Hole inner wall chamfering and punching device and method thereof

A technology of hole inner wall and chamfering, which is applied in the field of hole inner wall chamfering and punching equipment, which can solve problems such as chamfering deviation, achieve the effect of eliminating quality hidden dangers and ensuring product quality and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

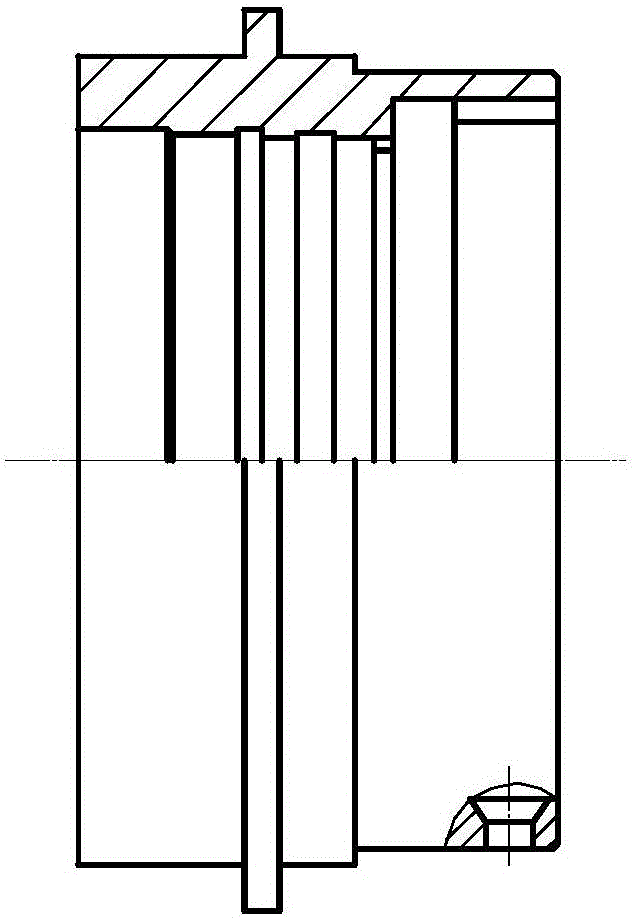

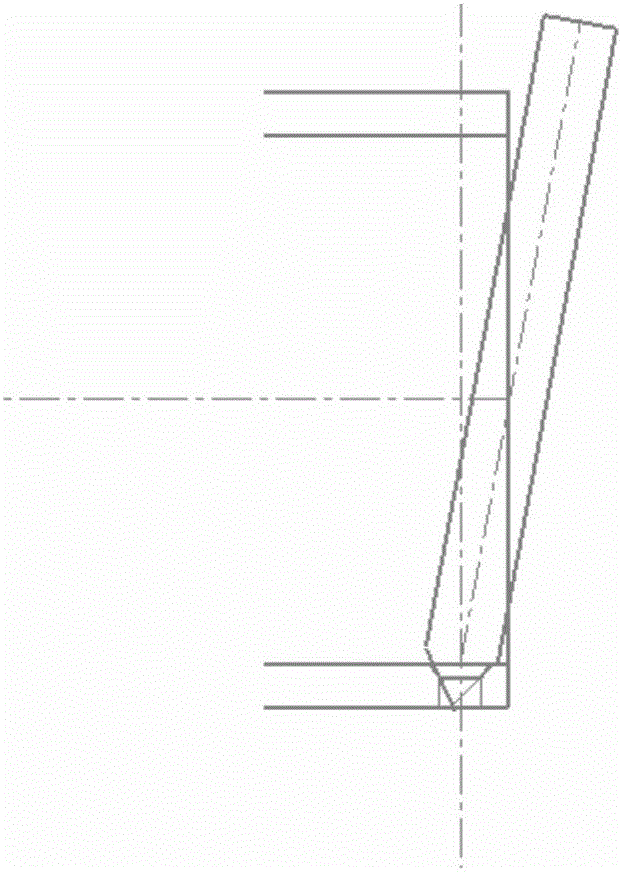

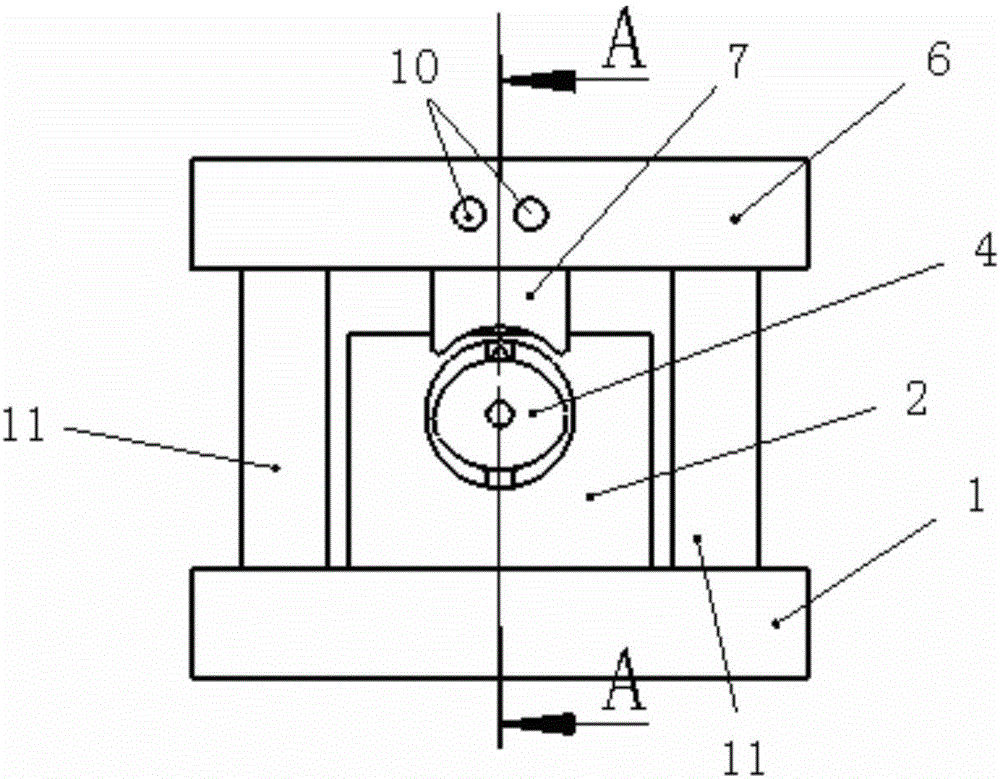

Embodiment 1

[0027] The hole inner wall side chamfering punching device is composed as follows: the hole inner wall chamfering punching device is composed as follows: lower fixing plate 1, inserting plate 2, lower punch 3, pillar 4, first pin 5, upper fixing plate 6 , the upper punch 7, the second pin 8, the bolt 9, the third pin 10 and the guide post 11; wherein, the pillar 4 is a columnar structure with an asymmetrical ellipse in section, and the two semi-arc contact ends of the asymmetrical ellipse There is an R5 chamfer structure 43, the pillar 4 includes an axial step through hole 41 and a first radial through hole 42, the axial step through hole 41 and the first radial through hole 42 communicate through each other, and one end of the lower punch 3 is connected to the The conical point structure 31 with the chamfering of the side wall of the punched part matches, the middle part of the lower punch 3 is provided with a second radial through hole 32, and one end of the conical point str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com