Process and apparatus for melting and welding plastic sheet to produce pipe

A technology for manufacturing equipment and plastic sheets, which is applied to tubular items, other household appliances, household appliances, etc., can solve the problems of the limitation of the diameter of the round pipe, the limitation of the production volume, and the high production cost, and achieves a simple processing method, improves efficiency, and improves production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

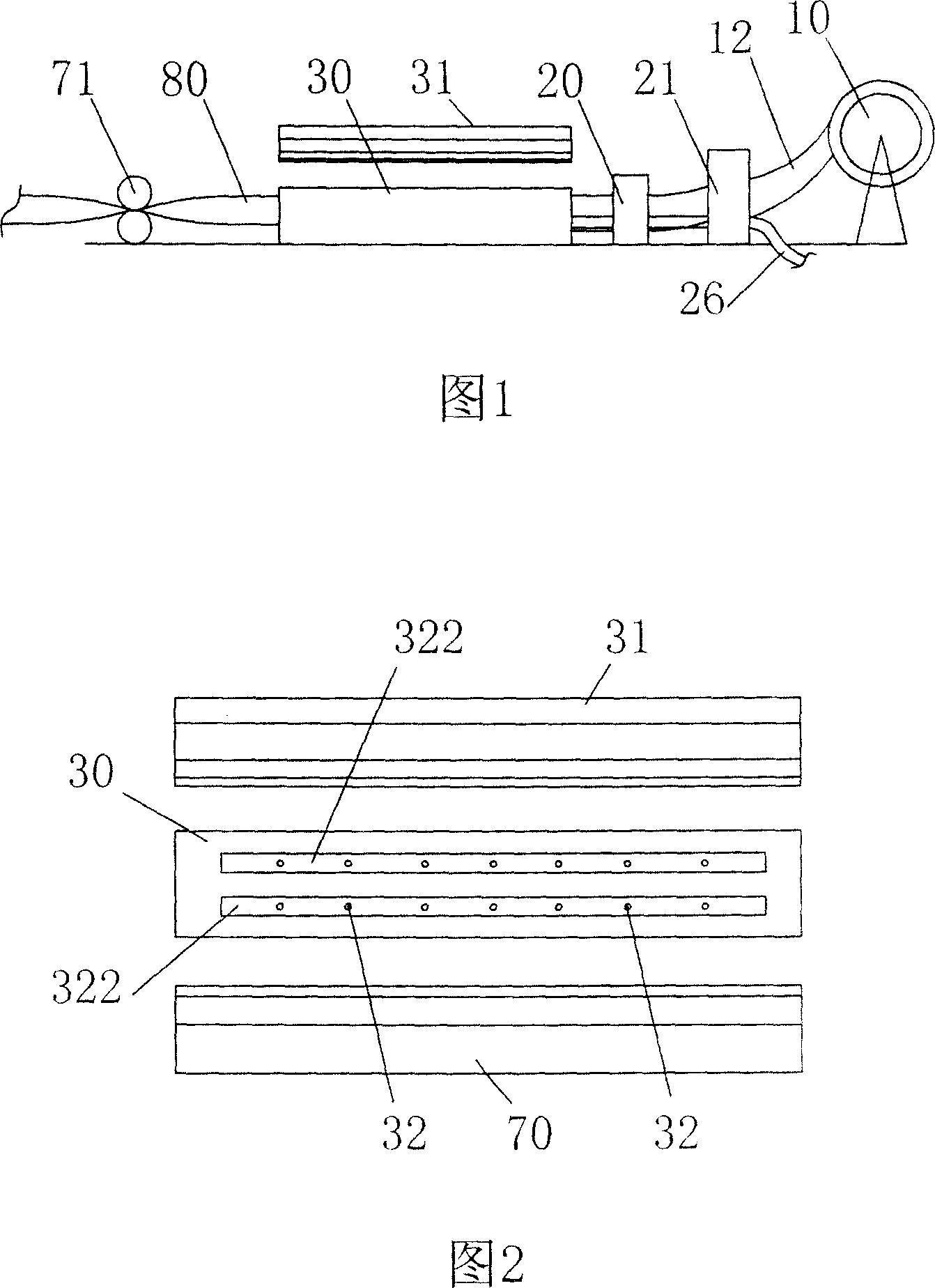

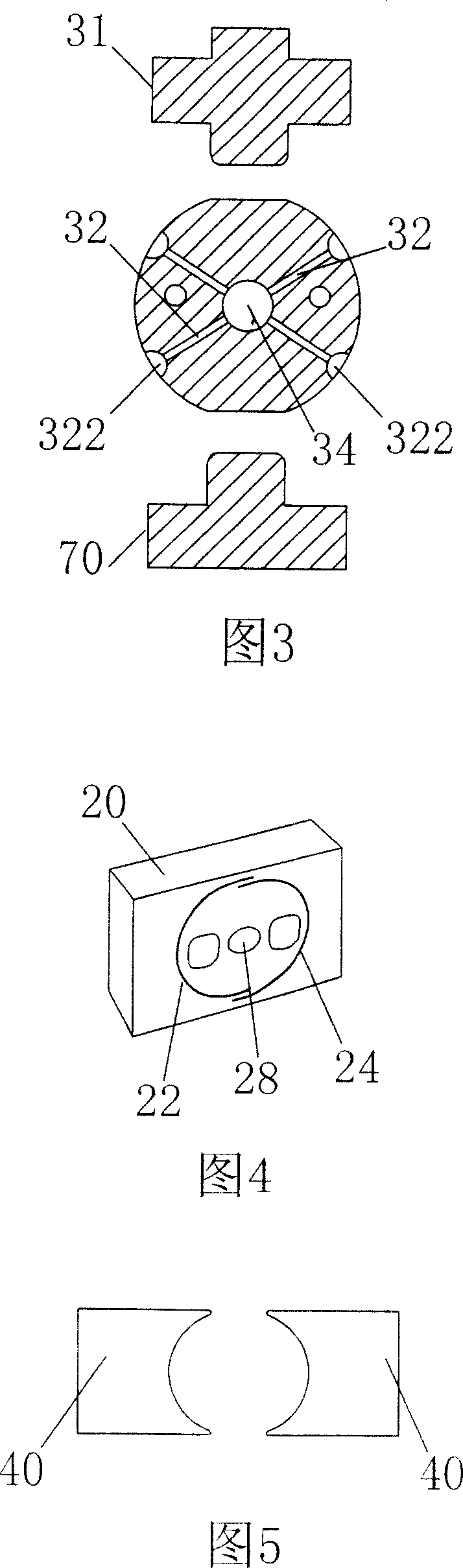

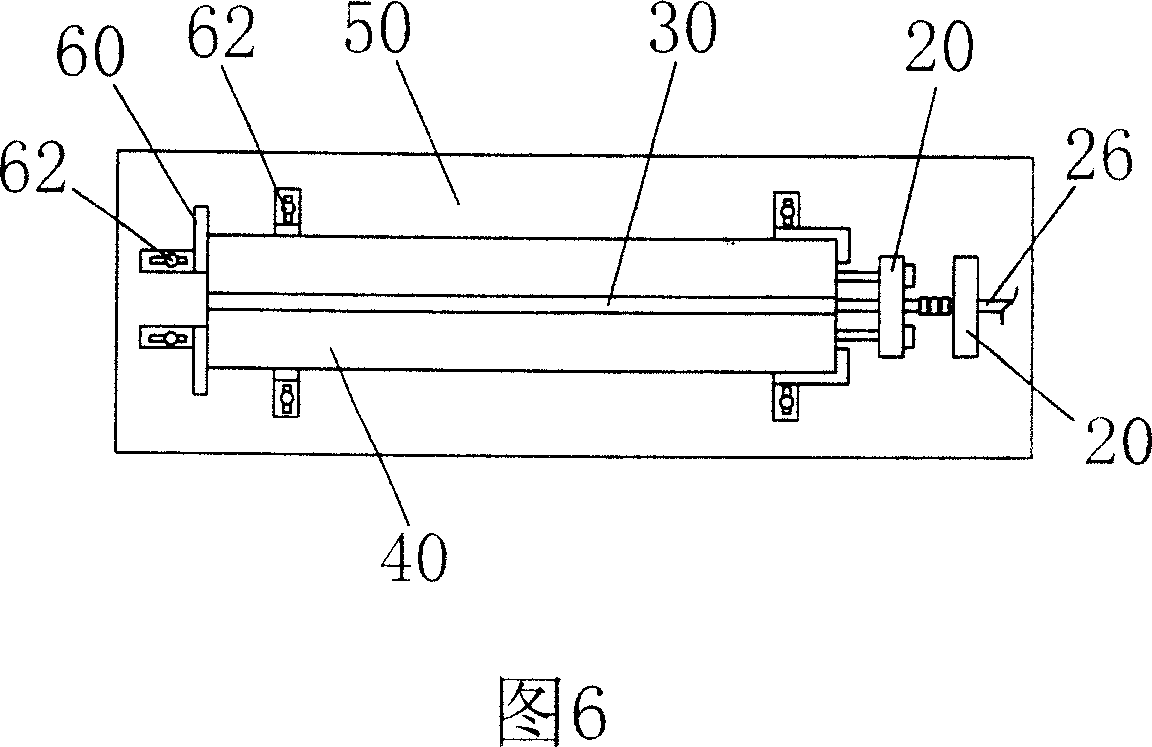

[0024] See accompanying drawing 1-6, the present invention provides the manufacturing equipment of seam welding of plastic sheet material into tubular shape, and it comprises material frame 10, bending guiding device, press-fit welding combination mould; Plastic substrate 12; two semicircular grooves 22, 24 penetrating the bending guide are formed on the bending guide, and the two semicircular grooves 22, 24 form an unclosed circle, and the two semicircular grooves 22, The ends of 24 have misplaced overlapping parts, and the said curved guiding device has two large and small ones, and the two curved guiding devices 20, 21 are placed side by side, and the curved guiding device 21 with the larger radius of the semicircular groove is close to the material rack 10 , through this arrangement, the plastic substrate 12 can be moved stably, and the misaligned overlapping parts of each section of the plastic substrate 12 processed by the press-fit welding combination mold can be kept un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com