Biological sludge drying and incineration cycle treatment method and complete set of equipment

A biological sludge and recycling technology, applied in dewatering/drying/concentrating sludge treatment, combustion methods, lighting and heating equipment, etc., to achieve the effect of high environmental protection and safety, wide application range and saving project investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

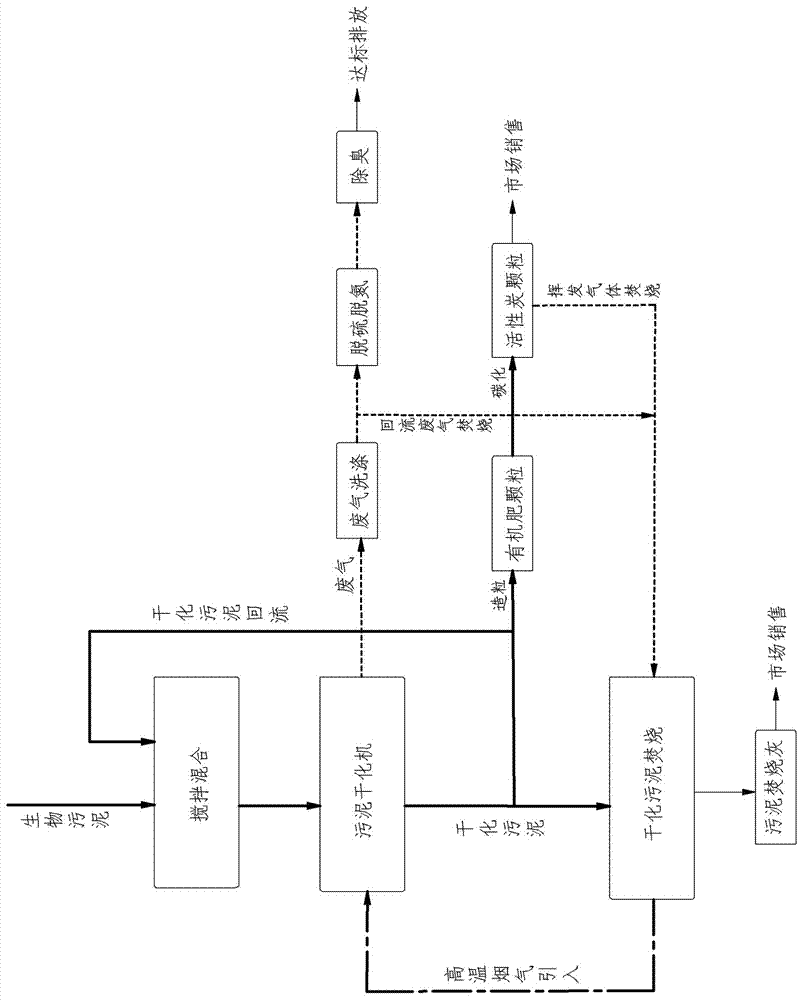

[0034] see figure 1 , the biological sludge drying and incineration cycle treatment method of the present invention, its realization process includes sludge drying treatment, dried sludge incineration treatment, biological sludge processing treatment, etc., wherein

[0035] 1) Sludge drying treatment

[0036] The biological sludge with a moisture content of 78-82% is added with reflux-dried sludge 1.2-1.5 times the weight of the biological sludge, fully stirred to obtain a mixed sludge with a moisture content of 38-42%, and then sent to the rotary sludge Drying treatment in the mud dryer;

[0037] 2) Dried sludge incineration treatment

[0038] Sieve 50-60% of the dried sludge after drying treatment, and send the sieved dried sludge to the fluidized sludge incinerator for incineration, and the high-temperature flue gas generated by the incineration is directly introduced into the rotary sludge dryer Intermediate drying treatment of mixed sludge;

[0039] The sludge inciner...

Embodiment 2

[0042] see figure 1 , the biological sludge drying and incineration cycle treatment method of this embodiment is different from that of Example 1 in that: during the sludge drying process, by controlling the feed rate of the sludge dryer, the speed of the dryer and the The high-temperature flue gas temperature generated by the incinerator is organically combined to control the discharge temperature and moisture content of the dried sludge. The discharge temperature of the dried sludge is 80-100 degrees, and the moisture content of the dried sludge is 15 ~20%, after cooling down to distribute moisture, dry sludge with a moisture content of 8-12% is obtained.

Embodiment 3

[0044] see figure 1 , the biological sludge drying and incineration recycling treatment method of this embodiment is different from that of Example 1 or Example 2 in that: it includes the biological sludge processing process, and the remaining 40 to 50% of the dried sewage will be incinerated. Add 22-28% biological sludge with a water content of 78-82% to the mud, stir thoroughly to obtain mixed sludge with a water content of 25-30%, and then use a sludge granulator to process the mixed sludge into biomass fuel Granules or organic fertilizer granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com