Hole inner wall side chamfer punching device

A hole inner wall and chamfering technology, which is applied in the structural design and application field, can solve the problem of chamfering and deflection of three holes in the shell cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

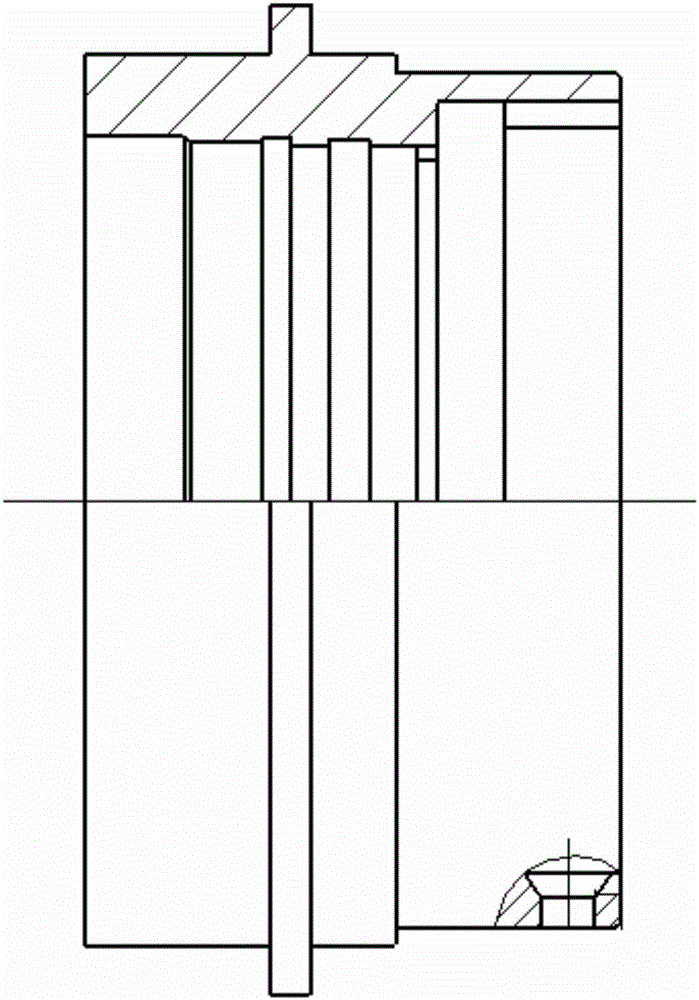

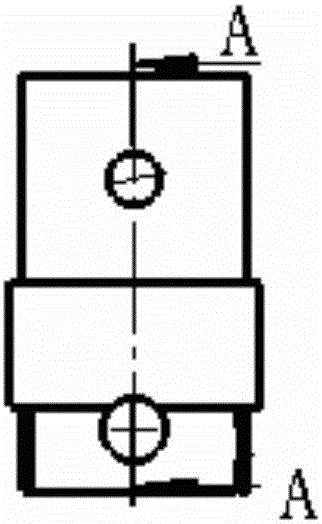

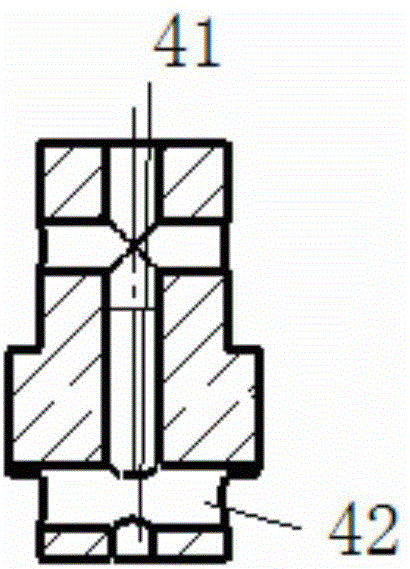

[0023] The hole inner wall side chamfering punching device is composed as follows: the hole inner wall chamfering punching device is composed as follows: lower fixing plate 1, inserting plate 2, lower punch 3, pillar 4, first pin 5, upper fixing plate 6 , the upper punch 7, the second pin 8, the bolt 9, the third pin 10 and the guide post 11; wherein, the pillar 4 is a columnar structure with an asymmetrical ellipse in section, and the two semi-arc contact ends of the asymmetrical ellipse There is an R5 chamfer structure 43, the half arc on one side of the asymmetric ellipse can be positioned and matched with the inner diameter of the punched part, and the form of the R5 chamfer structure 43 at the contact end of the two half arcs of the asymmetric ellipse ensures that the part can be inserted and taken out smoothly. The pillar 4 includes an axial stepped through hole 41 and a first radial through hole 42, the axial stepped through hole 41 and the first radial through hole 42 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com