Cloth chip gravity/capillary flow chemiluminescence method

A chip and gravity technology, applied in the field of microfluidic analysis, can solve the problems of complex process, large volume, and increased difficulty in chip design and processing, and achieve the effects of easy use, good biocompatibility, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

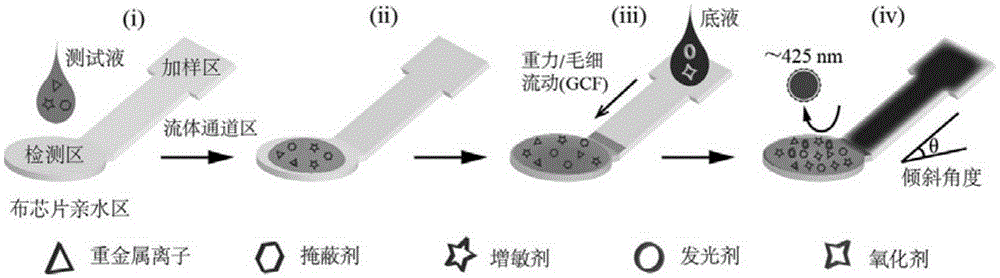

Method used

Image

Examples

Embodiment 1

[0070] A preparation method of a gravity / capillary force coupled fluid-driven cloth chip, comprising the steps of:

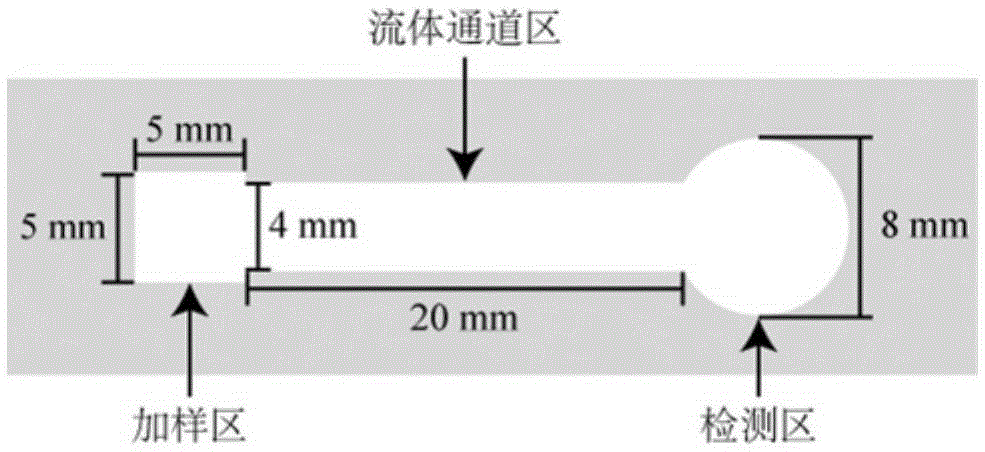

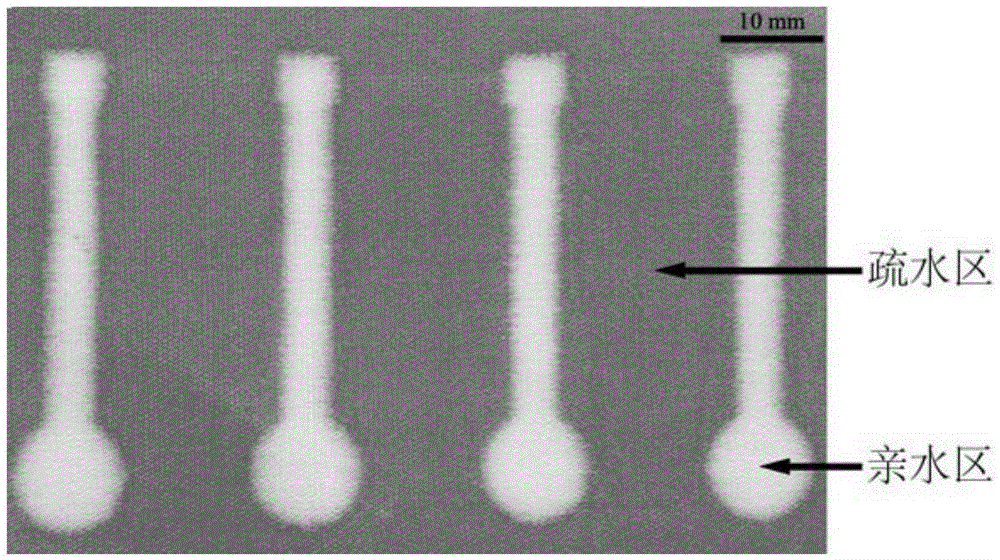

[0071] (a) Use Adobe Illustrator CS5 software to design such as figure 2 The pattern of the hydrophilic area of the cloth chip (the white area is the hydrophilic area) is shown, and then based on these patterns, it is processed into a 300-mesh mesh screen by Guangzhou Lianchang Printing Equipment Store.

[0072] (b) Take a piece of white cotton cloth with a size of 50mm × 60mm, stick the screen on the cloth, paint on the screen with a purple crayon, and grind it evenly with a smooth grinding spoon; after grinding, put Put the cloth and the screen together on a heating plate (model YH-946B) at a temperature of 90°C and heat for about 5 seconds (the side with the cotton cloth faces the heating plate), the wax penetrates into the cloth to form a hydrophobic area, and the other areas are hydrophilic. water area. Then, the cloth sheet and the mesh plate are remo...

Embodiment 2

[0077] The application of the cloth chip of embodiment 1 in detecting Cr (III), comprises the following steps:

[0078] (a) Put the PET plastic bracket assembled with the cloth chip into the dark box, align the detection area of the cloth chip with the macro lens (model M1614-MP) of the CCD camera (model MC15), adjust the CCD related parameters (such as exposure time, blue Chromatic light gain, etc.) and focal length to make the image clearest.

[0079] (b) 5-30 μL of Cr(III) test solution is added dropwise to the center of the detection area of the cloth chip, and then 5-40 μL of chemiluminescence base solution is dropped into the sample application area to trigger chemiluminescence.

[0080] (c) Using CCD camera video imaging GCF-CL process, the video imaging parameters are 15 frames per second, the bit rate is 3000, and through VGIF ( http: / / video-to-gif.watermark-software.com / ) software processes the imaging video during the period from the closure of the dark box t...

Embodiment 2

[0088] Several important factors (pH value, component concentration of the test solution and the bottom solution) that affect the luminous intensity of the cloth chip GCF-CL in Example 2 are optimized

[0089] a) Preferred EDTA concentration

[0090] 1. 30 μL test solution composition: Cr(III) concentration is 50 μg / mL, KBr concentration is 0.75M, EDTA concentration is to be determined, pH value is 3.0; 35 μL bottom solution composition: Luminol concentration is 3mM, H 2 o 2 The concentration is 0.1M, the pH value is 11.5.

[0091] 2. Set up several experimental groups: the concentration of EDTA in the GCF-CL test solution is set to several different values (0mM, 1mM, 5mM, 10mM, 15mM, 20mM, 25mM).

[0092] 3. The detection process of the cloth chip GCF-CL is the same as in Example 2, and the test results are as follows Figure 9 shown.

[0093] It can be seen from the experimental results that when the concentration of EDTA is less than or equal to 10mM, the relative lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com