Nanofluidic chip, processing method based on atomic force microscopy (AFM), and application

A nanofluidic and chip technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problems of easily damaged samples, expensive, easy to leave residues, etc., to achieve accurate cost, fast The effect of fast sequencing and processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

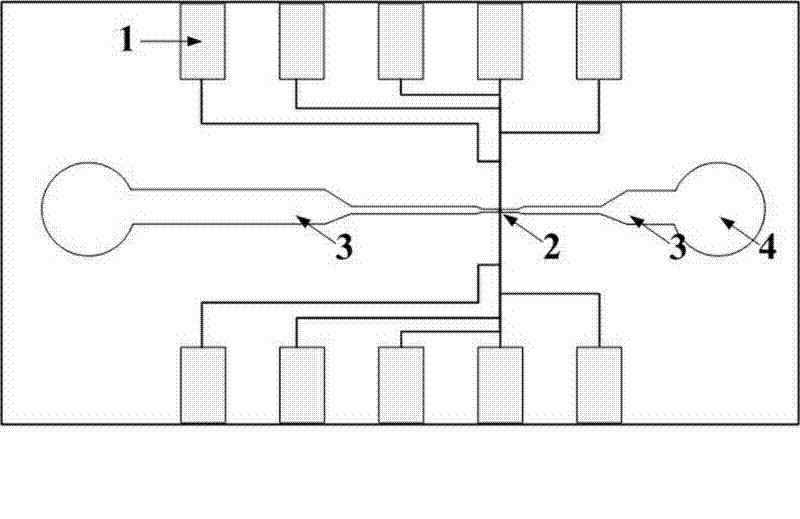

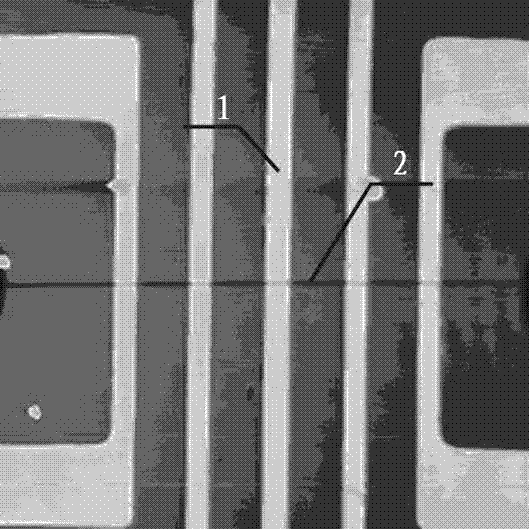

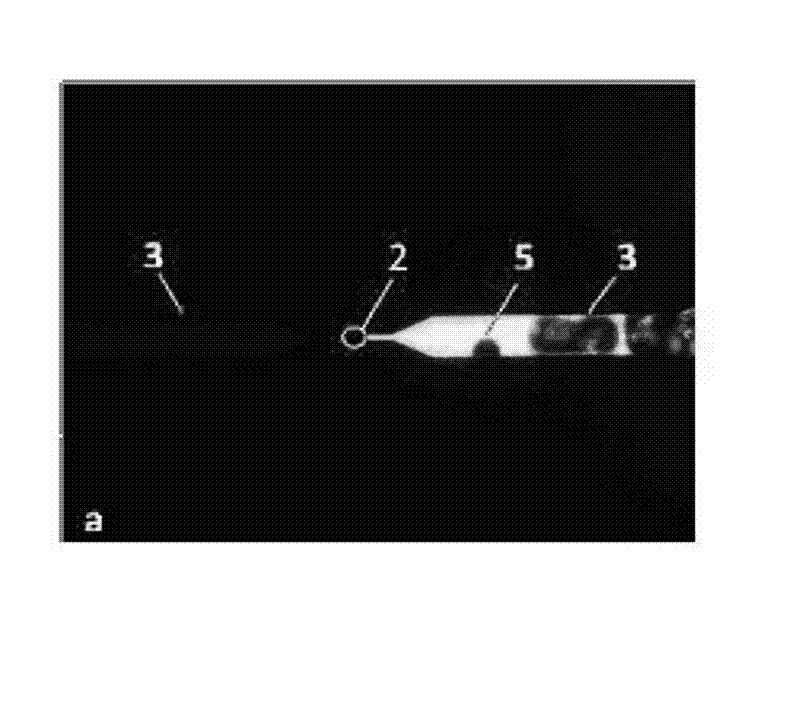

[0023] figure 1 It is the nanofluidic chip structure of the present invention, wherein the part indicated by 1 is an electrode, and 5 pairs of electrodes are designed on the chip, 2 is a nanotube processed by AFM, 3 is a micron tube, and 4 is a liquid storage pool.

[0024] The processing method is

[0025] 1) Design nanofluidic chips: design and process such figure 1 In the shown nanofluidic chip, the unconnected area in the middle of the micro-pipe 3 is the area to be processed, which is used for subsequent processing of the nano-pipe 2 by using the AFM processing method. In the chip structure, the electrode 1 can be used to detect and analyze the signal of the nano-object solution in the nano-pipe 2;

[0026] 2) AFM processing of nanopipes: by controlling the AFM probe to press into the surface of the chip to a certain depth and controlling the linear movement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com