A method for preparing diamond particles by plasma etching graphite

A technology of diamond particles and plasma, applied in diamond and other directions, can solve the problems of low quality, difficult to disperse, uncontrollable process, etc., and achieve the effects of simple treatment method, simple operation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

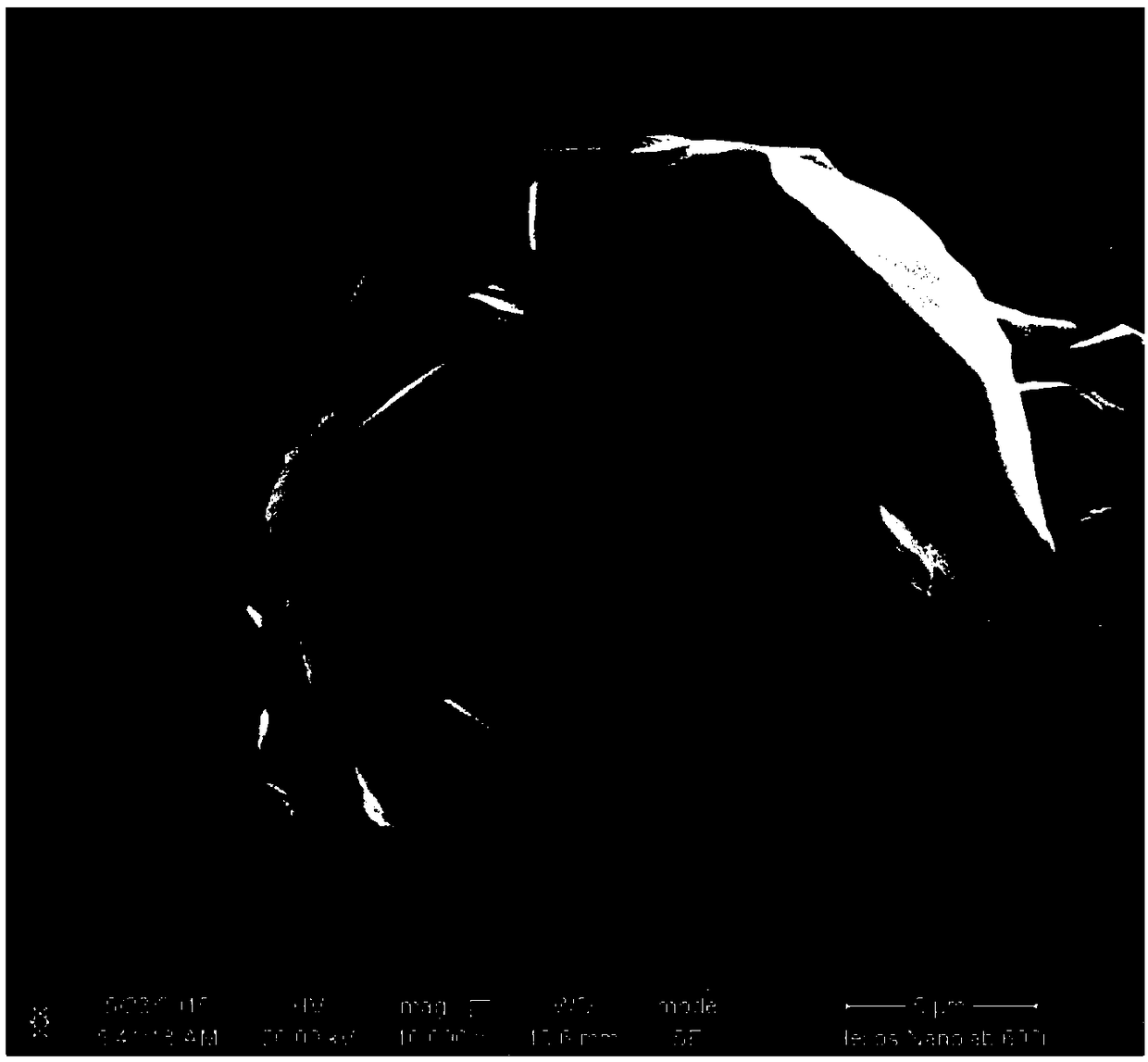

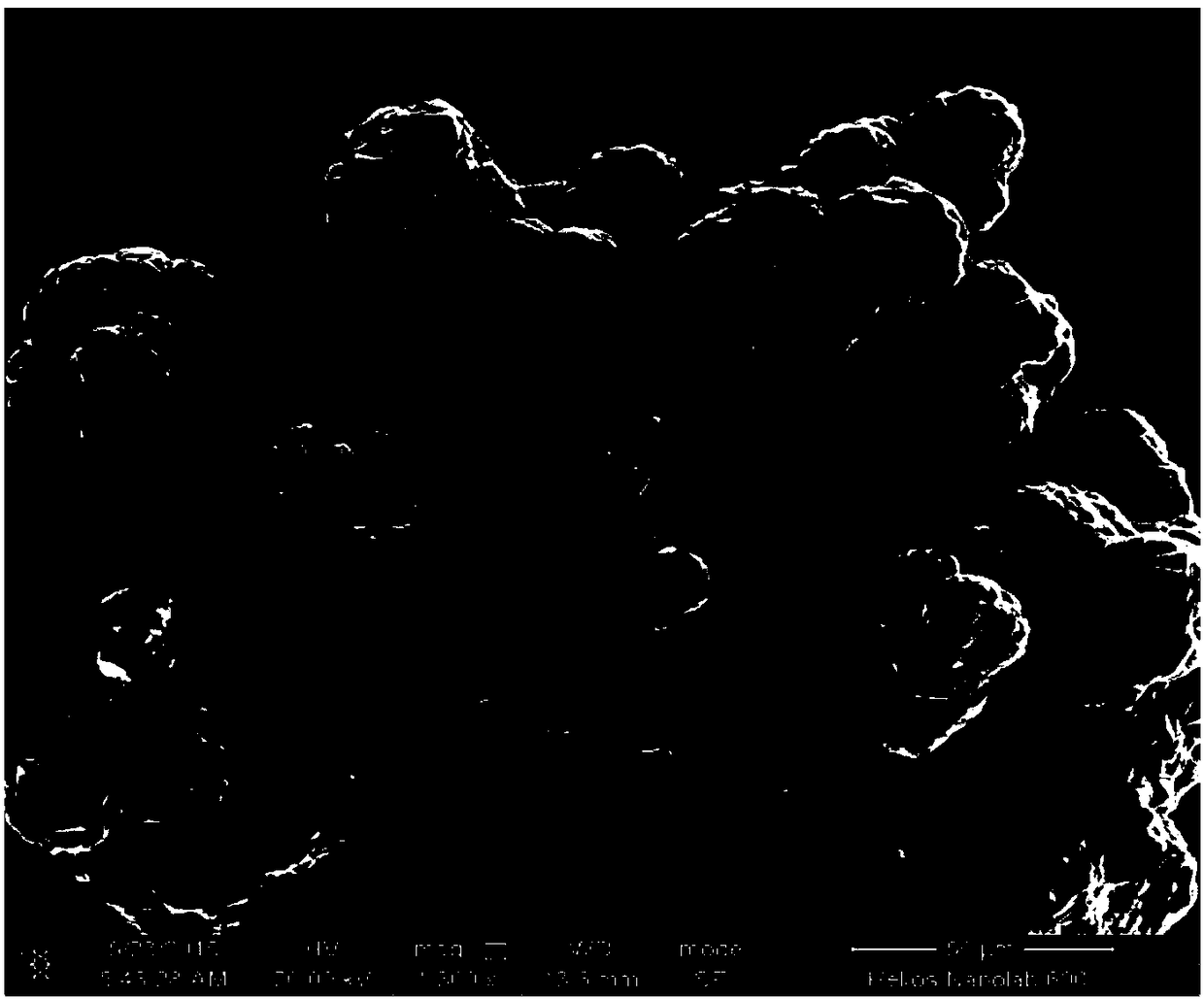

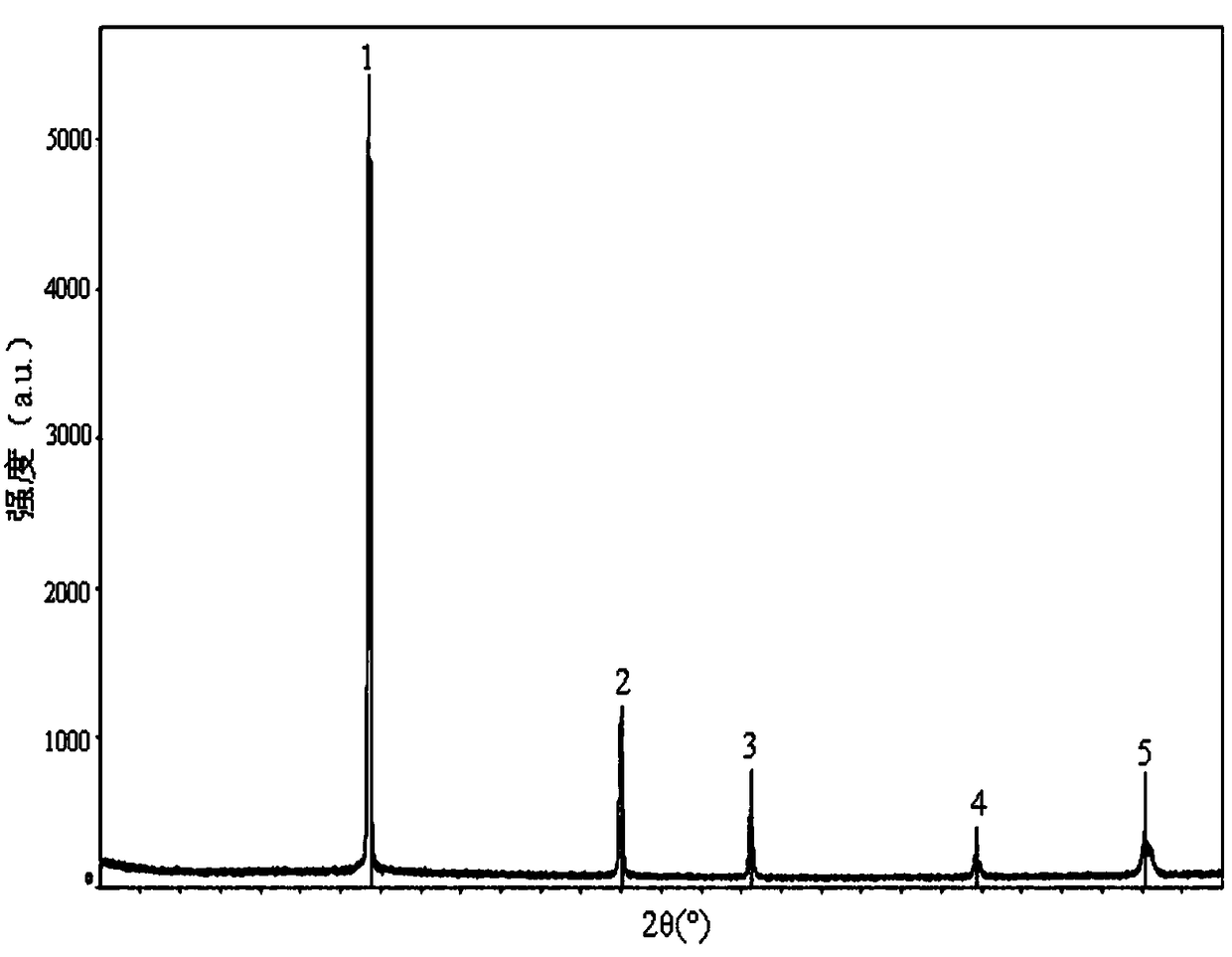

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the method for preparing diamond particles by plasma etching graphite described in the present embodiment is specifically carried out according to the following steps:

[0024] 1. Surface treatment of graphite sheet:

[0025] Stick the graphite sheet to the surface layer with scotch tape, and then use absolute ethanol, acetone and deionized water to ultrasonically clean it for 10min to 20min, respectively, to obtain the cleaned graphite sheet, and place the cleaned graphite sheet in a vacuum drying oven to dry. The drying temperature is 60°C-80°C, and the drying time is 15min-30min, and the dried graphite flakes are cooled to room temperature to obtain surface-treated graphite flakes;

[0026] 2. Preparation of diamond on graphite by plasma etching method:

[0027] Place the surface-treated graphite sheet in a microwave plasma chemical vapor deposition device, and deposit it under the conditions of a hydrogen flow rate of 50sccm to 1000sccm, a ...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that the graphite flakes described in step 1 are highly oriented pyrolytic graphite flakes, flake graphite flakes, earthy graphite flakes or polycrystalline graphite flakes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the size of the graphite sheet in step 1 is 10×10×1 mm to 30×30×10 mm. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com