Structure and manufacturing method of semiconductor device

A device structure and semiconductor technology, used in semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of unsatisfactory varistor characteristics and low resistance in high resistance states.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The manufacturing process method of the semiconductor device, comprising the steps of:

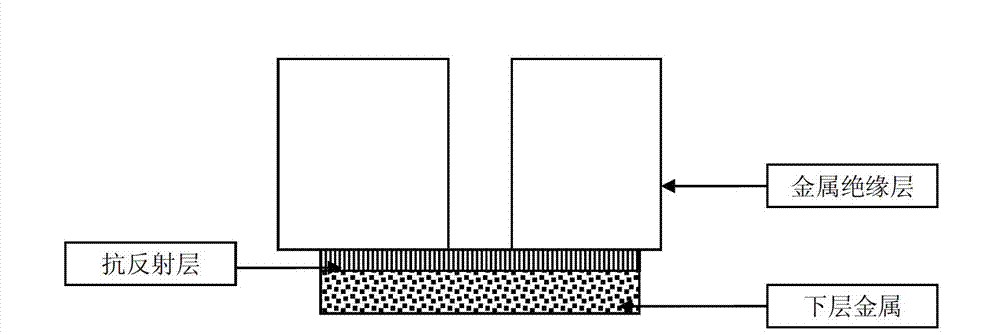

[0023] Step 1, see image 3 As shown, the lower metal layer, the anti-reflection layer and the metal insulating layer are sequentially formed from bottom to top.

[0024] Step 2. A through hole may be formed in the metal insulating layer by using various known techniques.

[0025] Step three, see Figure 4 As shown, a layer of metal is deposited on the sidewall of the via hole as a barrier layer. The metal material of the barrier layer includes but not limited to titanium nitride.

[0026] Step 4, see Figure 5 As shown, metal is deposited in the through hole and completely filled to serve as the bottom electrode; the metal material of the bottom electrode includes but not limited to metal tungsten.

[0027] Step five, see Figure 6 As shown, rapid thermal oxidation (RTO) is used to oxidize the metal on the upper part of the through hole to form a metal oxide layer on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com