Rubber composition for roller and ionic conductive rubber roller using the composition

A technology of rubber composition and ion conductivity, applied in coating, printing, printing devices, etc., can solve problems such as difficulty in using rubber rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

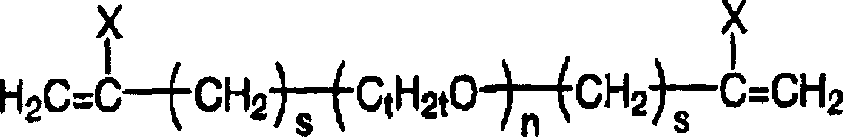

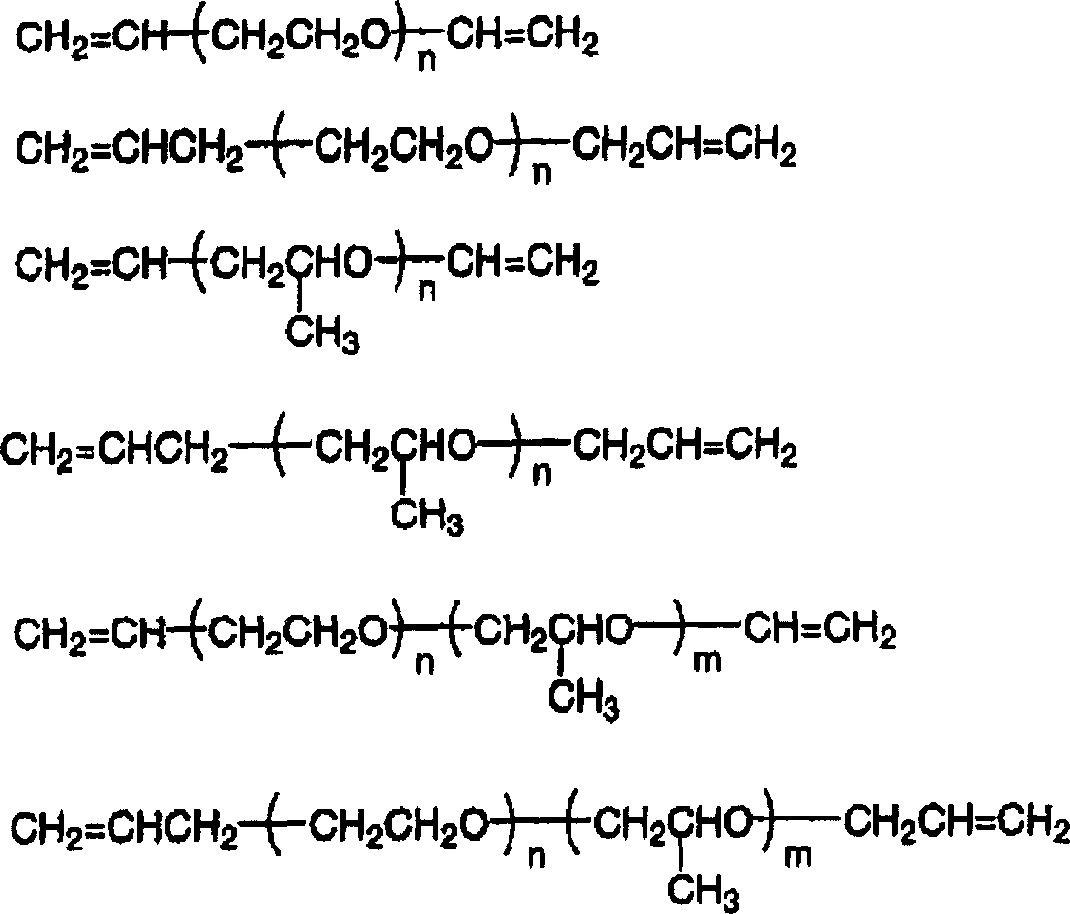

Method used

Image

Examples

Embodiment 1-

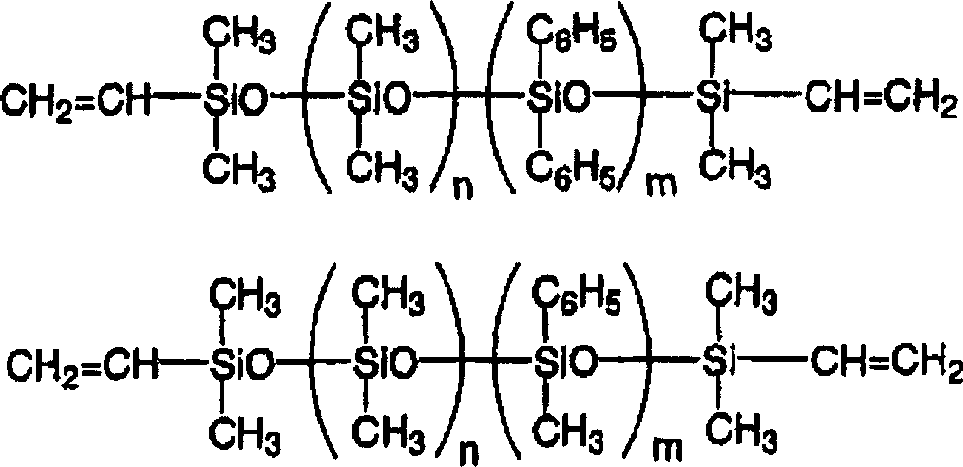

[0091] 100 parts by weight of polyoxypropylene (number average molecular weight: about 7,200), 20 parts by weight of the following formula (3)

[0092]

[0093] phenyl group-containing polysiloxane (phenyl group content ratio: 40 mol %) whose both ends are blocked by vinyldimethylsiloxy groups, 10.5 parts by weight of the following formula (4)

[0094]

[0095] A phenyl-containing methylhydrogenated diene siloxane (molar ratio of SiH / alkenyl: 1.5 mol / mol) with a viscosity of about 20 mPa·s at 25° C., 0.6 parts by weight of 1- Ethynyl-1-cyclohexanol was mixed. Then, with respect to component (A), 100 ppm (by weight) of platinum vinylsiloxane complex as a platinum metal component was added to the mixture obtained above, and mixed well until uniform. Next, 2 parts by weight of LiN(CF 3 SO 2 ) 2 , 15 parts by weight of titanium oxide particles as a heat resistance enhancer, fully mixed, and prepared to obtain a liquid rubber composition 1.

Embodiment 2-

[0097] In Example 1, except that the mixing amount of the phenyl group-containing polysiloxane (phenyl group content ratio: 40 mol%) represented by the above (3) was changed to Other than 50 parts by weight, the liquid rubber composition 2 was prepared in the same manner.

Embodiment 3-

[0099] 100 parts by weight of polyoxypropylene (number average molecular weight: about 7,200), 20 parts by weight of the following formula (5)

[0100]

[0101] The viscosity at 25°C represented by 6.5 parts by weight of the phenyl-containing polysiloxane (phenyl group content ratio: 10 mol%) blocked by vinyldimethylsiloxy groups at both ends is about 20 mPa·s phenyl-containing methylhydrogenated diene polysiloxane (SiH / alkenyl molar ratio: 1.2 mol / mol), 0.6 parts by weight of 1-ethynyl-1-cyclohexyl as a reaction control agent Alcohol is mixed. Then, relative to component (A), 100 mm (by weight) of platinum vinyl siloxane complex as a platinum metal component was added to the mixture obtained above, and mixed thoroughly until uniform. Next, 0.6 parts by weight of LiN(CF 3 SO 2 ) 2 , 15 parts by weight of titanium oxide particles as a heat resistance enhancer, fully mixed, and prepared to obtain a liquid rubber composition 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com