Patents

Literature

36results about How to "Fast processing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

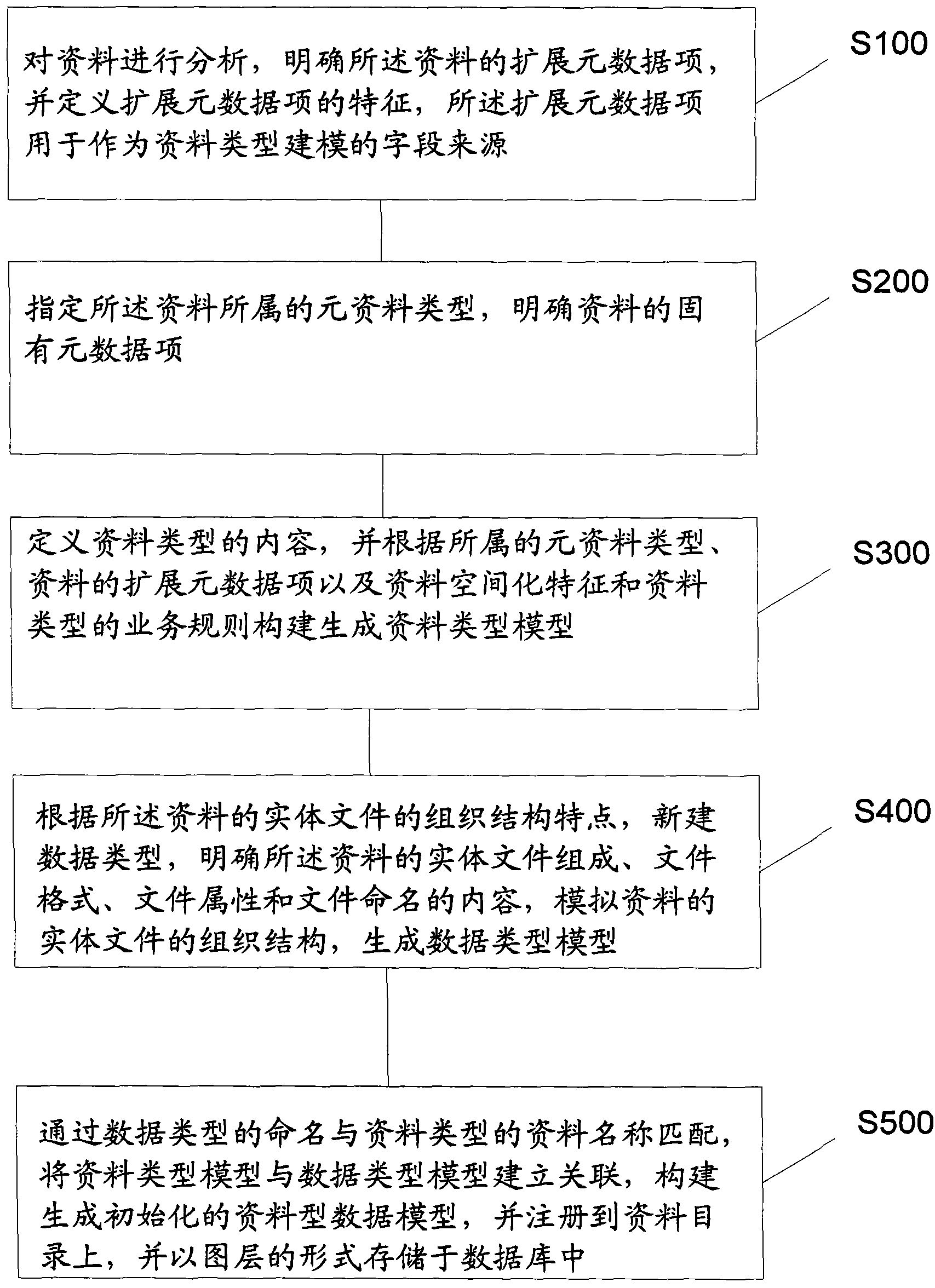

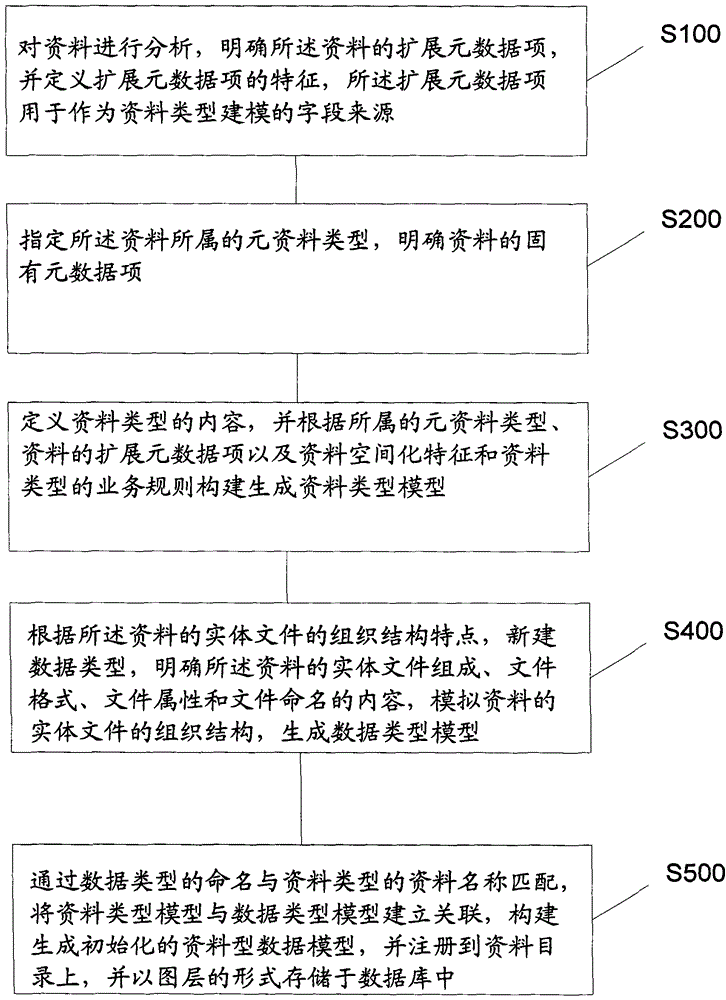

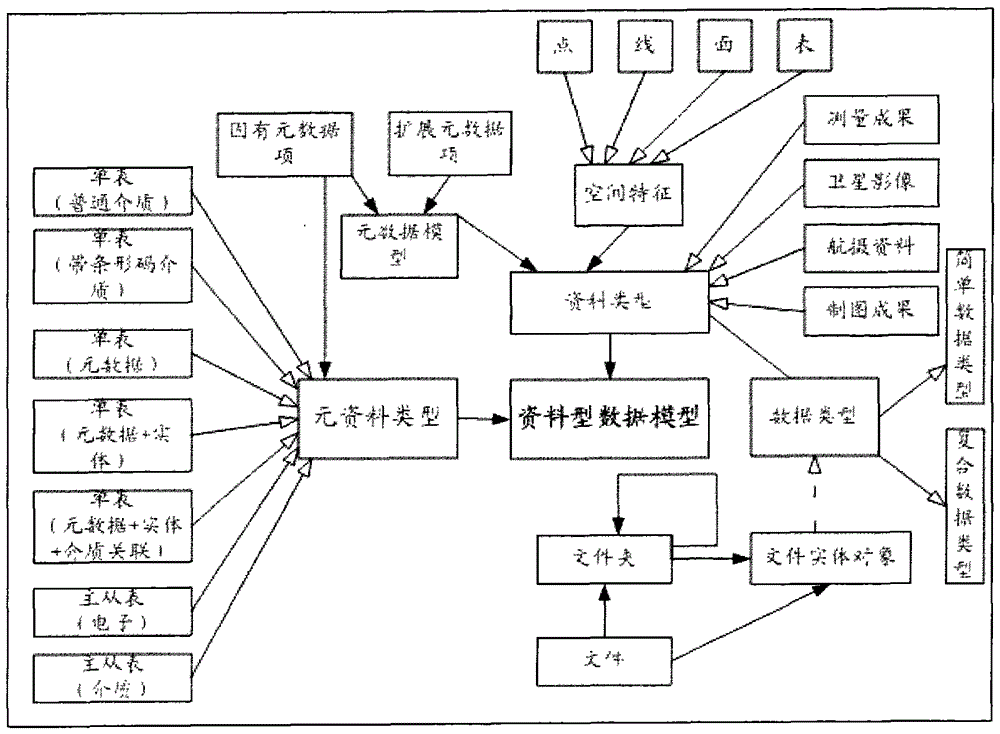

Material data modeling processing method

ActiveCN103886004ARapid expansionQuick buildSpecial data processing applicationsMaterial typeData modeling

The invention discloses a material data modeling processing method. The method includes: designating meta-material types of material and specifying inherent metadata items of the material; specifying extended metadata items of the material, and defining features of the extended metadata items; defining material type contents, and building a material type model according to the meta-material types, the extended metadata items of the material, spatial features of the material and business rules of the material type; generating a data type model according to structure features of a solid file of the material; correlating the material type model to the data type model by matching names of data types and material names of the material types, building an initial material data model, and storing the model in a database. The inherent metadata items and the extended metadata items are used as field sources for material type modeling. According to the method, the material types and the corresponding data types are classified and modeled by modeling, and data processing is more reasonable, more direct, faster and clearer.

Owner:BEIJING GEOWAY SOFTWARE

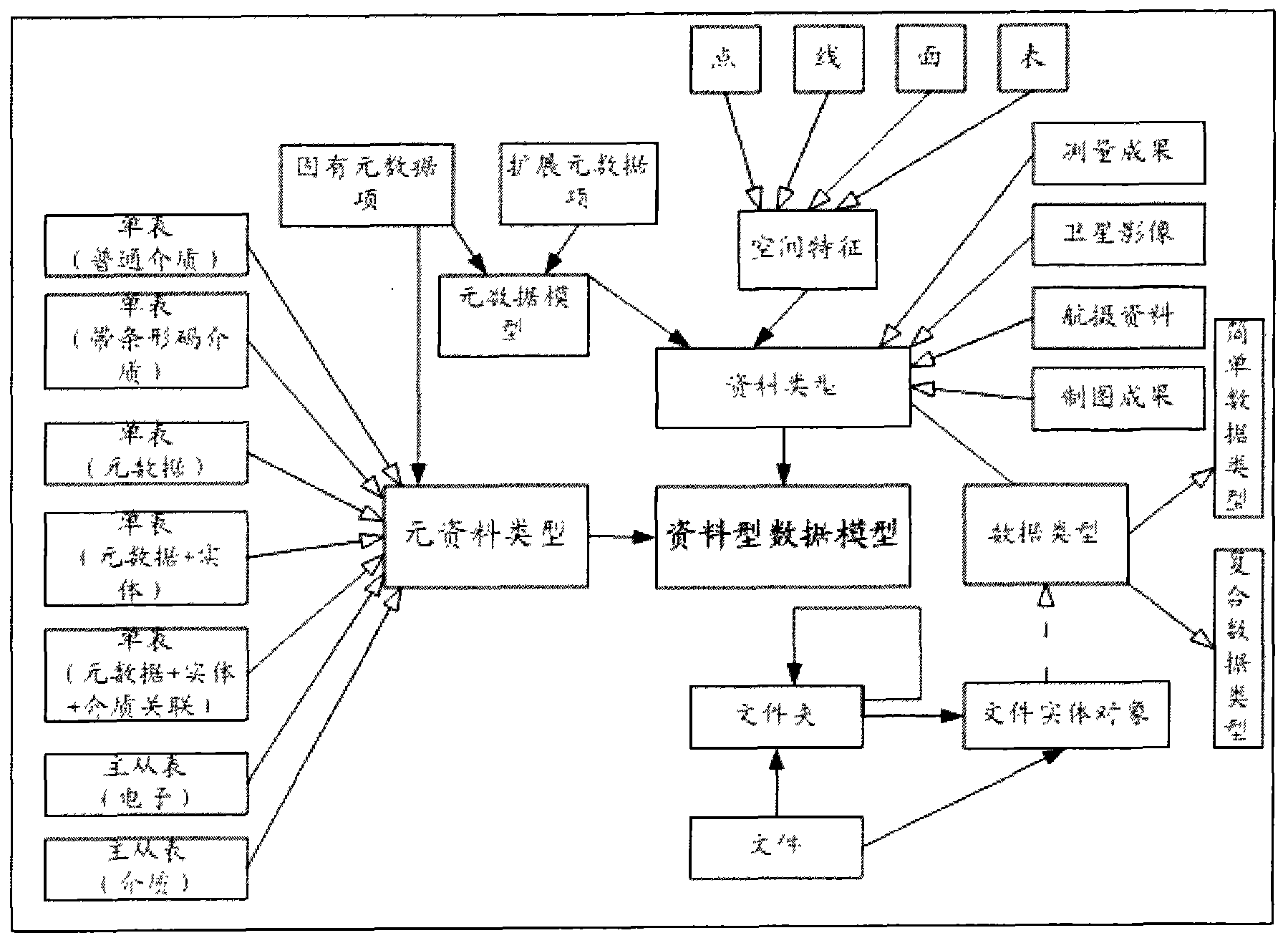

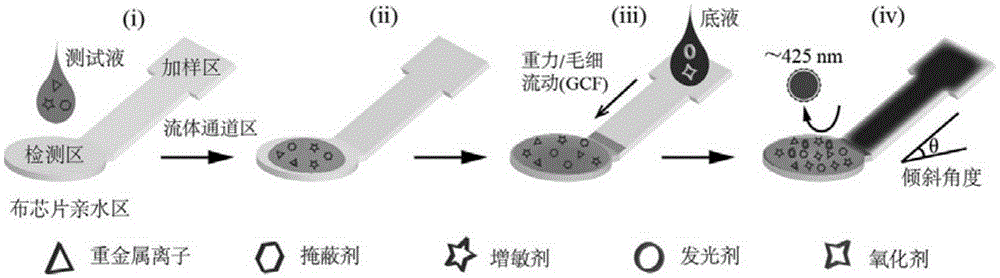

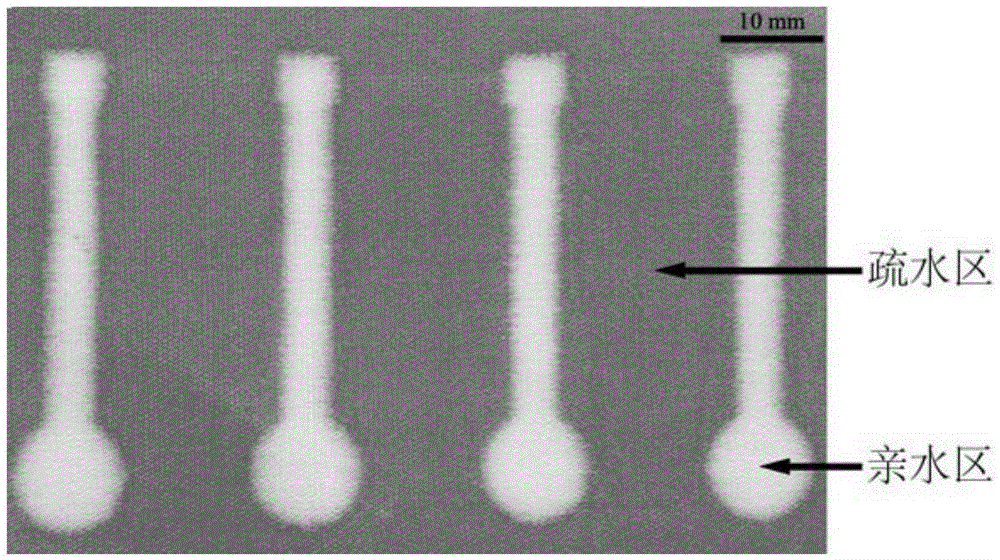

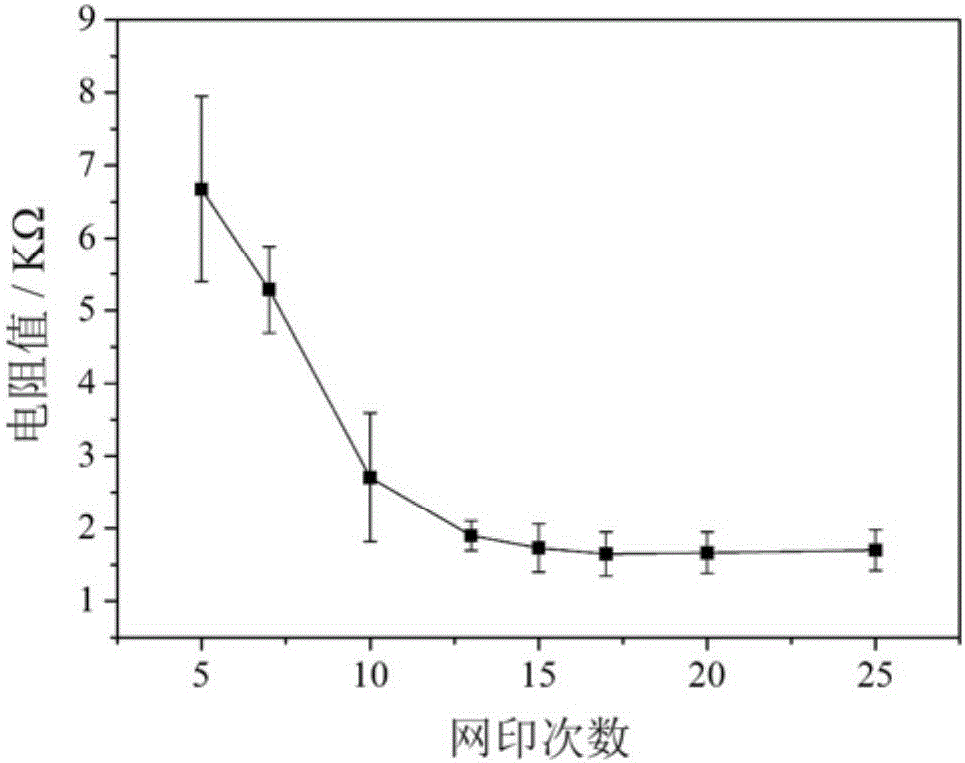

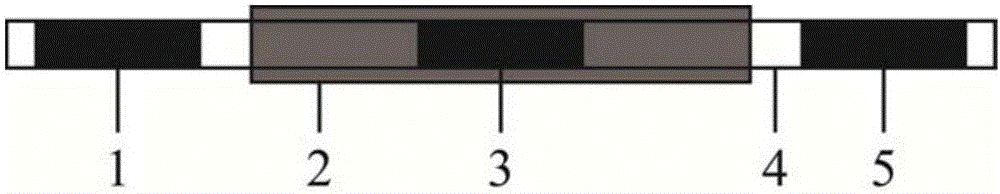

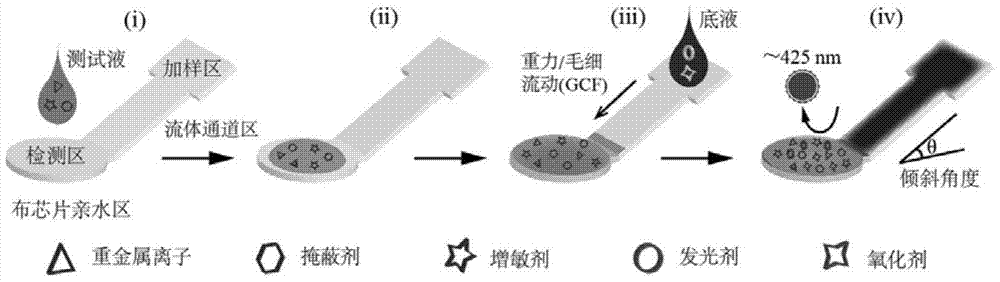

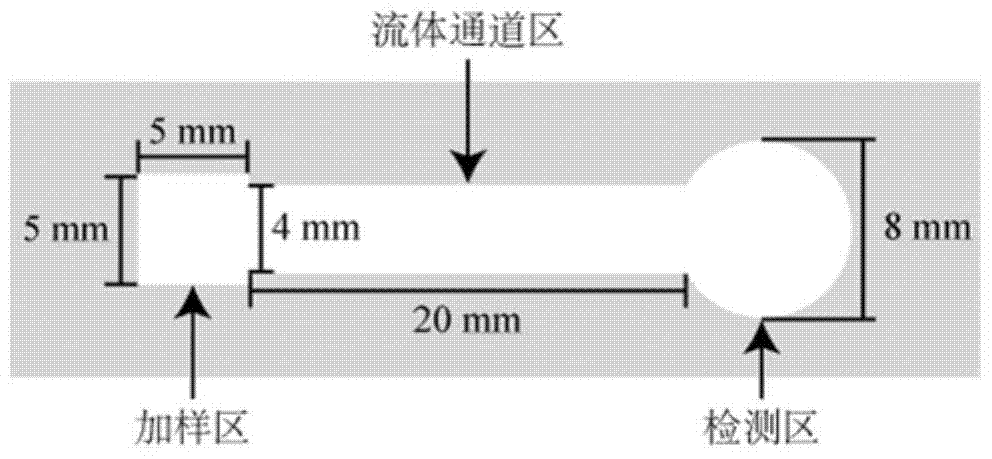

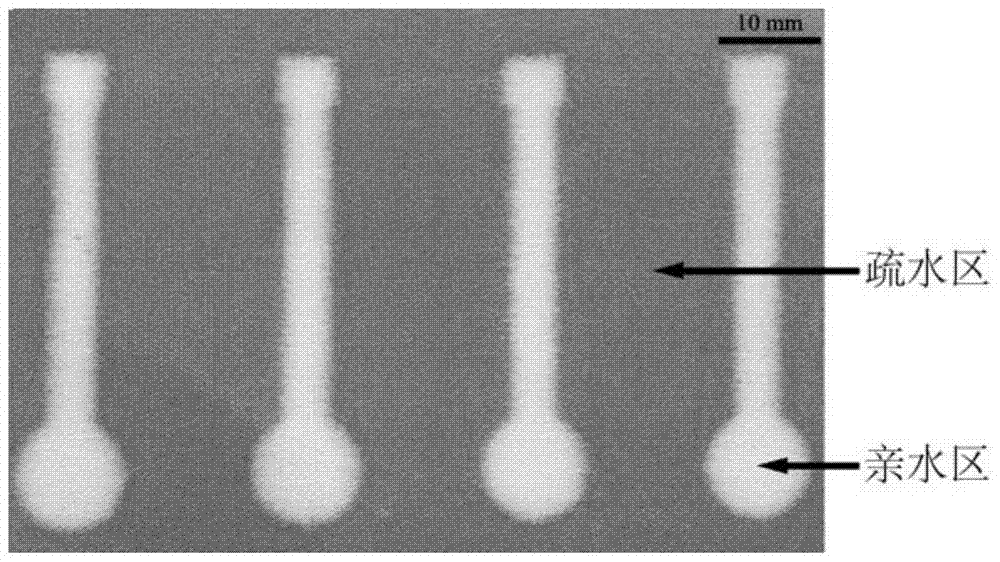

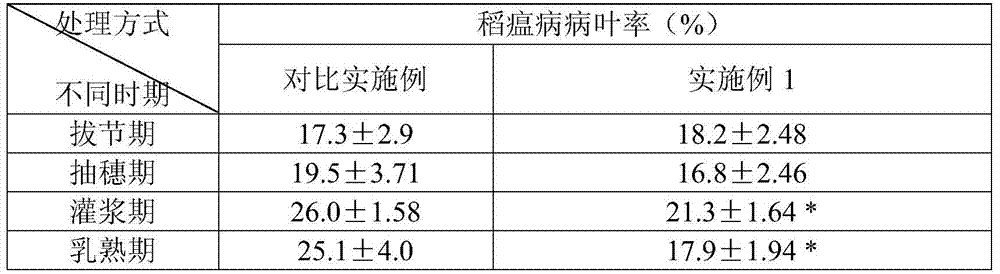

Cloth chip gravity/capillary flow chemiluminescence method

ActiveCN105344391AEasy to useGood biocompatibilityChemiluminescene/bioluminescenceLaboratory glasswaresPeristaltic pumpFiber

The invention discloses a cloth chip gravity / capillary flow chemiluminescence method and particularly discloses a gravity / capillary flow coupled fluid driving cloth chip and application thereof in heavy metal ion detection. The cloth chip is divided into a hydrophobic area and a hydrophilic area, the hydrophilic area is further divided into three parts of a sampling area, a detection area and a fluid channel area. When the cloth chip is used, the cloth chip is closely placed on a support, the inclined plane of the support and a horizontal plane form an included angle. After the cloth chip is arranged, the sampling area and the fluid channel area are required to be located on the inclined plane of the support, the detection area is located at the horizontal portion of the support, and meanwhile a hydrophobic sheet is cushioned under in the detection area of the cloth chip. Compared with traditional flow chemiluminescence detection, the cloth chip and a detection method do not need any expensive pump device (such as a precision injection pump and a peristaltic pump) for driving liquid to flow. The cloth chip gravity / capillary flow chemiluminescence method only utilizes the natural gravity of liquid and capillary force of cloth fiber gaps to drive the liquid to flow.

Owner:SOUTH CHINA NORMAL UNIVERSITY

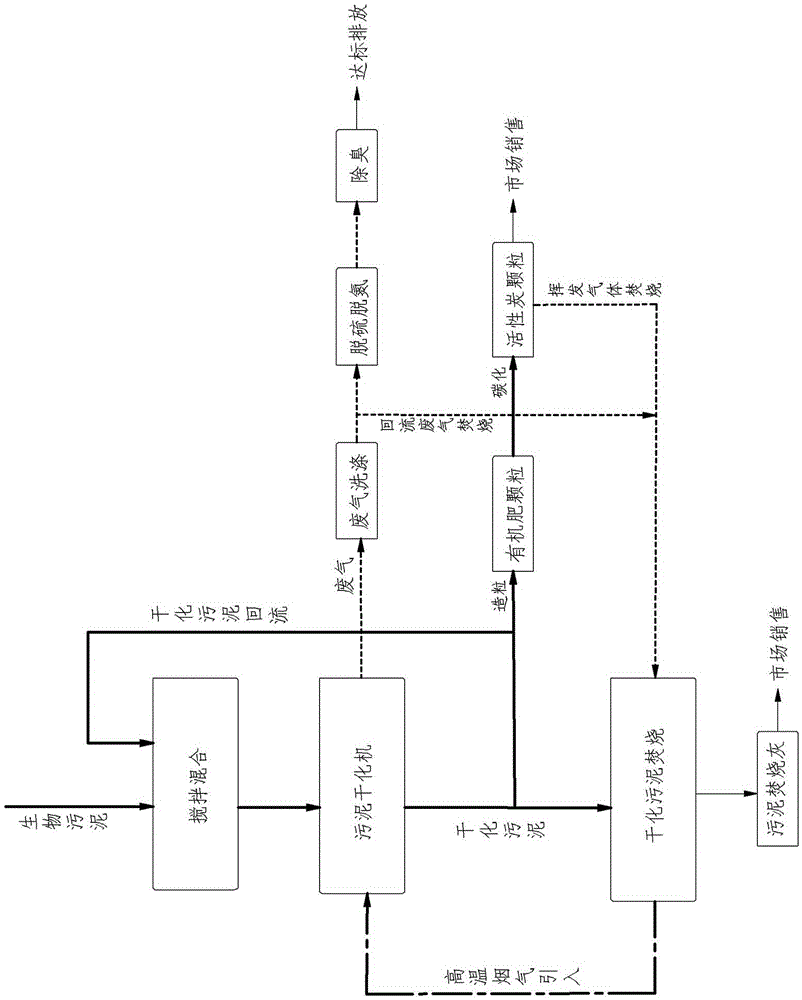

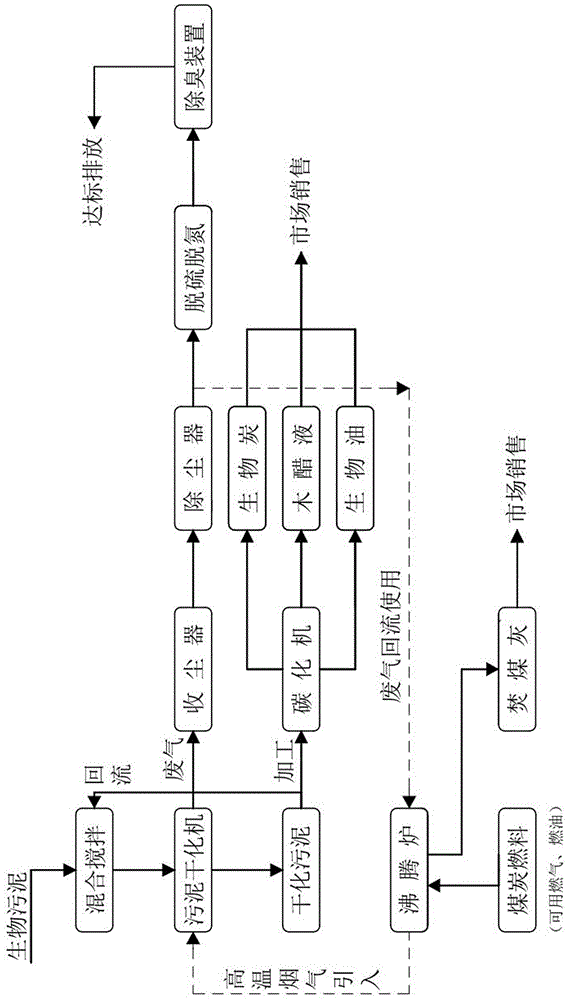

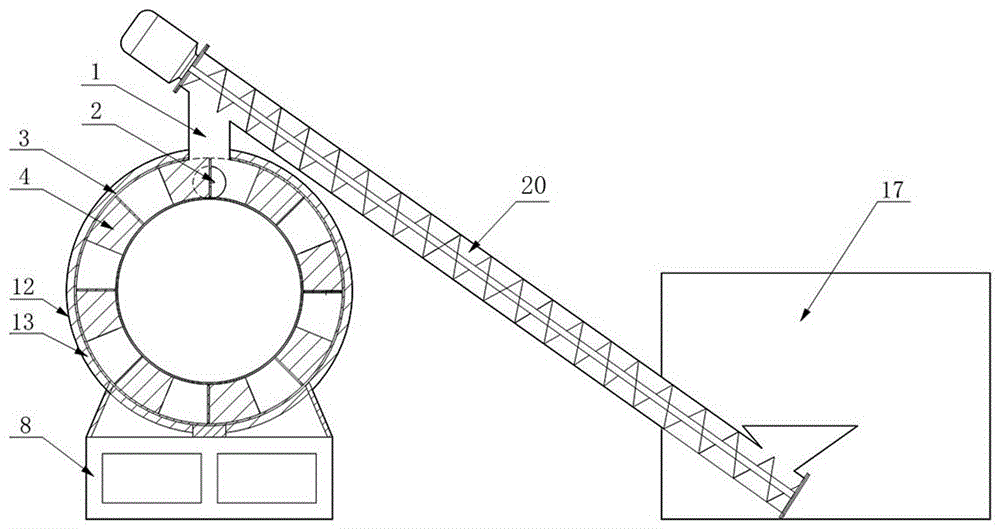

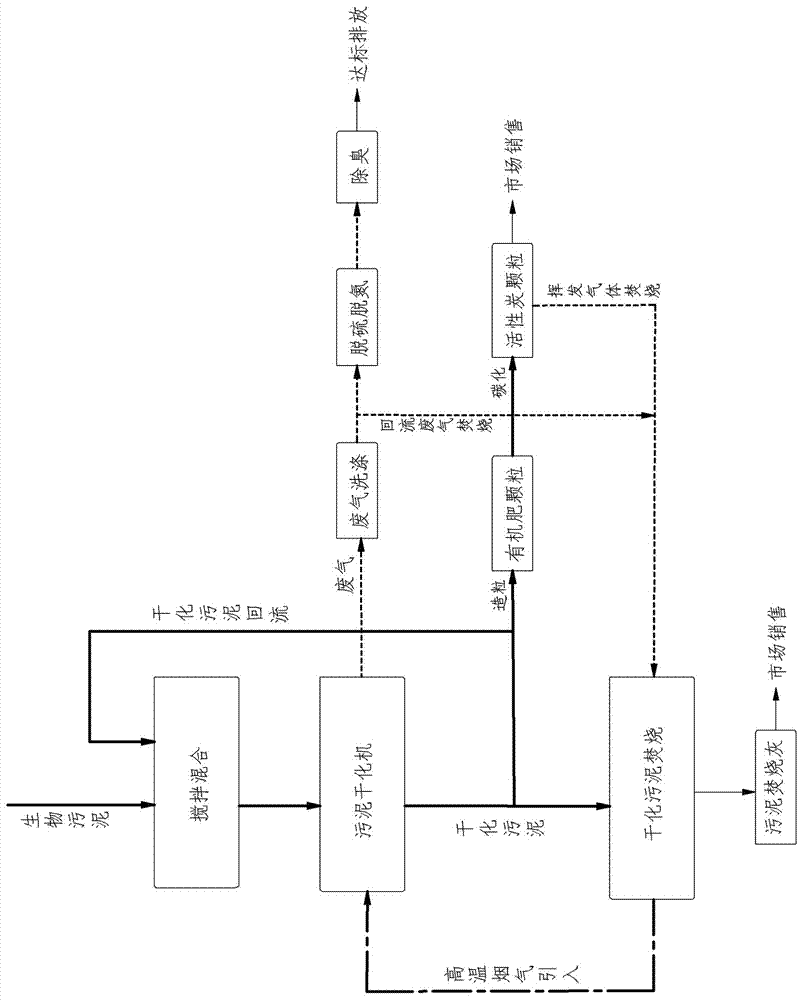

Biological sludge drying and incineration cycle-treatment method and complete equipment

ActiveCN105399304AThorough treatmentImprove environmental safetySludge treatment by de-watering/drying/thickeningRunoff/storm water treatmentExhaust gasTreatment completed

The invention relates to a biological sludge harmless and resourceful treatment method. A biological sludge drying and incineration cycle-treatment method comprises the following steps: 1) sludge drying treatment process: adding backflow drying sludge into biological sludge, fully stirring and drying by sending the sludge into a rotary sludge drier; 2) dried sludge incineration treatment process: sieving part of dried sludge after the drying treatment, incinerating the sludge by sending the sludge into a boiling-type sludge incinerator, directly introducing high temperature flue gas generated by the incineration into the rotary sludge drier so as to dry mixed sludge; introducing exhaust gas generated by drying and incineration of sludge into an exhaust gas washing tower, introducing exhaust gas which has undergone washing treatment back into the boiling-type sludge incinerator to be incinerated, and carrying out harmless treatment on residual exhaust gas; and 3) simultaneously carrying out the above biological sludge drying treatment process and dried sludge incineration treatment process and ceaselessly cycling the processes. Biological sludge drying and incineration cycle-treatment complete equipment comprises the rotary sludge drier and the boiling-type sludge incinerator.

Owner:宁波高新区纯丽节能技术有限公司

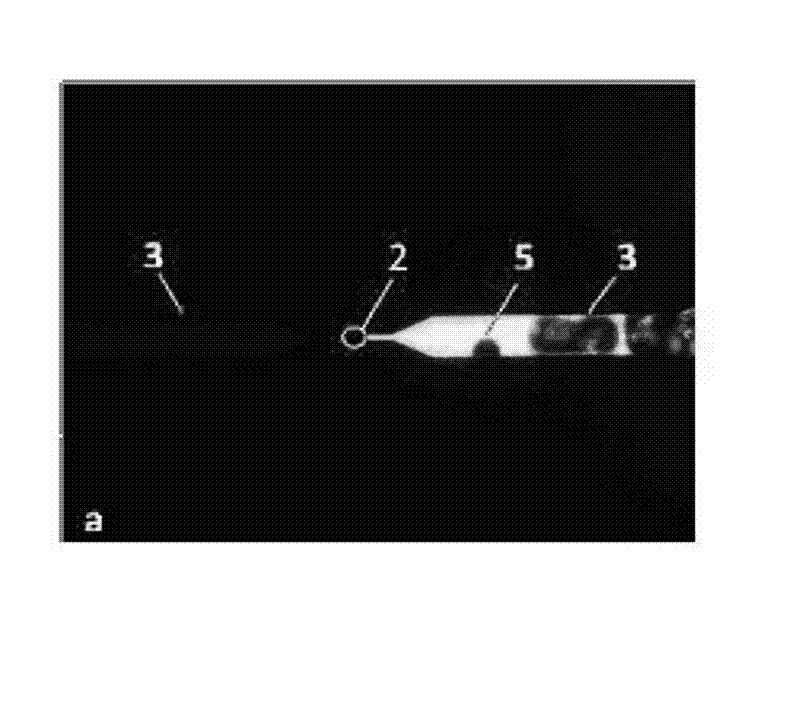

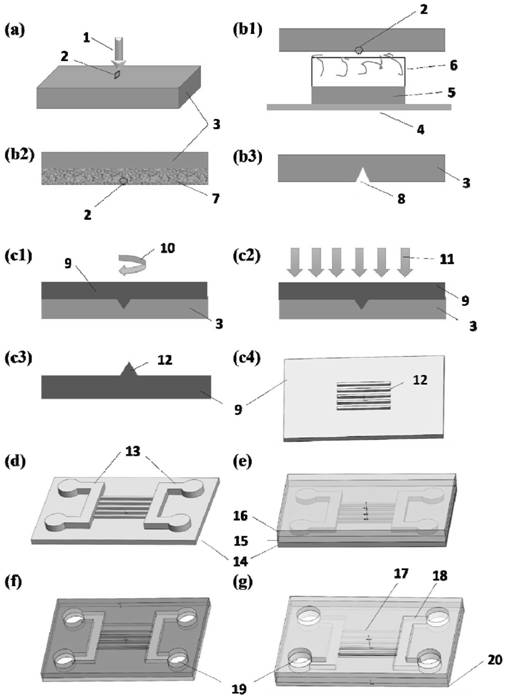

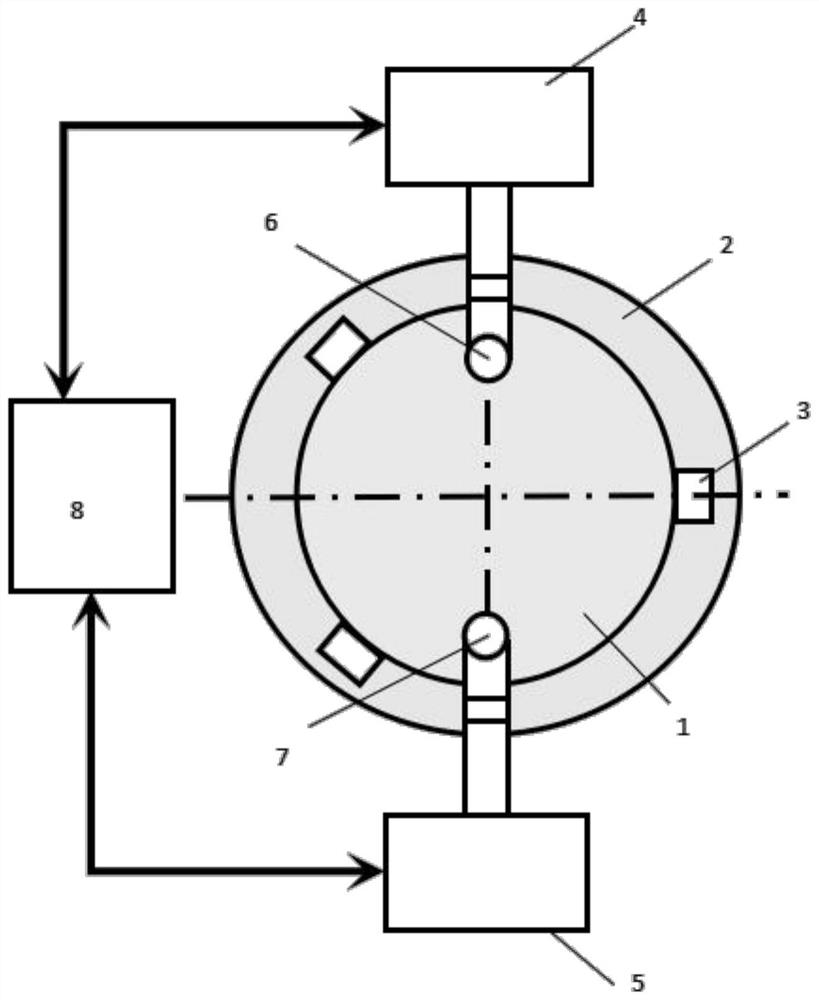

Nanofluidic chip, processing method based on atomic force microscopy (AFM), and application

InactiveCN102539503ALow costChange the speed of movementNanosensorsMaterial electrochemical variablesAtomic force microscopy3-deoxyribose

The invention discloses a nanofluidic chip, a processing method based on atomic force microscopy (AFM), and application. Each of two ends of the chip is provided with a liquid storage tank; each liquid storage tank is connected with a micron pipeline; a nano pipeline is arranged between two micron pipelines; and electrodes which are vertical to the pipelines are arranged on two sides of the nano pipeline. The nano pipeline which is communicated with the micron pipelines is processed by using an AFM probe. Certain voltage is applied between the liquid storage tanks of the chip, small voltage is applied to the electrodes on two sides of the pipelines simultaneously, and the change of a current signal is measured; and when an object flows through the electrodes in the nano pipeline, current changes, and signal detection can be used for analyzing the structural and physical characteristics of a nano material. Processing and signal detection methods for the nanofluidic chip can applied to low-cost and quick sequencing of deoxyribose nucleic acid (DNA) molecules.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

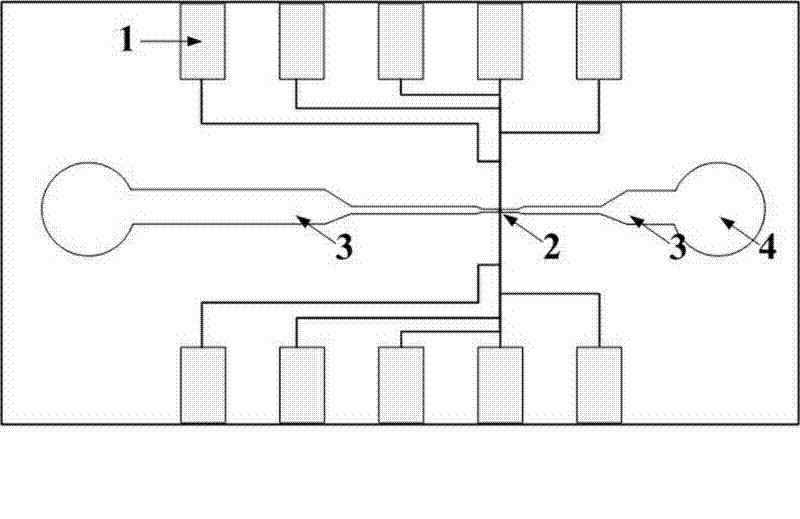

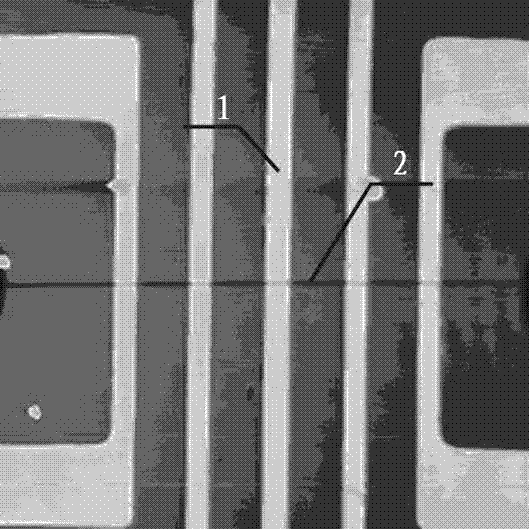

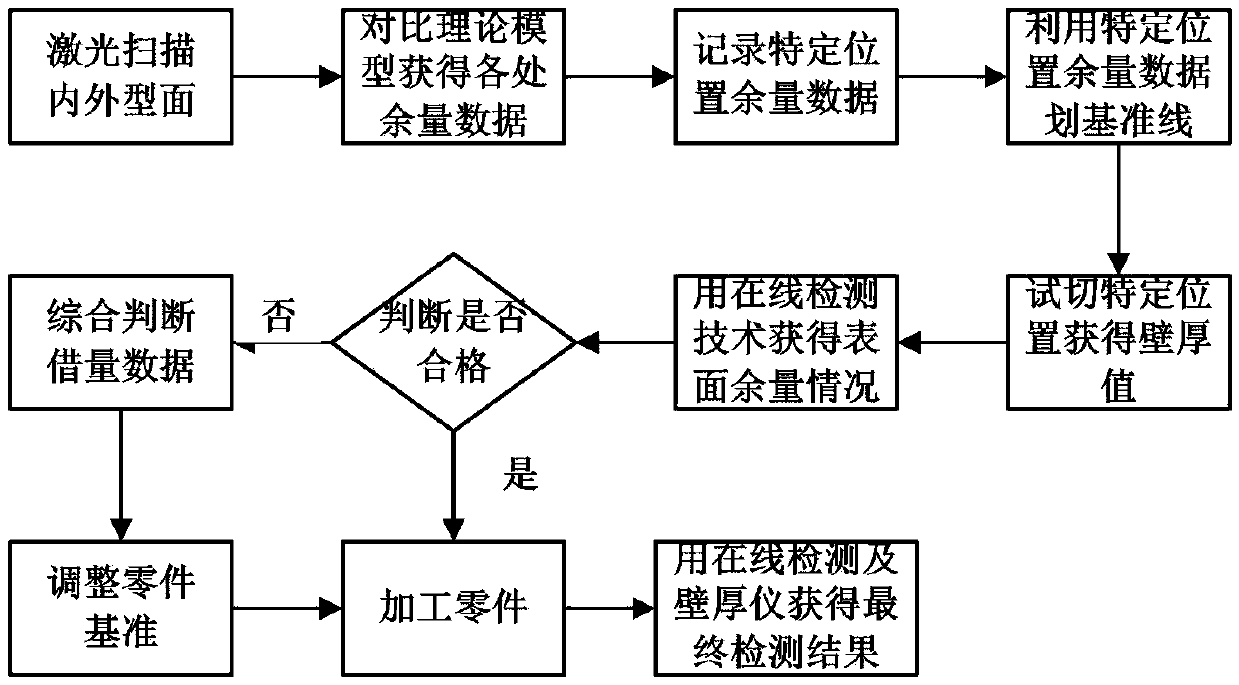

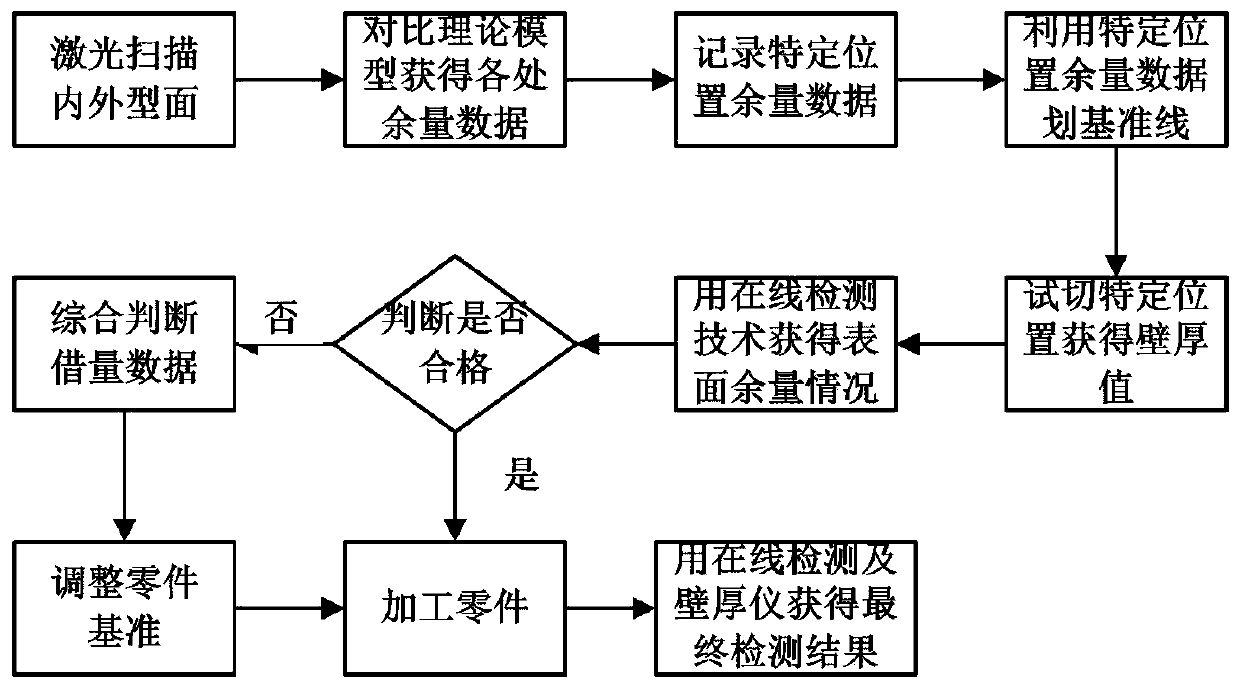

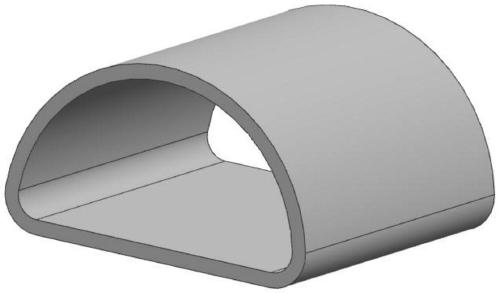

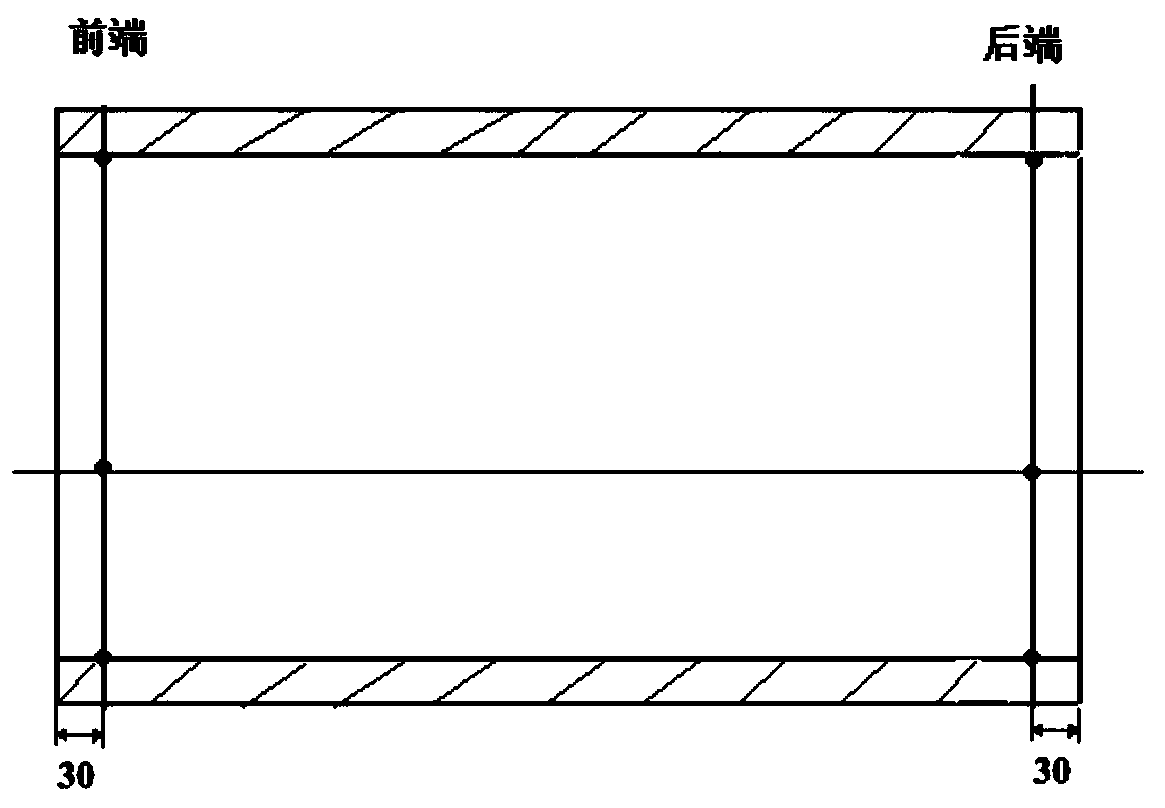

Casting cabin section processing method based on precision detection technology

ActiveCN109531273AGuaranteed machining accuracyReliable Machining BenchmarkMeasurement/indication equipmentsComputer visionLaser detection

The invention belongs to the technical field of precision detection and processing, and particularly relates to a casting cabin section processing method based on precision detection technology. According to the method, high-precision detection methods such as laser detection and on-line detection are used before processing, the conditions such as the allowance and the defective number of a complex cast part are mastered, compared with a correction feature point allowance median fetching method adopted in a conventional alignment method, since allowance data of all positions are considered, the machining accuracy of the part can be guaranteed, and a relatively reliable machining standard can be obtained. In practical application, the method is used for marking and correction, the deviationis generally small, the subsequent processing can be met, and the quantity borrowing adjustment step is not used. The method of directly marking according to scanning data to establish reference processing is adopted, and analysis and judgment are facilitated; and compared with the method of repairing the standard by using a standard block, processing time is shortened, occupation of the equipment is reduced, and the method is a relatively fast processing method.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

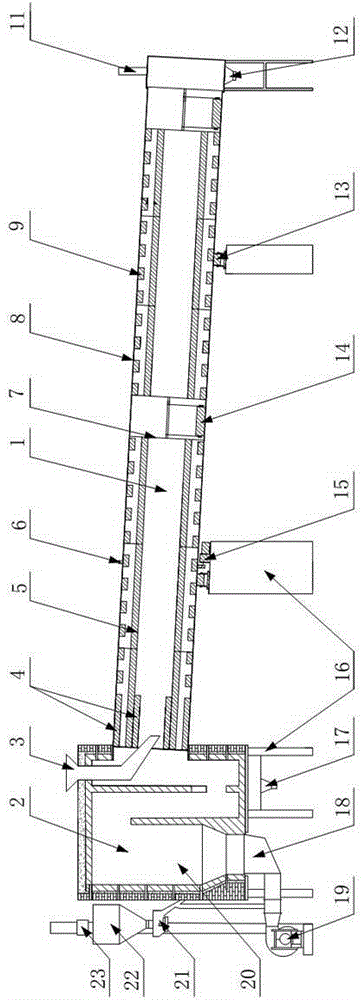

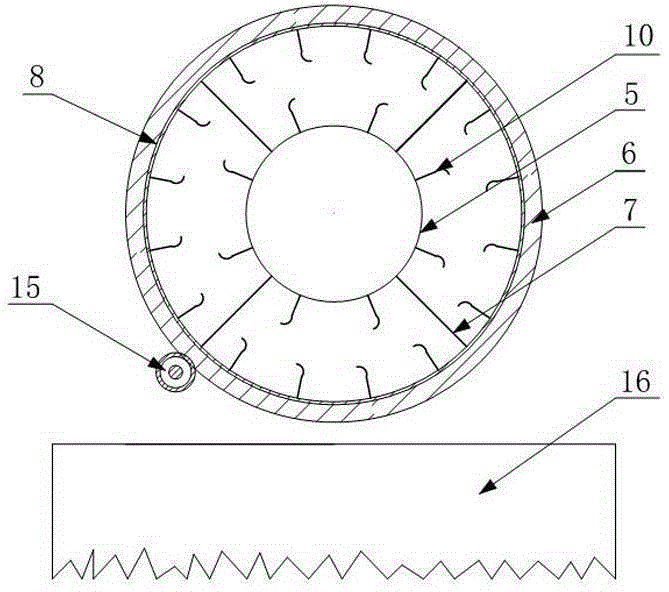

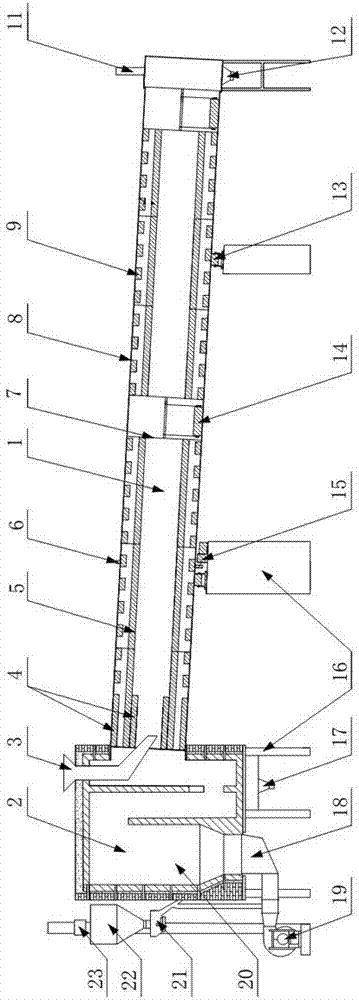

Commercial treatment method and system for biological sludge and rotary sludge carbonizing machine

ActiveCN105753281AImprove environmental safetyReduce processing costsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention relates to resourceful treatment on biological sludge.A commercial treatment method for biological sludge includes the steps that the biological sludge is dried, the dried sludge with the water content being 7-10% is carbonized and generates biochar, pyroligneous liquor and biological tar through high-temperature pyrolysis, and biochar, pyroligneous liquor and biological tar are packaged for sale; methane gas generated in the treatment process is recovered and used for carbonization treatment on the dried sludge.According to a rotary sludge carbonizing machine, a handpiece component and a tail component are fixed to the two ends of a rack, the two ends of a rotary cylinder are inserted into the handpiece component and the tail component and matched with the handpiece component and the tail component in a sealed mode, and a supporting and driving mechanism matched with the rotary cylinder is arranged on the rack; a guiding plate is arranged on the front portion of the rotary cylinder, a lifting plate is arranged on the inner wall of the rotary cylinder, and a combustor is arranged in a heat preservation outer cover below the rotary cylinder.A commercial treatment system for the biological sludge comprises biological sludge drying treatment complete equipment and dried sludge carbonizing treatment complete equipment.The harmful biological sludge is turned into wealth, and the commercial treatment method and system for the biological sludge have high socioeconomic performance and can create huge wealth for enterprises and the society.

Owner:四川泰翱农业科技有限公司

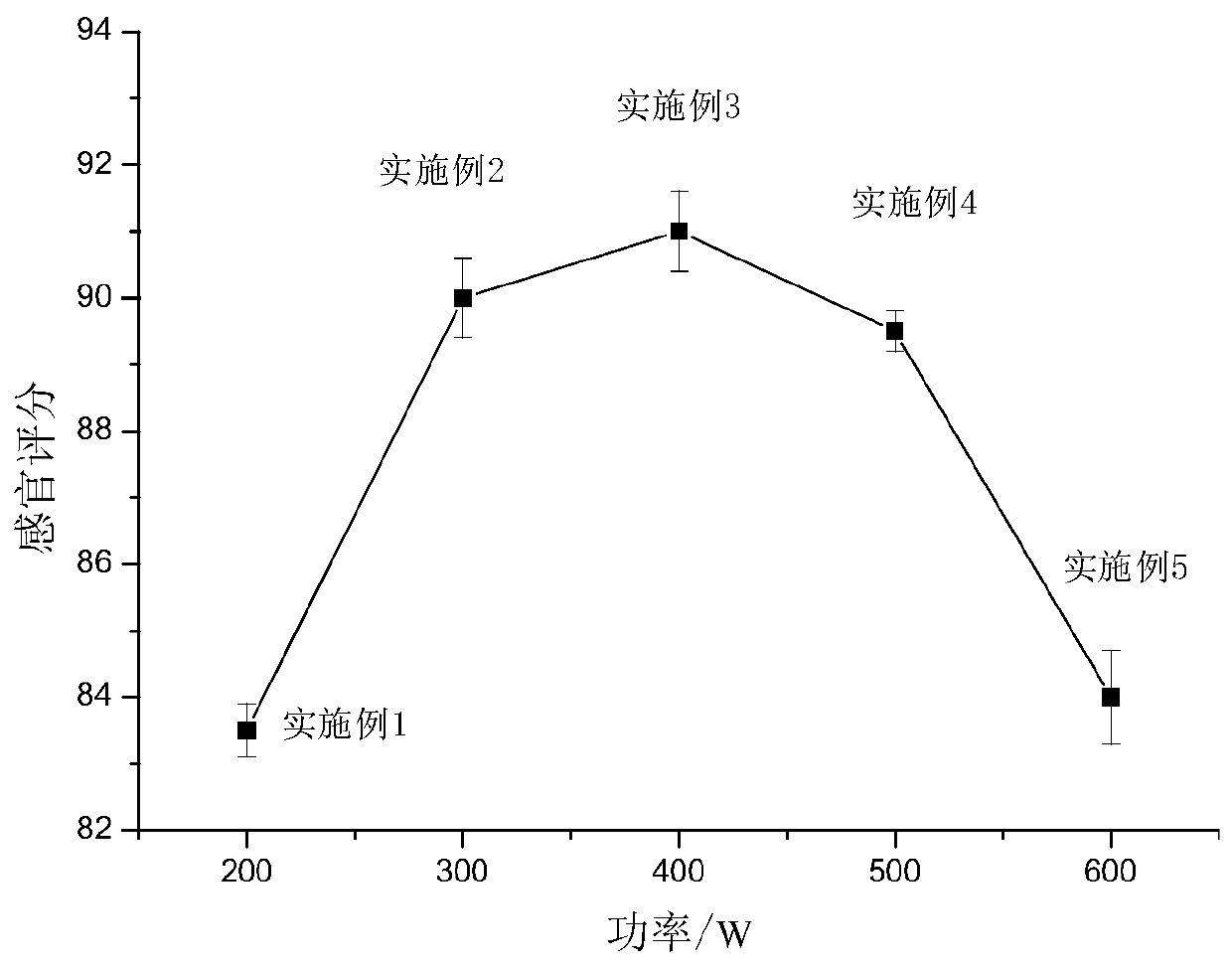

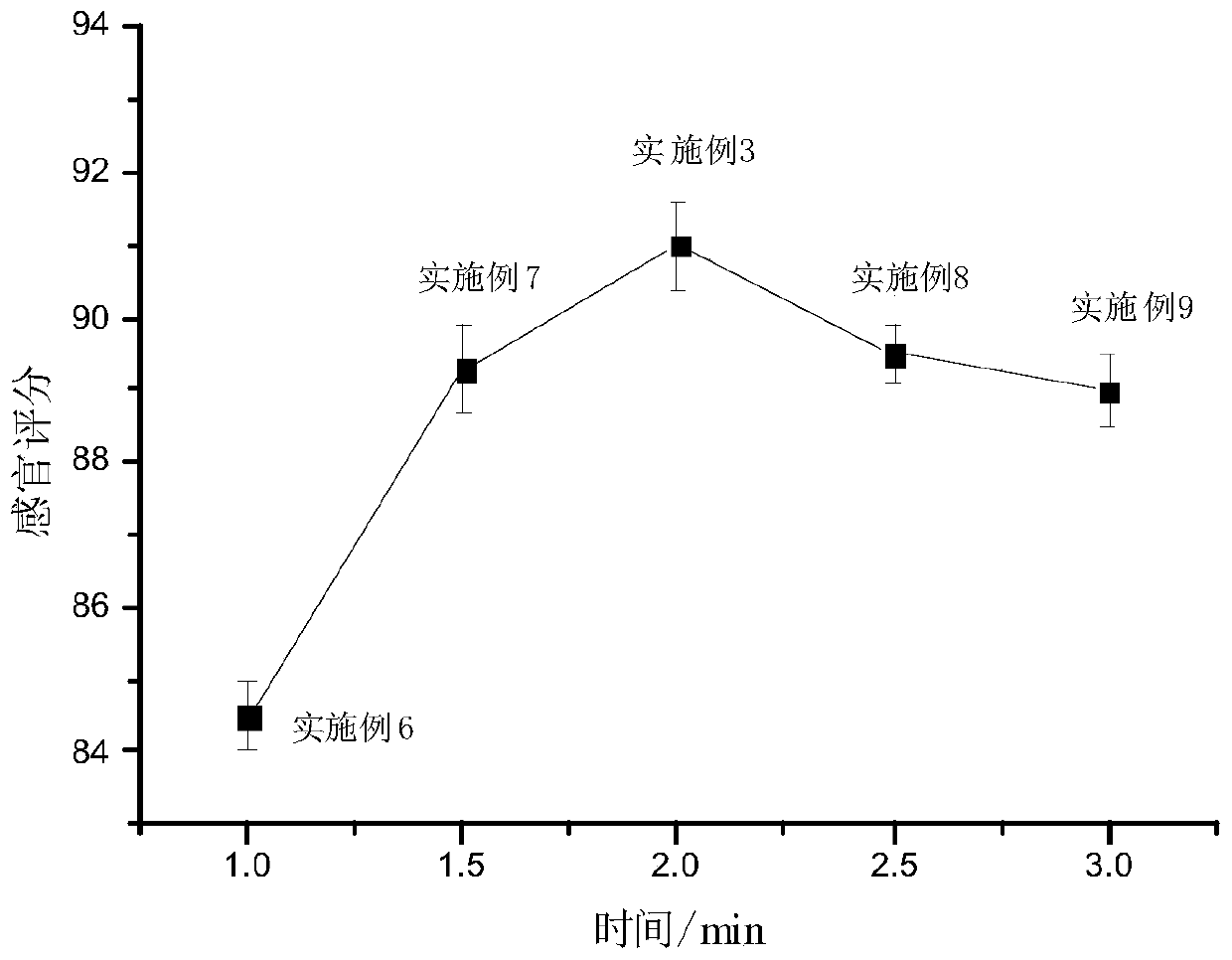

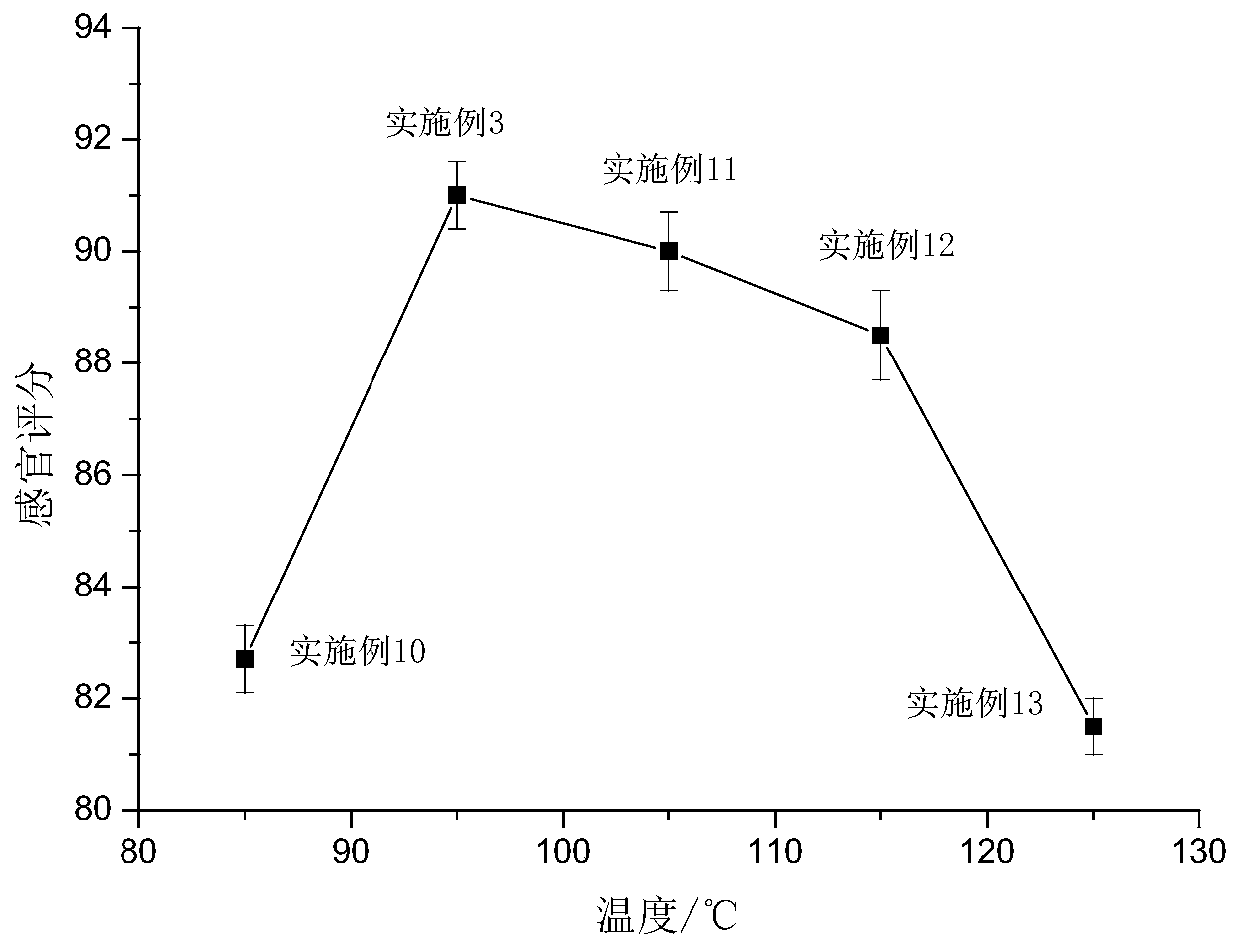

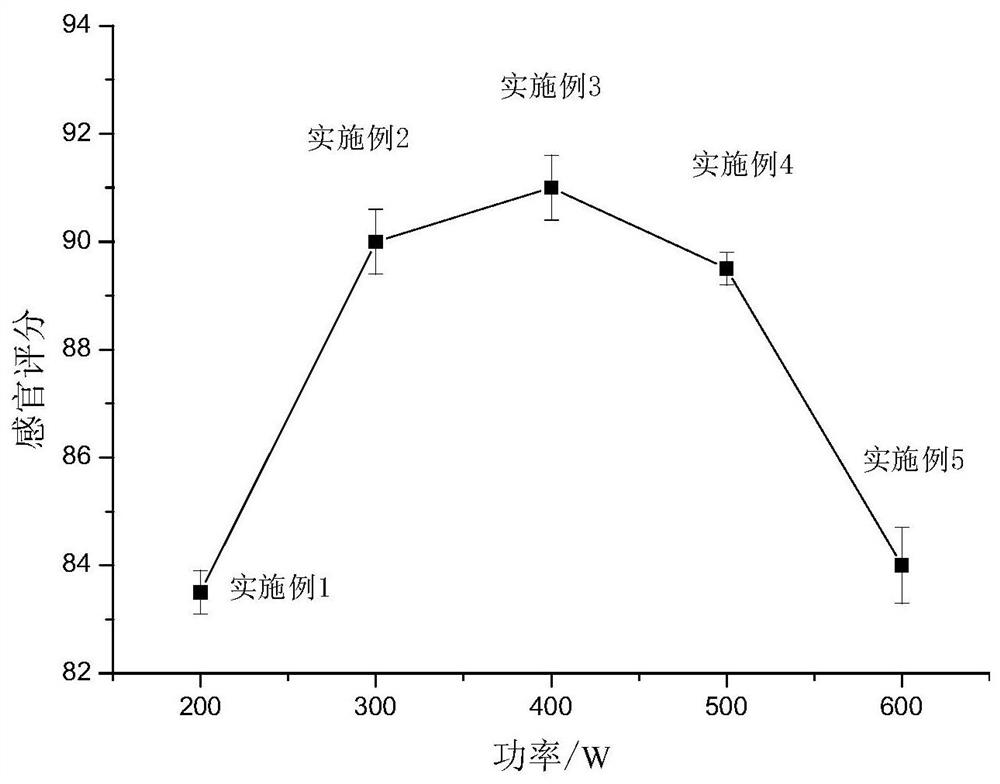

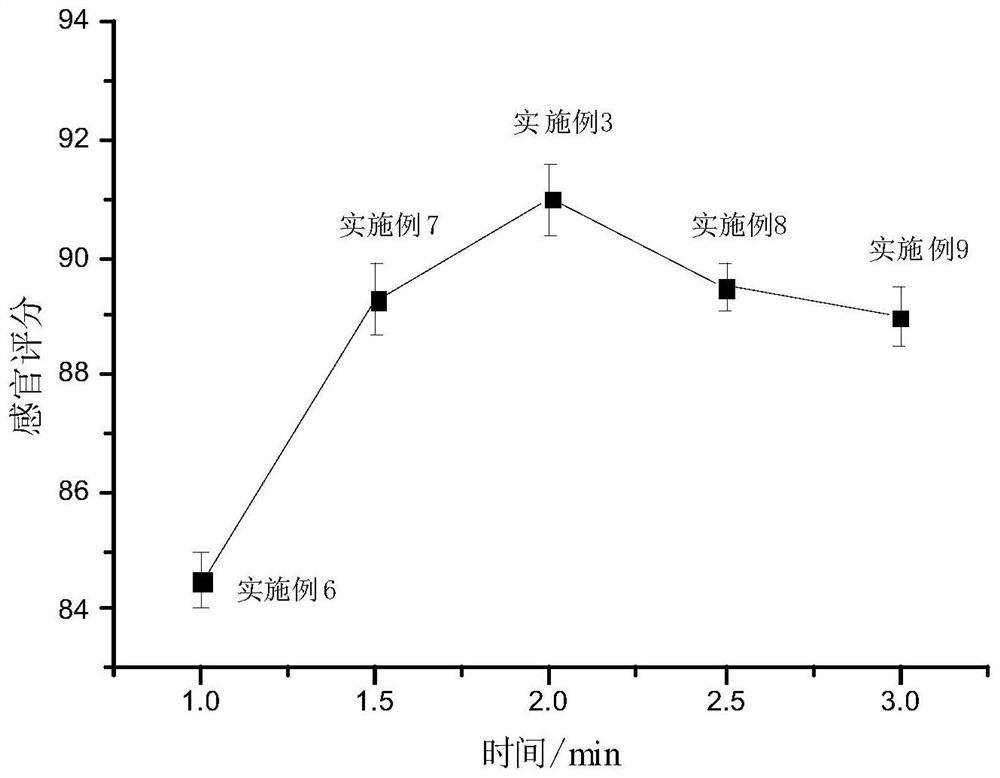

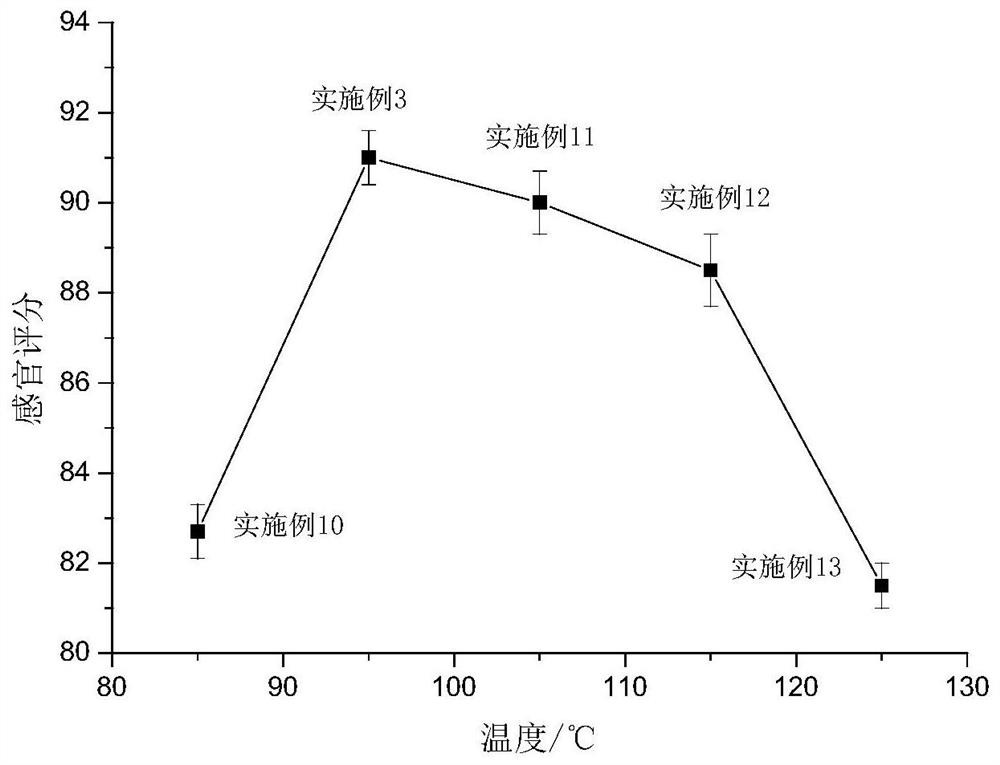

Processing method for reinforcing aroma of rapeseed oil and rapeseed oil

ActiveCN109777602AClear colorSimple production and processing technologyFatty-oils/fats productionEdible oils/fatsFlavorEconomic benefits

The invention discloses a processing method for reinforcing aroma of rapeseed oil and the rapeseed oil. The method includes the steps of sequentially conducting smashing, microwave treatment and dry-steaming on the rapeseed oil to obtain condensate, mixing the condensate with a finished oil product for standing and layering, and taking supernate to obtain the strong-aroma rapeseed oil. The strong-aroma condensate is obtained from dry-steamed and smashed rapeseed meal and then mixed with the rapeseed oil, the obtained rapeseed oil is strong in flavor and clear and bright in color and luster, the producing and processing process of the strong-aroma rapeseed oil is simplified, the problems that the oil yield is low and the production link is complicated in the traditional process are solved,the loss of aroma substances of the strong-aroma rapeseed oil in the refining process is reduced, cost is saved, the production time is shortened, and the production economic benefits of the strong-aroma rapeseed oil are improved.

Owner:长安花粮油股份有限公司 +2

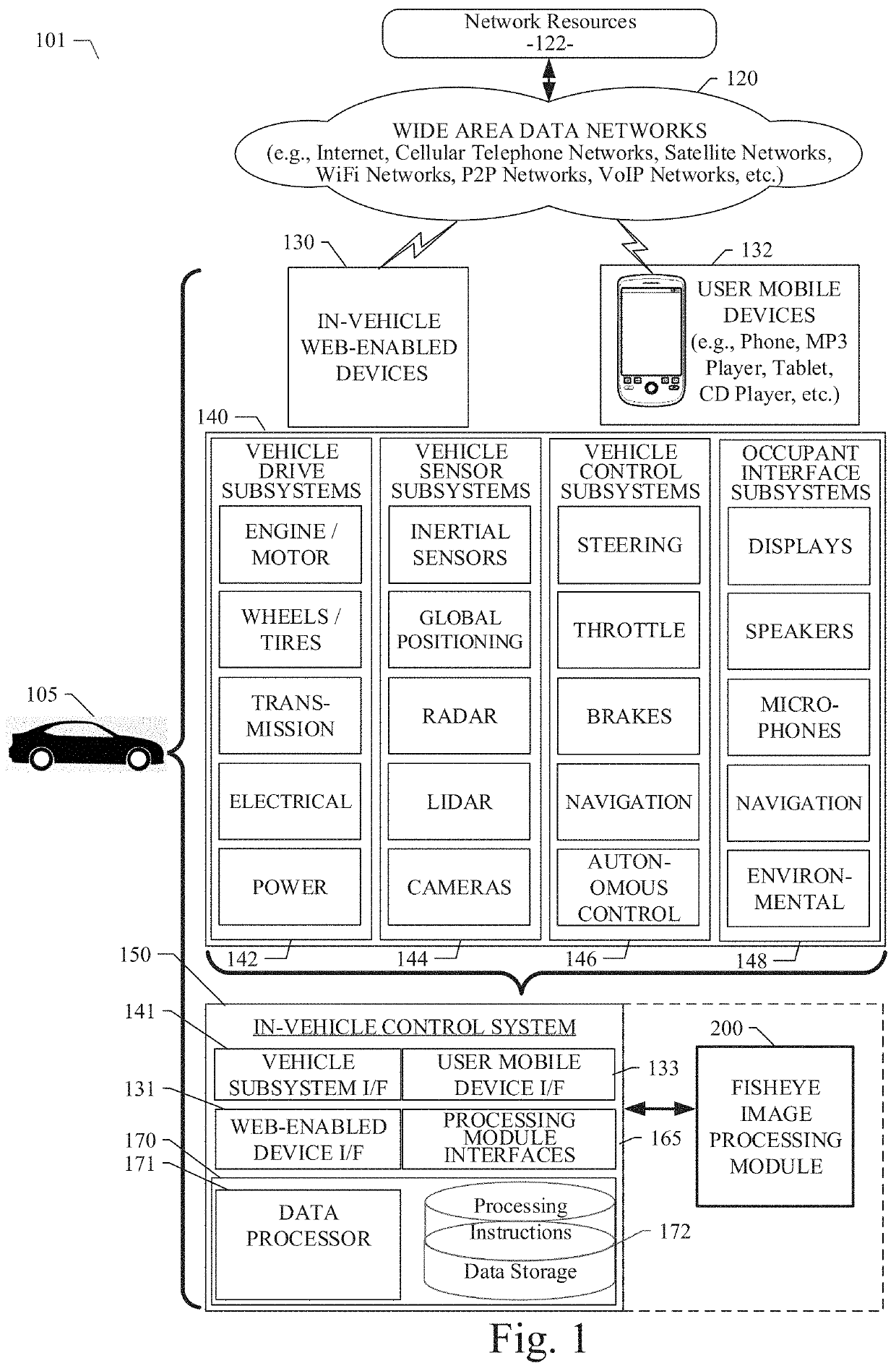

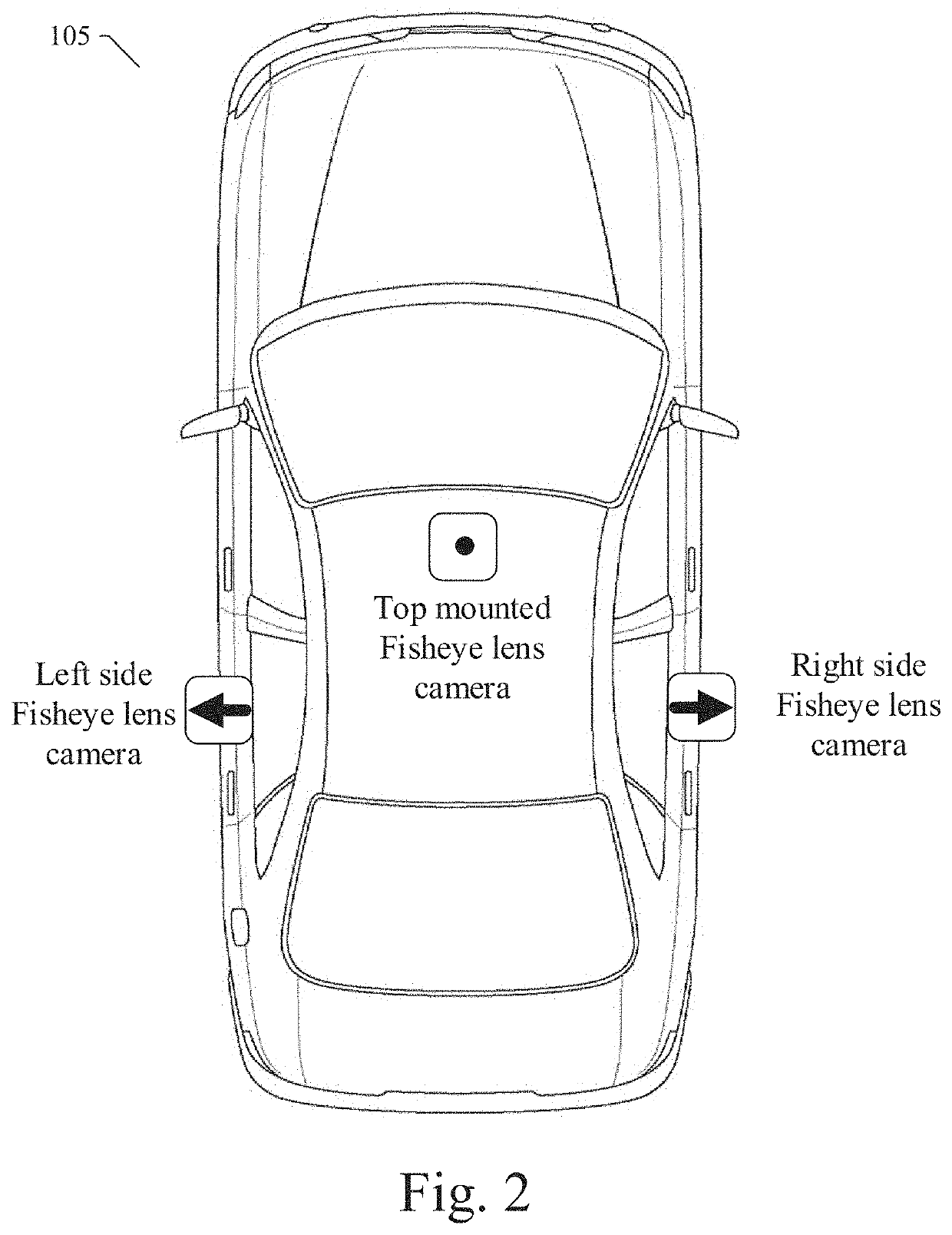

System and method for fisheye image processing

ActiveUS10796402B2Minimum of human effortFast processing methodImage enhancementImage analysisFisheye lensImaging processing

Owner:TUSIMPLE INC

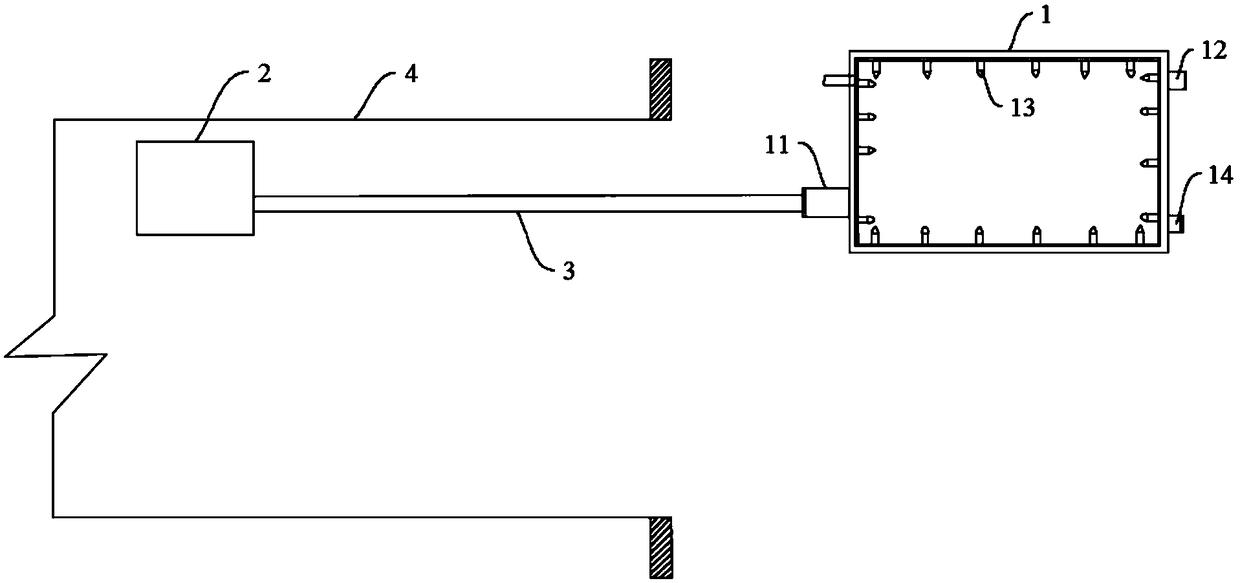

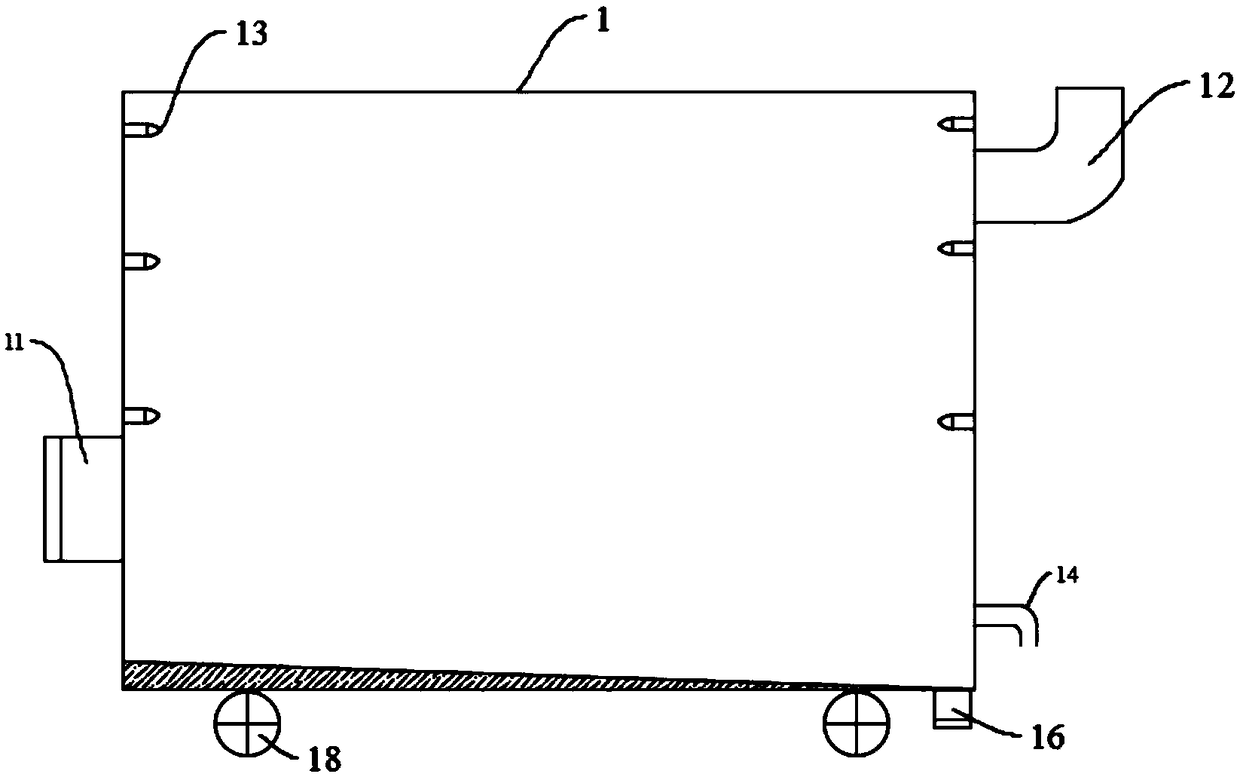

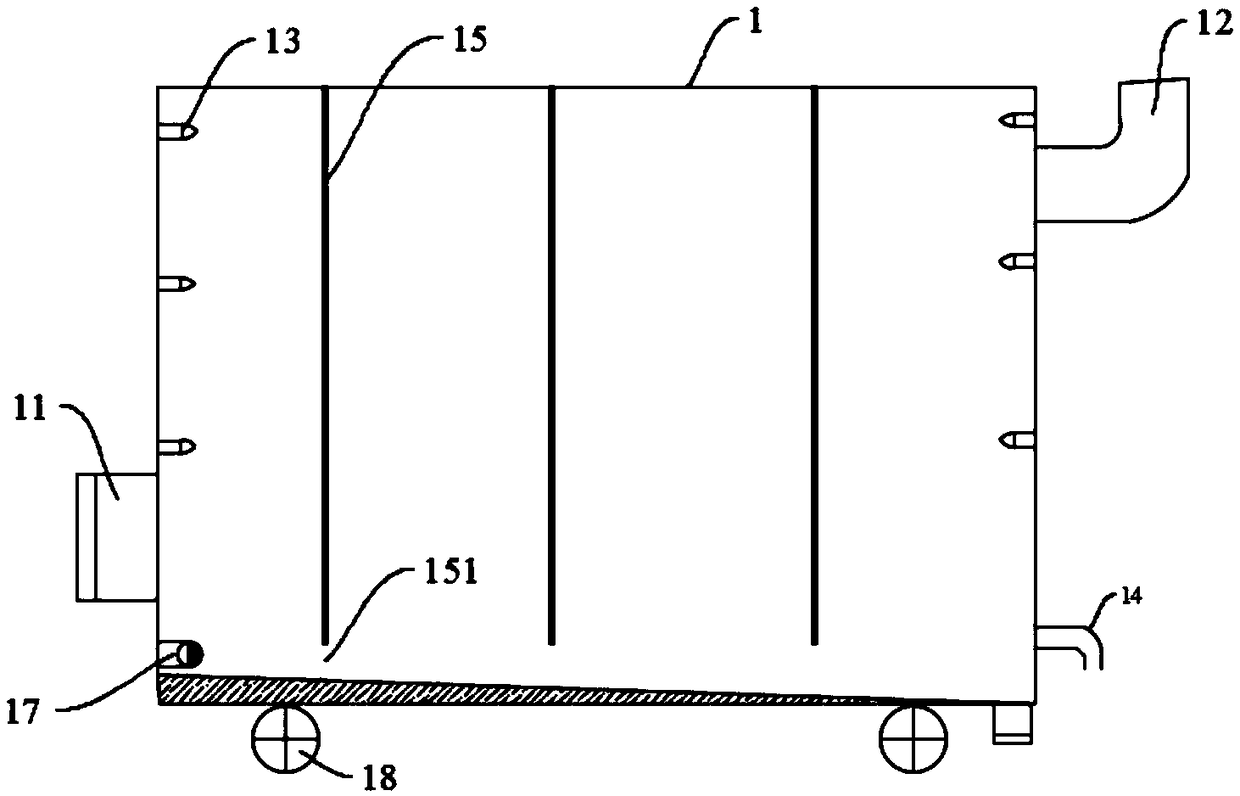

Box type tunnel water curtain dust fall device

The invention discloses a box type tunnel water curtain dust fall device. The device comprises a dust fall box and an exhaust fan which are connected through an air pipe, and the exhaust fan can convey dust-containing air into the dust fall box through the air pipe; a sprayer is arranged in the dust fall box; dust in the dust-containing air is captured through water spraying. The box type tunnel water curtain dust fall device has the advantages of being simple in structure, stable and reliable, high in operability, simple in processing method, rapid to use and the like; the dust can be directly controlled from the source, and the dust raising problem of a whole tunnel is thoroughly avoided. The device is remarkable in dust removal effect, the dust capture rate can reach 95-97%, and the device has extremely high popularization and application values.

Owner:CHINA MCC5 GROUP CORP

Processing method for polycrystalline diamond

ActiveCN108187586AAchieve high precision machiningInexpensive processing methodUltra-high pressure processesHydrofluoric acidSand blasting

The invention discloses a processing method for polycrystalline diamond. The processing method comprises the following steps: (1) preparing a die; (2) filling a graphite pipe or a metal cup with diamond micropowder with the particle size of 1-30 mu m and the die according to the shape of a finished product, and carrying out sinter molding under the conditions of high temperature and high pressureto prepare a semi-finished product; and (3) removing the die on the semi-finished product by using sand blasting or a corrosive liquid to obtain the polycrystalline diamond with the required configuration or structure, wherein the corrosive liquid contains hydrofluoric acid and nitric acid. By using the processing method disclosed by the invention, the configuration or structure of the polycrystalline diamond can be processed into the required specific shape, the high-precision processing of the complex surface and spatial shape of the polycrystalline diamond can be realized, and therefore, special-shaped polycrystalline diamond is obtained; and compared with a traditional method, the processing method disclosed by the invention is cheaper, more convenient and rapider, free of special equipment and relatively high in operability.

Owner:ZHUHAI JUXIN TECH DEV

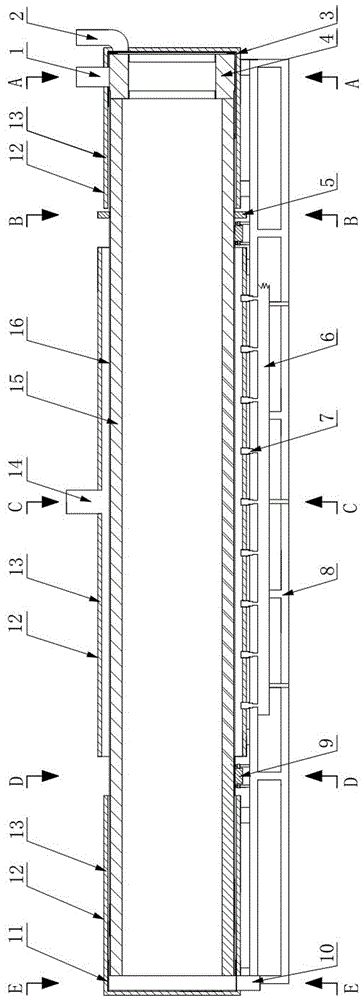

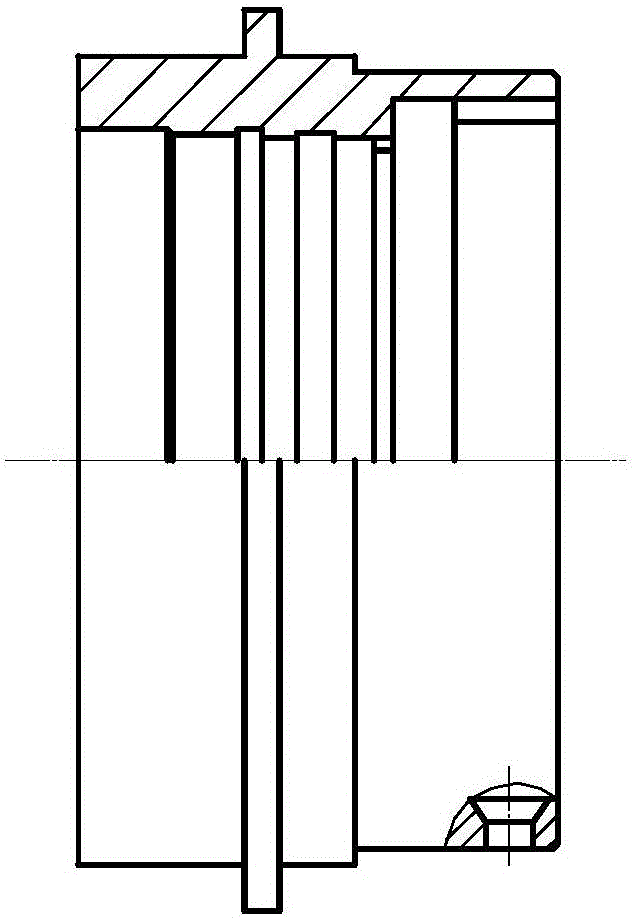

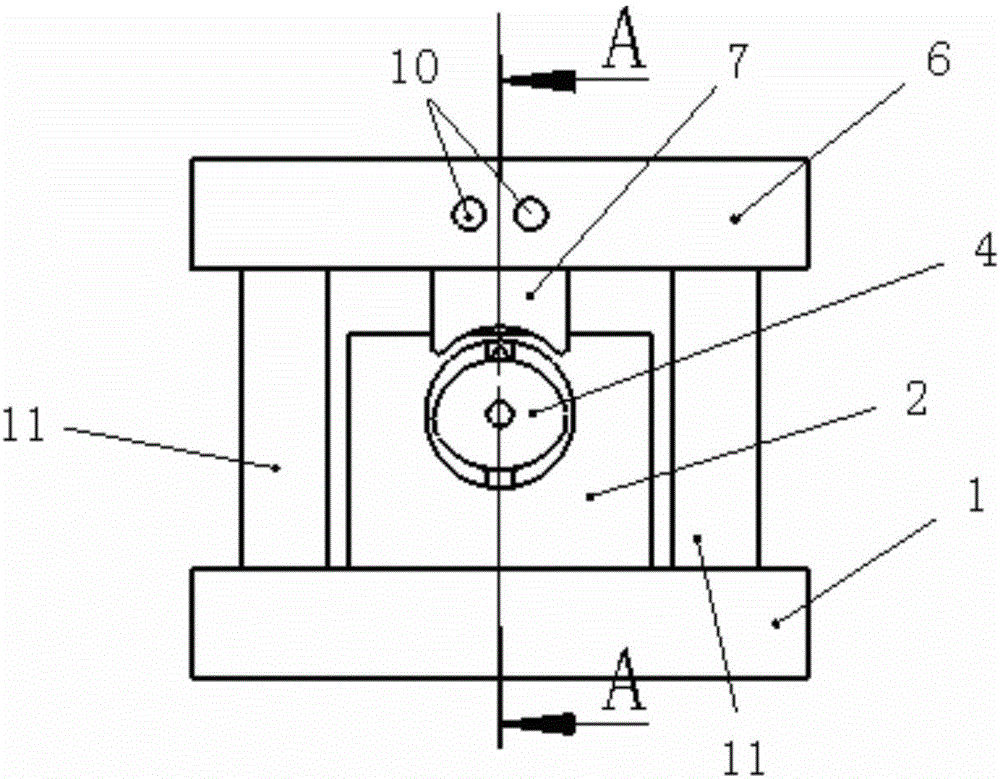

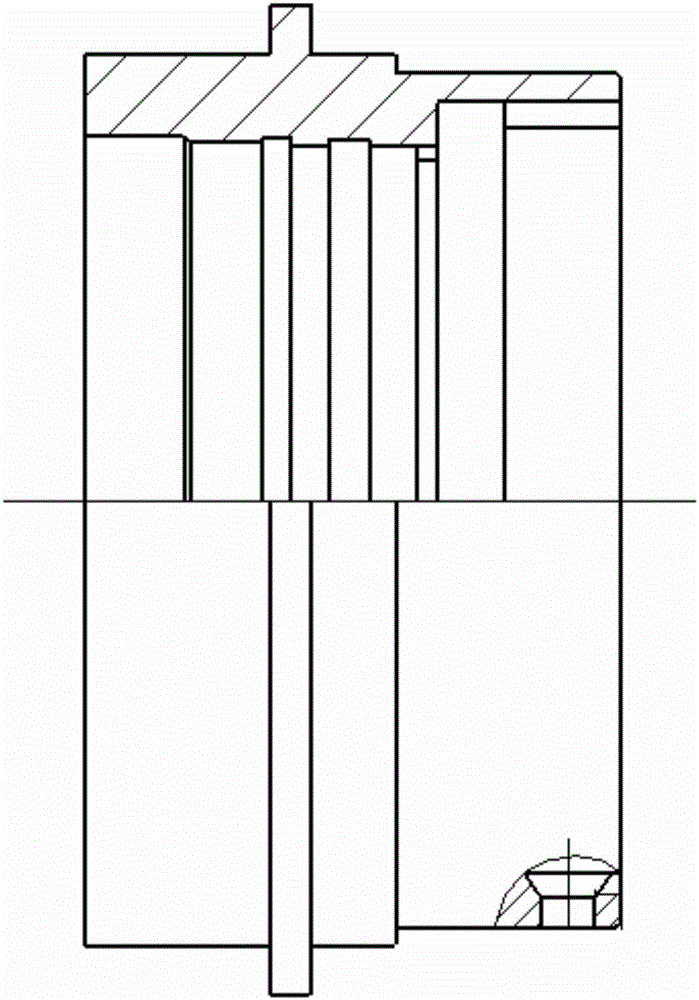

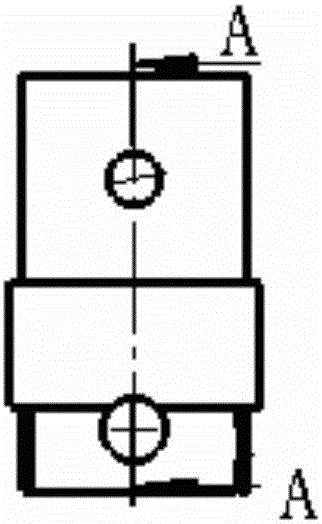

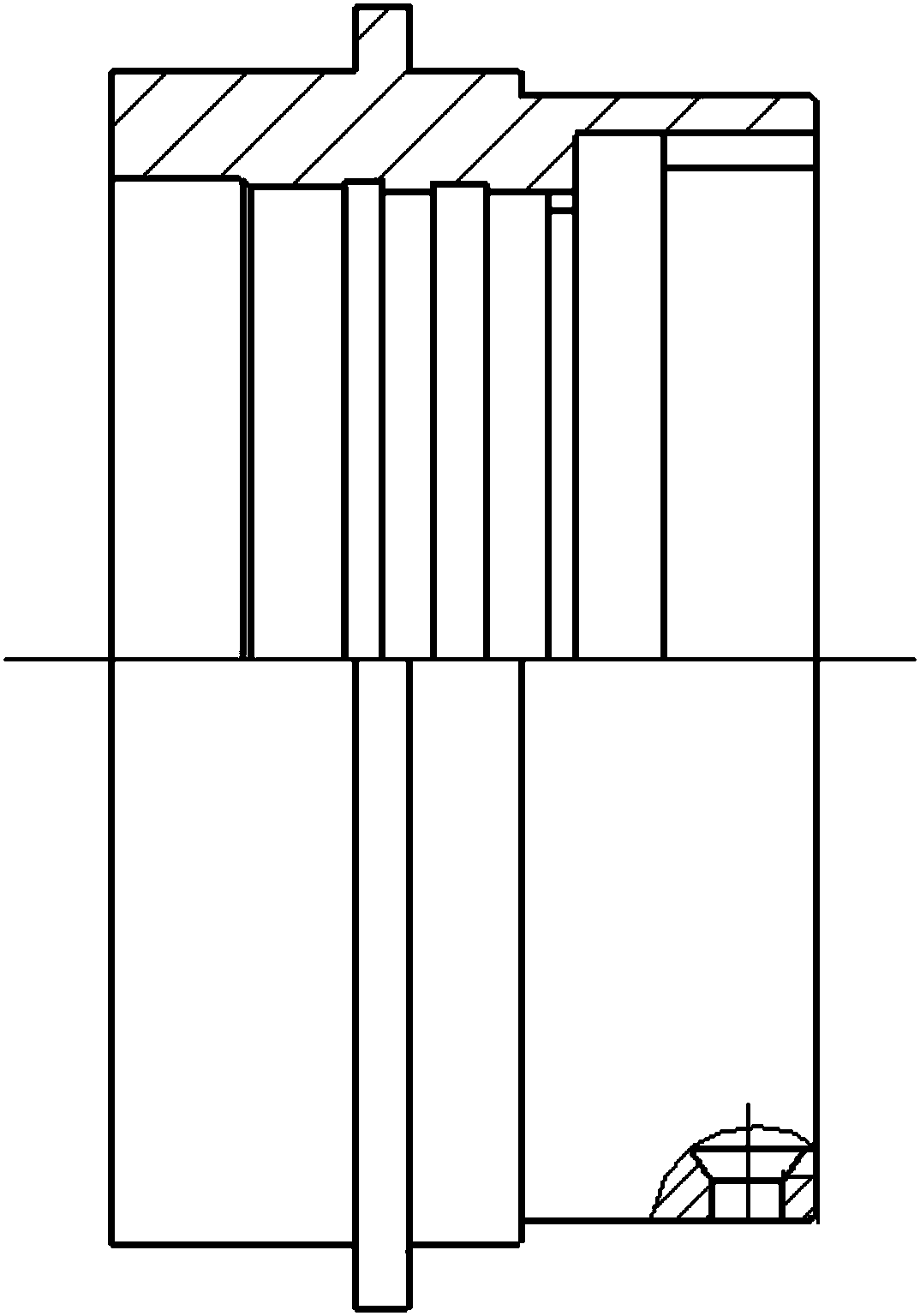

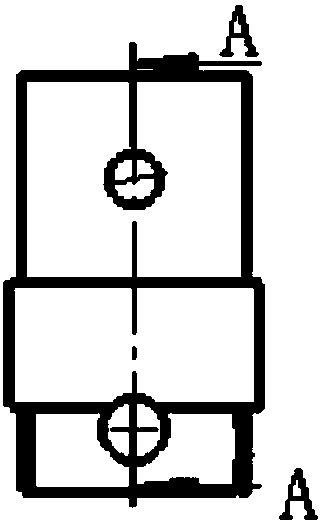

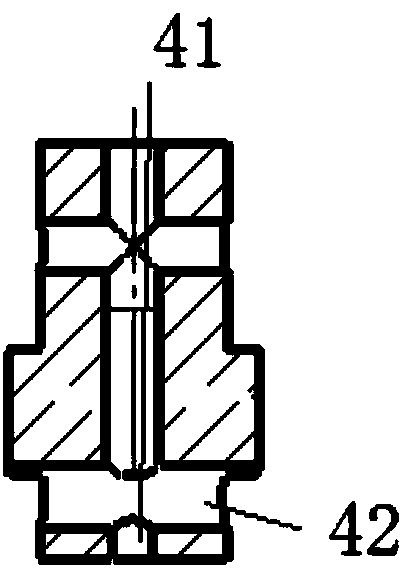

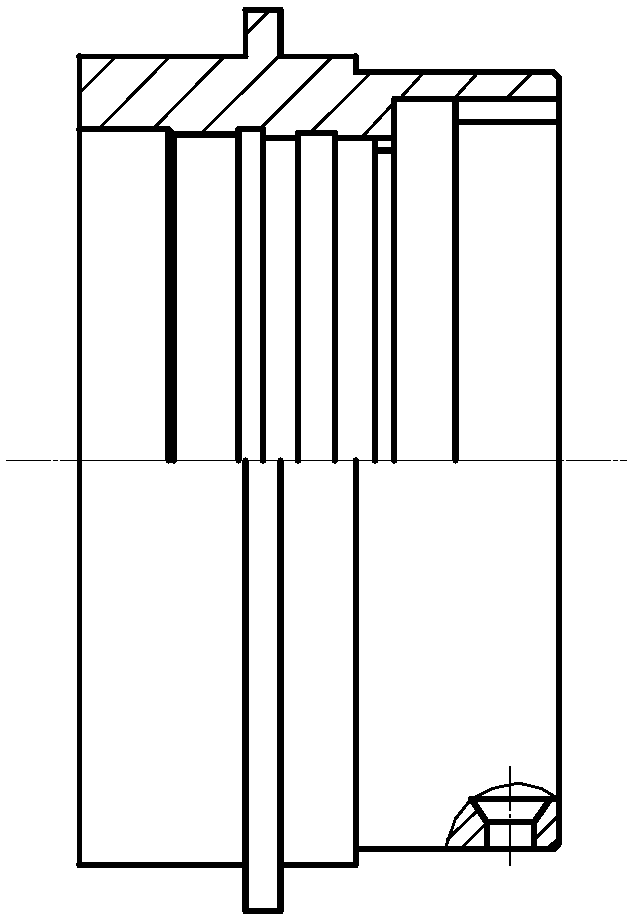

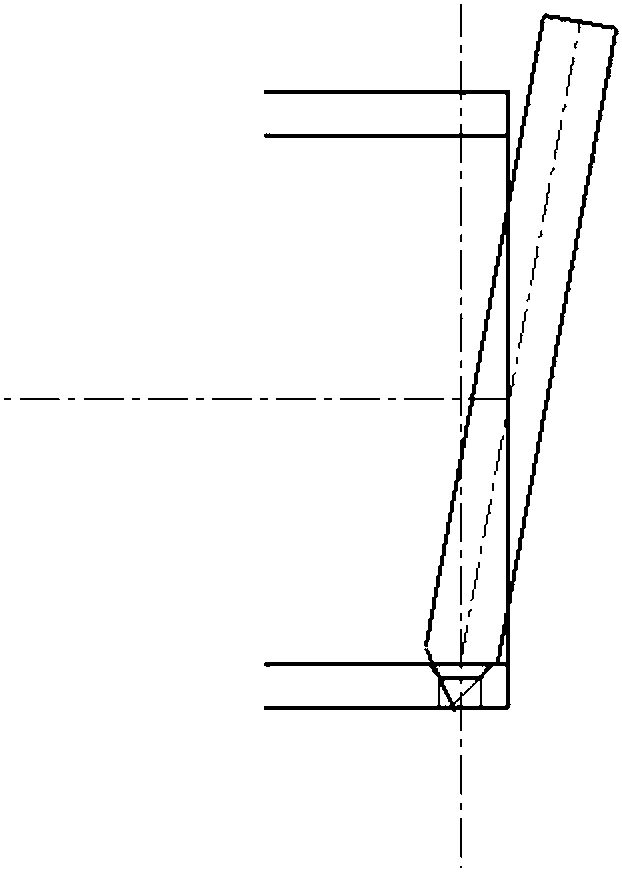

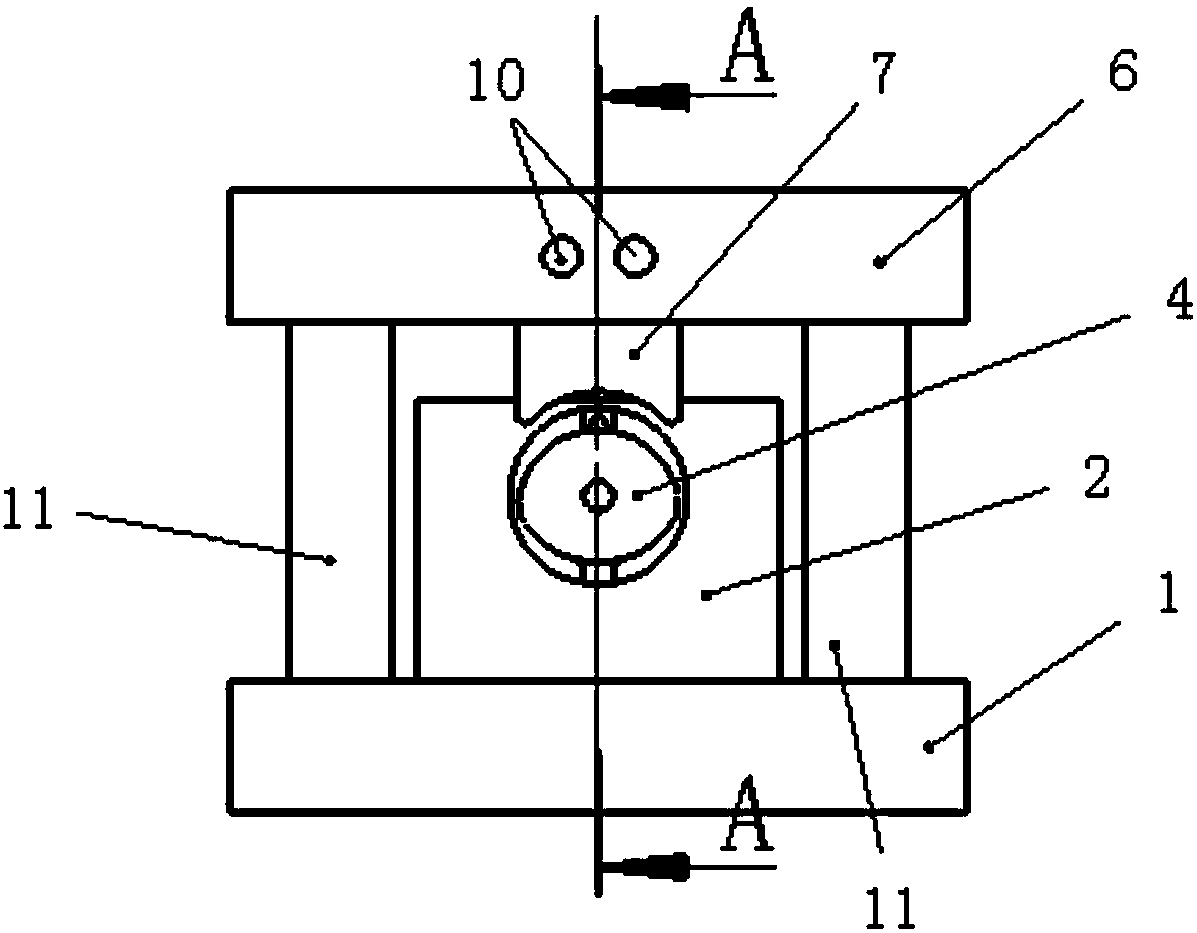

Hole inner wall chamfering and punching device and method thereof

ActiveCN106424265AGuarantee processing qualityMeet the riveting force requirementsPunchingEngineering

The invention discloses a hole inner wall chamfering and punching device and a method thereof. The hole inner wall chamfering and punching device is composed of a lower fixing plate (1), an inserting plate (2), a lower punch (3), a supporting column (4), a first pin (5), an upper fixing plate (6), an upper punch (7), a second pin (8), a bolt (9), a third pin (10) and a guide column (11). The supporting column (4) is of a columnar structure with the section being an asymmetrical oval. The hole inner wall chamfering and punching method is a rapid and consistent machining method for a hole wall inner chamfering structural element, the problem that inner chamfering is oblique due to previous drilling machining of bench workers is solved, and the hole inner wall chamfering and punching method is especially important to the aspects of ensuring the machining quality of part inner chamfering, meeting the requirements of bayonet lock rivet force and improving the quality stability of products and has an important application value in machining of other similar part structures.

Owner:沈阳兴华航空电器有限责任公司

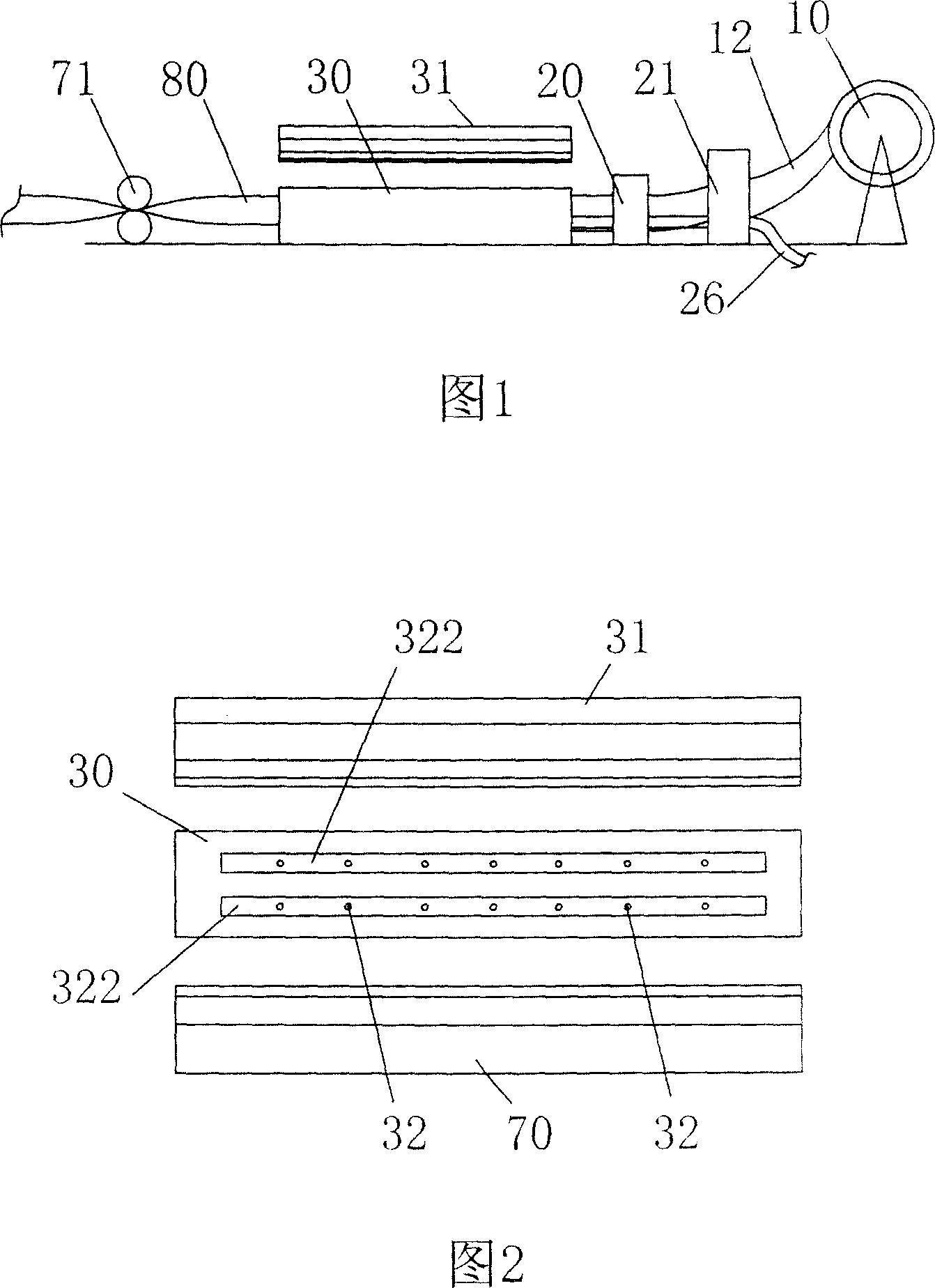

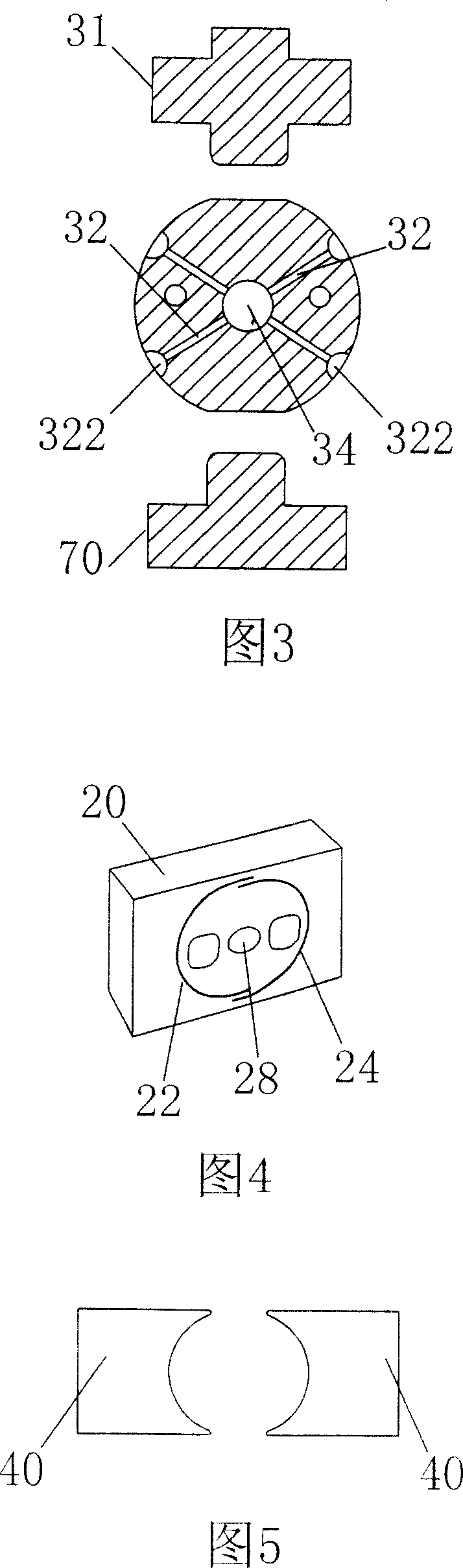

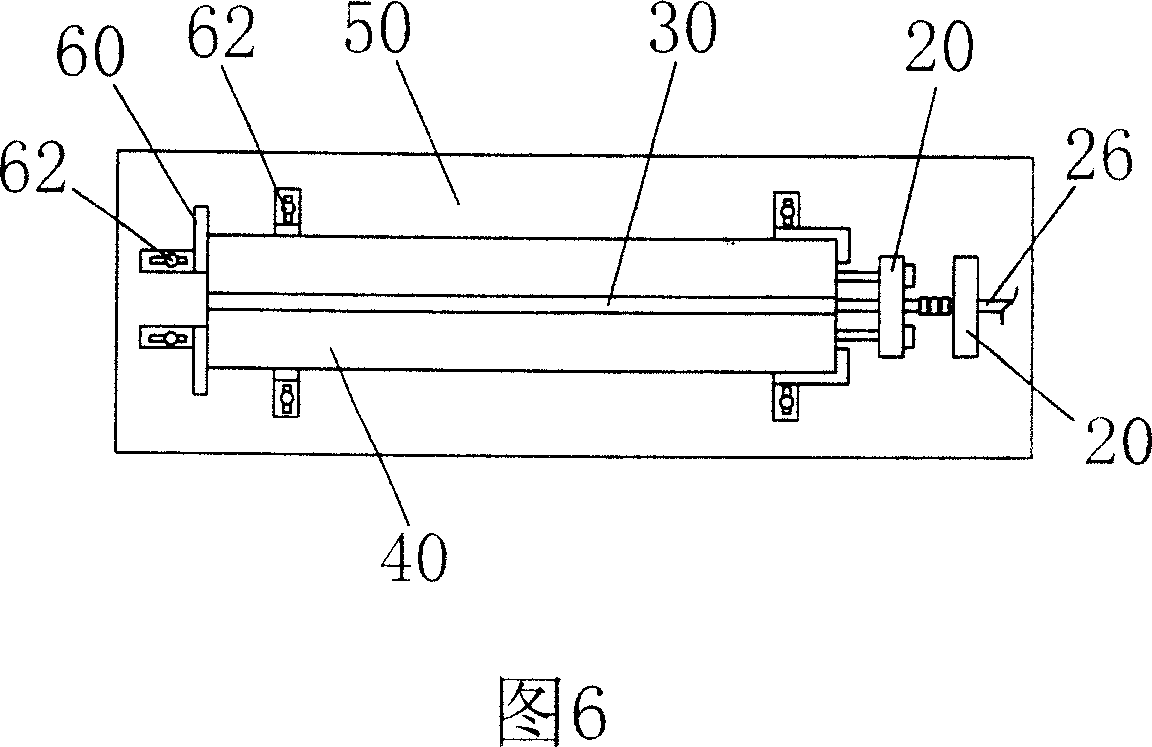

Process and apparatus for melting and welding plastic sheet to produce pipe

InactiveCN101020359ASimple processing methodFast processing methodTubular articlesEngineeringPlastic film

The present invention relates to process and apparatus for melting and welding plastic sheet to produce pipe. The process includes the following steps: 1. bending two plastic sheets to constitute one pipe with overlapped edges; 2. melting and welding in a combined mold to form integral plastic pipe; 3. feeding air to the plastic pipe for reducing resistance and drawing out the pipe; and 4. discharging the plastic sheet. The present invention has simple fast production process, high product quality, high production efficiency and other advantages.

Owner:东莞中志鞋材有限公司

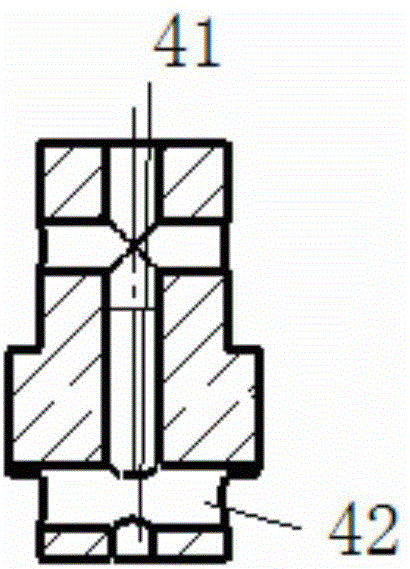

Hole inner wall side chamfer punching device

ActiveCN106583520AGuarantee processing qualityMeet the riveting force requirementsMetal-working feeding devicesPositioning devicesEllipseBiomedical engineering

The invention discloses a hole inner wall side chamfer punching device. The hole inner wall side chamfer punching device consists of a lower fixed plate (1), an insertion plate (2), a lower punch (3), a support column (4), a first pin (5), an upper fixed plate (6), an upper punch (7), a second pin (8), a bolt (9), a third pin (10) and a guide column (11), wherein the stand column (4) is a columnar structure with a section as an asymmetric ellipse; and R5 chamfer structures (43) are arranged at two semiarc contact ends of the asymmetric ellipse. The hole inner wall side chamfer punching device solves the problem of inner chamfer inclination caused by old locksmith drilling, guarantees the part inner chamfer machining quality, satisfies the clamping pin riveting force requirements, is particularly important in improvement of the product quality stability, and is important in application value in machining of other similar part structures.

Owner:沈阳兴华航空电器有限责任公司

Nanoscale detection chip

InactiveCN102911861ALow costChange the speed of movementBioreactor/fermenter combinationsBiological substance pretreatmentsPower flowMicrometer

The invention discloses a nanoscale detection chip. Two liquid storage tanks are respectively arranged on the two ends of the chip, each liquid storage tank is connected with a micrometer pipeline, a nanometer pipeline is arranged between the two micrometer pipelines, and the two sides of the nanometer pipeline are respectively provided with an electrode which is vertical to the nanometer pipeline; and the liquid storage tanks are rectangular, and a plurality of electrodes which are vertical to the liquid storage tanks are arranged on one sides of the liquid storage tanks. The chip can accurately apply current and voltage according to different detection requirements, so that only one group of the electrodes can be prevented from influencing the current when generating the regulation voltage.

Owner:沈阳市东陵区(浑南新区)卓科技术开发中心

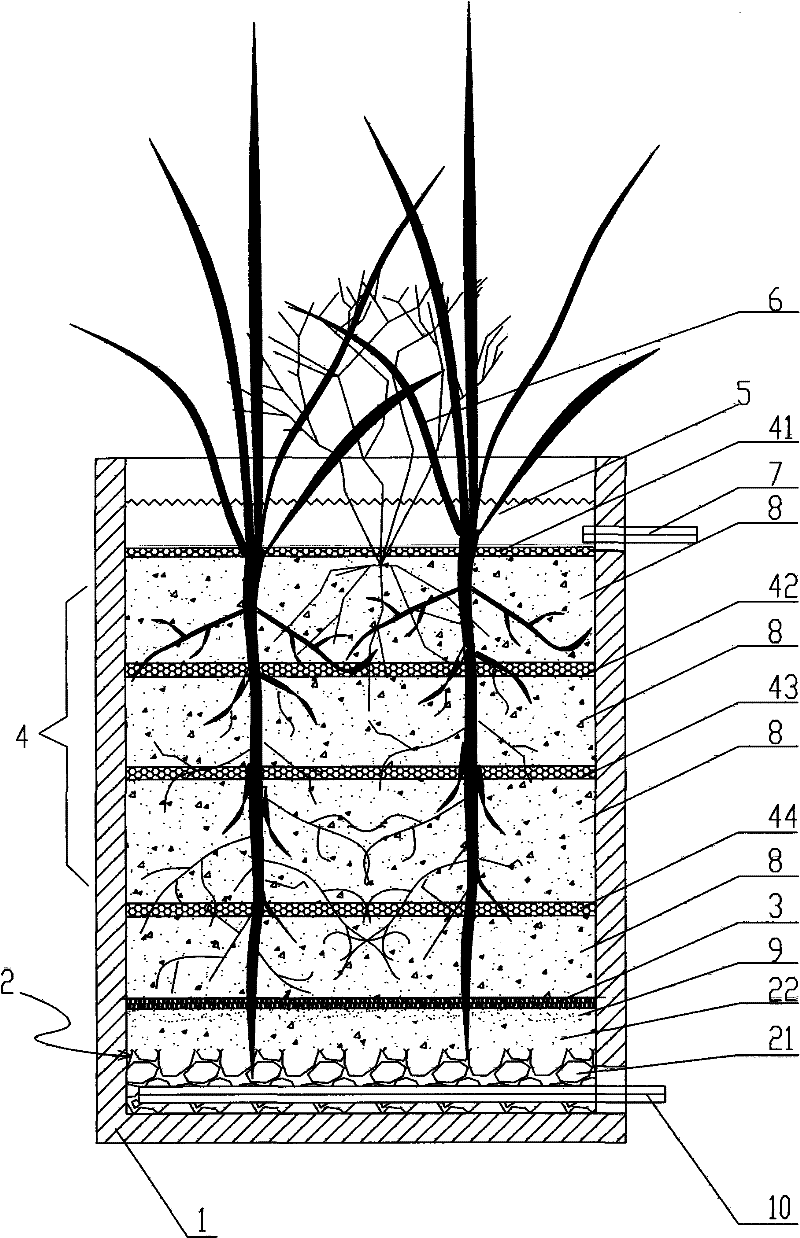

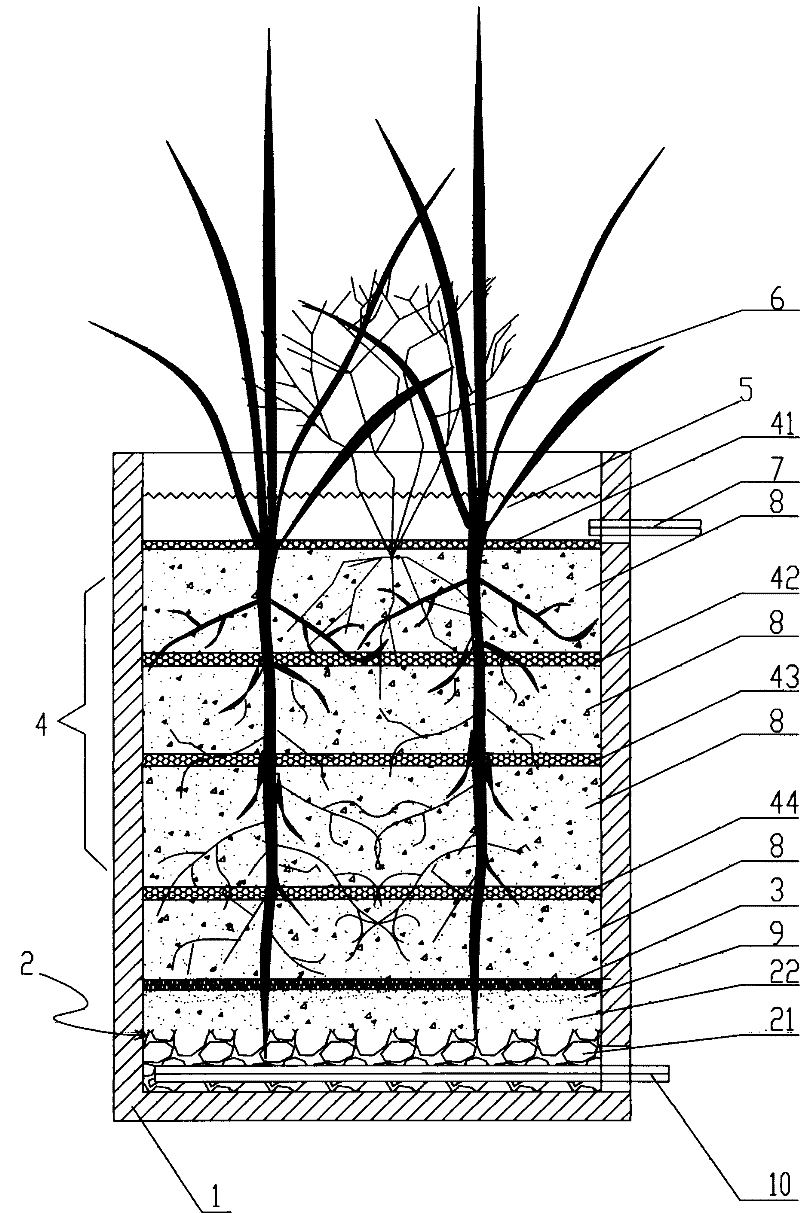

Method for treating wastewater in artificial wetland and wastewater treating device for implementing method

ActiveCN101665310BHigh removal rateGood removal effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandPlant roots

The invention discloses a method for treating wastewater in an artificial wetland and a wastewater treating device for implementing the method, wherein the method for treating the wastewater comprises the following steps: firstly, taking advantage of plant roots to absorb N, C and P from the wastewater so that part of N, COD, BOD and P can be removed; then utilizing nitrobacterium, aerobes and polyphosphate accumulationg bacteria to remove ammonia, organisms and phosphorus from the wastewater; then, utilizing acidified hydrolytic bacteria and anoxic bacteria to remove macromolecular organisms; and finally utilizing methane bacteria and anaerobes to remove organic acid and micromolecular organisms. In addition, the wastewater treating device comprises an artificial pond. The bottom of the artificial pond is provided with a bearing layer. An active carbon filter layer for filtering and purifying water is arranged above the bearing layer. A bacteria layer for eliminating and decomposing various pollutants in the wastewater is arranged above the active carbon filter layer. A layer of wetland filler is arranged between the active carbon filter layer and the bacteria layer. In the artificial pond, the bottom of the bearing layer is provided with a water draining pipe.

Owner:ZHONGSHAN ENVIRONMENTAL PROTECTION IND CO LTD

A punching device for chamfering the inner wall of a hole

ActiveCN106583520BGuarantee processing qualityMeet the riveting force requirementsMetal-working feeding devicesPositioning devicesEllipseBiomedical engineering

The invention discloses a punching device for chamfering the inner wall of a hole. The punching device for chamfering the inner wall of a hole is composed as follows: a lower fixing plate (1), an inserting plate (2), a lower punch (3), a pillar ( 4), the first pin (5), the upper fixing plate (6), the upper punch (7), the second pin (8), the bolt (9), the third pin (10) and the guide post (11 ); wherein, the pillar (4) is a columnar structure with an asymmetrical ellipse in cross-section, and the two semi-arc contact ends of the asymmetrical ellipse have R5 chamfering structures (43), and the chamfering and punching device on the inner wall of the hole solves the problem of Solving the problem of inner chamfer deflection caused by the old fitter drilling process is especially important for ensuring the processing quality of the inner chamfer of the part, meeting the riveting force requirements of the bayonet pin, and improving the quality stability of the product. For other similar parts structures It has important application value in processing.

Owner:沈阳兴华航空电器有限责任公司

Traditional Chinese medicine composition for improving constitution, preparation method and application of traditional Chinese medicine composition

InactiveCN110507693AEliminate bitterness and astringencyEliminate sticky tasteAntinoxious agentsFood ingredient functionsFiltrationChinese drug

The present invention discloses a preparation method of a traditional Chinese medicine composition for improving constitution. The preparation method comprises the following steps: firstly washing selected traditional Chinese medicine composition clean and then drying and grinding into micro-particles having a particle diameter of 0.8 mm-1.2 mm; putting the traditional Chinese medicine compositionmicro-particles into a clamping groove of an extractor, conducting cooking and heating for four times, and obtaining the traditional Chinese medicine composition for improving constitution after overpressure purification and filtration, and even slow release. The preparation method of the traditional Chinese medicine composition for improving the constitution saves raw materials by means of instant drinking after instant extraction, and besides, the processing method is natural and fast, and has very good commercial prospects. The traditional Chinese medicine composition prepared by the method has nutrients of 2 times or more of the nutrients of conventional cooking.

Owner:炁艾生命科技(深圳)有限公司

A processing method for casting cabin section based on precision detection technology

ActiveCN109531273BGuaranteed machining accuracyReliable Machining BenchmarkMeasurement/indication equipmentsEngineeringLaser detection

The invention belongs to the technical field of precision detection and processing, and particularly relates to a casting cabin section processing method based on precision detection technology. According to the method, high-precision detection methods such as laser detection and on-line detection are used before processing, the conditions such as the allowance and the defective number of a complex cast part are mastered, compared with a correction feature point allowance median fetching method adopted in a conventional alignment method, since allowance data of all positions are considered, the machining accuracy of the part can be guaranteed, and a relatively reliable machining standard can be obtained. In practical application, the method is used for marking and correction, the deviationis generally small, the subsequent processing can be met, and the quantity borrowing adjustment step is not used. The method of directly marking according to scanning data to establish reference processing is adopted, and analysis and judgment are facilitated; and compared with the method of repairing the standard by using a standard block, processing time is shortened, occupation of the equipment is reduced, and the method is a relatively fast processing method.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

A chamfering punching device and method for hole inner wall

ActiveCN106424265BGuarantee processing qualityMeet the riveting force requirementsPunchingEngineering

The invention discloses a hole inner wall chamfering punching device and a method thereof. The hole inner wall side chamfering punching device is composed as follows: the hole inner wall chamfering punching device is composed as follows: a lower fixing plate (1), an inserting plate ( 2), lower punch (3), pillar (4), first pin (5), upper fixing plate (6), upper punch (7), second pin (8), bolt (9), The third pin (10) and guide post (11); wherein, the pillar (4) is a columnar structure with an asymmetrical ellipse in section, and the chamfering and punching method of the inner wall of the hole is aimed at the structural member chamfering the inner wall of the hole It provides a fast and consistent processing method, which solves the problem of deflection of the inner chamfer caused by the old fitter drilling process, and improves the processing quality of the inner chamfer of the part and meets the riveting force requirements of the bayonet. The quality stability of the product is particularly important, and it has important application value for the processing of other similar parts structures.

Owner:沈阳兴华航空电器有限责任公司

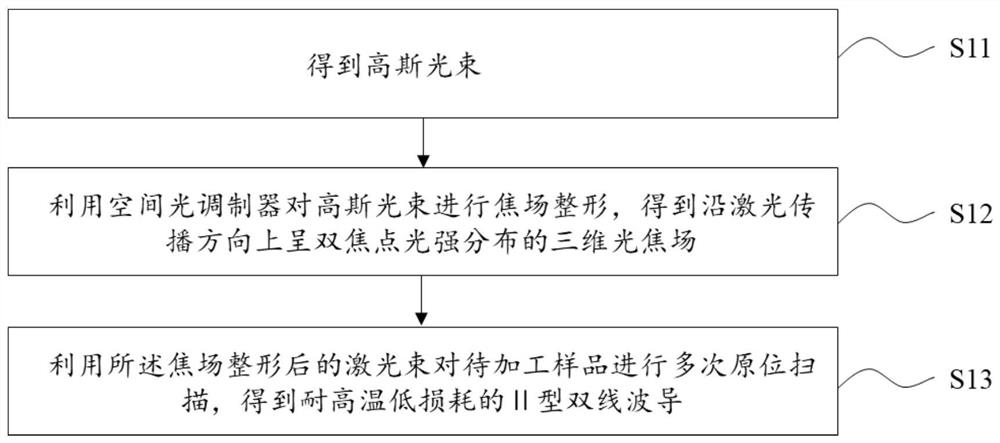

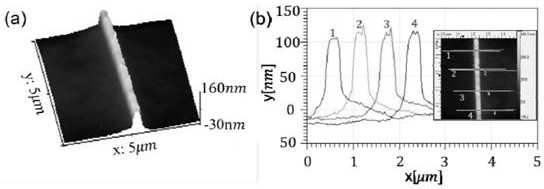

High temperature resistant type Ⅱ optical waveguide processing method, system and high temperature resistant type Ⅱ double wire waveguide

ActiveCN112894128BFast processing methodConvenient bindingLaser beam welding apparatusOptical elementsGaussian beamSpatial light modulator

The application provides a high temperature resistant type II optical waveguide processing method and system and a high temperature resistant type II double-wire waveguide, which relate to the technical field of waveguide preparation. The invention can solve the problem of how to quickly obtain the high temperature-resistant type II double-wire waveguide. The method includes: obtaining a Gaussian beam; using a spatial light modulator to perform focal field shaping on the Gaussian beam to obtain a three-dimensional optical focal field with bifocal light intensity distribution along the laser propagation direction; using the laser beam after focal field shaping to treat The processed samples were scanned multiple times in situ to obtain a type II double-wire waveguide with high temperature resistance and low loss.

Owner:PEKING UNIV

A data modeling and processing method

ActiveCN103886004BRapid expansionQuick buildSpecial data processing applicationsMaterial typeData modeling

Owner:BEIJING GEOWAY SOFTWARE

A processing method for enhancing the aroma of rapeseed oil and rapeseed oil

ActiveCN109777602BClear colorSimple production and processing technologyFatty-oils/fats productionEdible oils/fatsCoriander seedEconomic benefits

The invention discloses a processing method for enhancing the aroma of rapeseed oil and rapeseed oil. In the method, the rapeseed oil is sequentially crushed, microwave-treated and dry-steamed to obtain a condensate, and the condensate is mixed with the finished oil and then statically prepared. Put layers, take the supernatant to obtain the fragrant rapeseed oil. In the present invention, the condensate with strong fragrance is obtained by dry steaming and pulverizing rapeseed powder, which is mixed with rapeseed oil, and the obtained rapeseed oil not only has strong flavor and clear color, but also simplifies the production and processing technology of strong fragrance rapeseed oil , to solve the problems of low oil yield and cumbersome production links in the traditional process, and reduce the loss of aroma substances in the refining process of aromatic rapeseed oil, save costs, shorten production time, and improve the economic benefits of aromatic rapeseed oil production.

Owner:长安花粮油股份有限公司 +2

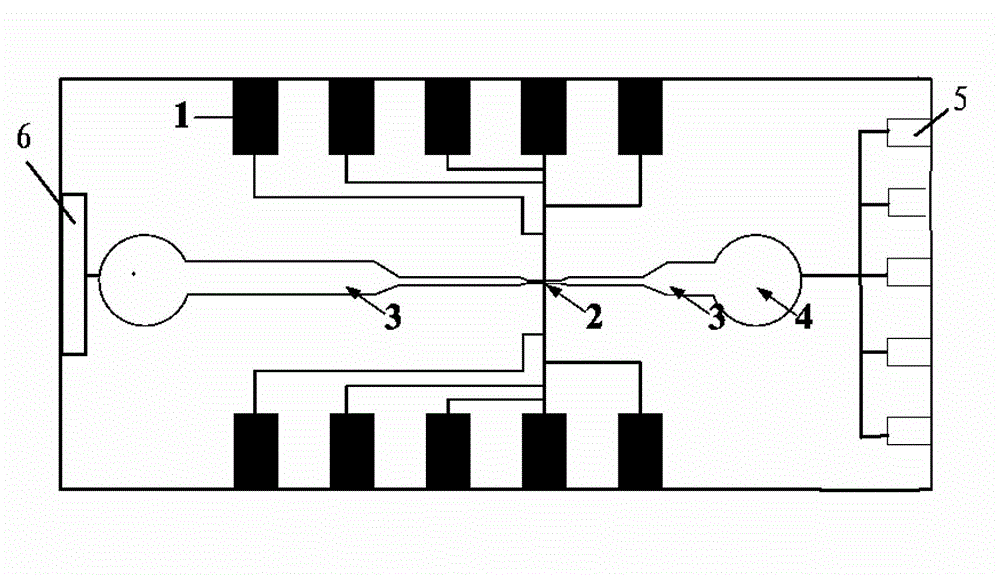

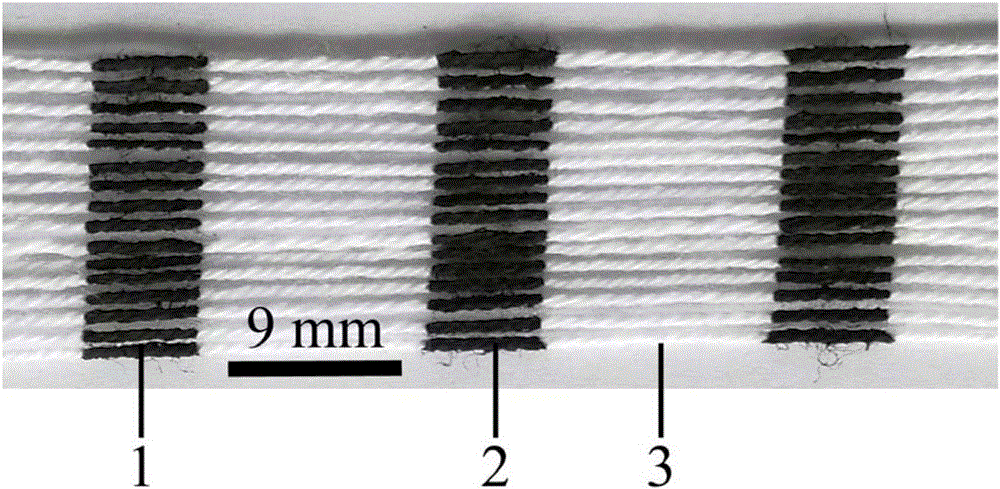

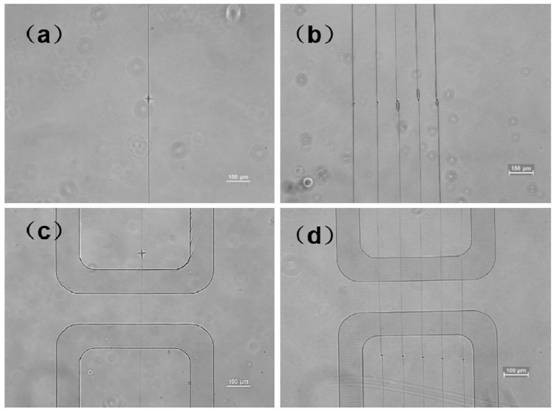

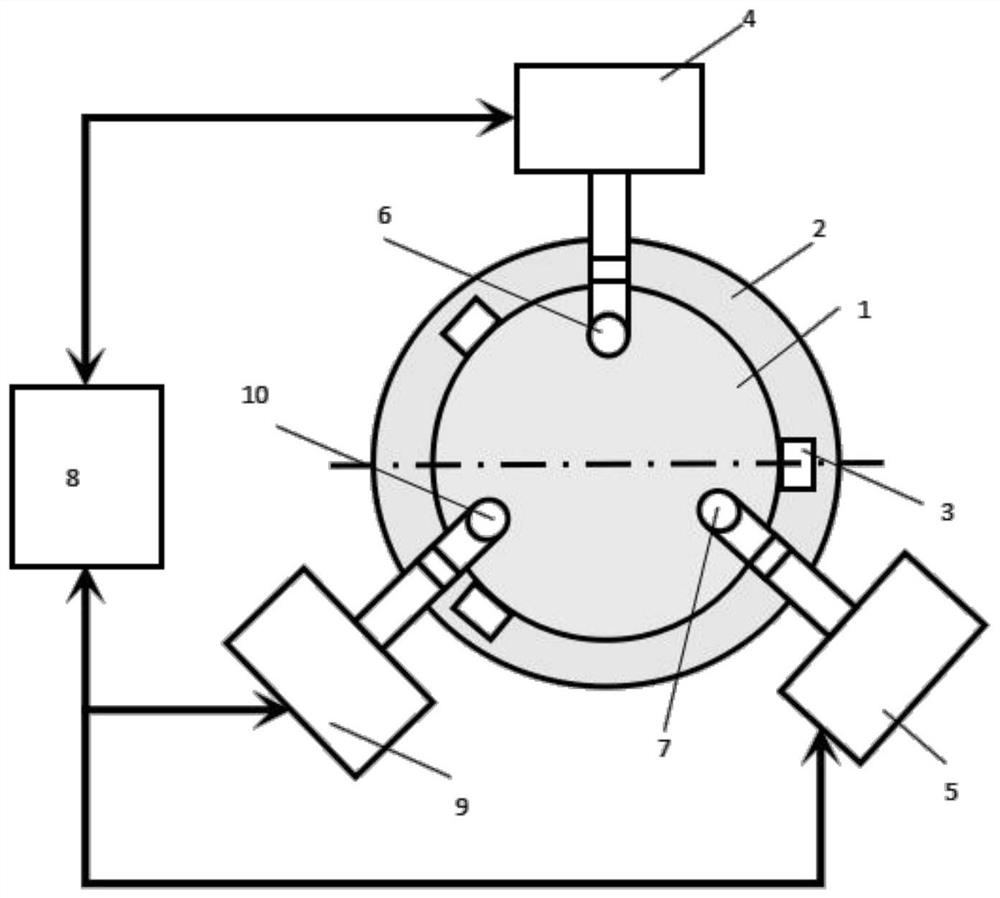

Capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device and application

ActiveCN106353303AHigh resolutionControllable intervalChemiluminescene/bioluminescenceEngineeringLuminescence

The invention discloses a capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device, and a preparation method and the application thereof. The luminescence device consists of a capillary and a patterning line electrode, wherein the patterning line electrode consists of not less than three wire base electrodes and bare wire areas; the wire base electrodes are manufactured by conductive carbon paste; the wire base electrodes on two sides are driving electrodes; the wire base electrode between the driving electrodes is a bipolar electrode; an area between the every two wire base electrodes is the bare wire area; the capillary coats the patterning line electrode, needs to coat all bipolar electrodes, and simultaneously can not be in contact with the driving electrode. According to the luminescence device, the capillary micro-channel is applied to the line of the patterning carbon electrode for the first time to manufacture the capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device. The integration device has the remarkable advantages that the loading speed of a sample is high and the samples can be evenly distributed on the patterning wire electrode.

Owner:SOUTH CHINA NORMAL UNIVERSITY

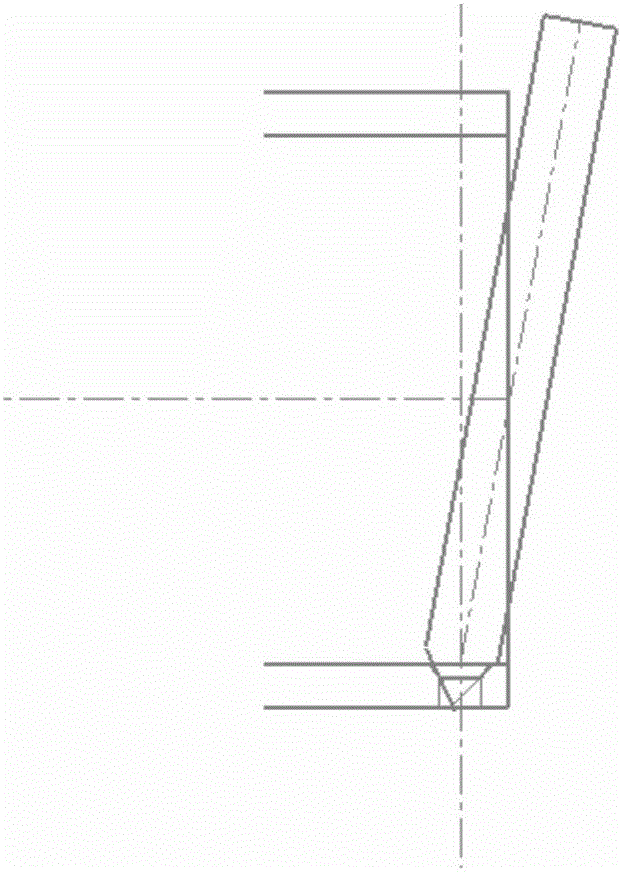

A cloth chip gravity/capillary flow chemiluminescence method

ActiveCN105344391BEasy to useGood biocompatibilityChemiluminescene/bioluminescenceLaboratory glasswaresFiberPeristaltic pump

The invention discloses a cloth chip gravity / capillary flow chemiluminescence method, in particular discloses a cloth chip with gravity / capillary force coupling driving fluid and its application in detecting heavy metal ions. The cloth chip of the present invention is divided into a hydrophobic area and a hydrophilic area, and the hydrophilic area is further divided into three parts: a sampling area, a detection area and a fluid channel area; when in use, the cloth chip should be placed on a support closely, The inclined surface of the bracket forms an included angle with the horizontal plane. After placement, the sample loading area and fluid channel area should be on the inclined surface of the bracket, and the detection area should be on the horizontal part of the bracket. At the same time, a hydrophobic sheet should be placed under the detection area of the cloth chip. Compared with traditional flow chemiluminescence, the cloth chip and detection method of the present invention do not need any expensive pump device (precision syringe pump, peristaltic pump, etc.) to drive liquid flow. The invention only drives the liquid flow through the natural gravity of the liquid and the capillary force of the cloth fiber gap.

Owner:SOUTH CHINA NORMAL UNIVERSITY

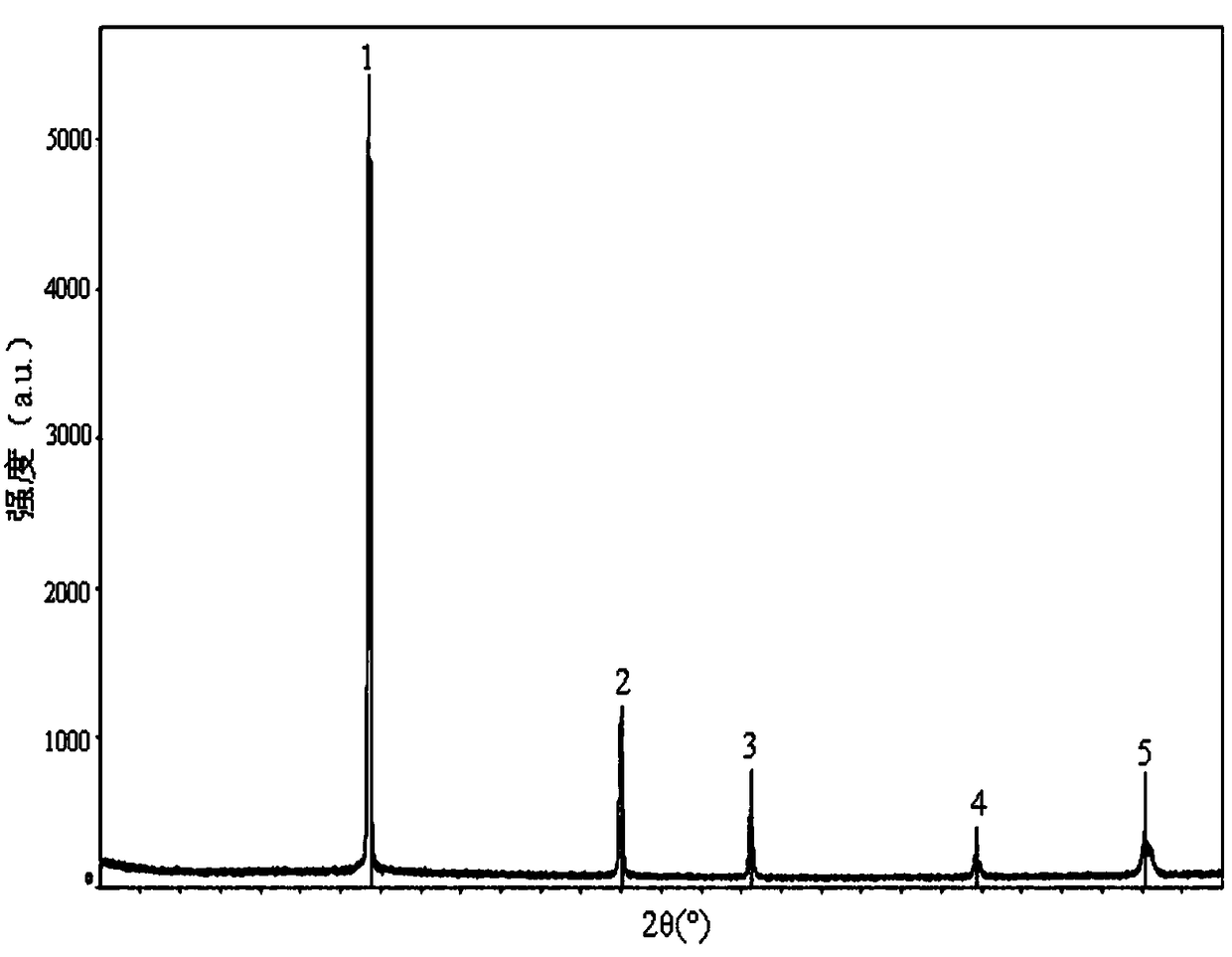

A method for preparing diamond particles by plasma etching graphite

The invention provides a method for preparing diamond particles by etching graphite through plasmas and relates to the technical field of growth of diamond micro-powder, aiming at solving the problems of existing preparation of artificial diamonds that the cost is relatively high, the quality is relatively low, the artificial diamond is not easy to disperse, a process is not controllable and the selection of a substrate is limited. The method comprises the following steps: 1, carrying out surface treatment on a graphite sheet; 2, preparing a diamond on graphite by adopting a plasma etching method; 3, dispersing the diamond particles so as to finish the method for preparing the diamond particles by etching the graphite through the plasmas. The invention provides the method for preparing the diamond particles by etching the graphite through the plasmas.

Owner:HARBIN INST OF TECH +1

Biological sludge drying and incineration cycle treatment method and complete set of equipment

ActiveCN105399304BThorough treatmentImprove environmental safetySludge treatment by de-watering/drying/thickeningRunoff/storm water treatmentTreatment completedFlue gas

Owner:宁波高新区纯丽节能技术有限公司

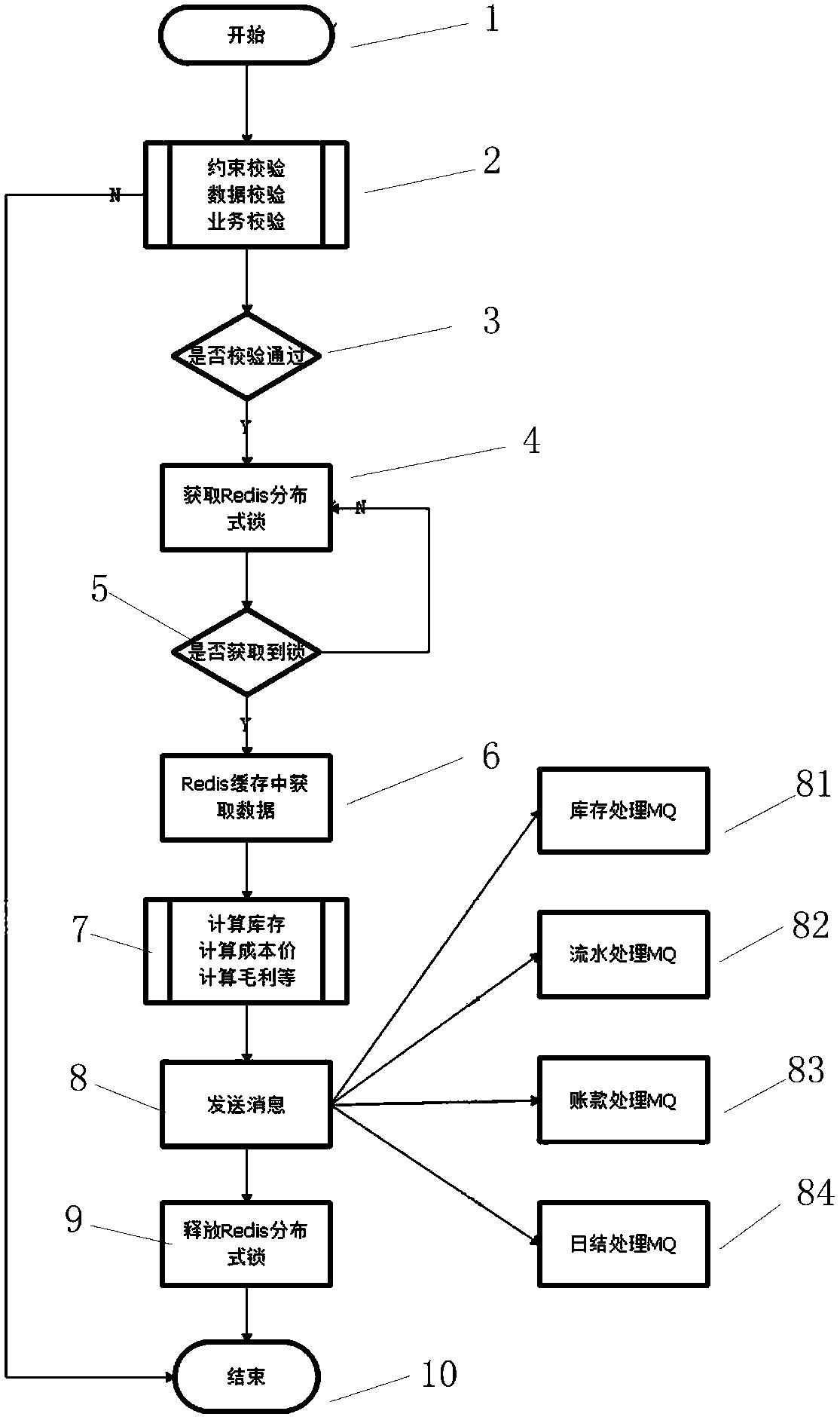

Method for processing inventory data based on dynamic weighting and splitting algorithms

InactiveCN108229887AImprove statistical information capabilitiesThe processing method is simpleProgram synchronisationInterprogram communicationData verificationData information

The invention discloses a method for processing inventory data based on dynamic weighting and splitting algorithms. The method comprises the following steps of (1) starting; (2) verifying data; when the data verification fails, directly entering the finishing step; (3) judging whether the data verification is successful or not; when the data verification is successful, obtaining a distributed typelock; (4) further judging whether the distributed type locked is obtained or not; when the distributed type lock is not obtained, returning back to the previous step; when the distributed type lock is obtained, obtaining data in the storage system; (5) calculating cost; (6) after cost calculation is completed, sending starting information; (7) after information sending is completed, releasing thedistributed type lock; (8) finishing the processing method. The method has the advantages that the commodity retailing information and inventory change data can be solved, the data information can becalculated in real time, the data processing ability is strong, the data is conveniently and rapidly processed, and the running is safe and reliable.

Owner:深圳友门鹿网络科技有限公司

Nanofluidic chip based on nanocracks and processing method thereof

PendingCN114433260AHigh repeatabilityEfficient processing methodLaboratory glasswaresPhysicsSiloxane

The invention provides a nanofluidic chip based on nanocracks and a processing method thereof. The nano-fluidic chip is formed by bonding a polydimethylsiloxane channel layer and a glass substrate, the polydimethylsiloxane channel layer contains a micron channel and at least one nano channel, the nano channel is connected with the micron channel, the tail end of the micron channel is connected with the outside through a liquid storage tank, and the liquid storage tank is used for adding and extracting a nano-fluidic chip sample. The processing method is simple, efficient and rapid processing of a single nano-channel array or a multi-nano-channel array can be achieved, and the length, the position and the size of the nano-channel are accurate and controllable. The problems of long time consumption, high cost, complex operation and the like of a traditional semiconductor processing technology are solved. The processed micro-nano fluidic chip can be used in the fields of biosensing, chemical analysis, micro-nano energy collection and the like based on the nanofluidic technology.

Owner:DALIAN MARITIME UNIVERSITY

Large-aperture optical mirror surface rapid polishing method based on multiple polishing systems

ActiveCN112775724ASolve the problem of long production cycleEfficient processingOptical surface grinding machinesAutomatic grinding controlPolishingMaterials science

The invention provides a large-aperture optical mirror surface rapid polishing method based on multiple polishing systems, and belongs to the field of optical element processing. The problems that an existing large-diameter optical mirror face is long in processing period, and the production efficiency is affected are solved. A plurality of polishing systems are included, after mirror surface milling and grinding forming treatment and optical mirror positioning and fixing are carried out, and surface shape rough grinding, surface shape fine grinding, surface shape grinding and repairing and polishing are carried out through the multiple polishing systems till surface shape processing is completed. The large-aperture optical mirror surface rapid polishing method based on the multiple polishing systems is mainly used for quick polishing of large-aperture optical mirror surfaces.

Owner:CHANGGUANG SATELLITE TECH CO LTD

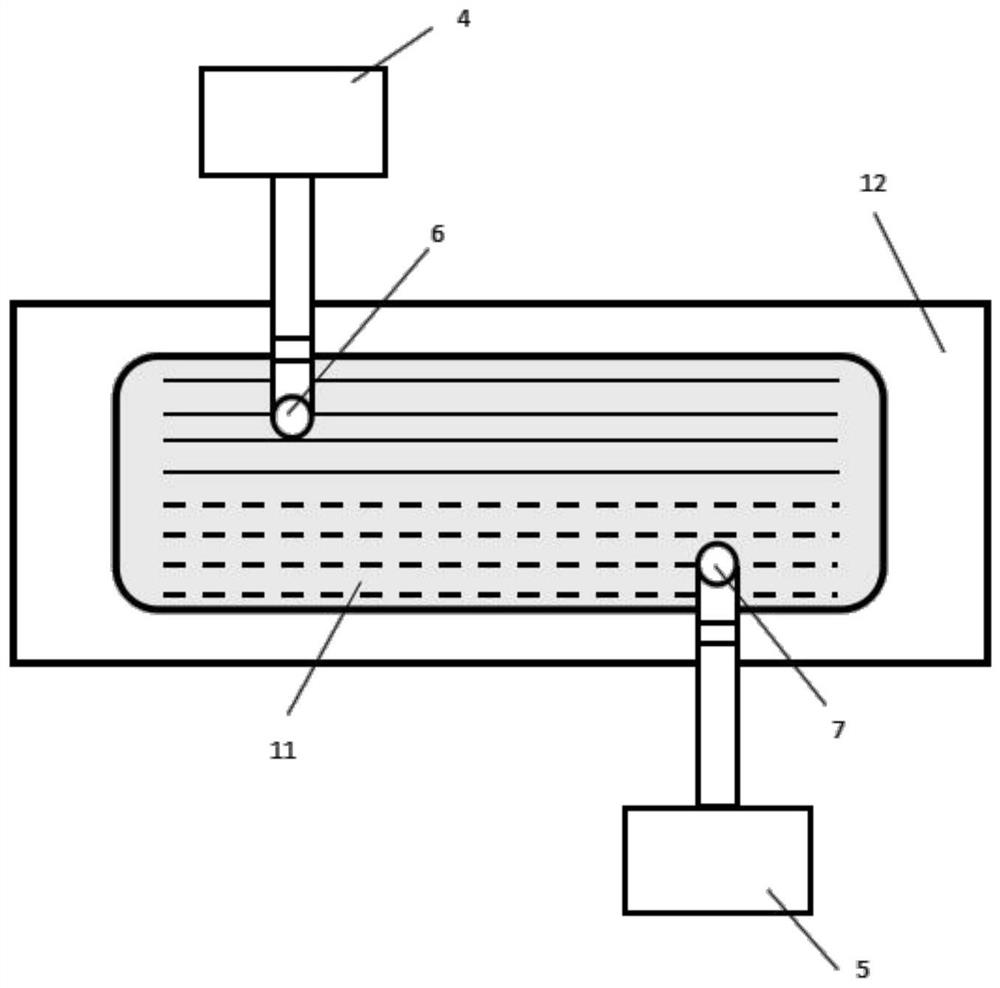

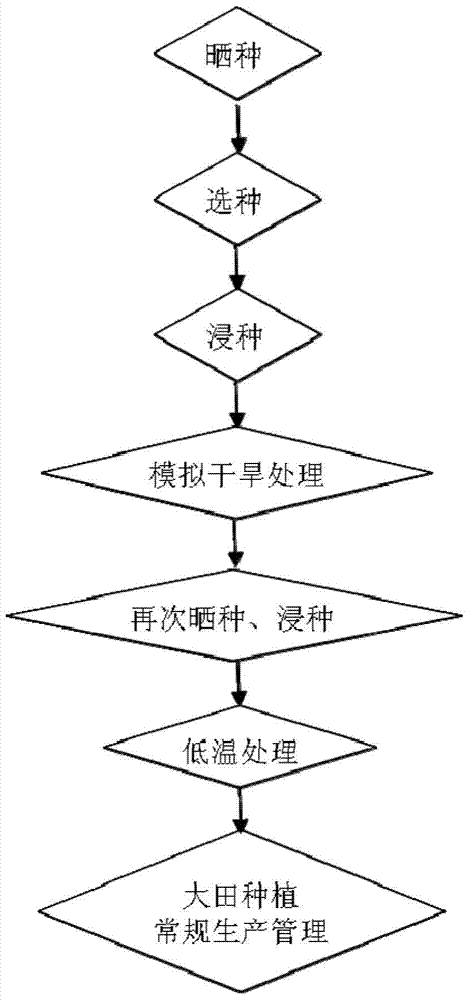

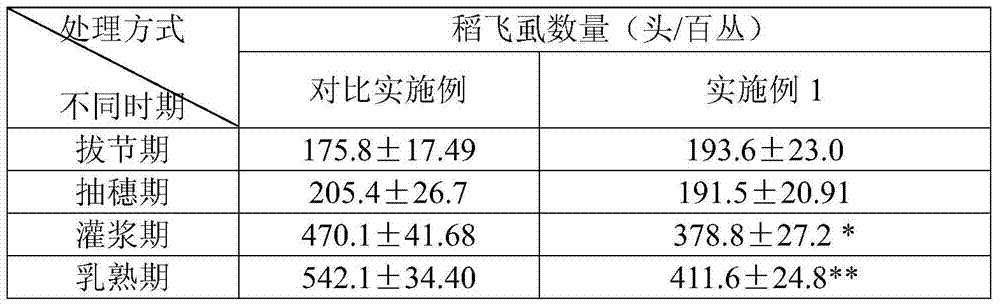

A method of treating rice seeds and seedlings to improve rice resistance

ActiveCN104982271BImprove resistance to pests and diseasesReduce pests and diseasesSeed and root treatmentHorticulture methodsDiseaseShoot

The invention belongs to the technical field of agriculture cultivation and specifically relates to a method of processing rice seeds and rice shoots for improving the paddy rice resistance performances. By simulating drought and low temperature to respectively process rice seeds and rice shoots, the ability of rice plants to resist diseases and insects is increased; at the filling stage and the milk-ripe stage of the rice, leaf blast rate of the rice plants that are processed by simulating drought and low temperature is respectively reduced to 22.1 percent and 28.7 percent in comparison with the rice plants that not processed; and at the same time, at the filling stage and the milk-ripe stage of the rice, the number of brown planthopper of the rice plants that are processed by simulating drought and low temperature is respectively reduced to 19.4 percent and 24.1 percent in comparison with the rice plants that not processed. After the rice seeds are processed by simulating drought and low temperature, the ability of the rice to resistance leaf blast and planthopper is significantly strengthened while significantly increasing the rice production to 9.2 percent; and the use of pesticide during the production process of the rice is reduced, thus the rice is ensured to be produced with safety, high quality and pollution-free.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com