Conductive rubber member

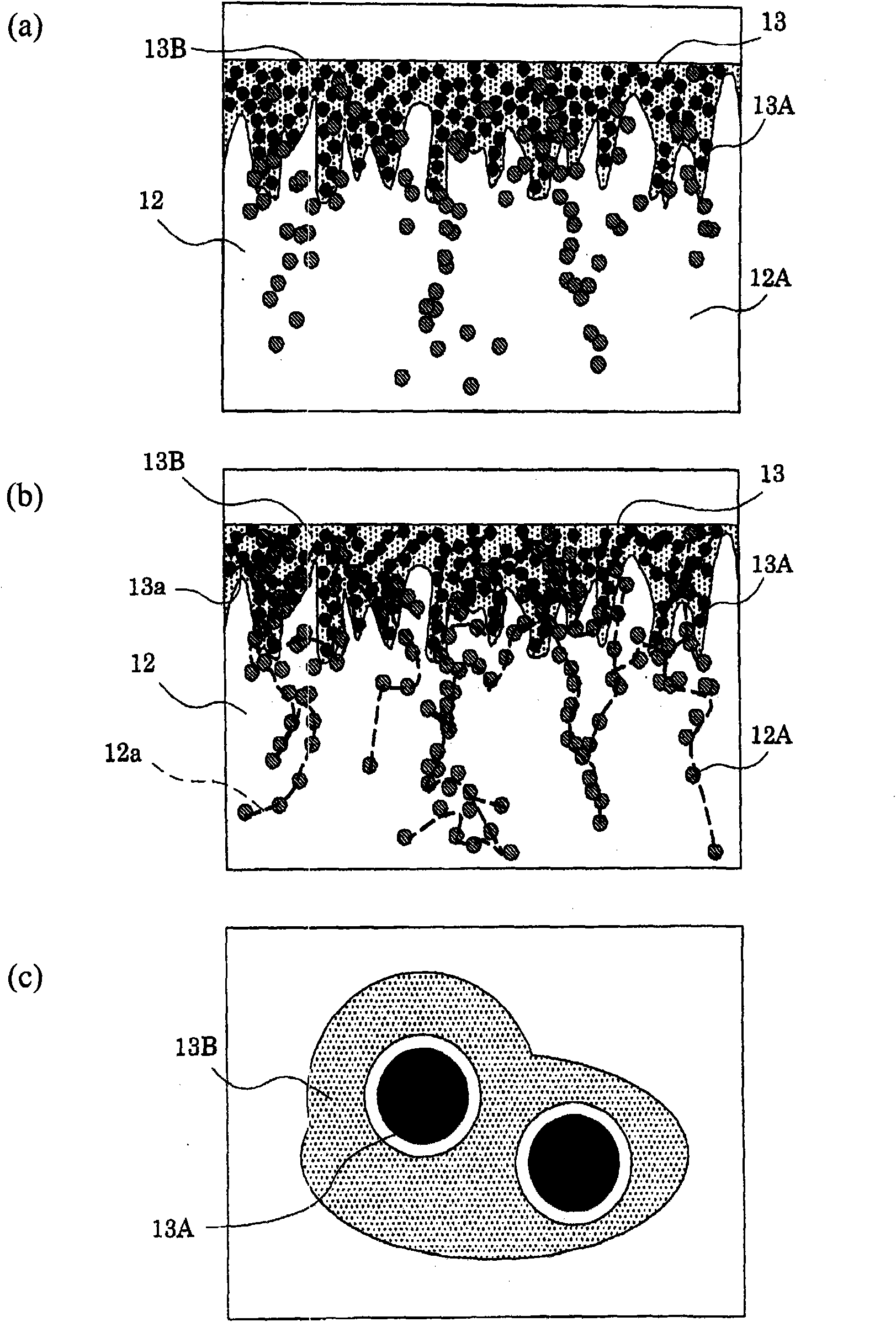

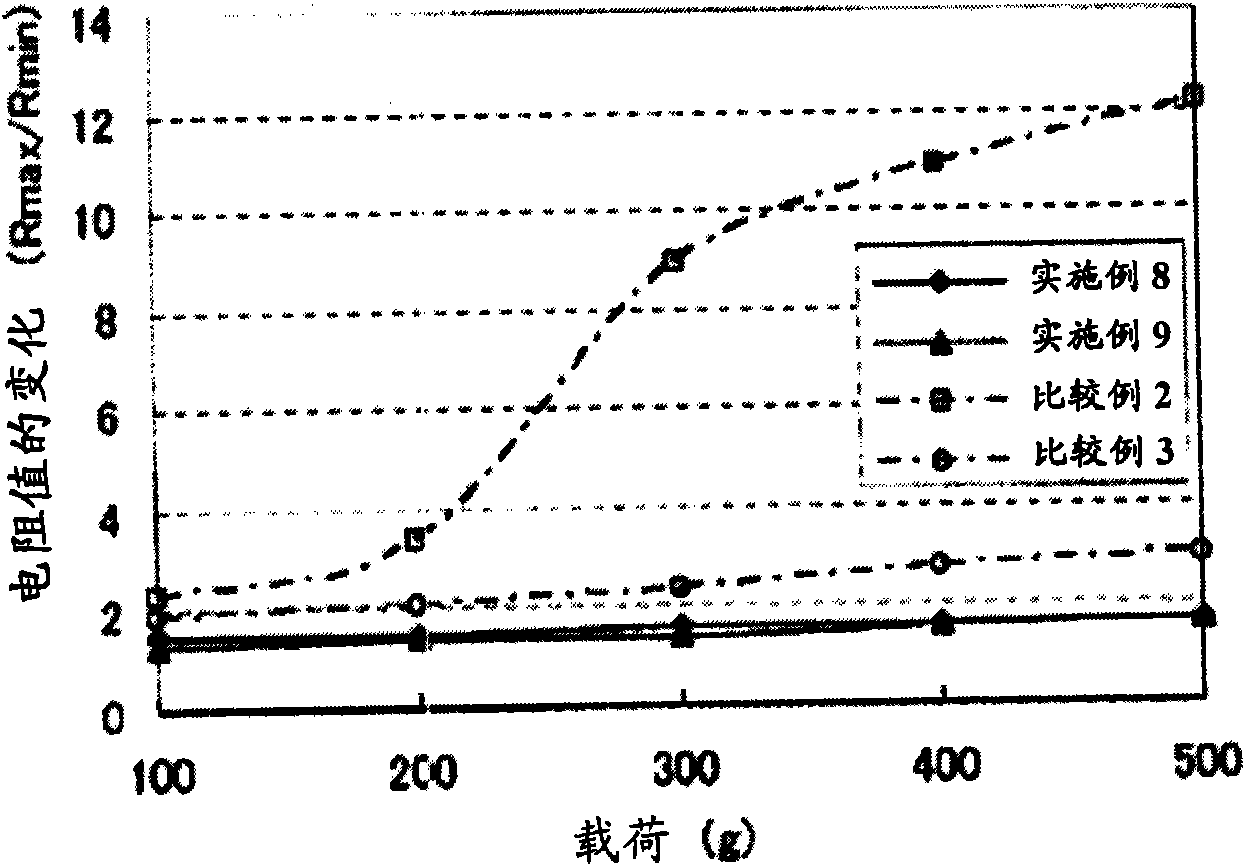

By using a surface treatment liquid of over-dispersed carbon black and isocyanate compounds on the surface of the conductive elastic layer of the conductive rubber component, a uniform conductive path is formed, which solves the problem of large changes in the resistance value of the conductive rubber component and achieves a change in resistance value. Stability and image quality improvements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

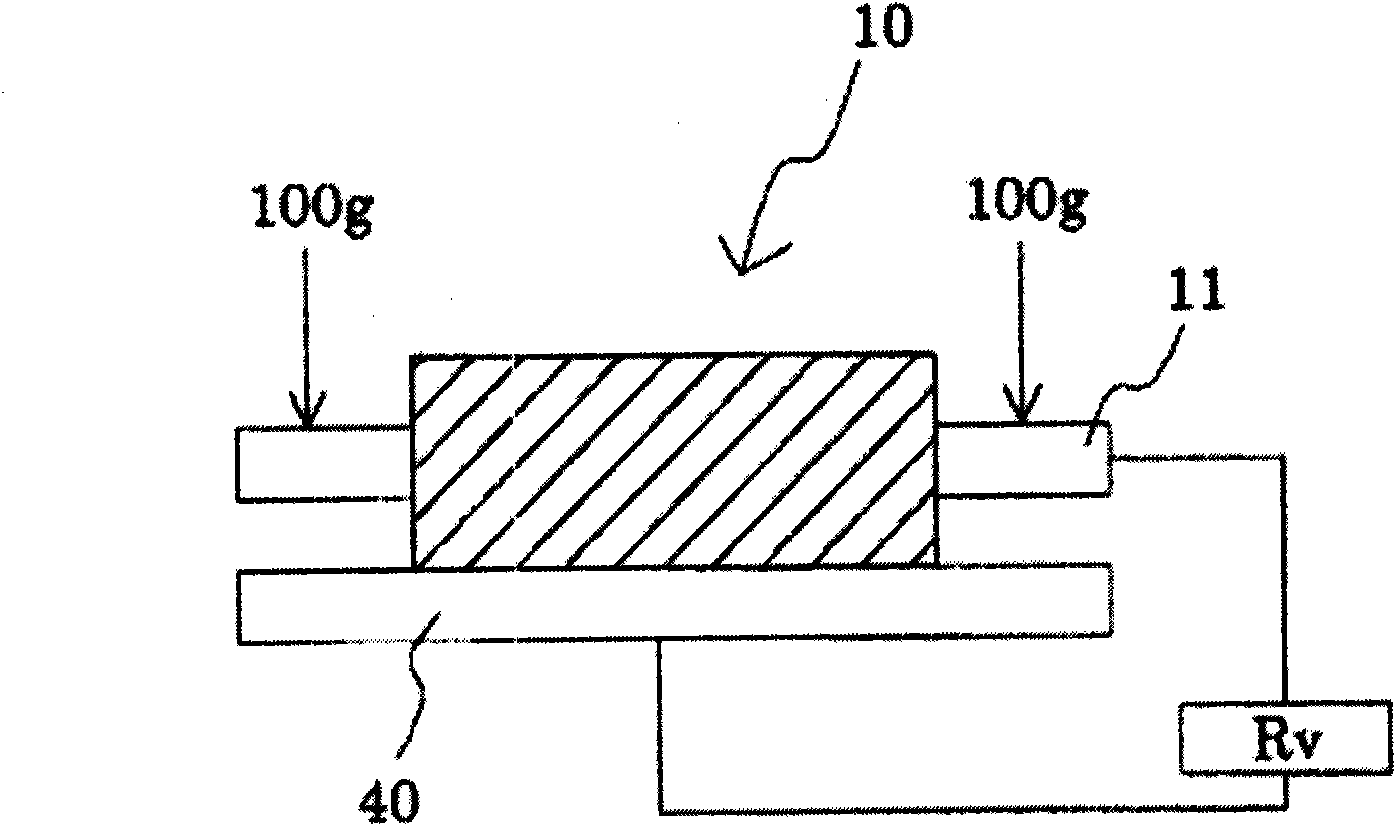

Method used

Image

Examples

Embodiment 1

[0070]

[0071] In 100 parts by mass of epichlorohydrin rubber (Epichlomer CG-102, manufactured by Daiso Co., Ltd.), 0.3 parts by mass of sodium trifluoroacetate and 5 parts by mass of zinc oxide (ZnO) as a conductive material were mixed as 2-mercaptoimidazoline (Accel-22) of 2 parts by mass of the vulcanizing agent is kneaded with a roll mixer, extruded on the surface of a metal shaft with a diameter of 6 mm, ground to a diameter of 14 mm, and formed on the surface of the shaft. A conductive elastic layer comprising epichlorohydrin rubber, an untreated roller 1 was prepared.

[0072]

[0073] Using a ball mill, 20 parts by mass of acetylene black, 1.5 parts by mass of polyethylene glycol-polypropylene glycol monomethacrylate (weight average molecular weight 1500) (referred to as "dispersant A1" in the table), 78.5 parts by mass of acetic acid The butyl ester was dispersed and mixed at 50°C for 3 hours to prepare a carbon black dispersion 1.

[0074]

[0075] Mix 20 mas...

Embodiment 2

[0077] Except using polyoxyethylene alkylamine (weight-average molecular weight 3000) (referred to as "dispersant B" in the table) to replace polyethylene glycol-polypropylene glycol monomethacrylate (weight-average molecular weight 1500), the same as in Example 1. The conductive roller of Example 2 was prepared in the same manner.

Embodiment 3

[0079] The conductive roller of Example 3 was produced in the same manner as in Example 1, except that acetylene black which had been preliminarily treated with alkali was used in the dispersion treatment of carbon black. It should be noted that the acetylene black was prepared as follows: after being placed in 2M sodium hydroxide solution at 80°C for 15 minutes, it was washed with pure water and dried at 120°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com