Casting cabin section processing method based on precision detection technology

A processing method and detection technology technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve the effects of fast processing methods, reducing processing time and equipment occupation, and facilitating analysis and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

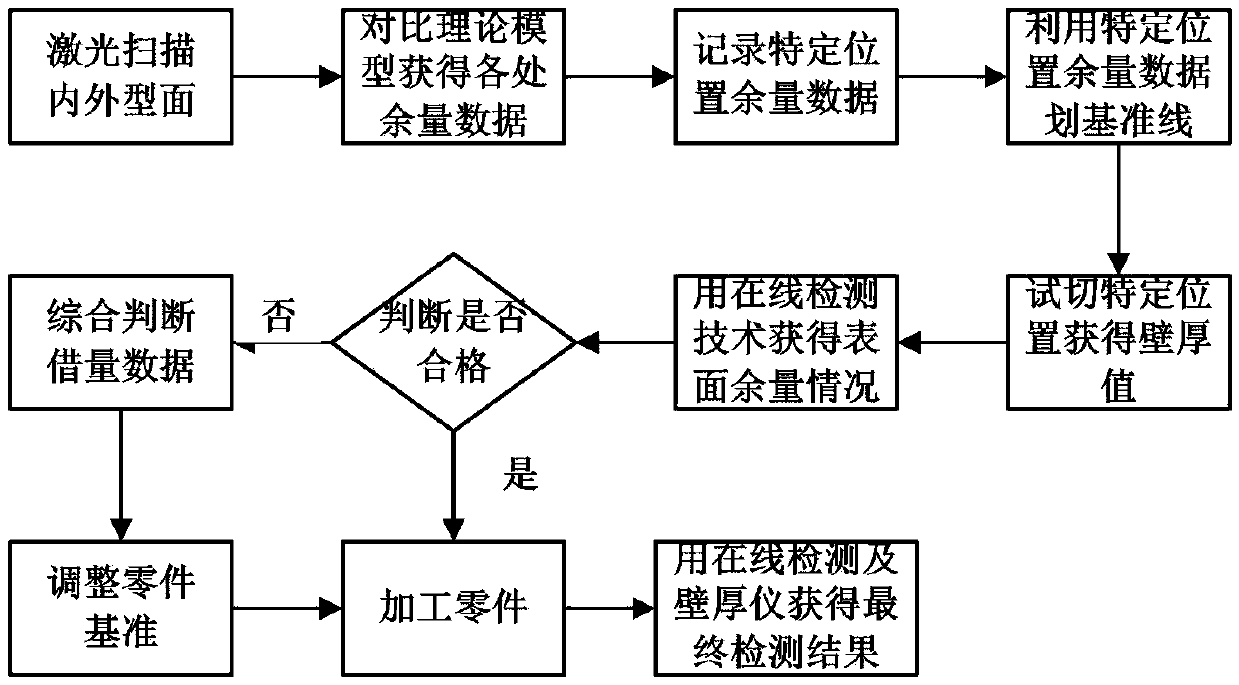

[0027] This embodiment proposes a casting cabin processing method based on precision detection technology, the main flow of the method is as follows figure 1 As shown, it specifically includes the following steps:

[0028] S1. Detect the inner and outer surface of the casting cabin by laser scanning method (such as figure 2 shown); compare the laser scanning detection results with the theoretical model of the casting cabin, and obtain the allowance data of the inner and outer molding surfaces of the casting cabin.

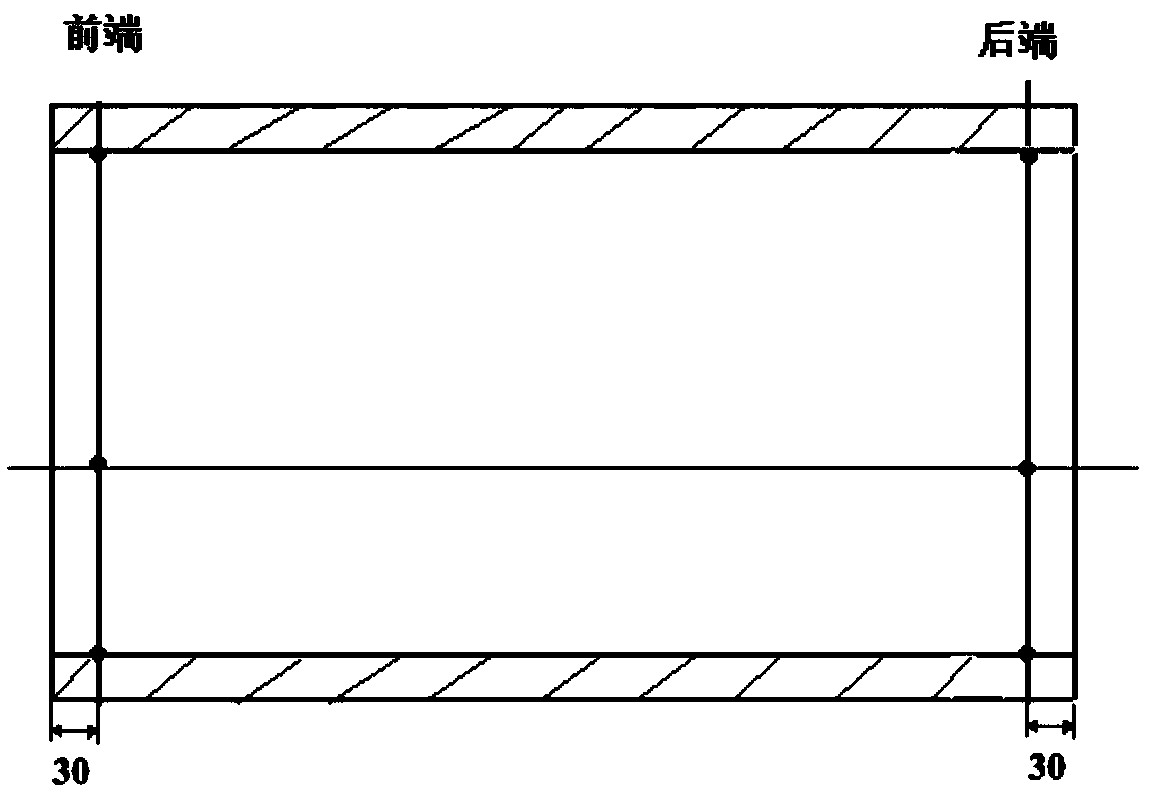

[0029] S2. Record the margin data at a specific position, and use the margin data at a specific position to align and mark the casting cabin datum: for cabin parts, the machining datum involves horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com