Grapheneelectrothermal material and preparation method thereof

An electrothermal material and graphene technology, applied in heating element materials, electrothermal devices, ohmic resistance heating, etc., can solve the problems of difficulty in dispersion and inability to fully utilize the electrical conductivity of graphene, and achieve stable resistance value, fast heating time, and electrical energy. The effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

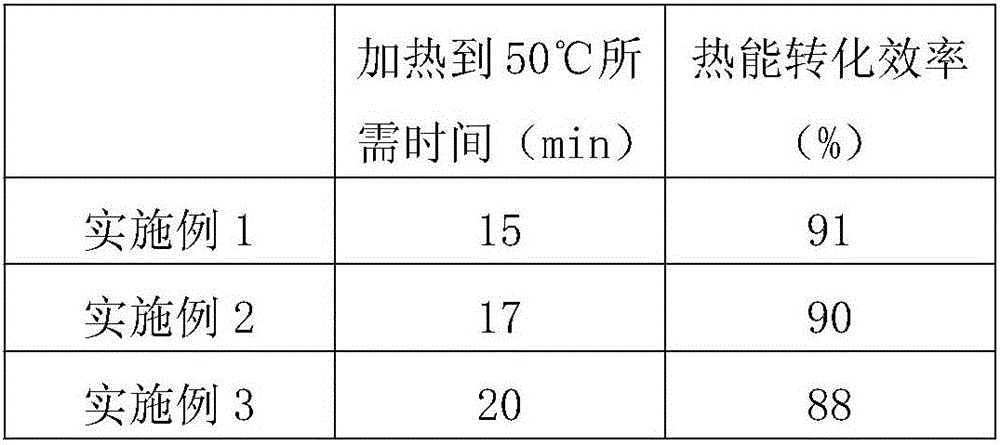

Examples

Embodiment 1

[0018] A graphene electrothermal material, comprising the following components by weight: 60 parts of epoxy resin, 5 parts of carbon fiber, 5 parts of carbon nanotube, 15 parts of graphene, and 3 parts of red phosphorus.

[0019] Further, the carbon nanotubes are single-walled carbon nanotubes or multi-walled carbon nanotubes with a length of 2-5 microns.

[0020] Further, the carbon fiber has a length of 10-20 microns and a thickness of less than 0.4 microns. The number of layers of graphene powder is less than 10, and the size is 1-10 microns.

[0021] The preparation method of above-mentioned graphene electrothermal material, comprises the steps:

[0022] (1) Weigh epoxy resin, carbon fiber, carbon nanotube, graphene, red phosphorus according to the above weight ratio. Place carbon fibers, carbon nanotubes, graphene, and red phosphorus in ethanol in sequence for ultrasonic dispersion to obtain a mixed solution;

[0023] (2) heating and melting the epoxy resin, adding the...

Embodiment 2

[0026] A graphene electrothermal material, comprising the following components by weight: 90 parts of silicon rubber, 10 parts of carbon fiber, 10 parts of carbon nanotubes, 20 parts of graphene, and 6 parts of phosphorus polyol.

[0027] Further, the carbon nanotubes are single-walled carbon nanotubes or multi-walled carbon nanotubes with a length of 2-5 microns. The carbon fiber has a length of 10-20 microns and a thickness of less than 0.4 microns. The number of layers of graphene powder is less than 10, and the size is 1-10 microns.

[0028] The preparation method of above-mentioned graphene electrothermal material, comprises the steps:

[0029] (1) Weigh silicone rubber, carbon fiber, carbon nanotubes, graphene, and phosphorus polyol according to the above weight ratio. Place carbon fibers, carbon nanotubes, graphene, and phosphorus polyols in ethanol in sequence for ultrasonic dispersion to obtain a mixed solution;

[0030] (2) heating and melting the silicone rubber,...

Embodiment 3

[0033] A graphene electrothermal material, comprising the following components by weight: 80 parts of polyurethane resin, 7 parts of carbon fiber, 8 parts of carbon nanotube, 18 parts of graphene, and 4 parts of phosphorus halide.

[0034] Further, the carbon nanotubes are single-walled carbon nanotubes or multi-walled carbon nanotubes with a length of 2-5 microns.

[0035] Further, the carbon fiber has a length of 10-20 microns and a thickness of less than 0.4 microns. The number of layers of graphene powder is less than 10, and the size is 1-10 microns.

[0036] The preparation method of above-mentioned graphene electrothermal material, comprises the steps:

[0037] (1) Weigh polyurethane resin, carbon fiber, carbon nanotube, graphene, phosphorus halide according to the above weight ratio. Place carbon fibers, carbon nanotubes, graphene, and flame retardants in ethanol for ultrasonic dispersion to obtain a mixed solution;

[0038] (2) heating the polyurethane resin, addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com