Antifuse device

A technology of anti-fuse and components, which is applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as difficult effects, achieve the effect of stable resistance value and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145] According to the production method described in the above-mentioned first embodiment, a sample in which the trigger voltage was set to 20V was produced. However, when the electrostatic capacitance is measured at 1 kHz, it is 0.015 μF.

[0146] Table 1 shows the forming material, film thickness, and forming method of each layer.

[0147] [Table 1]

[0148]

[0149] Next, the sample was connected to a constant current circuit whose maximum current was set to 300 mA, and the resistance value after operation was measured. As a result, it was found that the average value of the resistance value was 1.2Ω (maximum 1.7Ω, minimum 0.7Ω, n: 20), and the operation was stable. In addition, it was confirmed that the resistance value did not change even when the maximum current was changed from 50 mA to 1.0 A.

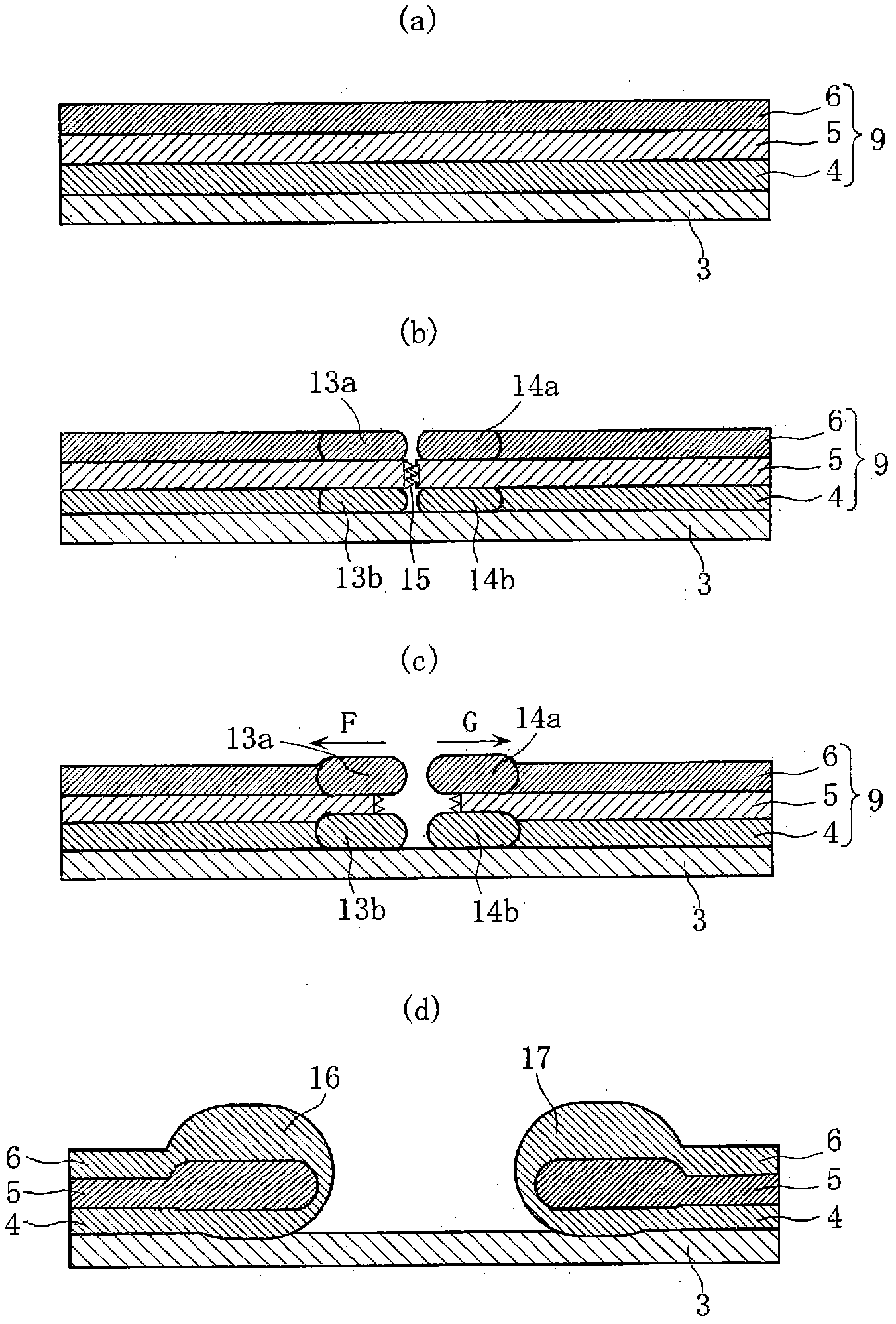

[0150] Next, with respect to the above-mentioned sample, the cross-section of the sample at the welding position where the first electrode film and the second electrode ...

Embodiment 2

[0157] According to the production methods described in the second embodiment and the third embodiment, samples of Example 2 and Example 3 in which the trigger voltage was set to 20V were produced, respectively. However, production was performed under the same manufacturing conditions as in Example 1 except that the number of laminations of the element main body was increased (see Table 1 of Example 1).

[0158] In addition, when the electrostatic capacitance was measured at 1 kHz, it was 0.030 μF in Example 2 and 0.045 μF in Example 3. (The capacitance of Example 1 is 0.015 μF as described above).

[0159] Next, each sample of Examples 2 and 3 was connected to a constant current circuit with a maximum current of 300 mA, and the resistance value after operation was measured. However, the measurement was performed for each of 20 samples, and the average value was calculated.

[0160] Next, a machine model was prepared for 12 samples of each example, and the maximum voltage fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com