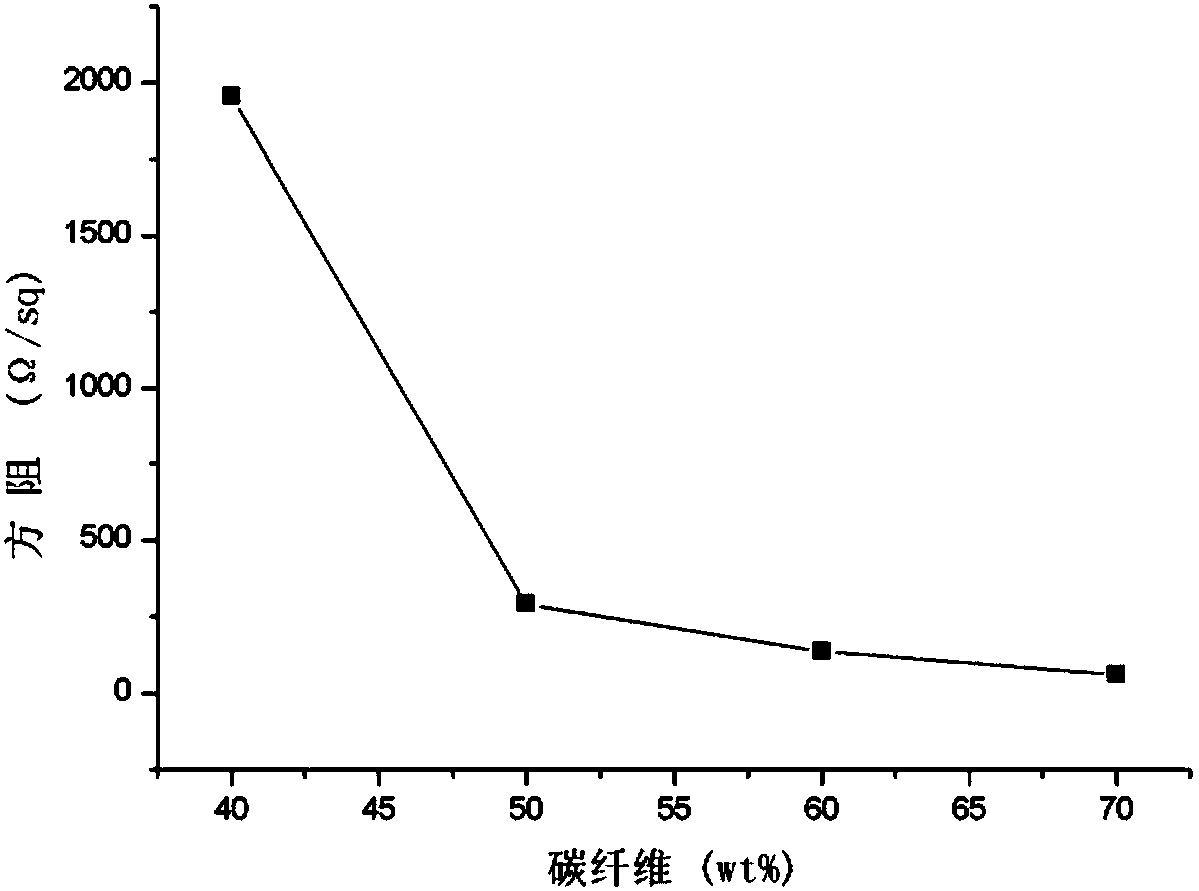

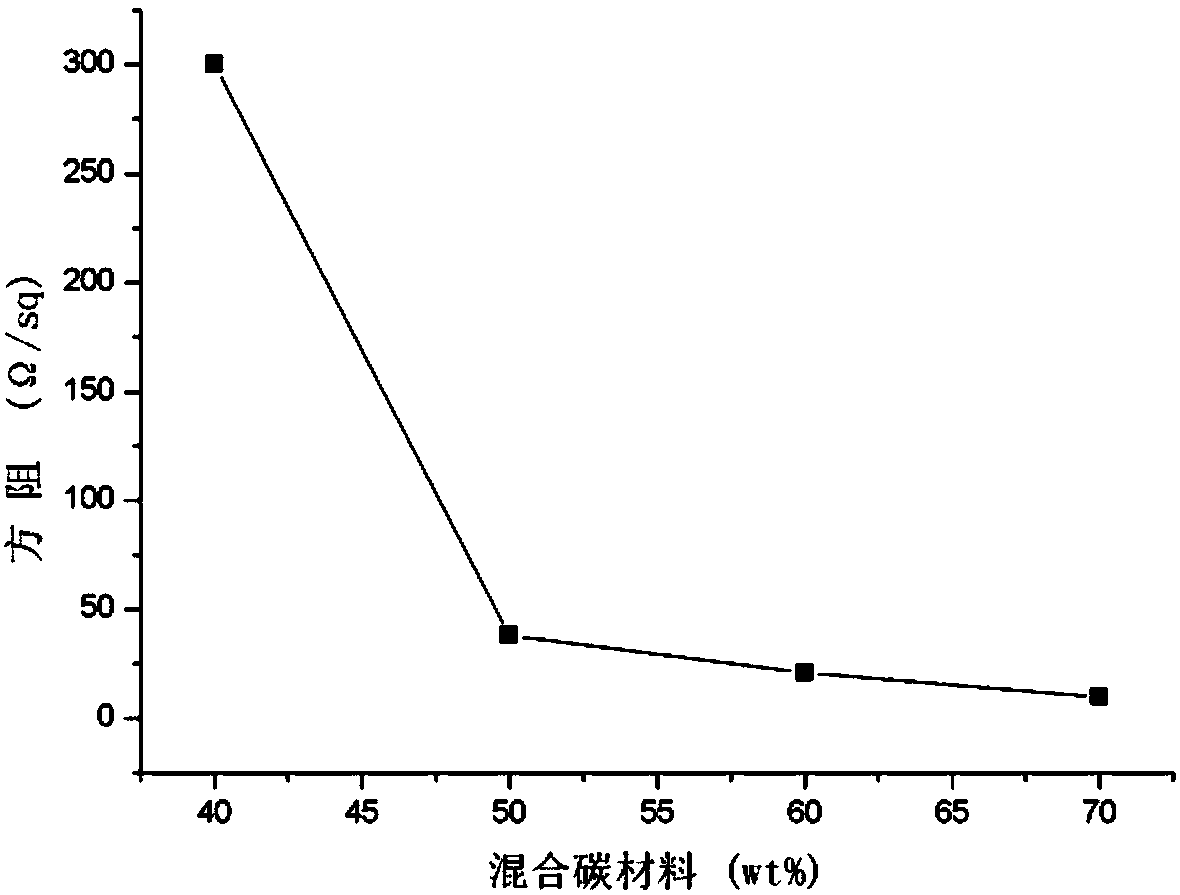

Image

Examples

Embodiment 1

[0032] The environmentally friendly low-resistance graphene carbon fiber conductive carbon paste, in parts by weight, includes the following components:

[0033]

[0034]

[0035] The number of layers of graphene microsheets is 10 layers.

[0036] The method for the environmentally friendly low-resistance graphene carbon fiber conductive carbon paste comprises the following steps:

[0037] (1) According to the formula, take carbon fiber, graphene microflakes and conductive carbon black, adopt the mode of airflow dispersion, disperse for 1 hour, and disperse three kinds of carbon materials evenly;

[0038] (2) by formula, take resin, solvent, dispersant, adhesion promoter and defoamer, disperse and stir evenly;

[0039] (3) adding the homogeneously mixed carbon material in step (1) to the mixing system in step (2), and performing pre-dispersion to obtain a pre-dispersed mixed slurry;

[0040] (4) Using grinding equipment to grind and disperse the pre-dispersed mixed slu...

Embodiment 2

[0045] The environmentally friendly low-resistance graphene carbon fiber conductive carbon paste, in parts by weight, includes the following components:

[0046]

[0047]

[0048] The number of layers of graphene microsheets is 100 layers.

[0049] The method for the environmentally friendly low-resistance graphene carbon fiber conductive carbon paste comprises the following steps:

[0050] (1) According to the formula, take carbon fiber, graphene microflakes and conductive carbon black, adopt the mode of airflow dispersion, disperse for 3 hours, and disperse three kinds of carbon materials evenly;

[0051] (2) by formula, take resin, solvent, dispersant, adhesion promoter and defoamer, disperse and stir evenly;

[0052] (3) adding the homogeneously mixed carbon material in step (1) to the mixing system in step (2), and performing pre-dispersion to obtain a pre-dispersed mixed slurry;

[0053] (4) Using grinding equipment to grind and disperse the pre-dispersed mixed...

Embodiment 3

[0058] The environmentally friendly low-resistance graphene carbon fiber conductive carbon paste, in parts by weight, includes the following components:

[0059]

[0060] The number of layers of graphene microsheets is 50 layers.

[0061] The method for the environmentally friendly low-resistance graphene carbon fiber conductive carbon paste comprises the following steps:

[0062](1) According to the formula, take carbon fiber, graphene microflakes and conductive carbon black, adopt the mode of airflow dispersion, disperse for 2 hours, and disperse three kinds of carbon materials evenly;

[0063] (2) by formula, take resin, solvent, dispersant, adhesion promoter and defoamer, disperse and stir evenly;

[0064] (3) adding the homogeneously mixed carbon material in step (1) to the mixing system in step (2), and performing pre-dispersion to obtain a pre-dispersed mixed slurry;

[0065] (4) Using grinding equipment to grind and disperse the pre-dispersed mixed slurry obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com